|

I ordered the 60-pound struts and the 3/4” long ball-studs. You can shim the ball studs with washers for tuning strut final locations.

I used some 5 inch long, 1-1/2 inch by 1-1/2 inch by 3/16-inch thick angle iron to make up brackets that will be fastened to the underside of the package tray.

This bracket caused the strut to be to high causing the strut body to hit the underside of the package tray.

I cut two 5 inch long, 1-1/2 inch wide by 1-inch thick pieces of aluminum (what I had on hand that was thick enough) for shims. This turned out to be just right, putting the bracket lower and allowing it to clear the package tray.

This means the brackets should be made from 2-1/2 inch by 1-1/2 inch angle.

The width of the steps in the package tray where the angle needs to be mounted is 1-3/4 inches wide and allows the bracket to be angled slightly in the step to clear the strut body.

I drilled 3/8” holes in the angle iron and aluminum shims in the drill press. I then drilled the hinges and package tray with the 3/8” bit to allow for adjustments. I used 5/16” bolts to fasten the brackets to the package tray.

After mounting the struts I could see a big difference in the angle of each hinge where the trunk lid is mounted.

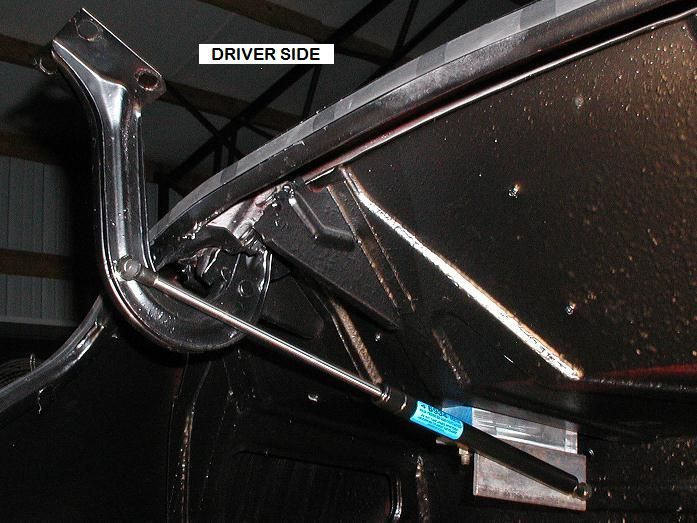

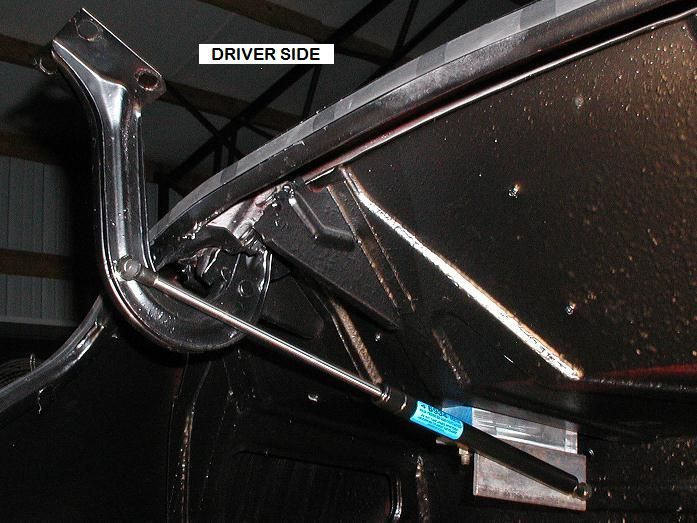

First thing I did was to determine the angle of both trunk hinges.

I could see that the passenger side came up much farther than the driver side.

I used a Dial Gauge Angle Finder ($5.00 from harbor freight) to see what angle the hinges were at.

The angle you get may be different than mine.

With the hinge in the fully open position, the left one (driver side) was 90 degrees or straight up and down. The passenger side was 70 degrees.

I shimmed the passenger side until it was 90 degrees to keep both hinges of the trunk lid parallel while opening or closing, to keep the lid from twisting.

Ray J.

|