|

|

|

Hello, I'm a new member here and although I have lurked on a number of these forums I don't often post so I'll apologize in advance if I break any rules. I have a 1987 244 that I have owned since 1995 or so. Recently, when starting,the engine barely runs for thirty seconds or more then smooths out and runs fine after. This is only after sitting a while, like overnight. I assumed the fuel pressure was dropping and started checking things which led to eventually replacing both pumps with check valve and sending unit and filter, fuel pressure regulator, throttle switch, and injectors. none of these parts had been replaced before so it was time. When the problem persisted I went back and checked the check valve both with air pressure and vacuum and the regulator also. I did find the new regulator was bad but replaced it with another new one which I tested before installation.The fuel pump relay seems to be okay according to checks in Bently manual. I'm kind of at a loss here and am hoping one of you might have some insight. The car runs great as soon as it starts running right and I'm not sure where to look next.

|

|

-

-

|

|

|

Okay so I'm here with an update,I had some domestic obligations yesterday and couldn't work on the car.

Today I jumped the fuel pump at the fuse box, as some of you suggested, and started the engine. It's actually worse than before, it wouldn't turn fast enough to even put out the alternator light. After a minute it stalled. I tried it a second time and had the same result.

Since it doesn't seem like a problem with the fuel system I'm beginning to think the idea of a cold start circuit problem is making sense. I wanted to check the temp sensor and according to Bentley terminal #2 on the ECU plug should read resistance to ground according to a chart. My garage was 55 degrees F and according to the chart the reading should have been around 3000 Ohm. What I got instead was open circuit.

I haven't been able to come up with a pin-out for that ECU plug but I did find a diagram that I must have found on the internet years ago. according to that chart #1 is the wire on the opposite end from the cable and the row with thirteen wires. If this is correct then it looks like I have an open circuit from the temp sensor.

Using that same #2 wire I ran a jumper from there to the engine and checked for continuity between there and the temp sensor plug. There are two wires in that plug and they both are open circuit to the #2 wire on the ECU plug.

The sensor is under the intake manifold and is pretty tough to probe but I think it checks OK, I will replace it anyway but I need to sort out the wire problem first.

|

|

-

|

|

The wire color should tell you you've got the correct pin. Having an open wire here is less likely than just a connector that isn't clean. It is a blue wire from pin 2 on the ECU to the engine coolant temperature sensor.

Edit: By the way, the suggestion to use a jumper to run the fuel pumps is being made to give you the chance to troubleshoot fuel delivery without the noise and danger of running the engine while you do it. Not to help you start or run the motor.

--

Art Benstein near Baltimore

A man was driving down a muddy road when his car unexpectedly became stuck in the puddle of mud. Despite his best efforts, he was unable to get his car out of the hole.

He abruptly noticed a villager riding his bullock cart near him.

He asked him to extricate his automobile from the mud as soon as the bullock cart arrived. The farmer used his bullocks to pull the car after they agreed to a price of Rs 1000 for the service.

He gave him the money after giving him a huge sigh of relief.

“There must be many cars that would get stuck in the muck like this,” he inquired of the local man.

The villager responded, “True sir, “You are the sixth guy since morning whose car got trapped in this mud.”

Man: “Oh my God! so you pull all of them off. “

Villager: “Yes, sir.”

Man: “This service keeps you busy for a full day pulling the cars from the mud, having no time to do your own work.”

Villager: “Very true, Sir. I have to do all my work at night only. “

Man: “Oh, I see! By the way, what is the main work that you do during the night? “

Villager: “I just ensure that this mud is never dry.”

A good part of the government’s job is to ensure that the mud is never dry. -- famous paraphrased by Abhishek

|

|

-

|

|

|

Thanks for the diagram, that's exactly opposite the diagram that I have so I'm checking the wrong wire. I have a Haynes manual that I haven't looked at in years and the diagram was tucked in there. Maybe I'll finally be able to get to the bottom of this.

I know the jumper was just to troubleshoot, I have been getting myself convinced that the problem isn't with the fuel system but having had the leaking injector originally I've been stuck on fuel system and being able to run the pump when starting gave me the final push to start looking elsewhere.

|

|

-

|

|

The ECT sensor's operation is worth checking. It is the "choke" and a most important part of the fuel system for starting and warmup.

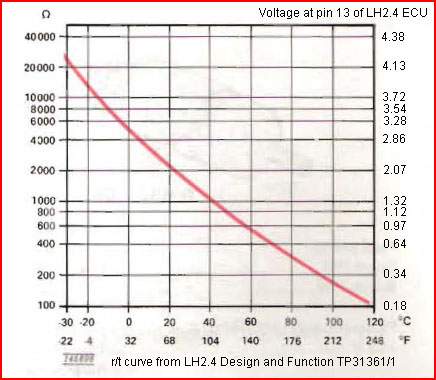

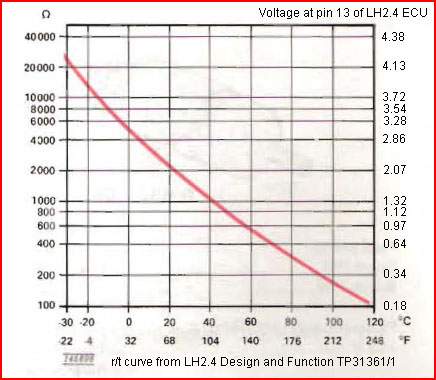

The way I would check it and have done in the past, is meter the voltage on ECU pin 2 at key on before cranking, and then continuously as the motor warms up. This is better than just replacing it, because you will immediately know whether you even need to get dirty under the hood to guess at the condition of the wires and connectors under the manifold. And it checks everything; wiring, connector, and sensor.

Take the shell off of the ECU connector and probe the side of it just as described on page 241-11 in the Bentley. Observe the voltage with reference to ground at the blue wire. Some will just divide the blue wire from the cable and pierce its insulation to access, instead of using a probe on the connector.

The voltage you'll expect follows this temperature curve. The particulars are shown for the dual element thermistor used in LH2.4, but the single element in yours for pin 2 yields the same results.

--

Art Benstein near Baltimore

An elderly father asked his son if he could borrow a newspaper.

“Father, this is the 21st century,” replied the son. “I don’t waste my money on newspapers. But if you like, you can borrow my iPad.”

The spider never knew what hit it.

|

|

-

|

|

|

Well I hate to confess to something so stupid, but In my meager defense, when I started this attempted repair there was a leaking injector. I checked for residual pressure at the fuel line connection to the fuel rail and there was none. I changed the primary pump because it had never been changed and the main pump and filter because that was done about twenty years ago. this led to the pressure regulator, injectors and everything else. after all this the car kept running better and better but still had the starting problem. I kept opening that fuel line and there wasn't pressure so I was stuck on fuel system. Only after some of you guys started talking about temperature sensor did I start to realize that the car started right up regardless of weather there was sufficient pressure, It just didn't run after. Just like starting without the choke. I had changed that sensor some years ago so I wasn't sure but I know things don't last forever. There was resistance at the sensor and I wanted to check the wiring but didn't have the right diagram of wires in the ECU plug. Again you guys came to the rescue and when I checked the voltage at the ECU plug I did get a voltage reading although it was slightly high, and it did drop as the engine warmed up just not within spec. I think Bentley wanted around one volt warm and mine was two point something, nearly three. I checker everything else o2 sensor etc. and the temp was the only thing that didn't seem within spec. I decided to change it anyway and the car started properly. and I feel like an idiot.

So thanks for all your help and U promise to try to be more observant in the future.

I'm blaming it on old age.

|

|

-

|

|

|

Hi,

Well that should help raise your mileage up some …depending?

According to Art’s post and chart provided that is a lot if the almost 3 volts was during warmups or when the engine was declared up to operating temperature. You are saying it still wasn’t in specification so therefore it something pending.

Do you track the mileage as most of us only know when it gets really terrible?

I assume you had a colder ambient temperature than 68 degrees and so the engine was getting a lean mixture that explains the lack of fuel or lean symptom notions.

I’m starting to think that instead of having two separate coolant sensors on the engine we need only one as a voltage meter off from that ECU pin?

There Should be a more accurate observation being presented to the driver than a check engine light. Whoops, you don’t even have that until 1989.

Voltage and resistances are inversely interchangeable as the chart shows.

Fuel management engineers tossed the the idea and wanted their own territory! A human trait thing!

The instrument clusters uses a heating element to “approximate” the temperature with ambient differences in the mix.

Same for a fuel gauge.

I wonder if changed to voltages on the new cars after some debate?

It is why you shouldn’t trust one at very low fuel tank levels. 😥 Some mean empty when says empty and others can be off a gallon if the pump can draw it up on a hill?🫤

No body really cares how full a gas tank can be? 🤠

You can end up like “Cramer” in a Seinfeld episode trying to find out far it can go on E.

We only get smarter after we learn what dumb was!

Phil

|

|

-

|

|

"I’m starting to think that instead of having two separate coolant sensors on the engine we need only one as a voltage meter off from that ECU pin?

There Should be a more accurate observation being presented to the driver than a check engine light."

The average driver only wants a binary indicator: Worry. Don't worry.

Average drivers don't head out on the highway with 30-year-old cars. We want Distant Early Warning. The ECU knows what the temp is with granular precision, so we could add a gauge reading in degrees based on the voltage seen on the that wire. A accessory Wagonmeister could offer, you think? Backup to the old hot wire gauge and its oft errant Temp Faker.

--

Art Benstein near Baltimore

"The one thing that I love on a long trip is the occasional smell of diesel. It is one odor I know doesn't get produced by my car."

|

|

-

|

|

|

Hi Art,

I got what you are saying about those that like kiss information.

As far as David Samuels a.k.a. Wagonmeister doing a kit that might it be a long ways out.

He could be running out of Volvos that he cares to refurbish.

His fixes, for said, thirty plus year old cars are probably fading as well.

I haven’t seen him on the BRICKBOARD in ages.

A voltage meter would read out how cold the engine is in the morning.

I like your term “Distant Early Warning.”

This type gauge would not just sit in the same ole place for what seems like an eternity.

It could give the owners more knowledge on how long they can still use a cell phone or multitasking with the kids. 😵💫

So no need for an outside temperature reading from a door hinge area or under a bumper.

Ford use to recommend warmups of 30 seconds to allow for oil delivery and piston skirt expansion.

On motorcycles I was taught to warm up an engine until you could feel some heat coming from a cylinder’s barrel fins with your fingers.

Boy, that was back in the late sixties! Definitely a KISS method.

A .34 reading volt would be a normal operating temperature zone.

More towards zero volts would be the red zone.

A ECU voltage meter could tell you how much more the crankcase heater needs to be on.

Luckily, I have never used one of those.

I don’t know if they have thermostats? Do they?

Do they even heat the coolant?

Jeez, I Never had to ponder this before.

Living back East in the snow belt and owning a car must be a bear?

I would bet the white coat LAB boys, in fuel management, had some accurate meters.

I used thermometers filled with Mercury.

I still have a pimento jar, about one-fourth full of Mercury.

I salvaged it from high current relays and switches.

Probably an ecological no-no today and rare to buy anymore.

I have a few Volvo trunk lights. I have one of those left plus other vials with wires hanging out for experimenting. Pack rat? I could be?

Hey Art … are we or am I stealing the thread a little?

Nice chat and Have a nice evening. 🤐

Phil

|

|

-

|

|

Your symptoms match what I've had when just one injector is leaky. The flooding occurs slowly after you shut down the engine. It takes a half minute to clear it.

A fuel pressure measurement will show the rest pressure decreasing more quickly than spec, which is after 20 minutes, must be more than 1 bar.

The fuel may run into an open cylinder, so you'd be able to find it if you pulled the plugs in the morning instead of trying to start it, but the wet cylinder may not correspond to the adjacent fuel injector. You might pull the rail instead to check the injectors after the engine is shut down and cooled. Without a fuel pressure gauge, guesswork must be employed.

Edit: On more careful reading, I see you've replaced all your injectors. I'd definitely want to get a gauge on the rail, or at least pull it with the injectors to check for leaks.

--

Art Benstein near Baltimore

Sometimes I wonder if our lives are all about the challenge of keeping gases and liquids where they belong.

|

|

-

|

|

|

Well, I really appreciate all the help, as I said this has me stumped.

This morning I opened the fuel line at the engine ( the car has been sitting two days) there was no pressure and only a dribble of fuel. I opened it before the regulator and there was a fair amount of gas but no pressure. Then I removed the plugs and they all looked dry and not sooty at all. they were a nice light grey .

I had my wife turn the engine with the starter and I watched the plug holes. There was a little vapor but no liquid gas. The car has 166,000 miles so I wouldn't expect the rings to seal gas for too long anyway.

Then I removed the fuel rail and injectors and pressurized it. they held 35-40 PSI with no signs of leaking anywhere. When I did this with the old injectors there was one that I suspected of leaking.

when I replaced the fuel rail I left the line a little loose and there was gas almost immediately. I have been hesitant to actually test the fuel pressure because I don't know how to attach a gauge. I think there's a Volvo adapter for this but I haven't found a source for one. I don't know what thread is used and don't know how to go about making up some adapter for a gauge. I'm a little afraid of starting fire.

I know there are two temp sensors and I did replace one of them a few years ago, the rear one. I'm not sure which one the computer uses and I don't really remember why I replaced it but this problem hasn't been going on that long.

I can't seem to condemn the fuel system and I'm wondering if there is some problem with the computer in the cold start circuit. I tried finding tests in the manuals (I have Haines and Bently). Bently gives some tests but they reference numbered terminals in the computer plug and I can't find a reliable diagram of which wires are numbered.

|

|

-

|

|

"I think there's a Volvo adapter for this but I haven't found a source for one. I don't know what thread is used and don't know how to go about making up some adapter for a gauge."

This might help: https://mrotools.com/71305-lang-volvo-adapter-14mm-lh-jetronic.aspx

"Then I removed the fuel rail and injectors and pressurized it."

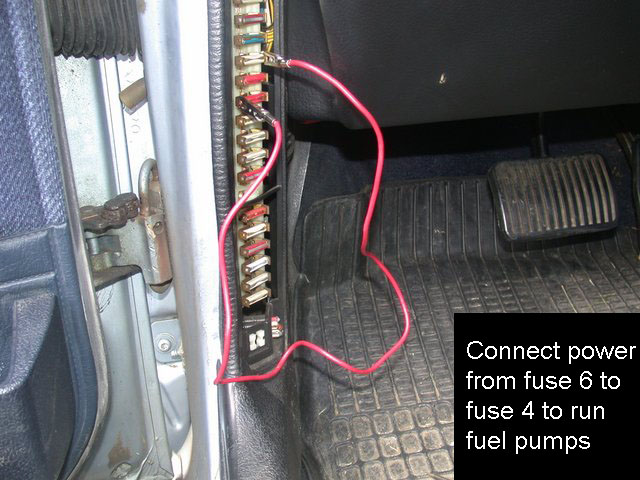

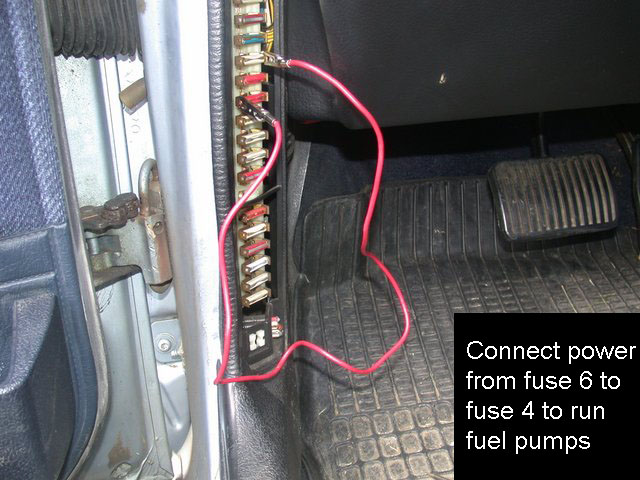

A safer way to test fuel pressure: Run the pumps, but don't start the motor. Jumper fuse 4 to 6.

--

Art Benstein near Baltimore

“Music is enough for a lifetime, but a lifetime is not enough for music.” - Sergei Rachmaninov

|

|

-

|

|

|

I'm not sure how many realize how easy it is to force the fuel pumps to run on a 240 as you've shown with a jumper wire, bypassing a possibly troublesome relay or simply just forcing them to run as in your suggestion. Don't have to get yourself dirty, barely needing to open the door. I was very impressed when an AAA(CAA) tow truck driver once said he packed around paper clips just for such purposes, to get a stranded 240 owner going again and home under their own power. (I'd have to double check this as my diagrams aren't handy, if you go hot bottom left to main fuel pump upper left, a paper clip can be firmly affixed into the tab holes to run the main pump with the fuses removed, albeit no longer with fused protection or the in-tank pump, remove it immediately once the engine is off). A later tow truck driver similarly impressed me, saying he knew to try pulling the AMM connector and force limp home mode so people could get home with a bad AMM. Note to earlier K-Jet 240 and 140 injection system owners, it's fuses 5 and 7 that get jumpered rather than 4 and 6 here with the later LH Jetronic. Check the labelling on the fuse panel cover to be reminded of the main fuel pump fuse.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

|

>I don't know how to attach a gauge. I think there's a Volvo adapter for this but I haven't found a source for one.

I don't have an adapter to offer but I do have a solution. The pieces you need are available from an old fuel rail.

While they used 8mm tubing on the fuel rail 5/16" fittings and fuel hose are a direct replacement. I have been using the set up in the photo for years with no problems. If you want to make up one of these but don't have access to an old fuel rail I can supply the two pieces you need.

I haven't had any luck in using the Brickboard email for some time now, but you reach me at: vguy240atyahoodotcom (if you send email to that address please respond to this post as that mailbox is not monitored unless I know I have something coming)

Randy

--

Any twenty minute job is just a broken bolt away from a three day ordeal

|

|

-

|

|

|

One additional note, on second thought I wondered if the oil might be suspect so I changed the oil and marked the dipstick so I'll know for sure if it's gas getting in.

|

|

-

|

|

|

Interesting set of symptoms you're developing here. There are a number of factors you've established:

I'll try to summarize some of the more notable factors as I see them. Everything starts and runs fine with a warm engine. Everything seems capable of functioning okay under normal conditions. An overnight cold start allows the problem to arise. So block/ambient temp and most especially time are key factors that need to be accounted for in solving this mystery. The excessively cold rough running, almost stalling, is suggestive that things may not be equal in all cylinders. And last, but perhaps not least, you've replaced a lot of stuff that might normally be associated with such problems.

Art and I have been on the leaking injector possibility from the start as your symptoms are very suggestive of this, also it's been a topic here recently. That you've replaced the injectors is what led me to ask about a cold start injector (my LH 2.2 didn't have one, just wasn't sure if that applied to all, similar to the LH 2.4 engines, some had them, some didn't). The absence of wet plugs doesn't mean one or more cylinders aren't slightly flooded. Deposits elsewhere in the cylinder could be damp, especially at the valves, especially the intake valve, next stop along the way from a leaking injector. The absence of notable residual fuel pressure in the morning can be considered reasonably normal. Once the pumps spin up enough for it to catch, fuel pressure should quickly return and the engine should not keep cranking or hesitating for more than a moment or two. That's why I asked if it takes longer to catch when cold cranking, which you indicated it doesn't.

As an aside after that last thought, as a quick and easy test and not all LH systems do this, when you turn the key to the ON position (KP-II) the pumps will spin-up for a second to build initial fuel pressure prior to cranking. In a quiet environment you can hear the pumps buzz if you stick your head low by the door sill. If yours can be heard doing this then you can try the following. In the morning, turn the key to the ON position a couple of times to fully prime the fuel system. Does it now start and run notably better? Again, not all LH 2.2 systems do this, but Art has previously suggested that most do. This would then be indicative it's a fuel side supply problem.

I have one new thought as a possibility and that's cylinder compression. A sticky or badly worn piston ring can act very much like this on a stone cold engine after everything gets a chance to cool and leak down. Cylinders and pistons warm faster than the rest of the engine and will quickly expand to seal in a matter of a minute or so, much like you describe, unlike at the block temp sensor where things change more gradually. That also agrees with yours soon becoming normal when warm and stays that way until stone cold. BTW, you changed the correct temp sensor, the rearmost. I would not have put it on my suspect list, just checked the electrical connection in that harsh environment, especially as your is at the tail end of the 240 wiring insulation issues. IMO, these often get unnecessarily replaced. Symptoms of a failing sensor usually show up as increasingly high rpm as the engine warms.

Given all you've replaced and checked, and not having a fuel pressure gauge handy, my next step would be a warm compression check and then a morning cold compression check, both done dry (no added oil), both done with the injectors unplugged. After the cold compression check, now do a wet cold compression check, a half to a whole teaspoon of oil into each cylinder. Crank it a couple of times to work it in, then do the compression check. If my theory is right, you'll likely find a cold compression check shows one or two very different cylinders and for the wet check all cylinders will be much more even and closer to normal. Even more indicative, if I'm right, after doing the wet compression check with the rings now better sealed, re-install the plugs and reconnect the injectors, then try starting. If I'm right, it should cold start and run much more normally, perhaps a couple of stumbles while the oil burns off.

If that's not it then I'd go back to Art's train of thought further diagnosing at the fuel rail. That's too bad if yours doesn't have a Shrader valve like the later LH systems. You can even use a tire gauge on those to get a quick and approximate reading. Harbour Freight and Amazon will of course have suitable fuel pressure tester kits with the needed European metric adapters, but a cheaper solution is of course a homemade setup as you were thinking (I keep meaning to make one). As I recall, Art has published the details for making up a K-Jet gauge with brass fittings from McMaster, either on his website or over on T-bricks. I'm not sure if he's got the details for the needed LH Jetronic fittings.

Failing all that, I'd change tracks and think about the ignition and electrical side. Do double check that all ignition boots (especially the plugs) are fully seating and pull off, go back more or less the same as the others. Problem with reading brand new plugs is they won't show fuel damp carbon as noticeably or have much time to accumulate deposits, especially if it's mostly accumulating at cold starts. You mention a worn distributor oil ring. That's a definite problem area with the rear mounted cam distributors on the 700/900s, but perhaps not so much on the side mounted ones like yours. Should be fairly easy to remove the rotor and plastic shield for a quick check of that lower area with a paper towel. If the seal is leaking that whole area should be oily.

I'll finish by reminding us that weak or partially corroded electrical connections can behave much differently on a cold or damp morning, such as at this time of year. Our Volvo electrical systems are rather prone to this. Maybe check/spin the key fuses just to be sure.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

"As an aside after that last thought, as a quick and easy test and not all LH systems do this, when you turn the key to the ON position (KP-II) the pumps will spin-up for a second to build initial fuel pressure prior to cranking. In a quiet environment you can hear the pumps buzz if you stick your head low by the door sill. If yours can be heard doing this then you can try the following. In the morning, turn the key to the ON position a couple of times to fully prime the fuel system. Does it now start and run notably better? Again, not all LH 2.2 systems do this, but Art has previously suggested that most do. This would then be indicative it's a fuel side supply problem."

LH2.2 (1985-1988 in a 240 n/a) does not "prime" when you turn the key on. None do.

"As I recall, Art has published the details for making up a K-Jet gauge with brass fittings from McMaster, either on his website or over on T-bricks."

No, I have a page on using a commercially made k-jet adapter, but k-jet isn't the topic here. There's a recipe for home-cobbled k-jet gauges on Turbobricks, but I've got the store-bought one so I haven't made one.

http://cleanflametrap.com/kjetGauge.htm

"I'm not sure if he's got the details for the needed LH Jetronic fittings."

I've referred to the one I made from a junkyard fuel rail in '99 as a result of finding this forum. Made it in belief knowing fuel pressure was an essential part of troublehooting fuel injection. Still use it today, despite the fact the adapter fittings have been available for years now.

--

Art Benstein near Baltimore

"Somebody tell me why I work so hard for you" Everything She Wants

|

|

-

|

|

|

Now that no longer sounds like flooding. The is no cold start injector because the computer enriches the mixture on cold starts. There is a temp sensor the computer uses. So, maybe enrichment is not happening and normal mixture is not enough for cold starts. I can't be more specific, I'm not familiar with the '87 models.

|

|

-

|

|

|

Hi,

Glad to see you are a new member.

You are receiving lots of agreements to causes and your course of actions. I’m with them too.

I have noted that you said the car runs fine after it get over the early warming up period.

This is with the engine being dead cold overnight that leads you to thinking it’s lacking fuel.

The ticket here is not so much a rest pressure but having a full or filled up fuel rail static wise.

You appear to not be thinking it’s too rich enough to cause foul plugs.

You are mentioning having to do restarts for it crashing to a stop.

It is just lopping over and not getting complete combustion but hits in an orderly fashion.

This sort tells mean it hitting on lean cylinders.

So the question lies in between.

Lack of fuel or too much air?

Since this is mostly on a cold engine of which means things are not fully expanded or oiled up it turns on my imagination.

The lack of oil doesn’t exactly figure in much as causing a miss but the engine is tighter dry.

The IAC compensates for many variables unless they get sticky and is a wear item.

So going back to thinking lean and factoring in the years of splendid service.

I’m thinking like you it must be time for replacements.

This could be a leaking intake manifold gasket. They do not last forever and most newer replacements are IMO too thin to last. I try to get something beside FelPro in this area. Victor Reinz seem like OEM to me but are hard to locate in brick and mortar stores.

I say this because I have found this symptom can happen so slowly that it gets disregarded easily.

Probably only one runner get a tear or split at first but this is a progressive symptom.

So in time it goes up to two runners or you can have three runners, each, doing just a little bit at a time.

The head and the manifold masses are always moving.

The gasket gets soaked with gasoline vapors as the injectors spray right on top of the intake valves.

Oil vapors are introduced from the crankcase.

Aluminum being what it is, it’s not a thermoplastic, of which, is another animal in the automotive zoo.

With this ingredient plugged from your post is making a notable variation in how much when cold and none later.

The slight heating time will change to longer.

The symptoms are going to get worse as vacuum leaks do that by their own nature.

Same goes with a tiny split in the accordion tube behind the AMM. The symptom creeps into the mixtures until it can cause sudden idling failures.

Another possibility, not mentioned, is the coolant sensor for the fuel management system. It could be out of calibration or even have a bad connection if it is rich or lean running?

But for only 30 seconds of time makes it NOT a likely candidate, especially, if your mileage is decent.

A 92 C thermostat helps that a bit for in town short runs. IMHO

Anyways I got out my thoughts.

We need an interesting thread and hopefully it’s going to get resolved quickly for you.

Phil

|

|

-

|

|

|

Your post is totally appropriate for these help forums. You've done a lot of the obvious stuff, possibly even a bit too much if you were able to do a more detailed diagnosis.

Questions:

-Does it take a lot of extra cranking to get an overnight cold start to catch and start running rough?

-Does your engine have a cold start injector on the intake manifold? A leaking cold start injector can relate to such overnight cold start flooding and running problems. This strikes me as a very likely candidate if you've replaced the other injectors and still have pressure loss at the fuel rail overnight with a new and presumably okay pressure regulator.

You've done a lot on the fuel side, so time to think of the ignition side.

-Did you pull and read the spark plugs? Fouled plugs can take a few moments to burn off when oil or gas soaked. If black, carboned then new plugs may be warranted. If not evenly colored then a compression check may be warranted.

-When was the last time the ignition wires or distributor/rotor were replaced? Fouled, worn, damp, poor contact of the ignition wires and connectors can take a few moments to regain enough electrical conductivity for a good spark. I've had rough starting and stumbling for just such reasons.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

|

The engine starts almost immediately but then stumbles for probably thirty seconds or more before it smooths out. By stumbling I mean it's barely running as if it will stall any moment. If it doesn't sit too long before restarting it starts right up.

As near as I know there is no cold start injector, this is the LE 2.2 system and if I'm reading the manuals right this system doesn't use one.

The cap rotor wires and plugs were recently replaced also.

I had the plugs out to check for flooding but didn't see any evidence, I also checked for gas in the crankcase by checking for the level to increase and also tried lighting the oil on the dipstick and I don't think the problem is there. However reading some of the posts on here there is mention of an "o" ring in the distributor that may leak and soak the components in the distributor. I'm not sure about this but I'm going to check tomorrow.

I'm also pretty sure that I've cleaned all the grounds I could find.

I haven't put a test light on the fuel pump yet to confirm that it's running when the engine starts but I'll do that tomorrow too.

Thanks for all your replies, this has me pretty well stumped.

|

|

-

|

|

|

Sounds like the engine is starting in a flooded condition. I can't imagine how fuel could be leaking into the engine considering the parts you've replaced. Does this happen only after the car has sat for a while like over night or any time it is started?

|

|

-

|

|

|

I'm not sure about flooding, even after all the new parts if I open the fuel line at the regulator there's no pressure after sitting overnight.

|

|

|

|

|