|

It has been many years since I was taught the correct method to torque bolts. As I recall, if no specification is given, assume dry except for head bolts, crank bearing caps, rod caps, and rocker arms which are always oiled.

When I was in school there were no thread locking compounds. Today I would use thread locker on any (dry) bolt that should not be removed for service before the next rebuild. Flywheel and clutch assembly comes to mind.

Anti-sieze is always applied to any high heat (exhaust manifold) bolt.

All fasteners must be cleaned and holes chased with a tap before reassembly. Just one grain of grit can create a false torque value.

"Click" type torque wrenches should be dialed back to zero before storage; the spring can take a set and throw accuracy off by as much as 25%. Both clicker and beam type torque wrenches should be calibrated annually. That once a year calibration is for a wrench that see daily use in a shop environment. For the home mechanic, I would think that every four or five years should be OK as long as you take care of your wrenches. Correct technique is essential to accuracy. If the torque wrench is off axis there will be more error.

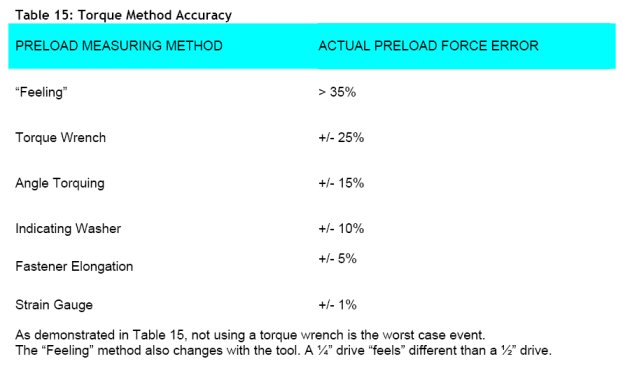

I have a copy of a document concerning torque wrenches, torque values, and accuracy in a service manual from my work. I want so much to post it but I have not received permission to do so (it is copyrighted). I will assume "fair use" for an excerpt. Here is a table from the document:

--

Mr. Shannon DeWolfe -- I've taken to using mister because my name misleads folks on the WWW. I am a 52 year old fat man. ;-)

|