|

|

|

1993 240 AT wagon

215k (I've had it since 182k)

Over the past few years, I've replaced:

- Distributor, rotor

- Ignition coil

- Ignition wires

- Spark plugs

- TPS

- Vacuum hoses

- Fuel filter

- Fuel pump relay

I also cleaned the MAF and TB a few times. All was done as part of tuning it up and getting it to run more smoothly - which worked well.

The car always took a longer time to start than usual - about 2-3 seconds of cranking. I never thought much of it.

Recently I replaced the fuel injectors, and, wow, what a difference. Engine is much smoother, fuel economy improved, and when cold, it would start right up - zero issues. However, when the engine is warm, it still takes 2-3 seconds to start.

This leads me to believe something else is still amiss and I want to determine what it is.

The crank position sensor looks like it's been replaced, and has a Volvo p/n. Since it's a PITA to change, I've not tried to tackle it.

I've also tried leaving the key in the ACC position for a 5 seconds to build up fuel pressure.

I've also inspected the FPR for fuel leakage - none to speak of.

Two questions:

1. Since the FPR and CPS are fairly expensive items, I'm searching for a method to determine if one of these may be at fault. How can I test them?

2. What else can I test to see if it may be contributing to the issue?

Thank you in advance.

|

|

|

|

|

Fuel pump check valve........

|

|

|

|

|

Pull the vacuum line to the FPR and check for fuel.

|

|

|

|

|

I had already done this - no fuel. Any other tests for the FPR?

|

|

|

|

|

HI,

There is only an operational test for the FPR because it's mechanical. It only passes fuel back to the gas tank above a certain pressure around 43 psi or what ever is printed in bars on the outside.

Specifications go like this per each part number configuration. Or at least that is the "game" they are playing to jack prices all over the place for a very simple, $12 to $20 manufacturing cost priced device, for the last 30+ years.

Mercedes, "Built like no other Car in the World," is such a lie! It and its parts are only priced that way!

No car brands mentioned here. It's just the normal practices.

A Naturally aspirated engine: 3.0 bar (43.5 psi)

A Turbocharged engine: 3.75: 3.95 bar (54.4: 57.3 psi)

A bar is one atmosphere or approx 14.7 psi. I call it 15! Stoichiometric combustion is 1 part gasoline in 15. 14:1

You go up in altitude say a 1000 feet, you lose almost 4 degrees in temperature.

That's close to metric 39 inches or a meter. One millimeter, that's .039 thousandths of an inch. Whoops, almost a 4 again!

3/8" is .375 add a .015 you have 10 mm or .390 again! Fractional (1/64 of what) thinking started all this chaos. Remember the old days of the stock market. Computers changed that, so there is hope to lose fractions altogether.

The world is not as complicated as they want you to think it has to be.

To see these readings you need to connect a dial gage to fitting on the fuel rail that leads to the FPR. Luckily on yours, the 1993 there is a factory one.

Some yard hunters snag the rails off these cars and fit then to earlier cars. I added a Schrader fitting to an '86 car years ago. I get them from a refrigeration supplies house.

This way you can watch it while it's running and after the shut down. You want see if it holds some pressure for about 10 to 30 minutes. This reduces vapor bubbles that can develop during a heat soak when the car is parked.

Things to remember is the ECU fires the pump up on each start cycle and at even zero pressure there can still be a volume filling the rail. So the pump should be able to refill the line very quickily unless there is a total drain down by either the FPR, a fuel injector (4 of them) or the main fuel pumps external check valve mentioned in another persons posting.

Another thing that changes with heat is the metal of the intake manifold. It is a very expansive hunk of metal when compared to old cast iron manifolds.

As with any air seepage passed the AMM, like vacuum hoses or a bad gasket, is more likely to happen when things are expanded from heat.

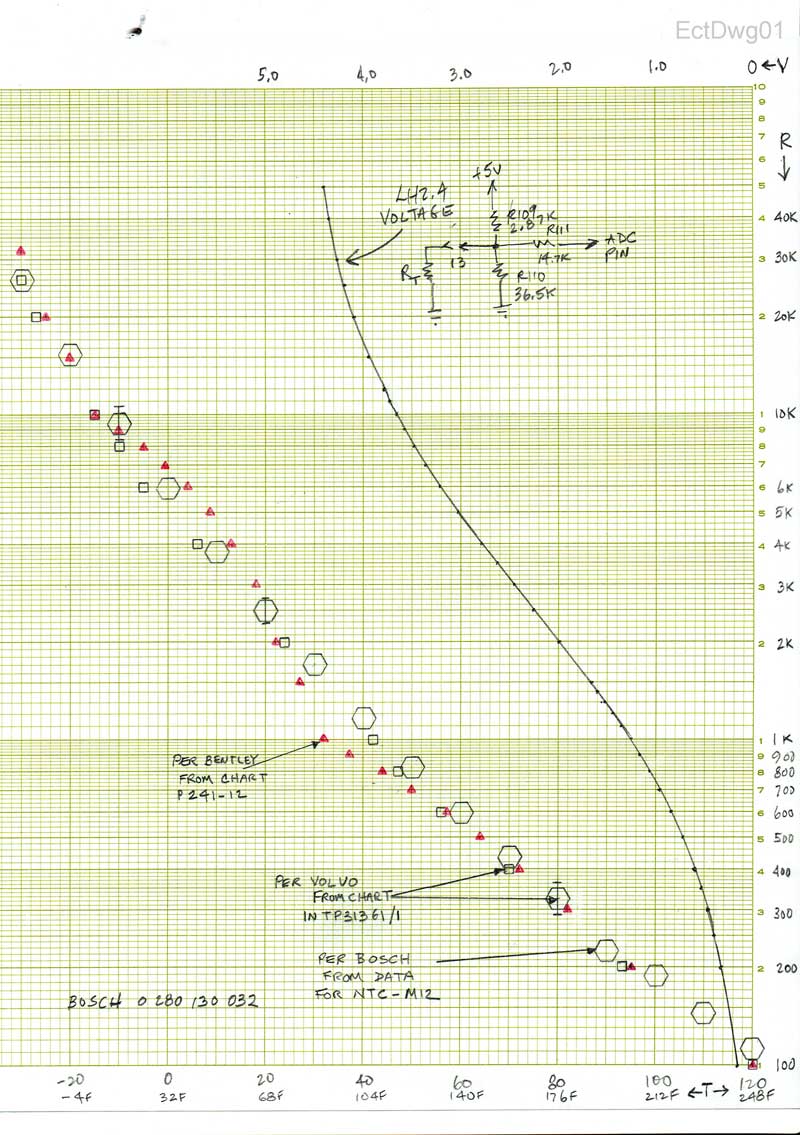

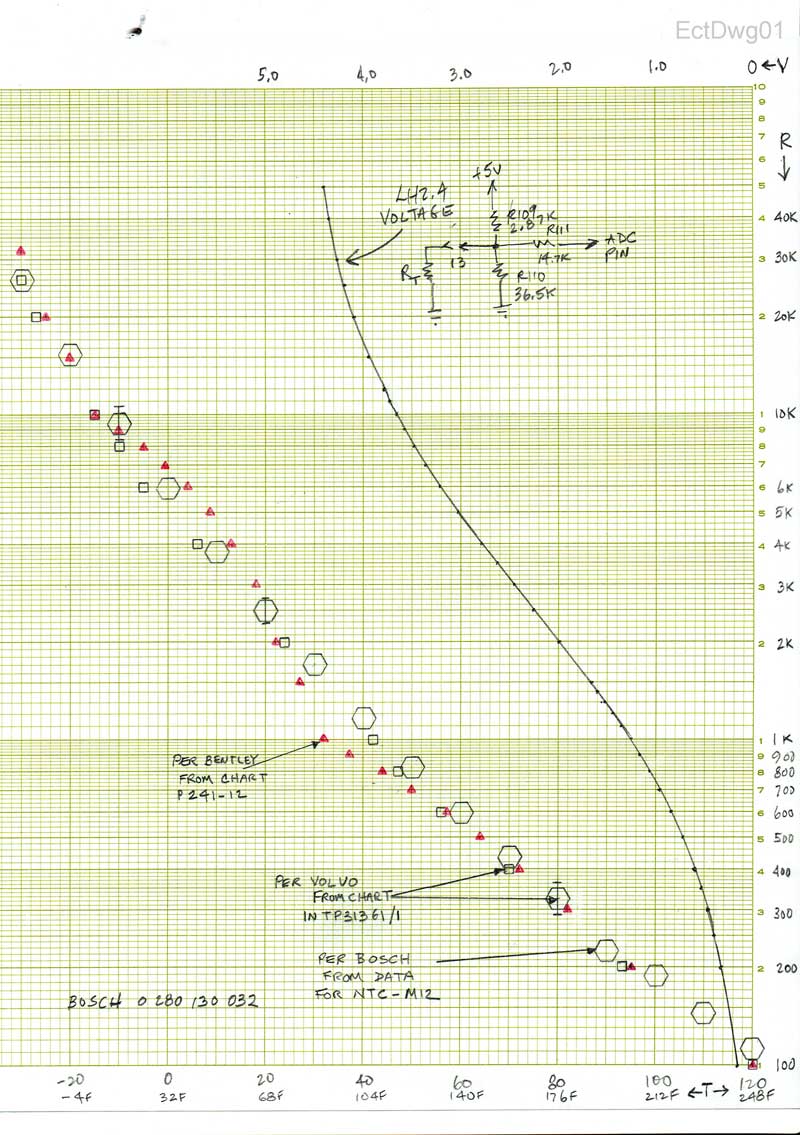

The heat thins down the density of air volume, the engine is going to start with a leaner mixture due to a report from the ECT sensor.

Similar to a low fuel volume or loss of rest pressure/volume.

The time frame you speak of doesn't seem to far off to me for a time to time, but not if a continuously mind bending issue.

The ECU pre primes the fuel rail, for a second or so, every time as the switch passes through position two to roll the engine in position three.

It got figured out over the years by the engineers hearing complaints of cranking that they decided if it was needed when cold, why not every-time for simplicity.

There is a warm start up mode or really it's just a "warming up" running mode section built into the programing.

These cars operate to change pluse width on the injectors only. There is no longer a cold start injector to dump raw fuel anymore.

The old Carburetors had squirt pumps operated by humans avoiding tune ups!

The Emissions restrictions closed down those "avenues of practice" of pumping excessive Hydrocarbons in the air.

The engine can run fine after the engine starts with the fuel management system dialed up. It still needs to have control of mixture and needs feed back coming forth.

This is when there are many unknowns creep in that can raise "temporary havoc" with normal smooth starts.

The systems are so fast it can cover up discrepancies unless components go really bad. This is what you are hoping for....a quick fix... being cheaper than this or that. That's normal for us 240 owners.

It would be nice to know, from you, how long of a time the engine was stopped to achieve what is considered a "warm start" and not a "hot start" too!

Laboratories work with new engines under repeatable controlled conditions.

We now, have what they don't get to tinker with!

We have to find out what got aged to provide its symptoms to make it different!

Check valves on fuel pumps don't get engine heat but can where out their springs. I had only one over the years, so it's Very rare.

If you have that problem it won't start nicely cold or hot, given enough time to sit. It takes time to leak down the lines and filter volume.

After seeing the insides of Art's FPR necropsies, I can understand why they age and wear.

They can lose rest pressure two ways. The seat or the diaphragm.

Failure is a slow process, "starting," of course, at any time.(:-)

A FPR is considered to be one of those things that have to be changed to see what happens.

Sort of like a NEW intake manifold gasket might do.

What is nice about these two items is that both are easy to do work on.

I think I would start with a simple change of the intake manifold gasket.

The intake manifold gasket is a lot cheaper than a FPR and either one will eventually go bye bye!

Like me! (:-) Good luck!

Phil

|

|

|

|

|

Finally got around to locating an OTC gauge and connecting it to the fuel rail. Pressure stays steady at 38 PSI indicated when idle, jumps to 40 when adding throttle, and only drops to 36/37 after 45 minutes. I think the FPR is operating correctly.

After letting a warm/hot car sit for 45 min on a 50 degree day, it is still takes longer to start, even with the fuel pressure showing 38 PSI.

Next step may be the manifold gasket. I've not had that apart yet, and may very well be original. I'm planning a TB change in the new year, and will throw this on the list as well to see if it makes a difference.

Thanks again!

|

|

|

|

Now that you have your gauge, try these somewhat educational exercises.

After a night to allow both rest pressure minimum and cold start, see how quickly the gauge indicates full pressure after cycling the key to KP-II for the 1-second pump buzz everyone thinks is there to "prime" the rail, not that everyone pauses at KP-II to inventory the warning lamp test when starting their 240.

Leave the gauge in place while it warms up to recreate the slow starting when warm. Start it once, verifying it still is hard starting. Shut it off (it is still warm) and verify it is still hard starting. Shut it off again, floor the accelerator pedal, and again, verify it is still hard starting with full throttle.

Bet you'll come away thinking less about power stage modules and more about too much fuel.

Which ECU are you running? 951?

--

Art Benstein near Baltimore

My luck is so bad that if I bought a cemetery, people would stop dying. - Ed Furgol

|

|

|

|

|

Hi,

I agree with you it is not a rest pressure issue. At those pressures, the volume is there.

I was going to suggest turning on the ignition switch to position two a couple of times before cranking the engine to start it. This would fill the lines up first. No need if you are holding pressure.

I’m not so sure that the two to three second delay in starting is so bad but I might be use to that though!

As I think through the system operations, it takes a second to get the CPS signals processed through the ECU & ICU. After that the pump and injector relay has to close. It’s at the end of the chain.

So with that said, you are feeling the engine has chugged through a hit, it’s has fired! When it doesn’t catch right on, with that “ tick over” into a quick up and running motor ... what could be wrong? Oh! Wait, you want us to think about it. OoooKkk?

Past the first second, it might be written off too the nature of the four cylinder beast.

When an engine is ever stopped all the pistons can be mid-way in their individual strokes! It’s a fact!

A piston equalizes against a compression and it’s own inertia that includes the flywheel. The actual stopping location varies with the number of cylinders of an engine.

It’s also a fact that an engine can back up a little bit upon stopping. More so with smaller engine due to the lack of internal friction.

Good reason to keep that timing belt tension adjusted regularly.

The first cylinder firing might be lost to a low piston speed to create enough compression. Consequently ending up with an incompletely burned fuel charge!

The engine now has got to move another 90 degrees of rotation all on the starter motors capabilities.

Hmmm hold that thought!

The first hit was there except for speed of the piston and from where it started out as discussed earlier.

By the second hit, 90 degrees later, this will surely be lots better as some ideal conditions are coming up to speed or in-line as a four cylinder engine is!

By the third hit, it is going to really good and starting to chug over. Now we know it’s going with some real speed as the speed is up that it’s at or just above the starters speed.

How much time it takes for all of this, you got me, but I can tell it’s going to catch. It’s then I might be thinking I will let go off the start mode of the switch. So now where are we, two seconds?

I personally think, that the Chevy cars and trucks start up faster than most any other vehicles.

That is, if they are at least a six cylinder or higher in piston numbers.

Their fuel management systems have always provided the best start method to get fuel and HEI spark, it seems, together.

I know that our Volvo’s are not as fast as them. Trust me, my old Harley, with only two cylinders, firing on those odd degrees of rotations, is about as slow as one can get. It’s almost a two single cylinder engines in one frame.

A Harley can give you new meaning to the term of “chugging” over! It’s more like saying, potato potato when it’s idling smooth! A potato farmers tractor engine. (:-)

So, with lack of anything conclusive, we are dealing with speed. Battery current is flowing or is it deficient? I suggest you study the starting circuit closer.

Those clip on ammeters work well to help diagnose excessive starter motor current or the lack of current being used.

Do readings of voltage and current flow “trending” when cold, warm and hot with a timer, I guess?

There might be such a current draw that it “temporarily” draws power from the other sensitive electronics?

There could be some cable(s) or a battery issue to start with. No pun intended!

Batteries can be surprisingly weird with temperature change.

Have you checked for anything related to the ignition like the component behind the battery.

There might be weak connections to it.

It’s like a relay that powers the ignition coil on and off per the ICU.

So, inspecting the color of the spark during cranking might give a lead.

Pull the coil wire and test it to a good ground. I like the strut towers studs, as I can see it from the drivers seat. Blueish with the length of the thickness of the spark cables is good.

Note,

If you remove the grounding wire to the injectors or unplug them, you will not flood the cylinders while testing for deficient spark arc and current draw of the starter.

I admit I’m with you!

Sometimes, for what ever reason, my 1984 kicks over in a blink. This is more so in the mornings, but not every time.

Then times come it cranks like the rest of my fleet of six!

It’s all that I can suggest short of saying, “It’s the nature of the beast.”

I get a little shaking, like from my dogs and they’re ready to go!

(-:)

Phil

|

|

posted by

someone claiming to be CB

on

Sun Dec 10 14:10 CST 2017 [ RELATED]

|

|

just a suggestion. the later 240s have a Power Stage Amp that is heat sensitive...to much so that there is a heat sink paste on the base where it mts to somewhere near the battery.

Do a search on the Brick Board

|

|

|

|

|

Is this what you reference:

https://www.fcpeuro.com/products/volvo-ignition-control-module-3501921oe

I've not been able to locate any pointers on testing this module, other than swapping out for a known working one.

|

|

|

|

|

Usually the power stage either works or it doesn't. There are some tests search for Art's posts on power stage / ignition amplifier.

https://www.brickboard.com/RWD/volvo/1430179/220/240/260/280/lucids_start_run_sequence_one_question.html

Also don't buy a new one, get one used from a junk yard or ebay.

Dan

|

|

|

|

|