|

|

|

Hi All, My usually trusty '90 240 wagon is suddenly not starting in the mornings. It cranks fine, has good spark, and initially will fire for half a second but die, and then will just crank after that without trying to fire at all. There are no codes on the self test unit; blinks 1-1-1. I put on a new fuel filter. The fuel pump puts out a good stream at the fuel rail connection on top of the engine. I just replaced the coolant temp sensor. Still no start. I unplugged the mass airflow sensor to see if she would run in "limp home" mode, but no difference. I have found that it started later in the day a couple times and thought I had fixed something, but the next morning, back to no start. Now it doesn't fire any time, except for a little burp first thing in the day. Help!

Chris

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Can we lay this 100 (now 101) responses long thread finally to rest?

Just to recap: did the failed wiring to the in-tank pump turn out to be the cause of the no start condition?

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

This thread is worthy---big players weigh-in.

The audience awaits the resolution.

Cheers for getting this one going

https://www.cartalk.com/

______________________________________________________

Unencumbered By Thought

Author

Magliozzi Brothers

There is a process for reaching nirvana and it is this: You must repeat the mantra. And the mantra, which happens to be emblazoned on our flag, is: Non impediti ratione cogitatonis. Which, of course, means: Unencumbered by the thought process.

--Tom & Ray Magliozzi (1999 MIT Commencement Address)

_____________________________

stimulation the little grey cells

The Lagonda

posted by CeeBee1 Posts made by you. on Wed Apr 6 21:14 CST 2022

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

After cranking the engine a few times, pull out a couple spark plugs. Are they wet with fuel? That might help you determine if the problem is fuel or ignition related.

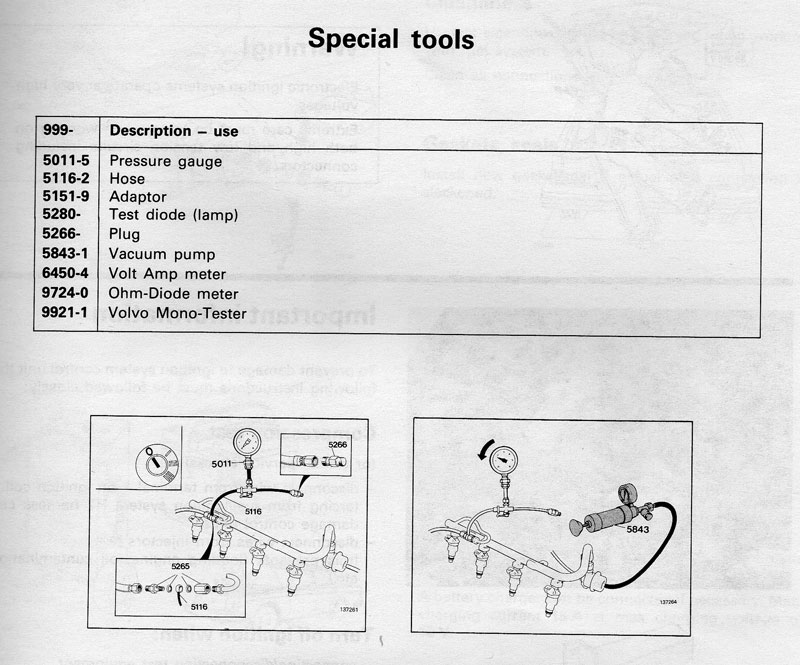

As a side note - a healthy flow of fuel at the injector rail is a good sign, however it may not be flowing at the required psi, which would point to a problem with the main (high pressure) pump or a faulty fuel pressure regulator. Can you get your hands on a fuel pressure gauge?

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Pulled the plugs, and they were dry. Closed up the gap to spec, but still no luck. I'm going to get a new set of plugs anyway. Haven't been changed in too long.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

concur with Peter's diagnosis.

you are throwing the wrong parts at the problem.

you are being led too deep into the weeds. CPS is your problem

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

“…. CPS is your problem…..”

In the opening post the OP reported the car has good spark.

If that’s the case then (proper) fuel delivery deserves attention at this point.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi Chris,

It sounds to me like his spark is intermittent. I don't think he's confident with it if he's gone out to get new plugs, and usually a sparking engine will react to starting fluid. I had a failing CPS that would come and go with the weather.

Peter

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

I may have been trying starting fluid in the wrong place. I just pulled off the big air intake tube from the throttle and sprayed in there. Please advise. Thanks.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi,

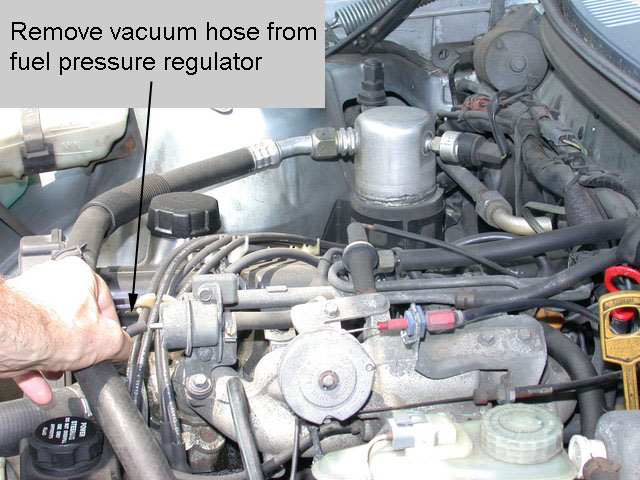

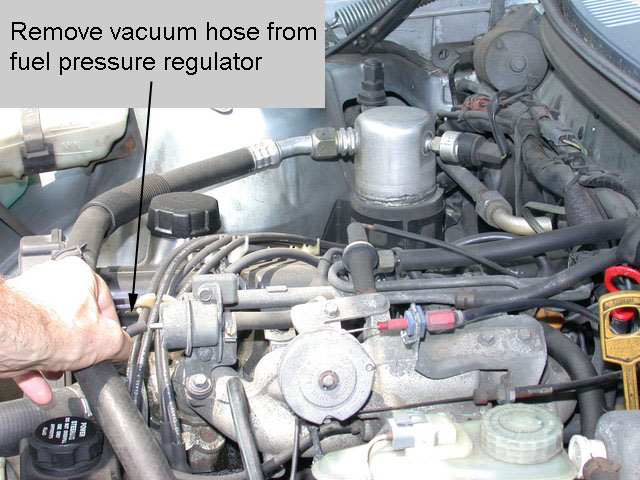

When I posted I said to use the port where the FPR’s vacuum hose connects to the throttle body.

You will need the tiny spray tube that comes with aerosols and fits the spray nozzles.

No wires on the distributor, means you have to have a CPS.

The CPS sits down on the transmission housing and directly behind the cylinder head. The space for all of this is in between the head and the firewall of the cabin of the car.

It’s held in by one ten millimeter bolt head.

It’s a pain on the elbows and belly to lay on top of the engine bay. You need to get over the area to see down in there.

I have used a thick blanket and a wooden board to support myself.

For me, You have to get comfortable or a whole lot of indescribable words will be muttered from under the hood (:-)

You are also going to need a bright narrow beam of light down in that area too!

I use a 1/4” drive set with an extension bar and sometimes a universal joint swivel helps me line up with a little bit of angle of the dangle. The whole engine is on a slant.

On that swivel, I slip a small o ring over it and get it to fit around and into the joints. I have several kits of O rings

It stiffens up the swivel a bit. Those sockets are fairly heavy.

Most inexpensive swivels are pinned too loosely to be stable and its a cheap fix for it.

In others words, it’s a matched set of cheapness! (:)

If that CPS is original and I doubt it, change it anyway. Moisture works it’s way down the wires and sheath. Time and heat does the rest. I believe Art Benstein has done necropsies on these.

If nothing else the tip might need to be cleaned of debris.

That bell housing is not always the cleanest mechanical area, especially, if you have a clutch. Even the starter can spin up small specks or filings from the ring gear.

That gear is large enough to provide them and will never really show up by just looking at a few teeth when the starter is out.

There needs to be a small air gap between the flywheel and the CPS.

Have you ever removed the battery and checked out the spark coil relay setup there?

It can be a corrosive environment and it’s out of sight and out of mind.

That simple component is an important middle man in the ignition supply chain.

CPS, ICU, system relay, spark relay, ignition coil, coil wire, distributor cap, rotor button, spark plug wires and plugs.

Nothing is more important than the other one.

We are learning how fragile our world is through supply chains.

Phil

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Here's the latest, to various replies from ya'll. Ether sprayed into the small vacuum hose nipple consistently gets it to run smoothly for a few seconds till the ether is gone.

OBD DTMs 3 and 2 all check out fine, with lots of clicking and injector pulsing, and good test codes showing up.

The orange wire at the AMM shows power with the key on. Also the notorious 25a fuse and holder on fender well is flowing voltage no problem. Next???

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

If you're still asking what your next step ought to be, consider that I arrived at the same point with our first Volvo, an 83 I was trying to get in shape for my youngest then in driver training.

EFI was new to me; electronics not. As I understood the formula for a running motor to be compression, spark, and a fuel/air mixture stoichometery conducive to combustion.

The amount of fuel is apportioned by open time the fuel valves (injectors) times the pressure behind them. The EFI computer in these Volvos calculated this most basically from the measurement of air flow (air mass meter) with adjustments for temperature (ECT Sensor), RPM, cranking state, and eventually fine tuned by the lambda system (Oxygen Sensor).

So the first thing I needed to know was the fuel rail pressure. I could guess, like you, that there is pressure, but how much? I found this forum in '99 and asked, after spending too much time in local auto part stores not finding any adapter fittings for the Volvo's fuel delivery plumbing.

Advice I received was to visit the junkyard, grab a fuel rail, and use it to make an adapter for a fuel pressure gauge. I did. I still use it, still thankful for the advice. Now, there are adapters to be had by mail order. I think one of the posts in this thread has a link to them.

The next hurdle was deciding when an air mass meter was malfunctioning. There are many references to a resistance reading you can take purportedly looking at the hot wire. In doing some extensive examination of the Bosch AMM I found that measurement was actually looking at a reliable reference resistor with very little influence from the hot wire, but enough so that a reading outside of the specification would identify a completely broken hot wire. And your more modern LH3.1 thick film-based meter doesn't even have a fragile hot wire.

Chalk this up to the technical publications folks who needed to put something in the green manual for dealership technicians to use their 1982 multimeters on. End conclusion is, there's no definitive way to test an AMM good without a laboratory flow bench with temperature control.

But back in '99 the junkyards were full of 240s. I had my pick of $35 AMMs and knew I would always be keeping a spare that passed a driveability test, because how else can you know?

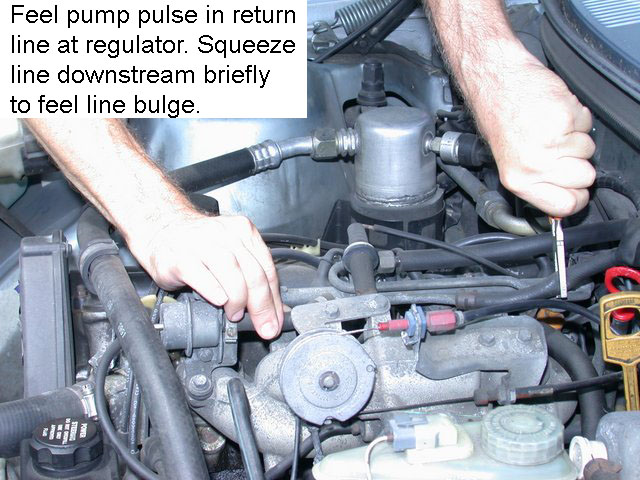

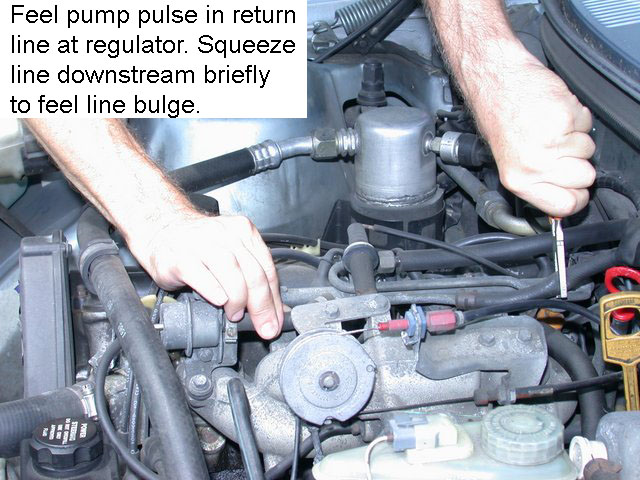

I believe if I were in your position, I would find a way to verify the fuel pressure. With lots of experience behind me, I can do this without a gauge, using the assumption Mr. Mullet suggests, that the regulator is okay. Not that they don't fail; they do, but usually in such a way your sense of smell will suspect them. They leak past the diaphragm. Learn to run the pumps without the key (jumper fuse 4 to 6) and feel the pressure in the return line.

Someone said "some" of the fuel gets returned. At the rate fuel is pumped nearly all of the fuel is returned. And if you're running just the pumps, it is all of the fuel that gets returned, just at a much lower pressure than what is behind the injectors.

But just as too little fuel will keep your motor from running, so will too much, such as when the regulator fails stuck in high pressure. You won't be able to guess this using a pair of pliers to squeeze the return hose.

Suggesting you get your fuel pressure measured or a spare AMM may not get your car fixed. There are plenty of off-the-wall troubles left to imagine. Poor connections in an engine wiring harness, nests built in the airbox, vacuum leaks past blown intake manifold gaskets, a broken lock pin on the cam, water in the control units ... on and on the list flows.

So, I say, try to find a way to convince yourself the rail pressure is correct and or find another AMM to substitute, if you're at the same point I was with my daughter's 83.

--

Art Benstein near Baltimore

"Wise sayings often fall on barren ground, but a kind word is never thrown away."

-Sir Arthur Helps

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi all, Today I checked the fuel regulator, in a fashion, by drawing a vacuum manually on the hose, and the diaphragm seems ok since it held without leaking down, which I would think it would do if failed, as it connects to the tank return line on the fuel side of the can.

A possibly significant discovery is that I need a new in-tank pump. I don't have a helper to listen at filler neck when first turning key on, and the tank is fairly full, plus I was getting good flow out the fuel rail, so I figured it should run regardless of primer pump condition, as the manual says it should with plenty of gas in the tank. Anyway, today I wanted to definitively check both pumps, so I dropped and disconnected the main pump again so I just was powering up the tank pump to an open hose. Gravity flow was stopped by light thumb pressure and with the key on it didn't seem to increase pressure. So I pulled the sender ( not any fun since it was untouched since 1990) and bench tested the pump. No good. Power is good at the wire connector at tank. No parts houses out here in the woods had a pump on hand but I have one coming in the morning. Not sure if it'll make a difference, but it's needed anyway. This problem isn't mentioned as a source for no cold start, but maybe a new pump will do it!

Sent from my iPad

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

So this morning I went to the parts house to get the new pump, but they had gotten the main in-line pump! Their computer system had it listed under in-tank pumps. The correct pump is special order only, and wouldn't arrive for a long time. Plus extra shipping fees.

So good old eBay to the rescue. Two vendors are shipping me a pump and a new filter sock for good prices and quick free shipping direct to my house. To be continued.......

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi CLL,

Do you have a functioning fuel gauge, and if so what does it say ?

I just re-read your 21 posts, and while there are plenty of references like 'there's fuel at the rail' and ' #4 fuse shows power', nowhere does it actually say in plain english that you've heard the main pump run.

I'm hard of hearing but I can clearly hear the main pump run with the engine stalled using any of the 3 methods outlined in the responses.

If I missed it somewhere, please humor me. Tell me that you can hear it run.

Peter

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Oh yeah, main pump runs strong, either by direct jumper from battery, or just connected to the harness, with key on. Fuel gauge shows over 3/4 tank. Project on hold a few days till new in-tank pump arrives by mail.

Sent from my iPad

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Probably the failed in-tank pump has been that way for months or even years. I'm fairly sure that won't change your situation.

But I have a question about your clear and plain words: "Oh yeah, main pump runs strong, either by direct jumper from battery, or just connected to the harness, with key on. "

If your pump(s) run more than 1 second just by turning the ignition key to KP-II your car has been doctored by someone in the past. Fuel should not be pumped, except for that initial bzzzt, unless the engine is turning! Dangerous in a crash.

--

Art Benstein near Baltimore

"Any intelligent fool can make things bigger and more complex. It takes a touch of genius - and a lot of courage - to move in the opposite direction."

-Albert Einstein

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi CLL,

"Probably the failed in-tank pump has been that way for months or even years. I'm fairly sure that won't change your situation."

I agree with Art since you said the engine didn't fire with a good slug of starter fluid into the throttle body.

Several early posters suggested the fuel relay and the RSR. I'm with them.

Either can kill your engine when they fail.

Did you replace with a NEW RSR? You never confirmed that.

A flaky RSR can disable your injectors and ignition coil.

Don't trust a junkyard pull for RSR or Fuel relays.

You can get a new RSR for $20 @ Ebay.

I also wonder if you disconnected the battery before unplugging your ICU?

Good luck, Bill

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Bill, OP does get the engine to start consistently using ether through the fuel pressure regulator's vacuum source port on the intake manifold. Because of this report I believe spark is not his trouble.

Also, no 240 has an RSR. That's a 7/9 thing. We all are cheering him on wishing he will soon post the answer because it is clear he isn't giving up on it.

--

Art Benstein near Baltimore

"When they tell me I'm too old to do something, I attempt it immediately." -Pablo Picasso

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

At the beginning of this marathon thread I thought the problem would be a failed main pump. OP reported having a healthy flow of fuel at the injector rail, the pressure of which was unknown - maybe not enough pressure to produce a combustible air/fuel mixture. I thought maybe the fuel was flowing due to a working LOW pressure pump and that the MAIN pump might not be working as he was able to get it to briefly run on starter fluid.

Then my thinking shifted as the OP reported that he had found a dead low pressure pump. So if that’s the case then it must be the main pump that is pushing fuel to the rail. Can we assume that if the main pump is the one doing all the work that it must be working at proper (high) pressure? Can a high pressure pump “partially fail” in a way that it still pumps but at a reduced pressure? I don’t think I’ve ever heard of that.

So if we assume for the moment that the main pump is working OK then why are the injectors not injecting adequate fuel? It can’t be because of a failed CPS as the car has spark. So are the injectors opening?

On the 240s are the injectors constantly fed a + electrical signal and the computer controls a grounding path of varying duration? Just thought I’d throw out some more food for thought.

And the saga continues……

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi Chris,

The OP reported that the injectors could be heard clicking on OBD mode 3. The other unknown with regards to fuel is the FPR. He tested the diaphragm, but that does not guarantee that the valve is holding back enough gas to develop sufficient pressure. The fuel may be all returning to the tank.

Without an investment or access to a pressure gauge we'll never know. A less professional alternative might be to throw this at it after the new in-tank pump doesn't cure the fault.

https://www.ebay.com/itm/232513724090?fits=Model%3A240%7CMake%3AVolvo&epid=7021314850&hash=item3622e5deba:g:fj4AAOSwW4ViDa81

I know it's too cheap, but I bought one and 3 years and 30k later it's doing fine.

Phil's point about the check valve is interesting. I've been under the impression that the pump could develop pressure without it, but perhaps it can't.

The odd thing about this is that the engine coughs once in the morning and then goes back to sleep, but runs fine after lunch. As a morning person, I find that quite disturbing.

Peter

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

"Phil's point about the check valve is interesting."

Yes. I was going to remark about this, but at the time felt I'd cluttered this thread up enough.

As a veteran of several fuel pump check valve failures, I can relate some experience. These failures I experienced all happened in the neighborhood of 20 years ago, and after a couple necropsies, were due to the spring rusting and breaking in two. This was during the time when our gasoline supply was not augmented (or contaminated) by ethanol, but MTBE was used as an oxygenator to our fuel here in Maryland.

The symptom of a failed check valve, if I remember, was slightly longer crank times, as the main pump needed to fill empty lines and not just the space behind the regulator's diaphragm.

Since ethanol replaced MTBE, any condensation moisture seems to be spread throughout the fuel mix instead of dropping out in the low areas of the fuel plumbing, or perhaps it is just our habit of keeping a full tank as much as possible compared with the previous owners of our cars. My spare check valves go unused.

But the reason I wanted to remark, was Phil's suggestion to test one by blowing. I can assure you that spring is more powerful than my cheeks. I am not able to blow through the new unused fuel check valve in either direction. Nothing like testing a check valve used in the vacuum lines.

"The odd thing about this is that the engine coughs once in the morning and then goes back to sleep, but runs fine after lunch. As a morning person, I find that quite disturbing."

Funny. I'm also a morning person, and not everyone in my house appreciates that. I've learned to make the most of my nose troubleshooting fuel issues, and this symptom, combined with an unburned fuel odor reminds me of leaky injectors or regulator diaphragm flooding the engine. I'd hold the pedal down to keep the throttle wide open to see if it would burn off, but I think OP has done this. One of the symptoms of covid (earlier variants I think) is loss of smell. I'd hate to lose that sense driving old cars as I do.

EDIT: By the way, Peter, I meant to thank you for your anti-seize recommendation in another thread. I have it on my list to find the Permatex product but so far the only place I ever visit for automotive supplies, Walmart, does not carry it. I will soon brave the NAPA nearby now that I know where they moved to. So many times I've gone in a local auto parts store and walked out empty handed, I just never bother anymore.

--

Art Benstein near Baltimore

"If you can't fix it with a hammer, you have an electrical problem." -vwbusman66

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi Art,

I agree with you thoughts on the thread being long and cluttered with responses.

A lot of things have “circled the wagons” around the lack of fuel for sure.

We usually do not get this much feedback on a cars progression.

I’m not going to complain as I like the chat entertainment.

It’s the only thread moving along with lots of follow up. I appreciate him doing that.

As far as the testing, of my “one and only” failed check valve, it was off my 1978. It failed in the late eighties. So, I will say I don’t remember how I checked the new one.

The ball may not have moved either but it was different than my broken one.

I treat all check valves as with a go and no go of direction.

I had only the one car, not my collection today.

I was so young, I wouldn’t have know what a “necropsy” was either. Don’t know when I looked that up, probably, since seeing and knowing your posts, Art.

I definitely had less of a vocabulary let alone the experience to think with it sanely. (:-)

I may have sucked on a new one instead of blowing into it from either end.

That way, I would have about 15 lbs. of atmospheric pressure to assist in moving the ball. All I know it cannot leak, period.

I cut mine open and found the broken collapsed spring inside. I don’t think it even rattled but passed air.

I figured that since the valve is mounted horizontally the ball is subjected to gravity, in the mid or open position, inside the threaded canister.

It’s suspended in fuel on that spring fluctuating very minutely from the pulsating flow.

The spring gets distorted by having to support the weight of that steel ball horizontally.

I do not remember any kind rusting or having fuel additives issues with gas at that point.

The spring was fairly shiny and the coils were very thin.

A coil spring was even thinner where it cracked that could have reach the barrel of the fitting.

What I was trying to imply is that the check valve has more than a one way purpose.

By it just being in the line it should have “some” influence with the workings of the pumps pulsations.

Not so as it “is” an intentionally true purpose, but it does have a “mass in that is in movement” and it is a wear item in the process. It’s not static.

That tiny resistance, I believe can have a minor influence of how the pump can percolate gas through its clearances. Add age to those functions of wear and it what we will get.

A failed pre pump will shake the check valve even more, like running on an empty tank but it’s is 80% filled.

Nothing about the fuel pump system will get off lightly, in either case that causes cavitation.

Roller and vane (PS) pumps have some natural leakage and therefore don’t have as much suction capability. Power steering pumps are surrounded by reservoir or are gravity fed fluids

It’s simplicity and low costs.

The more traditional gear pumps, used for engine oil or piston pumps with valves are a different story.

On turbine vane pumps it’s the impeller diameter and the close fitting area of the volute, that makes for it to have large volume and suctions. Its capacity and capability is influenced greatly by the clearance tolerance of their wear rings.

In the Navy I repaired huge amounts of those for petroleum products and various type of waters aboard ships.

On a car, it’s the Size that matters with pressures needed versus a large volume output.

The roller pump has a simplicity of both designs but comes with compromises to get it so compact.

A compromise is to have the feed pump to keep it from cavitation.

Back in the K jet car, of 1978, a spring loaded accumulator was used for a slight back pressure and absorber of noise.

I think the pump was even slightly smaller in diameter.

The check valve still had to stay the same but untimely, an even larger filter was added lower or closer to the pump as a muffler.

The pumps increased slightly in size but so did the engines got bigger. Still the principles stated the same All through the LH s.

Yep it’s a long thread, maybe, slightly worse than my long posts, (:-) Nah it’s long!

Phil

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Got the filter sock the other day, but still waiting for the new pump to arrive. Maybe tomorrow! I'm not confident that the tank pump will be the cure, but it'd be wonderful if it was. I found out Advance Auto has loaner pressure test kits, so will try that next if necessary. Not sure if it will have the proper adapters for a 240. Got to be something fuel related since it starts and runs smooth on ether. Thanks for mentioning possible FPR malfunctioning. Chris

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Just can't win on this deal! I got the new tank pump today and carefully installed it on the sending unit. Before wriggling it into the tank, etc., I thought I'd test run it for a second just to be sure everything was good. Used a jumper from the battery, and the brown ground wire in the harness. No action! So started to check continuity various places. Ends up the only break in continuity is the one inch inside that sealed plastic block on top of the sender mounting bung ; external. The pump runs by jumping to the underside of that block, just inside the tank, on the little soldered post terminal, and the harness is good right to where it disappears into the plastic. What is that thing anyway? Are there components inside it? Is there a field repair I can do, or am I now looking at replacing the otherwise good sending unit? Btw, the old pump was indeed bad when bench tested separately.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi,

If your sending unit looks anything like Grey's photos then it's a goner. On most of them the pipes are toast by the time the wiring has failed.

I had one on a southern car that I bought 6 years ago that still had the cadmium on the pipes and most of the top, but no continuity on the pump wire.

I cleaned up any rust around and under the epoxy knob as best I could and drilled a 1/8" hole right beside the knob on the side toward the smallest pipe. I fed a new wire of the same gauge as the black pump wire through the hole with some shrink tubing around it so that it was a snug fit, and soldered it on the underside to the interior wire.

On the outside, I zip tied the wire to the epoxy knob, and then liberally applied 2 part epoxy around the base of the knob and to both sides of the wire I'd put through the top. JB Weld might be better, as it's thicker and easier to build up.

I then brushed on some tar based undercoating over the whole mess for protection, but also because I knew it would turn gummy if there was a leak and be easy to inspect.

I did this as a temporary repair until I could get a new sender, but have still not got around to replacing it. I've inspected it each year as part of my pre inspection inspection and there's no leakage, but I can't guarantee it's safety in the long term.

Peter

Edit - I recall putting 2 layers of shrink wrap over the wire and then measuring for the hole.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Great, I'll drill, and run a new wire and seal it in well. The sender piping looks good for many years yet so I'll see what happens by doing the bypass surgery.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Crossing my fingers, but it starts and runs again. Maybe the nightmare is over! I patched up the tank pump wire and put in the new pump. Turned the key on and some fuel came out the open hose. So re- attached and re-mounted the main pump and got fuel out the disconnected fuel rail fitting. Put that back together and after some faltering she took off much to my surprise. With an almost full tank this new tank pump shouldn't have made much difference, but it seems to have. We'll see if all is still good tomorrow morning. Thanks to you all for sticking with me and keeping me on task with logical troubleshooting progression. The only parts I bought were a new fuel filter, coolant temp sensor, spark plugs, and tank pump. The only thing that probably wasn't necessary was the temp sensor.

Later, Chris

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

"Put that back together and after some faltering she took off much to my surprise."

Much to my surprise also. Pleasant surprise!

--

Art Benstein near Baltimore

"A gentleman is someone who can play the accordion, but doesn't." -as retold by Monte Leister

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Finally a result!

I would also keep my fingers crossed, as in your very post you wrote: "The fuel pump puts out a good stream at the fuel rail connection on top of the engine."

But if the problem really turns out to be cured, then I'd say perhaps it would be wise to carry a spare main pump, just in case.

The reason I say this is that I probably drove around with a non functioning in-tank pump for about six years. Not until I started getting cold running problems did I go through the fuel system like you did discovering several worn or broken items which did not actually stop the engine running.

In my case I replaced the sender unit with a new one as I deemed the fuel pipes too rusty. It was then that I discovered Art's website.

I know of someone who ran a new wire through the unused fuel pipe (instead of drilling a new hole) and then sealed it with the same epoxy stuff as is in the "knob".

Oh, and about the temp sensor, at least you now have a known good spare.

If you have not yet discarded the old fuel filter, then it might be interesting to cut it open and look at its innards. In one I disassembled, I found a very fine grey discolouration, and nothing else.

As you may have seen in the photos I linked to, even after 25 years the tank looked pristine inside and I was most likely the first to remove the sender unit since the car left the factory.

I would guess this fine grey dirt to be carbon brush particles of both pumps.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi,

I read Grey245’s solution and seems to be a bypass surgery alright.

I hear that in “gut surgery,” they use super glue. (:)

I guess they trust that stuff for intestinal gasses too. (:-)

Not so much for gasoline though.

I have used a product that I use to could get in a hardware store to seal float balls for gasoline senders.

It’s called “Seal All”.

It used comes in a tube that is bubble packed and mostly yellow with red writing for about $3.00.

On the package it says it gasoline resistant, so I encapsulate the whole float. It stays on.

It’s not an epoxy. This stuff was probably around before epoxy.

I have a much earned respect for JB Weld products. Devcon is another.

I Never get bad results, when it does cook and cure.

I would use them long before any Loctite products.

Some Loctite products go bad right in the tube. That makes it really expensive.

I know because, I had no other choices but them and then go to use it again and its gone kaput. (:-(

They find good products from companies that they cannot compete with and buy them or have them repackaged their quantities for them. By then it’s really overpriced.

Loctite is too profit minded against the average car owner/Consumer” IMHO.

You might try “Seal All” on both wire sides for a distance each way for protection on regular wire.

If you can, get “oil and gasoline resistant” wire to use in there.

It will be printed on the outside in tiny black letters on whatever color you can find.

Good luck with the surgery, DOC! (:-)

Phil

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

As you've probably read already here In The Tank I have replaced many of those sending units after corrosion has set in. Look for a response from Grey245 and maybe a link to his adventure dealing with what you have.

There are no active electrical components buried in the epoxy, just conductors designed to penetrate the sealed tank unit for the purpose of powering the pump and delivering the float height information.

--

Art Benstein near Baltimore

How come nothing rhymes with orange?

What? Nothing doesn’t rhyme with orange?

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Just for fun I once dissected this part to locate the break in continuity.

Here's a link to the photos I took:

View post on imgur.com

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

"Can we assume that if the main pump is the one doing all the work that it must be working at proper (high) pressure?"

From experience I know it can, and even then it can provide enough pressure to flood the engine should the FPR allow too much pressure to the injectors.

Perhaps the only tell tale of a non functioning in-tank pump is a main pump that starts to become more noisy when the tank is below half or quarter full.

"Can a high pressure pump “partially fail” in a way that it still pumps but at a reduced pressure?"

Yes, I think so. On one trip I felt the engine hold back a little while at the same time I heard a slight howl from the main pump. After filling up the tank, I could drive home just fine. Suffice to say I quickly replaced the main pump.

Later I found the in-tank pump had stopped working due to a sheared wire in the epoxied little bucket on top of the sender unit. The pump itself turned out to be functional.

"So if we assume for the moment that the main pump is working OK then why are the injectors not injecting adequate fuel?"

The assumption that the injectors are the cause is still to be determined. They may actually be functioning properly but an external cause (like incorrect fuel pressure) leads them to inject the wrong amount. Especially during a cold start is it important that this pressure is correct.

The ECU controls injection duration based on sensor inputs. However, during a cold start, it cannot rely on the O2S feedback which - in my experience with a slowly failing FPR - is more than just a "fine tuning" feedback, it actually seems to have a lot of influence.

Without its data, the ECU calculates ball-park injection durations for which it is essential that the fuel pressure is correct.

If the pressure is too low, the mix will never become combustible, the same goes if it is too high.

Gas engines only have a narrow window around the optimum fuel to air ratio in which they will work.

In my case the FPR had failed in a way that fuel pressure was slightly high leading to a good start followed immediately by very rich running (eneven idle, grey pungeant smelling smoke), until a minute later the O2 sensor started giving feedback. From that moment on, the engine ran just fine as the ECU "knew" the mix needed correcting. Hence I concur with those that say fuel pressure should be measured next.

"So are the injectors opening?"

If I'm not mistaken, OP determined they are working by using control function 3.

Note that all injectors are working simultaneously, so if one isn't functioning, it won't become immediately apparent by just hearing them click.

To determine every single injector opens, I would unplug all but one injector and run control function 3. If it clicks, I'd unplug it and plug in the next one and repeat the test until all four injectors are eliminated as a possible cause.

"On the 240s are the injectors constantly fed a + electrical signal and the computer controls a grounding path of varying duration?"

Yes, that is how they are controlled. The ECU "pulls the signal down to ground" when the injectors must open.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi all,

Yes a main pump can still pump gasoline to the rail and flow as long as the pump stays running.

It can do this with a fail check valve on the main pump outlet but will not hold pressure immediately after shutting off. It can also be a slight restriction to the pump to keep the pump primed, per say, even though it’s almost a positive displacement pump but has only guided rollers.

One more reason for a feed pump besides tank level.

Trash around the rollers does not help the capacity either.

The check valve was about $11 back in my day but probably about $18 now but has to comes with a new pump for the above reasoning.

He can take it off the present pump and check it by trying to blow through it in both directions. In one direction it will not or should not any air pass.

The spring In these can wear on one side and the spring collapses and it goes bye-bye.

It can have trash inside there. The tank filter sock is the only thing that protects the main pump.

The main pump can also wear excessively and that trash, from inside the pump, hits the check valve.

Both are rare but I have lost one check valve so I know about the collapsed spring. It’s not a theoretical guess, for me this time, but a fact. (:)

The check valve can cause all kinds of issues, if you don’t know the pressure in the rail or if it’s being held in the rail after shut down.

So Art is correct, the in-tank fuel pump probably has been out for a long time and now the end result is no fuel!

A long “on going” bad thing can lead to a “no going” worse thing!

(:-). 85 posts and counting.

Phil

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Dear Phil,

Hope you're well during these covid times.

You mentioned

"The tank filter sock is the only thing that protects the main pump"

There's another filter mesh after the inlet of the main fuel pump. Its inside the body of the pump. Have to dismantle the pump to see it.

Or at least I've seen it in my old pump Bosch 0580464068

Amarin

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

let us know how that works out.

A thread worth of Stump the Chumps---Click & Clack the Tappet Brothers

It makes soooo many turns from the original post---No Start Situation April 5---from a mere 9 days ago.... makes your head spin.

Cheers

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi,

My-my aren’t you the lucky one with this thread!

Feeling the pain for you too!

Phil

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Sorry you had to go thru all that to determine whether or not the in tank pump was working.

Art's site---for future reference----he's also got much to say about what pumps are available and what you may run into.

http://cleanflametrap.com/transferPump.htm

^^^^^^^^^^^^^To test the pump itself, plus the sender wiring, apply battery power (in this example, from fuse #6) to the load side of the tank pump fuse. This is fuse #4 in 85-93 models, or fuse #5 on the earlier cars or 85 Turbo. Beginning in 89, the oxygen sensor heater is also powered here. If the fuse is removed, you’ll power up the tank pump on the right-hand terminal, and the main pump on the left. Test the pump a number of times to be sure it starts with each try, and the brushes don’t wind up in a bad spot on the commutator.^^^^^^^^^^^^^^

http://cleanflametrap.com/transferPump_files/image008.jpg

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

"... he's also got much to say about what pumps are available and what you may run into."

Possibly a little too much. :)

--

Art Benstein near Baltimore

Be careful of your tongue: It's kept in a wet place and could easily slip.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Click or Clack

cheers

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

True, I wasted many "perfectly good hours" in the 80's and 90's laughing with Tom and Ray.

--

Art Benstein near Baltimore

-volvo advice unencumbered by the thought process

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Chris

it's not for the LH 3.1----but I believe aside from the Electronic bits, the plumbing is pretty much the same.

Go to this website

https://ozvolvo.org/archive/

type in LH in the search bar

dnload

TP31361-1_LH-JET_2.4_B230.PDF

Happy hunting

Charlie

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

We’ve had fuel injected Volvos in the family since 1976. Never owned a carbureted one. The first one was a ‘72 144 D-jet that my bride-to-be owned before me. Fortunately we had a really good (and fair) local Volvo-only mechanic that generously shared his knowledge with me. Otherwise I would have been lost as this was all pre-internet. One thing I’ve learned along the way is that if you are going to drive one of these cars there are two tools that you MUST have in your arsenal - a multimeter and a fuel pressure gauge. Even if you aren’t an electronics genius, which I’m not, knowing how to make a few simple measurements goes a long toward troubleshooting rather than indiscriminate parts swapping. For most shade tree mechanics, like myself, you don’t have to break the bank. Example is my Harbor Freight fuel pressure gauge. Cheap but effective.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

on Sat you wrote: ' I'll try attacking all this again tomorrow. Spraying ether in the proper spot, doing the OBD function tests, checking crank pos. sensor, etc.

_________________________________________________________________________

Seems that aside from checking the OBD Codes again---you did not check the CPS, by removing it and and giving it a hands-on examination---a good looking at.

Don't know what you value your time or your at but..... 43 bucks....and then even if you still can't get the car to run---you'll know for sure that you have renewed it and crossed it off your list.

Consider it a maintenance part---like a timing belt or brake pads, spark plug wires, cap and rotor.

Art even posted the pics---on where it is and how to remove it.

https://www.fcpeuro.com/products/volvo-reference-sensor-rpm-240-740-760-780-940-271949#fitment

Here's the business end of a new one---- the part that sits in the bell housing at the flywheel.

https://www.fcpeuro.com/public/assets/products/175915/large/open-uri20141114-27671-cj4f24.?1496446081

You posted way back in this thread that you bought new spark plugs because yours had not been changed in ??? and looked worn-----

Well if you have no idea how long the CPS has been in the car----look again at that 'business end' and then decide if you might want to take yours out and give it a look. Just for grins.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

One of the best reasons to change this part before it fails occurs when the plastic sheath in its cable cracks. Because the sensor is installed at the top of the tone ring or flywheel it monitors, there's no way to form a drip loop; any water that enters the cable sheath will wind up inside the sensor, rust the magnet core and swell it into the fragile alloy bracket. Most of the time the sensor will keep doing its thing, not calling attention to itself.

One reason NOT to change this part in preventive mode is the incidence of out-of-box failures is high as reported many times in the forums. The fine wire and epoxy encapsulation combine to make this sensor a difficult manufacture. And you can imagine, those making it are doing short runs compared with when it was used in production cars.

So, look at the cable sheath at least, to judge the one you have. If it is broken, do change the sensor as soon as you can. My experience says there's no advantage to buying the "OEM" brand (Electricfil/Bougicord) and my skeptical nature suggests the replacements are all made on the same line in China now. Volvo is not doing rigorous incoming inspection on parts for cars 30 years out of production.

--

Art Benstein near Baltimore

"There are three kinds of men: The ones that learn by reading. The few who learn by observation. The rest of them have to pee on the electric fence and find out for themselves."

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

“…. Ether sprayed into the small vacuum hose nipple consistently gets it to run smoothly for a few seconds till the ether is gone….”

At this point I’d say it’s safe to say you’ve got good spark, meaning the CPS and its associated wiring have to be OK.

But you aren’t getting fuel…..

If the pumps are working properly, and if the pressure regulator is working properly, then there should be some amount of fuel flowing FROM the regulator, through the return fuel line, back to the tank. Without a pressure gauge on hand you’ll have to assume, at least for now, that the regulator is good. So if you can disconnect the return line and cycle the pumps a couple times there should be fuel flowing out of the regulator return port. Or a good ear listening down the fuel filler neck might be able to hear the returning fuel splashing into the tank.

Can you hear each of the two pumps buzzing for a second or two when you turn the key on? You may have to disconnect the power wire from each pump, one pump at a time, in order to really tell if one or both pumps are working or NOT working. If you find a non working pump check for 12v at the pump connector. It would be good to know if you have power to each pump both at initial ignition-on and while cranking the starter.

If you find a non-working pump with no electrical power showing at its connector try running a long jumper wire from the battery directly to the pimp. If that makes the pump run and the engine run then you know you have an upstream electrical issue.

Try this stuff and report back.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

I'll recheck both pumps again and verify that both are working with key on. I agree it's got to be a fuel delivery issue. Either pumps or injectors somehow. Runs great on ether.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Further update: my manual suggested checking resistance at the injectors, so I did and all vary between 15.7 and 15.9 ohms. Manual specs out 16, but maybe mine are within usable range?

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

\If starter fluid doesn't start the car then your spark isn't continuous. Replace your ignition amplifier module. Inspect the electrical plug. Place a long screw driver onto the injectors and place your ear against the screw driver handle and listen for clicking while cranking the motor. Easy way to now if the injectors are working. Have you tried re-soldering your fuel pump relay ?

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi there,

Ok now, you have asked for it. I and others have pointed and suggested that you are not getting fuel for sure and you followed up.

Some have suggested and I have hesitated but I will now tell you to forget that OB diagnostics, half baked piece of equipment.

If it was so good then, they wouldn’t be having the OBD II system and more standardization that it has now.

You are going to read the following post from Art Benstein to realize that you need to think things out a wee bit more and use your observation skills that you are developing.

We all had to do it.

Here is the example to see how we “all” get humbled down into doing the basic thinking thing.

https://www.brickboard.com/RWD/volvo/1610579/220/240/260/280/update_crank_start.html

EDIT,

Just saw another post. He is giving you good advice.

Your car may not have the one second pre-pumping cycle.

I’m saying this as I’m under the impression that that didn’t start until 1991.

Phil

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi Phil,

The priming fuel pump began in 1989 with the change from 2.2 to 2.4, I believe. I don't know about LH 3.1.

Peter

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi ,

Thanks for setting me straight on that. I don’t have a 89 or 90 car but I have the other three.

I wasn’t sure it started that early in the series of using the CPS ignition systems.

I thought I would throw it out there in case he didn’t hear the pumps do it.

He definitely has a pump starting problem if he doesn’t hear them.

Phil

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

To be fair, the "priming" was a byproduct of the electronic fuel relay introduced to the K-jet cars in 1978. It had no priming function then and doesn't now, but the 1-second buzz before the engine noise drowned it out was an extremely helpful tell to a technician troubleshooting.

When LH was introduced in 1982, and fuel pump control moved to the computer, the initial buzz was left out of the program for LH1.0, LH2.0, and LH2.2. Since it was easy to do in firmware, someone convinced Bosch to incorporate it for LH2.4 (and 3.1) beginning in 1989 for the 240. In practice, if the fuel pressure regulator and check valve function at all, fuel pressure is maxed out before the starter cranks the motor one revolution without need for the 1-second buzz.

--

Art Benstein near Baltimore

The Art Collector's Wife:

A New York attorney representing a wealthy art collector called and asked to speak to his client. "Saul, I have some good news and, I have some bad news."

The art collector replied, "I've had an awful day; let's hear the good news first."

The lawyer said, "Well, I met with your wife today, and she informed me that she invested $5,000 in two pictures that she thinks will bring a minimum of $15-20million. I think she could be right."

Saul replied enthusiastically, "Well done! My wife is a brilliant businesswoman! You've just made my day. Now I know I can handle the bad news. What is it?"

The lawyer replied, "The pictures are of you with your secretary.”

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

"It’s a pain on the elbows and belly to lay on top of the engine bay. You need to get over the area to see down in there."

Yes, for sure. If your 240 is a 91 or later. It is the GM-style orifice tube AC with the huge accumulator which makes access from above tricky.

The 89 and 90 models are a tad easier. A short 10mm combination wrench is all you need unless the old sensor is swollen and stuck in its fragile aluminum alloy bracket.

--

Art Benstein near Baltimore

My brother is a dyslexic, agnostic insomniac. He lays awake in bed each night and wonders if there really is a dog.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Lucky I've got a '90! I'll try attacking all this again tomorrow. Spraying ether in the proper spot, doing the OBD function tests, checking crank pos. sensor, etc.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Thanks for all the tips! I'll check the cps and cable. I got the new plugs just because the old ones looked pretty worn, though they still had good tan burn color. I never had the car not throw a good spark when I pulled a plug wire and used screwdriver to get near a ground. Besides the plugs, I just put in a new coolant temp sensor to see if it helped. Also the fuel pump relay is only a few months old, and fuel gets to the injector rail ok. Unplugging the mass air meter makes no difference.

However, first thing in the morning it fires for half a second, then just cranks. In the late afternoon it will sometimes start right up and run normally. Not every day though......

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

“…. I never had the car not throw a good spark when I pulled a plug wire and used screwdriver to get near a ground…”

Now that you have a spare set of plugs, how about connecting them to all four plug wires, ground the plugs, and see if all four fire when you crank the engine?

Also, when you say you have good fuel flow to the rail, can you describe at which hose you tapped into to witness the fuel flow? It would be good to know if the regulator-to-tank return line is flowing.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

I checked fuel flow by taking apart the pipe connection where the line from main pump hits the fuel rail on top of the engine. A lot of gas shoots out, but I can't test for pressure accurately.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

This is actually not a no-start, I think, in the way no-starts are diagnosed. We need a category for starts-once-and-dies.

I fixed one with those symptoms a couple months ago by replacing the AMM. Trying to run with it unplugged and attaining drivability is not the reliable diagnostic you see touted on these forums.

Do you have a DMM and the skills to make a careful voltage measurement?

Edit: I found where I have described that fix I mention: http://forums.turbobricks.com/showpost.php?p=6260374&postcount=6

--

Art Benstein near Baltimore

Regarding Grey245's post in the blipping throttle thread on OBD Mode 3 Actuator testing (I can't reply there -- it is blocked)

Turns out something in my praise is causing my reply to be blocked. I'll try to add bits and see what fails:

My praise refers to the need to join Google to upvote the video put in different terms I suspect are thrown aside for looking like spam.

Makes me want to remake my frozen wiper drive video and choreograph a dance to these.

Bravo!

https://www.youtube.com/channel/UCmsU0s9bx3otmMDnFkn1KXA

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi Art, Good to get your input. Yes, I'm an electrician and have a good meter. Is there a good test to really determine if the mass air meter is ok? Don't want to buy one if I don't need to. Also mystified on the CPS location and testing. 1990 240 wagon with I think the 3.1 fuel injection setup. Thanks.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Sorry. I forgot you've got LH3.1 where I have no experience, so those meter readings on my LH2.4 AMM won't provide any reference. Same sorry lack of clear diagnostics exist with LH3.1 AMM, though, making substitution the only definitive method.

--

Art Benstein near Baltimore

Two cannibals are eating a clown. One says to the other: "Does this taste funny to you?"

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

?Well, the only way I figured I had the LH3.1 was because the plug terminal numbering and wire color coding on the AMM plug conformed to the 3.1 and not the 2.4 schematic in my Haynes manual. Is there an easy way to see what system is really in the car? No under hood stickers refer to the jetronic type installed. Just says the engine is a 1990 B230F.

Sent from my iPad

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

"Is there an easy way to see what system is really in the car?"

My first clue would be manual transmission, model year 1990-1992. But that's not definitive, so I'd look at the AMM and its wiring like you did and Grey245 posted. Don't recall if I've ever in person seen an LH3.1 car.

According to Bentley, digits 6 and 7 of the VIN can be decoded: 47=B21FT, 88=B23F, B230F (except LH3.1) and 82=B230F LH3.1

This might be helpful to those who aren't the original owners and wonder if a previous owner decided to change the transmission type.

--

Art Benstein near Baltimore

"Never attribute to malice that which is adequately explained by stupidity" Hanlon's Razor

Occam's Razor: That among competing hypotheses, the one with the fewest assumptions should be selected.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

The earlier versions (1.0 up to and including 2.4) have six pins in the connector in what looks like a separate box on top of the AMM. The 3.1 has a four pin connector that is more integrated, it looks like it's sticking out the side.

The Bosch part# of the AMM for the 3.1 is 0280217001.

2.2; 2.4

3.1

Source.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Do the 1990 240’s have the infamous 25 amp fuse on one of the inner fenders - the one that gets corroded contacts? I don’t think I’ve seen it mentioned but there have quite a few posts.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

"Do the 1990 240’s have the infamous 25 amp fuse on one of the inner fenders ..."

Yes, they do. The fuse holder and its wiring are what makes this infamous; I've not seen one conclusive report that the fuse itself has been defective aside from oxidation on the terminals inside the holder. http://cleanflametrap.com/emfuse.html

The way I rule these out is to check for battery voltage at the AMM with key on engine stalled. This check provides the assurance the fuse wiring, FI relay (system portion) and its distribution is functional under load. You can't do that with a DMM on the wiring itself either with power-off continuity checks or power-on voltage checks.

On a '90, check the orange wire going into the AMM for battery voltage with key on, engine not running. Proves the fuse wiring is good. This will work with LH2.4 and LH3.1.

--

Art Benstein near Baltimore

I went to buy some camouflage trousers the other day but I couldn't find any.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

I was thinking that oxidation/corrosion in that fuse holder might be the source of intermittent problems, which it sounds like we’re dealing with here.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

"I was thinking that oxidation/corrosion in that fuse holder might be the source of intermittent problems, which it sounds like we’re dealing with here."

I was thinking the same, as it is a no-start some-times. As in my notes on the web page, I mostly found this trouble with the cars where that fuse was moved back inside the car at #6 (1991-93) going against the common thought the placement on the fender was the design error. But that spot inside has its own set of issues.

The method I describe with the test light is effective at sorting those troubles where the corrosion or oxide provides a variable high resistance, variable over mechanical stress, time, and temperature. The mechanical part of contact resistance is what we see when a wire is jiggled or a terminal bumped, so I'd try to watch the test light while shaking the red wire or tapping on the FI relay housing. The latter might be a two-person trick, or something I do alone with the help of a piezo buzzer.

However, if the intermittent trouble isn't currently showing itself, the test lamp could be left in place until it does, providing an instant indicator that the main fuse and its circuitry is intact.

--

Art Benstein near Baltimore

It appears autocorrect has become my worst enema.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

My guess is that that OP doesn’t have a lot in the way diagnostic tools. Kinda thinking they should just go ahead and clean up the fuse and holder to eliminate the possibility that it’s making contact one day and not the next. Besides, it costs $0.00 to try. I can’t recall where it’s located or what the cover looks like. I’m picturing a thumb screw holding the cover on but I may be all wrong.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Yes, great idea.

There is something to be said for guessing vs. diagnosing, especially if your guess costs nothing in the way of pocket money or trips to town. Even replacing the "usual suspects" gives that feeling the money is being spent on parts that would eventually need to be replaced anyway.

Here's what it looked like:

There are more pictures in that link I posted.

In the case of the fender fuseholder, if it and its wiring is original, which is indeed rare 30 years down the road, there are 8 metal-to-metal joints each of which is a potential suspect. The oxide or corrosion capable of interrupting the 12-volt connection isn't necessarily visible to the naked eye.

It is my habit to recommend diagnosis over guessing (sometimes referred to as the "parts cannon") when the tools needed are a good investment, such as a cheap 12-volt test lamp. But wiring in a so-called waterproof fuse holder with new crimp connectors at each end could be an excellent improvement to the LH-equipped 240. This is the sort of fuse holder most of us are using:

--

Art Benstein near Baltimore

Brickboard members are the most likeable, smartest, and best-looking people on the internet. [Citation needed]

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi,

In Art's post that you replied to, there is a link to a Turbo Bricks post that illustrates the tests on the AMM. You must have missed it.

By the way, when you turn the key to position 2 before cranking, do you hear the fuel pump come on momentarily ?

Peter

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Shouldn't a faulty CPS throw a 1-3-1 on socket #2 and a 2-1-4 on socket #6?

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi Grey,

Possibly a 1-3-1 but he'd have to activate the system because it wont light up the check engine light. I had one fail a few months ago and forgot to do that.

I don't think 2-1-4 is a valid code. OBD 1 seems to be limited to 3 beeps.

Peter

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Partially.

In the FAQ, you'll indeed see that on socket #2 all codes with more than three flashes are printed bold with a "not applicable". However, on socket #6 up to 5 flashes are possible. The 2-1-4 on that socket also does not light the CEL.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi,

How long has the crankshaft position sensor been in the car, and what condition is it's cable in ?

If you have meter you can check for resistance at the disconnected plug.

Peter

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Thanks, I'll try pulling plugs to check for wetness. No I don't have access to a fuel pressure gauge.

Sent from my iPad

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

An old tire pressure gauge will work. A bit messy, but with a rag wrapped around the plug end, should work.

--

Keeping it running is better than buying new

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

"An old tire pressure gauge will work. A bit messy, but with a rag wrapped around the plug end, should work."

The 240 didn't get a Schrader valve on the fuel rail until '92, and yes, since it pointed downward with no clearance, a stick-type tire gauge could make a mess with the engine off and a fire threat with it turning, and that rag gets soaked pretty fast unless the rail is nearly empty.

--

Art Benstein near Baltimore

What's the fastest liquid on earth? Milk, because it's pasteurized before you see it.

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Once in a while (as in months and especially after having been stationary in cold weather for a couple of days) I get the same symptoms.

I don't yet know the cause, but the workaround I have found that works every time is this: if the engine won't fire within the usual few cranks, I try it one more time. If it then won't start, I proceed to do this: with the ignition turned off, I unplug and reseat the ECU's connector. You don't need to take it out all the way, just push away the lock tab and pull and then pivot the connector away and then simply reseat it again.

I don't know why this works in my case, but it does. There are no bad or corroded contacts in either the male or female connectors. This action erases the fuel trims, so the ECU will need to relearn them again, and in the first 20 or 30 miles this can be felt.

Simply lifting the fuse for the ECU power supply momentarily alse erases the ECU, however, I have found it does not cure the no start condition in my case. Only unplugging and reseating the ECU connector does. So far - and that's probably been three to five times in the last year - each and every time I can then start and drive away as if nothing is wrong.

Try it, maybe it helps for you too...

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi,

Have you tried starting fluid applied through the vacuum port of the fuel pressure regulator?

If you put in a good decent dose of it into the engine and it will burst to life for a few seconds to prove that you have spark with a working CPS!

It also proves that the relay behind the battery, mentioned by Dave is firing the spark coil per ICU signals.

It also proves a correct valve timing sequence, with compressions, so the timing belt is good.

You have not mentioned any smell of the engine flooding or by checking plugs to see if they are wet by getting fuel and no spark!

So yes, it might mean that the injectors are still not getting power from the system relay.

The relay has two sides. One for the pumps and one for the injectors. One side can fail or the whole thing.

From here, You need to go to Art Benstein’s site for pictures on how to troubleshoot the following things.

It’s Cleanflametrap.com and is full of helpful things to fix the 240s!

To check for power for the injectors.

You can access a orange wire from the AMM connector. It is controlled by the relay.

PULL back the boot and attach a tiny light bulb setup that he shows with pictures.

This orange wire loops the AMM and the injectors with 12v power to operate them. They get opened by being grounded by the ECU program pluses.

ECU’s are seldom a problem, it’s the peripheral stuff that screws with its world with inappropriate information being supplied! The AMM and the oxygen sensor, is on both sides of the engine. The in & out mixture and then it’s the coolant sensor with the TPS that cues up what the engine is going to do next.

So with this information you should be able to picture what not happening fairly quickly.

As far as the noisy main pump be suspicious that the in-tank pump might not be working or the rubber connecting hose on the sender itself is bad?

Otherwise you shouldn’t hear it run unless you lay down beside the cars pump or in my case, turn up my hearing aids and listen very carefully inside the car! (:-)

Phil

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi Phil -

1992 - 240 sedan

Having read the 100+ messages in this thread - (and counting!) I have the exact same situation that OP has except that I know I have a 2 working fuel pumps. My engine crapped out on me* and failed to start and I discovered that my coolant temperature sensor was disconected (after paying $30 for a new one) Installed the new one anyway, but a no start still. Based upon what you said about what gets the injectors going, I am betting the farm that disconnecting/reconnecting the ECU is gunna work. (I have already disconnected the neg terminal from my battery hoping it would clear, but something tells me there is some kind of 'residual memory' in the ECU. A guess.)

If this does not work, I will try the ether and then mess with the AMM.

*it felt like it was really trying to hold on to life, but after one big cough, died. I think I kind of felt that emotionally, like 'I killed it' lol

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Hi,

I see this is your first post on the Brickboard.

Welcome.

Yes in deed you found a very long post to sift through. It is saying 102 posts.

If you come back on here A LOT you can find a few of us that still respond.

I don’t know any history with you or the car unless you got it from a past Brickster.

Right off the top you are looking at trying to blame the electrical side of things when you shouldn’t.

These cars are more simple than you might think but it’s true they can still have faults.

You need to keep your troubleshooting simply down to the basics of the combustion triangle.

Heat, fuel and air.

A car not starting or hitting even one cylinder can be a slipped timing belt. You need compression and spark to get in there at the right moment.

The car will hit even without an AMM or a coolant sensor there. It’s called limp mode for a reason.

You need to say you have spark and you do that by taking the coil wire off the distributor center and placing it a very short distance (4mm) from a stud above the strut. Prop it there so you can crank the car.

This helps eliminate other components right away.

There is a CPS, that’s known to fail and an item that’s located in behind the battery that fires the coil.

It’s in a place that receives NO maintenance EVER and it is a middleman to the whole affair.

The connector on it should at least be unplugged and reseated out of good measure if you have Sparks.

These items should work even if you don’t have a timing belt. On older 200 cars that isn’t the case.

JUST Verify you are having spark as it has to be a number one priority.

You should hear the fuel pump turn on when you first turn the key to number two position. They should run about one second and turn off. This helps verify that you have a working fuel system relay working.

That relay located behind and under the glove box.

It turns on the injectors and the AMM. These relays have on two sides and one side can fail and do, even with a clicking sound and pumps. There are ways to check its operation if you live on the Brickboard more.

Take the oil cap off and crank the engine and make sure it is turning the cam inside. Observe, crank and see if the lobes moved if you don’t have a helper.

Using a fair amount of ether or starting fluid into a vacuum hose port is a fast and dirty way spot something is not working.

Pull the plugs to see if they are wet or not with gasoline and look for deposit color for condition of the engine.

I need to break away now but stay with us and your car can be fixed.

Phil

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Phil - Thank you so much for the welcome and the useful information. I have been lurking on this site and a few others for a while. I found your expertise, along with Art and all the rest very helpful. Someone said the 'Big Guns' latched on to this post and they were right! I am about mid-trail at this point on this latest non-start and I am determined to figure it out. Once I do, I will humble myself and ask why I didn't 'do that first'. I was looking in the thread for an answer exactly as you had it about 'what can we can say is true' when it fires a little bit with the ether. I just got the ether last night. I circled my wagon around the fuel question already but when I hooked up my handy pressure gage on the fuel line, I lost the damm adapter piece somewhere in the engine. (I actually kept the gage on there was I was driving it so I would see the pressure at any given time. PLus it looked cool. But then the hose started to leak and I took it off. I will keep you posted about what my solution as soon as I find it. /K

|

|

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|