|

|

|

Hey, brickers. 1990 740 Regina that was a late (RIP Doug) friend's. It had apparently low compression, but I think it's probably not as low as it seems (valve deposits maybe). I already had the parts for this year engine and figured I might as well change them, then try the seafoam trick with the correct timing and then see how the compression values look.

I squared away the "not for fuel injection" fuel line and put proper fuel injection "Barricade" line on the other day, and my garage no longer smells like an open pan of gasoline is sitting in it. I fired the car up with new plugs, and cleaned the IAC (still sticks open, unfortunately). It sounds right now, not crappy, and I can feel some suction on the dipstick tube.

It had OEM belts on it, including the timing belt, but it's cracked all over and the cam seal leaked (and was installed backwards... :S

I got a crank removal tool and got the bolt off incredibly easily. I got the cam seal changed out, but I can-NOT get the harmonic balancer to come loose. It won't even budge.

So far, I've yanked on it, smacked it with various tools, pulled on it and hit it from the side, pulled one side and hit the other, and finally blasted the hell out of the seam where the HB fits onto the shaft with brake cleaner, then some penetrating oil, left it an hour, hit it some more, more brake cleaner, then WD-40 (don't hate - I love it) and called it a night. Maybe it will come loose overnight.

If'n it doesn't come loose overnight, is there a pulley remover that will work and not damage the thing? I'd like to get this done as fast as possible so I can sell the Honda (ick) I've been driving for a few years and just drive this hoopty until my nicer 745T project is fully finished. I might also take this to drive up gravel roads for day trips.

The harmonic balancer has separated, and I cannot get the darn thing to budge even a little bit. This is the kind of time I wish I had a spare brake rotor sitting around to use as a BFH (Large Hammer). The one on my b230ft came off with just my hands tilting it left and right. I'm at my new place and most of my tools are over at my mom's.

Prying seems like a foolish approach, and I guess that this one might be hosed (still works pretty well for now). Any suggestions?

Happy Bricking

Will

|

|

-

|

|

|

Got it!

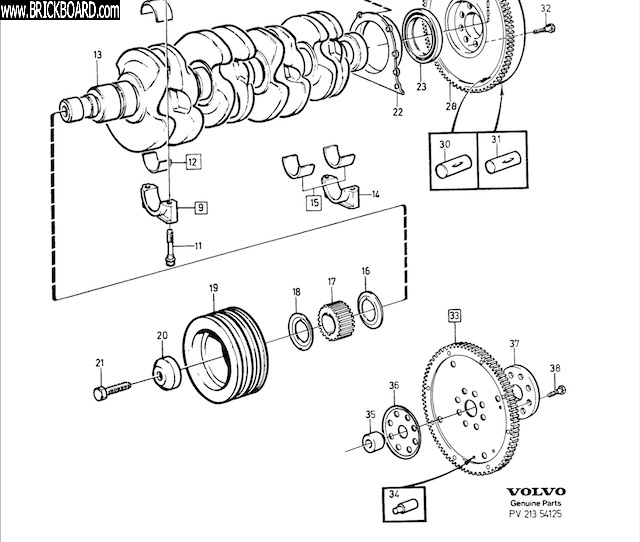

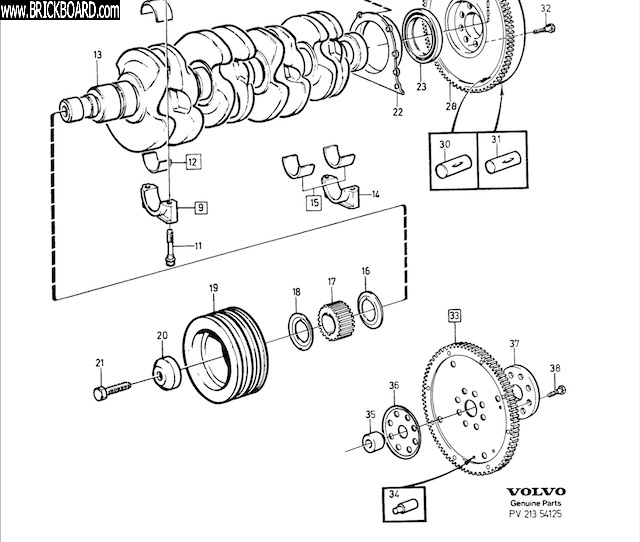

It took using a 2-arm puller. It was held on by rust and crusty oil. Also, there was mention of woodruff keys - there is and should be no woodruff key for these. The crankshaft timing gear has 2 integrated pieces that engage the harmonic balancer and the crankshaft as well.

For anyone who is interested - The pulley diameter is about 6.5 inches. On this non-turbo engine with AC, there are about 6-7 inches of space from the pulley to the radiator, and I put a piece of cedar fence board on the radiator to protect it from slips and mishaps. I inserted the crankshaft bolt 2 threads (or so) until my puller would fit.

My puller is not in great shape, so it liked to wander off the bolt. I had to smack the arms back onto the pulley, and noticed that giving it a few smacks 90 degrees from the arms towards the firewall helped make the other side tilt and break it loose. I had to use the puller pretty much the whole way, even after it started moving.

Word to the wise, this could put grooves in that pulley slot. Make sure you don't have burrs that will eat your belts after doing this.

|

This post has been marked as an answer to the original question.

|

-

|

|

|

Hi there,

I’m glad you got it off of there.

I was worried that the lower half of that engine may have been submerged in water from all of the recent floods over the years.

If it doesn’t have a belly pan that will help do it too!

Put some anti seizure “medication” on the diameters and the bolts threads before reassembling.

It will be appreciated the next time it has to come off, by you or someone else!

The puller tool that you borrowed from AZ was truly abused before you got it.

From the looks of it, it was too small in width on another job before. It may have been for the same thing. That one is an inexpensive tool, alright, for lending out to get customers in!

I have never seen one with curved jaws before as you don’t to pull anything at an angle, especially on sheet metal. I don’t think I would have walked out with that without taking a picture in the store first.

I have never liked having the jaws that are hinged without a way to move the hinge pins in or out.

A two jaw puller made with a single straight bar and different reaching lengths removes all of that mess to keep things shorter.

Looks like you had no choice and besides how often do we pull that pulley?

That’s why I didn’t remember the lack of a keyway either!

Things keyed on the face are not all that common. Make sure you get it back on there flat and engaged!

Only turn the bolt one extra flat after the initial first torque down. As I remember, it’s like 40 foot pounds plus “almost” one flat is what I use with an air impact because without a holder, or a manual transmission, you are not going to get it to stop turning.

The book is wrong on stated “degrees.” It’s Not 90 degrees.

I estimate that its like 110-120 ft.lb. When done! It about the maximum for home style 1/2” drive torque wrenches.

That can throw clickers out of calibration.

Unless, it’s the older beam and pointer ones.

They say you can drive over those and bend them. You just bend the needle to zero and that resets it too!

Sort of like that puller, maybe the same guy became a technical writer or for sure on You Tube now? (:-)

There might be a shade tree blowing in the wind nearby in all of this too??? (:-)

Thanks for the nice finale and feedback post.

Phil

|

|

-

|

|

|

Have just dealt with the same problem. In early efforts, knocked a divot out of the cast iron pulley. It was hard to find a straight line to hit the back of the pulley. I could not get arms of a two leg or three leg puller to hold in the tapers of the pulley and there was not enough space to get the legs behind it. Soaked it all in INOX for a couple of days. Applied heat (propane torch). Still no success. Made up new legs for two arm puller out of 3mm mild steel with an angle grinder. The arms could be rotated into position in the pulley slots then reattached to the puller cross bar. First attempt, the lugs straightened out . Rebent the lugs and heated the puller arms redhot and dropped into water in an attempt to harden them. Tried again (with propane torch heating the hub of the pulley) and gentle tapping and at last it came off. Lower plastic belt cover was damaged by the heat and I had to find a new one. No obvious reason why the pulley was so tight, although there was some evidence of rust. I cleaned this off with steel wool and Scotchbrite.

The crankgear was also stubborn but, after warming it up with a couple of litres of boiling water, I was able to slide it off. I'm still waiting for the new harmonic balancer to turn up in the mail.

On a related issue, when replacing the water pump I was unable to to stop it leaking from the gasket on the block face. It turned out that last time it was replaced, silicone sealant had been used and there was enough in the bolt holes to stop the bolts pulling up all the way. It was fine once I had pulled the pump off again and cleaned the holes out.

Andrew

|

|

-

|

|

|

As a caution to others here who might read this, I wouldn't have used a torch if I was planning to re-use it, which your weren't. It's a two piece harmonic damper pulley, aka. harmonic balancer. It wouldn't take much to destroy the rubber bond between the inner and outer segment. If someone did use heat or excessive force with a puller on the outer edge then it would be a good idea to scribe a mark across both segments of the pulley and check it periodically to make sure they don't move out of alignment. If it's really badly gone you might hear screeching.

That pulley must have really been on. First time I had a stuck pulley I tried using a jawed puller and like you couldn't get a decent grip. Someone said to use penetrating oil overnight and then to just keep giving it a bunch of solid taps around the outer edge, but of course not to the point of damage, and much to my surprise off it soon came. I'm wondering if the pulley may have a slight taper inside. If you can strike the edge with the head at a slight angle it will encourage forward movement. Tensioning it like you did with any kind of puller is even better. Even a pry bar from behind would help tension it while you're tapping.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

-

|

|

|

Not an ordinary key, but as Amarin and Will pointed out the “key” is actually a square-ish nub on the inside diameter of the sprocket that fits into the slot on the crankshaft when you slide the sprocket on - sort of a “built in” key. As I recall the damper pulley, in turn, interlocks with the face of the sprocket via a small ridge and groove. That way all three pieces (crank, sprocket, damper) all stay in proper relation to each other, as long as the bolt is good and tight.

|

|

-

|

|

|

Regarding the woodruff key, I posted that thread because I just replaced my timing belt (940 1994) months ago and didn't experience that difficulty. Just in case the 940 was different, I searched back my softcopy 740 parts catalog just to be sure, and the crank parts diagram was from this catalog (shown below). The red page numbers listing are for my own quick reference for access.

The best I could recall is that Volvo is one of the "progressive" brands that stopped using woodruff key in their cars. This compared to other "conservative" brands eg. Toyota.

Just my 2 cents opinion,

Amarin.

|

|

-

|

|

|

Thanks for the follow-up. My apologies for misleading you on the woodruff key. It’s been so many years since I replaced the timing belt on a red block I forgot how the sprocket was keyed to the crankshaft.

|

|

-

|

|

|

No worries. I just wanted to clarify it for posterity.

I even agreed with you until I had the gear in hand.

|

|

-

|

|

|

You were probably thinking about there being no woodruff key on the later timing belt sprockets which have a small key on the back end, while the harmonic balancer pulley is fully keyed on the shaft.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

|

The harmonic balancer is keyed to the crank timing belt sprocket. The key on the timing sprocket is 180 degrees off from the slot in the crankshaft, and on the harmonic balancer, it's orthogonal to where a traditional woodruff key would connect the balancer to the shaft.

There are no loose keys on these - granted I haven't done a timing belt on anything before 87.

|

|

-

|

|

|

Use the crank holder tool to turn the HB pulley right and left. Shake it if you like. Should be able to loosen it and pull out afterwards. No woodruff key there (refer diagram). Your pistons/valves are safe ie. its a non-interference engine.

Amarin

|

|

-

|

|

|

I followed, with interest, your previous thread about the low (BUT EQUAL) compression numbers and goofed up timing, etc. At the time it was almost sounding like you might have a sheared woodruff key on either the crank or cam but I didn't mention it as it's a possibility but not a probability.

But now the plot thickens as you report finding the damper bolt easy to unscrew and the damper is really stuck on the crank. You may be able to take a mirror and flashlight and get a straight-on look at the front of the crankshaft with the bolt and washer out of the way. If you can see the slots in the crankshaft and damper hub, are they offset to each other? If so the hub may be a real bugger to remove.

|

|

-

|

|

|

I did take a photo just now, and can see the key sitting in the slot and that the slot is lined up. Of all the parts, the key is most likely to rust, and I didn't try too hard to get penetrant into that slot.

This engine bay is pretty nasty (leaky cam seal plus tree droppings and I even see a few mouse droppings), so I'm avoiding fire, and I think I will rent a puller here in about an hour. It needs some whaling on, but a puller might be a lot faster and easier.

I remember I had to donkey-kick a wheel to get it off. Not too stuck,but definitely mated to what was behind it.

I'm a little tempted to put the belt back on the cam and let it run a few minutes to get a heat cycle going, but I should put the water pump and power steering pump belt back on to do that. Hmmm.

|

|

-

|

|

|

Hi,

I agree the pulley should not be that hard to pull off.

It’s two smooth diameters together but the it is either rusted or the key is jamming up the direction of coming off.

You need a slide hammer with a claw attachment.

It’s either that or a bearing puller with a two claw reach to pull on the remaining center hub, since its toast anyway!

If those are not available you can try to use some propane heat to make the hub grow slightly and break some corrosion. This will help the penetrant to do just that, penetrate.

The diameters were assembled originally, so it’s gotta come apart!

Almost a whole other topic!

As far as WD-40 goes it is a love it and a desperation product.

I liked it for being a reasonably decent inexpensive solvent.

I use it to loosen up or more or less clean gunk off things, that were stuck for that reason to begin with. Maybe from previous WD use?

It does not do much more than that, except it’s more fragrant than kerosene or more volatile solvents.

As far as the residue it leaves it’s not a very good rust inhibitor, IMHO.

I have seen it mess up delicate meter movements as well, since it collects dust from the air.

Like I said, desperation but its a convenient spray to squirt in tight places.

I like the swivel up spray stick.

Someone really did good to think that one up!

Keeps you from dropping and losing one, that doesn’t fit another cans nozzle, either!

That’s something that dumbfounding to me as why the OD has to change.

I understand the differences in viscosity changes the discharge patterns, but the OD?

They must be trying to think things out for us but create some frustration in the process.

It’s not so inexpensive anymore since the outfit “RPM” (a stock exchange company that produces nothing) has been buying into individual brand name companies.

Too much of this has gone on with in this country.

USA has been sold and divided up into a new global economy.

In Good and Bad ways! IMO, again.

Items get marketed into a “flasher” packages and when that happens, to any product.

I treat it as an excuse to raise the price

It’s the ways of resizing consumer excitement! (:)

Hmm?

By the time you have read all of this extra, you could have had that pulley off the crankshaft! (:-)

Phil

|

|

-

|

|

|

Ive taken off several crank pulleys cause they were loose or seemed to be separating,,I have never had to use a puller,,I think I just used a simple wedge a little on each side between it & the block & so it came off,,maybe itd be best to use a hardwood wedge so as not to damage it?

|

|

-

|

|

|

you were lucky you did not damage the shaft. most people have heard of a bearing splitter. there is a similar tool called a pulley puller. the jaws are angled so it clamps in the pulley grooves (where the belts go). prevents lots of damage.

|

|

|

|

|