|

|

|

I have a 1992 240, the car has 170k miles on it. A day ago while i was driving to work i noticed my gas pedal had less resistance on it than normal. Being concerned I pulled over and took a peek under the hood. I looked at the throttle body and noticed 2 wires. 1 running on the top it was spooled around the circular track and locked into place. The second was intact, but not in track nor connected. I found that trying to thread the cable back over top on the availble track would cause it to rub pretty badly.

I found a way to connect it to provide temporary resistance but the cable doesn't retract and hangs loose, it sometimes gets caught on a bolt holding the throttle to the engine. I am basically trying to figure out how to get this fixed, and determine if it is dangerous to drive the car in it's present state.

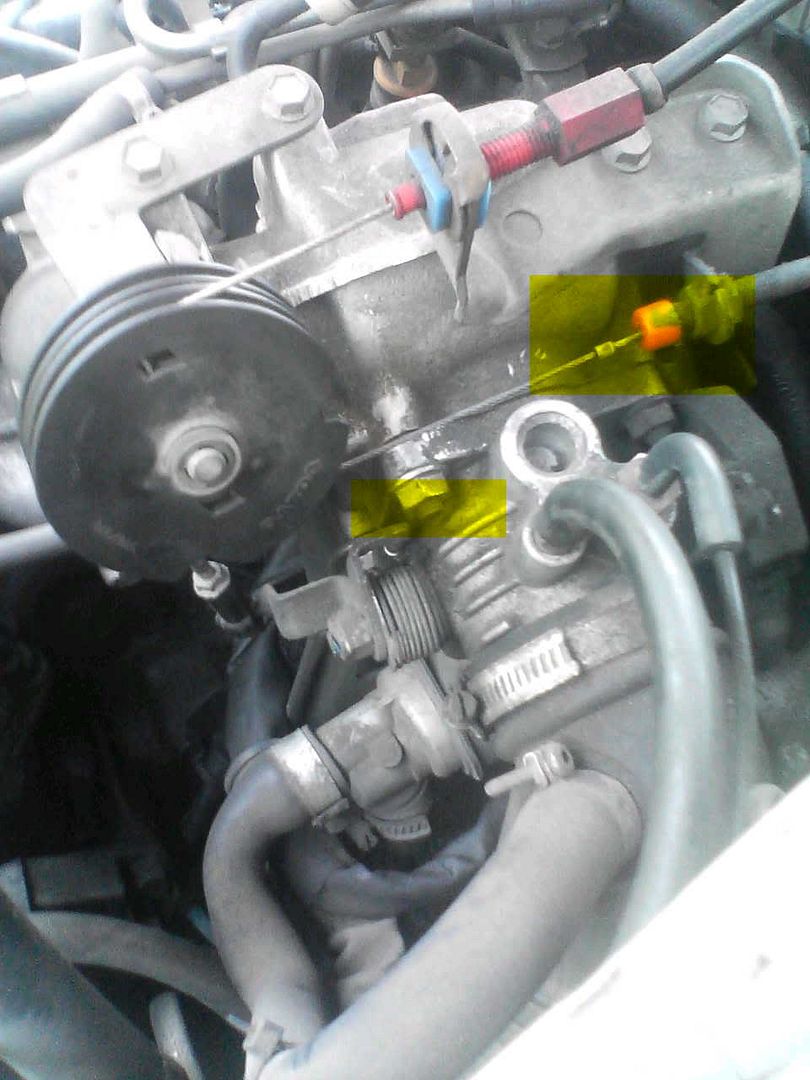

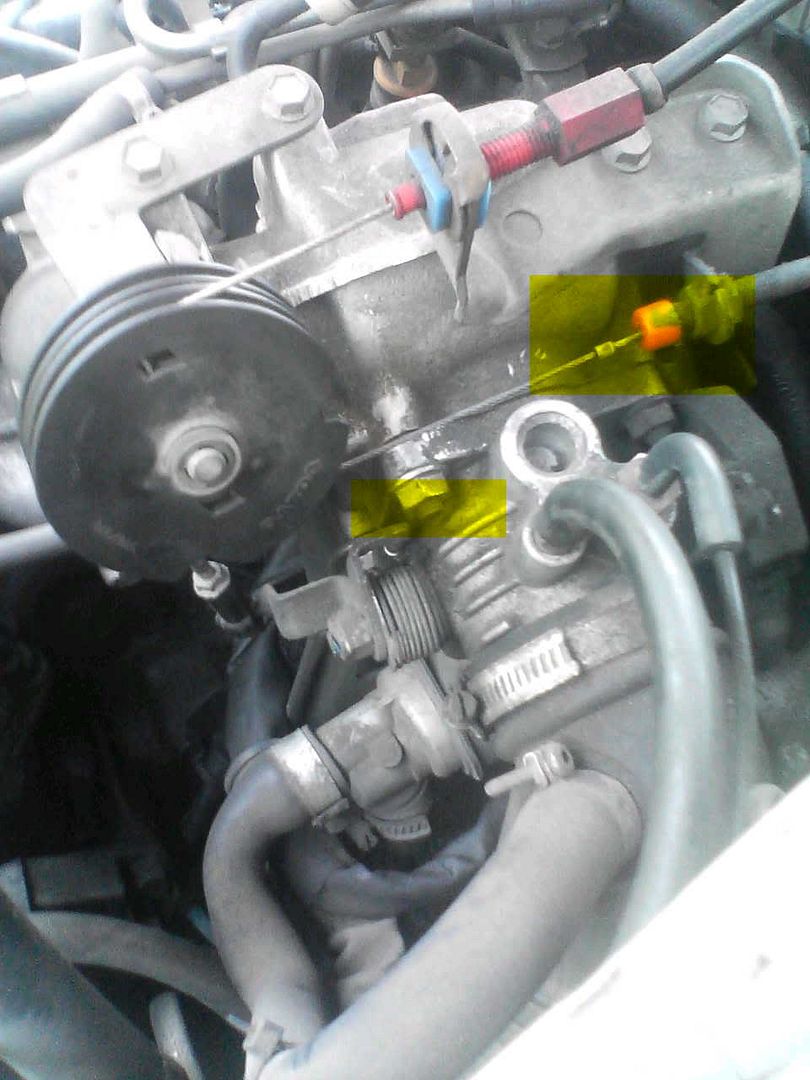

I am also enclosing a picture with two parts highligted. 1) the bolt the piece gets hung up on. and 2) the wire in question.

Any help would be greatly appreciated.

-Ross

|

|

|

|

I just went through the same process on our '90.

The lower cable - which is hanging up - is the kickdown cable.

It goes to the tranny. When cable tension is high enough the tranny downshifts, depending on engine speed, car speed, and throttle position.

You can leave the cable detached till you get it working again.

Tie it to the fat hose nearby with a plastic zip-tie to keep it from making trouble.

I'll post notes on fixing the cable next. Replacing is a pain, but I fixed mine with tranny fluid - notes to follow.

--

Sven: '89 245, IPD sways, electric rad. fan conversion, e-codes, 28+ mpg - auto tranny. 850 mi/week commute. '89 245 #2 (wifemobile). '90 244 (spare, runs).

|

|

|

|

Below is a copy from my post at

http://www.brickboard.com/RWD/index.htm?id=1081738#1081738

See that thread for other notes on this topic.

A common suggestion for stuck cable is WD-40 or PB Blaster. Those don't belong in my tranny. Also I tried that, and could not get the stuff down into the cable. So I really liked Gary's suggestion re. tranny fluid, and found how to make it work.

Before lubing the cable as below, I unhooked it from the throttle wheel and did what I could to work the cable in and out of its sheath as much as possible. Avoid kinking the cable. Replacement is an expensive job if done at a shop.

Tranny fluid: Dexron III or IV or Dexron/Mercon combination.

I'm not sure if you're an old hand at this stuff or if you'll have more questions. If you have questions, ask; I or someone will answer.

Quote from previous thread:

Tranny fluid in the kickdown cable did the trick.

Thank you, Gary H.

The challenge was to get the fluid to go down into the cable.

Basically, a rubber hose, funnel and a small clamp did the trick.

Unhook the top end of cable at the pulley.

Remove what's left of the rubber seal-cap at the end of the cable housing (reinstall seal-cap later).

Slip about 8" of 5/16" I.D. (8 mm.) tranny-fluid-rated hose over the cable.

That hose has a larger diameter than the fitting at the end of the cable housing - and so will accomodate the lug at the end of the cable itself, to be inside the hose.

Point open end of hose upwards at pulley. Hose-clamp lower end of hose to the threaded end of cable housing - small clamp. No clamp = fluid dribbling freely.

Stick small funnel into top end of hose.

Pour in tranny fluid. Not too much, because not much goes into the cable.

Let it soak in while you do other stuff.

--

Sven: '89 245, IPD sways, electric rad. fan conversion, e-codes, 28+ mpg - auto tranny. 850 mi/week commute. '89 245 #2 (wifemobile). '90 244 (spare, runs).

|

|

|

|

|

I had made a post on turbobricks and just now started to get some replies, what are your opinions before i try this?

|

|

|

|

|

I think we are/were having a similar problem, but my cable isn't really sticking. I think I have too much slack. The cable moves out really freely, but there is no way to get it to go back in without feeding it back into the hole. I am relatively new at repairs, but I catch on quickly. Is this cable supposed to retract on its own? Do I need to tighten it somewhere?

Thanks again for your help on this subject, I truly appreciate it.

-Ross

|

|

|

|

Maybe broke off at bottom end??

I hope not.

My shop quoted about $200 to install a new cable.

I'm sure that if it's broken off or the spring broke or popped off at the bottom end then the labor would be about the same as the job he quoted - maybe more.

I'd say try the lube process and see if you get lucky.

Detaching at the bottom end is beyond what I want to get into, and beyond what I know about. I read about it (try the 700-900 FAQ?) and I didn't want to go there.

If you read in the FAQ, your tranny should be an AW-70. Same as in lots of 740's.

--

Sven: '89 245, IPD sways, electric rad. fan conversion, e-codes, 28+ mpg - auto tranny. 850 mi/week commute. '89 245 #2 (wifemobile). '90 244 (spare, runs).

|

|

|

|

|

i dont think it is broken off. The cable does stop coming out after about 4 inches...

|

|

|

|

Just like mine.

Mine started stuck, barely movable. I worked it so I could slide it in and out.

Tension is provided from the tranny-end of the cable. It's supposed to get pulled back into the sheath by that tension.

The friction in the cable sheath is overcoming the tension that is actually there.

If you set up the funnel as I described the fluid will work down, and mine did fine. It continued to improve over the next few days. It's the combination of lube trickling down into the sheath plus cable sliding in and out that spreads the lube and eventually the built-in tension from the tranny overcomes the friction.

Just remember that cable's been there since '92 and whatever lube was in it is all dried up.

--

Sven: '89 245, IPD sways, electric rad. fan conversion, e-codes, 28+ mpg - auto tranny. 850 mi/week commute. '89 245 #2 (wifemobile). '90 244 (spare, runs).

|

|

|

|

|

All right. I just wanted to make sure. I will give this a try tomorrow morning. To clarify a few questions, The cap i am supposed to slide out is the red/orange one? And any suggestions where i can find such hose? I hope this is all it takes to fix the vehicle.

And also it is still safe to operate the vehicle until i can get it repaired provided i tie off the cable?

|

|

|

|

Yes, the cap to slide off is the red-orange one. On my car it was intact, it slides up the cable. After you unhook the cable from the throttle wheel the cap will slide off the tip of the cable. My cap was pretty stretchy. Avoid tearing the cap if you can.

I just looked at the hose I used - 5/16" oil cooler hose. Hopefully that's OK for tranny fluid. From an auto parts store. I have it on good authority that fuel line rated hose is also up to the job. Tranny fluid rated hose would be fine too.

5/16" is just big enough for the connector stub on the end of the cable to pass up through the hose without sticking. And small enough for you to clamp it onto the end of the cable sheath with a small hose clamp (get one of those too). The clamping makes sure the fluid can only go down the cable, not drip out thru the gap where the hose is slipped on. The clamps will probably be priced about three for a dollar or two. You only need a few ounces of tranny fluid, so if there's a bottle in your garage you don't even need to buy that.

And a small-tip funnel. I used the tip of a turkey baster.

--

Sven: '89 245, IPD sways, electric rad. fan conversion, e-codes, 28+ mpg - auto tranny. 850 mi/week commute. '89 245 #2 (wifemobile). '90 244 (spare, runs).

|

|

|

|

|