|

If you're still asking what your next step ought to be, consider that I arrived at the same point with our first Volvo, an 83 I was trying to get in shape for my youngest then in driver training.

EFI was new to me; electronics not. As I understood the formula for a running motor to be compression, spark, and a fuel/air mixture stoichometery conducive to combustion.

The amount of fuel is apportioned by open time the fuel valves (injectors) times the pressure behind them. The EFI computer in these Volvos calculated this most basically from the measurement of air flow (air mass meter) with adjustments for temperature (ECT Sensor), RPM, cranking state, and eventually fine tuned by the lambda system (Oxygen Sensor).

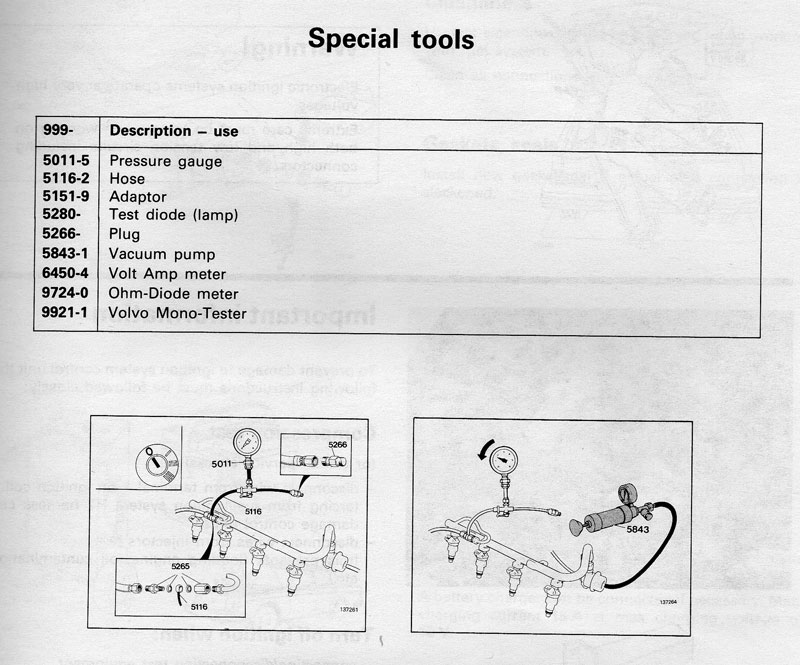

So the first thing I needed to know was the fuel rail pressure. I could guess, like you, that there is pressure, but how much? I found this forum in '99 and asked, after spending too much time in local auto part stores not finding any adapter fittings for the Volvo's fuel delivery plumbing.

Advice I received was to visit the junkyard, grab a fuel rail, and use it to make an adapter for a fuel pressure gauge. I did. I still use it, still thankful for the advice. Now, there are adapters to be had by mail order. I think one of the posts in this thread has a link to them.

The next hurdle was deciding when an air mass meter was malfunctioning. There are many references to a resistance reading you can take purportedly looking at the hot wire. In doing some extensive examination of the Bosch AMM I found that measurement was actually looking at a reliable reference resistor with very little influence from the hot wire, but enough so that a reading outside of the specification would identify a completely broken hot wire. And your more modern LH3.1 thick film-based meter doesn't even have a fragile hot wire.

Chalk this up to the technical publications folks who needed to put something in the green manual for dealership technicians to use their 1982 multimeters on. End conclusion is, there's no definitive way to test an AMM good without a laboratory flow bench with temperature control.

But back in '99 the junkyards were full of 240s. I had my pick of $35 AMMs and knew I would always be keeping a spare that passed a driveability test, because how else can you know?

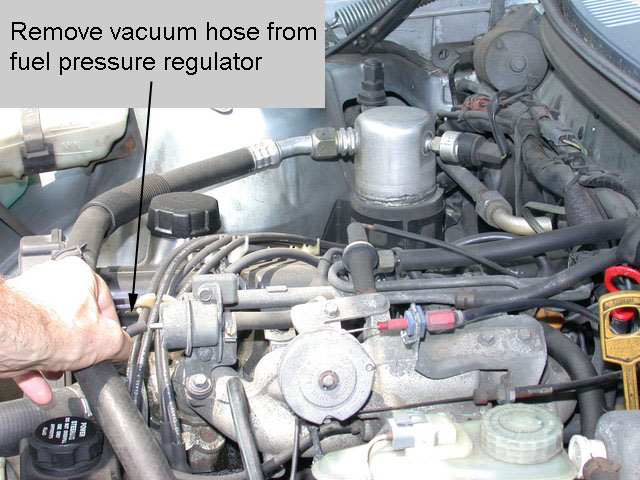

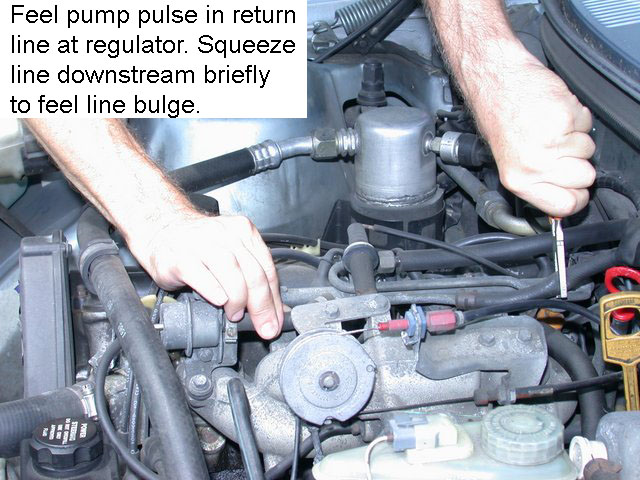

I believe if I were in your position, I would find a way to verify the fuel pressure. With lots of experience behind me, I can do this without a gauge, using the assumption Mr. Mullet suggests, that the regulator is okay. Not that they don't fail; they do, but usually in such a way your sense of smell will suspect them. They leak past the diaphragm. Learn to run the pumps without the key (jumper fuse 4 to 6) and feel the pressure in the return line.

Someone said "some" of the fuel gets returned. At the rate fuel is pumped nearly all of the fuel is returned. And if you're running just the pumps, it is all of the fuel that gets returned, just at a much lower pressure than what is behind the injectors.

But just as too little fuel will keep your motor from running, so will too much, such as when the regulator fails stuck in high pressure. You won't be able to guess this using a pair of pliers to squeeze the return hose.

Suggesting you get your fuel pressure measured or a spare AMM may not get your car fixed. There are plenty of off-the-wall troubles left to imagine. Poor connections in an engine wiring harness, nests built in the airbox, vacuum leaks past blown intake manifold gaskets, a broken lock pin on the cam, water in the control units ... on and on the list flows.

So, I say, try to find a way to convince yourself the rail pressure is correct and or find another AMM to substitute, if you're at the same point I was with my daughter's 83.

--

Art Benstein near Baltimore

"Wise sayings often fall on barren ground, but a kind word is never thrown away."

-Sir Arthur Helps

|