posted by

someone claiming to be 122phil

on

Sun Aug 8 12:19 CST 2021 [ RELATED]

|

|

Im in the process of signing in so posting annonomously

I did post whats below to another volvo forum but it didn't have much traffic.

i will try connecting a test lamp to the coil and see if i get spark consistently.

my 240 won't start

I'm trying to start my non turbo 89 240 with b230F auto trans.

I previously replaced the starter motor after someone froze on the key , she held it in crank position,gave it gas and that broke up the gear on the starter.

I might have done something during that process, I undid one motor mount a bit to get to the 19mm bolt on top. It's in a tight spot. wires along firewall may have gotten pulled on etc.

If I turn the key off then try to start it fires a few times, but won't start.

If i keep the key on then retry it does not fire at all.

If i return the key to off , then try,it fires a bit more.

I put the fuel line to fuel rail in a jar, it fills, so its pumping gas.

I tried quick start, in the throttle body, no difference.

When I start cranking the tachometer jumps for an instant so i think it is getting a pulse from the crankshaft position sensor. at least initially.

I tried swapping the fuel pump relay, under the drivers feet carpet, no difference.

If i put the key on and then connect battery it seems to charge the fuel rail for a moment

I'm trying to remember how to check the codes, it has the little box with LED and a jumper wire

Some fuses look choroded so I can clean fusebox and fuses

I have spare parts for most things, might swap ECU's.

any idea why it fires but only when I reset the key to off?

Any obvious things to check? I'm a bit stumped.

unrelated but i think i had an injector stuck on as it would start ok but ran as if one cylinder was flooded until i drove a mile, then ran perfectly until parked overnight so i put new plugs and swapped injector #2 out, plug seemed a bit loose and was wet. my theory is the stored fuel rail pressure was leaking into cylinder 2

compression is good i rebuilt it some years ago. new plugs.

Thanks, phil.

|

|

-

|

|

|

https://www.brickboard.com/IMAGELIB/volvopic.htm?js_link=1&id=13934

the gear appears to have bent the flexplate a bit

phil

|

|

-

|

|

That seems to confirm it then. Unfortunately, that means more work is ahead.

|

|

-

|

|

|

yes. i did straighten it out a bit but it still refused to start.

Phil

|

|

-

|

|

Edit: before doing anything else, first check for error codes on socket #6 on the diagnostic unit. If the rpm sensor signal is absent intermittently, a 2-1-4 code should have been stored.

|

|

-

|

|

|

thanks for that. it makes sense to verify if i can get the crank sensor to read the signal. I figured the distorted sensor plate was causing an unacceptable pulse, and i straightened it somewhat, but I can still feel imperfections if i turn the crank while feeling the part with the holes.

i got the link to the manual so i can check the orange wire to the AMM and also see if i can decipher the codes.

I don't know how critical the air gap to the sensor is. i wondered if its possible to grind off some plastic on the sensor, or some of the housing to get it a mm or so closer.

if i do need to pull the transmission to install a used flex plate,can i drain the torque convertor? is there a drain plug?

i have parts from a year older 740 with hall sensors and the ECU and ICU and the harness..

the Ecu will swap and run, but the ICU has a different connector and its not the same.

i guess it would be complicated to try to revert to the older system but if i could it might work and the tranny could stay where it is.

if i put carbs on it, then i could use an older distributor. my brother converted 2 - 240's that way. they had a little less power but ran well.

I dont have a shop so pulling the tranny in the back yard on the gravel is possible. the car is not a gem. i had it working perfectly though.i rebuilt the engine years ago so its still strong.

|

|

-

|

|

|

Hi,

I know you have been off working and you get too the car when you can.

With that said I suggest you keep looking into the posts in your thread. You are getting a lot of good help.

Art Benstein posted his pictures on the AMM Orange wire and explains that this simple procedure troubleshoots one half on the systems involved and instantly tells you if the CPS has turned something on at all?

Of course that's only one-half!

I wanted you to see his presentation, as it is why, I mentioned it before.

I have asked myself this before, but it seems to me, a person could manually fire a coil by connecting and disconnecting a power source on and off the coil to make it fire a spark each time to rule out a bad coil. I think Art has told me how it can be done but that escapes me?

Either way that definitely leaves the things in between on both sides of that!

Amarin has been aching over the fact that ignition wires go bad!

He is speaking with volumes of facts as these have plaque motorists for over a hundred years and that not counting bad quality!

If you have looked into those manuals provided recently in this or another thread you will notice that the ICU stops working after about two seconds of firing the coil on its own.

Anytime the RPM stays below 900 RPM for longer than the initial roll over of the key, it shuts down!

This explains the couple of hits and it quits.

So this endeavor leaves us hanging that we think we have it all, but NOT!

So the ECU/ICU never knew the engine hit!

The orange wire snitches on them!

These sensors are "tuned" for use on safety guards of hazardous machine or on bumpers of cars so people can back up or trigger warnings of impending crash. Distance is not so crucial as it once was. Call it sophistication or complication it's hand shake!

Sensitivity to distance varies wildly, so they can work without being highly critical of distances.

If you want you can imagine a magnetic window alarm that uses two parts. A magnet and a reed switch. Simple by comparison.

With closeness it works the same way but with a proximity sensor it can use only one part on the assigned sensing location or it can send a signal to a receptor.

Ihis stuff can almost be a play thing but it's scaled around an idea radar symmetry.

That signal going and coming back to the ECU will be studied for deviations with a comparing circuit.

It's the inter workings that's gauging perimeters.

As far a the distance range I personally don't think the CPS has to be all that close to the passing hole(s) or fas far that goes. The distance is probably very tolerable if it's within .010 of the diameter or more. I'm guessing because tight tolerances in manufacturing raise costs!

The CPS is a hard place to access from above.

You might be able to stick a soft wood dowel down through the hole in the bracket and feel it hit something solid. Hopefully not a hole!

Take a single edge razor blade or knife edge and cut a thin Mark flush with the top of the bracket into the wood. Compare it to the sensors length and see.

You can Do this over and over in a couple places on the flex plate. Use the dowel with the old marks and rotate it around to different spots.

This will show runout variances if you get to feeling the finesse and possible simplicity. (:-)

Sort of a Poor man's depth micrometer or depth gage, if you could even get one in there?

With a shot!

I have tried to understand if it's one and only blip from the flywheel and the other there cylinders are fired automatically in a timed succession or is are there four blanks around that it has to count?

It's the solid portion on the flex plate or of a manual flywheel timing diameter, that does the magic.

The holes moving laterally back and forth should no affect the shape of the back-feed of fluxes nearly as much as the solid part giving the spike that the ECU is needing.

Are you the one that said he had an oscilloscope? If so fancy! There is always a back probe on pin one of the ECU from the ICU. I saw that in that link for a manual.

I liked the orange wire or a shoestring around a suspected relay!

There's a little Scotty lurking around in all of on the Brickboard!

You can tell that I haven't spent much time with my head up between a bell housing!

I do not like the idea of having to yank a transmission to look in there either!

Phil

|

|

-

|

|

I have tried to understand if it's one and only blip from the flywheel and the other there cylinders are fired automatically in a timed succession or is are there four blanks around that it has to count?

It's the solid portion on the flex plate or of a manual flywheel timing diameter, that does the magic.

The holes moving laterally back and forth should no affect the shape of the back-feed of fluxes nearly as much as the solid part giving the spike that the ECU is needing.

TP31461/1 simply states the following about the CPS:

"It uses an induction sensor on the flywheel to indicate rpm and crankshaft position via the ignition control unit."

"Induction sensor" would suggest a hall sensor.

But your question may be answered by looking at this pinout diagram with values to be measured when the ignition is turned on and when the engine is idling.

It says at idle, the frequency of the signal generated by the CPS is 770 Hz. In other words, every second 770 periods are counted.

For sake of ease, lets assume that the actual value is 780 Hz when the engine is idling at 780 rpm. 780 rpm equals 13 rotations per second.

Those 13 rotations create the frequency of 780 Hz that the CPS picks up, so every single rotation must create 60 periods, or pulses if you like.

It's not one or four 'blips', it's 60.

What they also write is this: "engine speed (rpm) and position in relation to TDC". So there will most likely be some kind of 'glitch' in those 60 periods to identify TDC.

Every pulse received will mean the crank has turned another 1/60th of a rotation, or 6 degrees, and in relation to the 'glitch', the ICU knows exactly what the position of the crank is.

I don't think the ICU 'knows' this is a four cylinder engine. It just keeps timing single ignition pulses and the distributor takes care of the spark going to the right cylinder.

Now the real value is 770 Hz at 750 rpm (presumably), but you get the idea.

|

|

-

|

|

|

Thanks SO MUCH for all the help.

i checked the two CPS sensors and found it is a 3 pin sensor, so it's a powered sensor.

my old sensor was replaced a year ago for reliability, the newer one had what appeared to have some small 'insignificant' marks on it's plastic casing from the recent incident.

after the starter gear shattered I had put the old one back as a test but then replaced it with my newer one after seeing no change.

I checked both sensors with a meter, found continuity on two of the pins but no connectivity with the others and I read 184 ohms between those pins on the accident damaged sensor, and 252 ohms on the old sensor which had not been involved in the accident. -this is with sensor unplugged and just connected to the meter.

after I had straightened the flex plate with the metal windows,it would not start. (it had 3-4 dents with about 1/8" deviation and about an inch or so long because part of the starter gear was rolling around in there)

Today I replaced the sensor a second time with my old one and it started

to sum up it had a bent flex plate and a bad sensor and the trick was to fix both issues and not just 1.

It was much easier to straighten the flexplate from under the car than to pull the tranny or the engine.

I did not read codes yet and i did not try to probe the sensor but if others wanted to.. If you have a computer with a soundcard there are free oscilloscope programs that run in windows and utilize the microphone imputs.

I yried one before and it worked well.

with my old 70's scope you can't freeze the screen but one could do that in windows. it's a good use for an old desktop computer. i wouldnt use a new computer for this but you can probably put a 1 meg resistor on the probe to protect it from loading the circuit.

Eureka ! - it starts fine now so thanks again to all who replied.

Phil

|

|

-

|

|

|

Hi,

I’m glad to hear you got it running!

So you had 1/8” dents in that diameter.

Wow!

You said a chunk of the starter gear twisted around in between the flex plate and the bell housing! I never heard of a gear that is made around a shaft, with the Bendix clutch attached, being able to disintegrate in such a manner.

Sort of makes one think that an engine cylinder hit prematurely or a super defective starter drive.

I have been thinking about the statement made in that “linked manual” in a thread on the forum.

It’s about about the system shutting off the INITIAL spark from the roll-on key switch system.

If it stays below 900 rpm, just doesn’t seem right.

Normal Idle speed is 750, of which, slower than that, so, it must be a misprint?

Maybe 90 rpm.

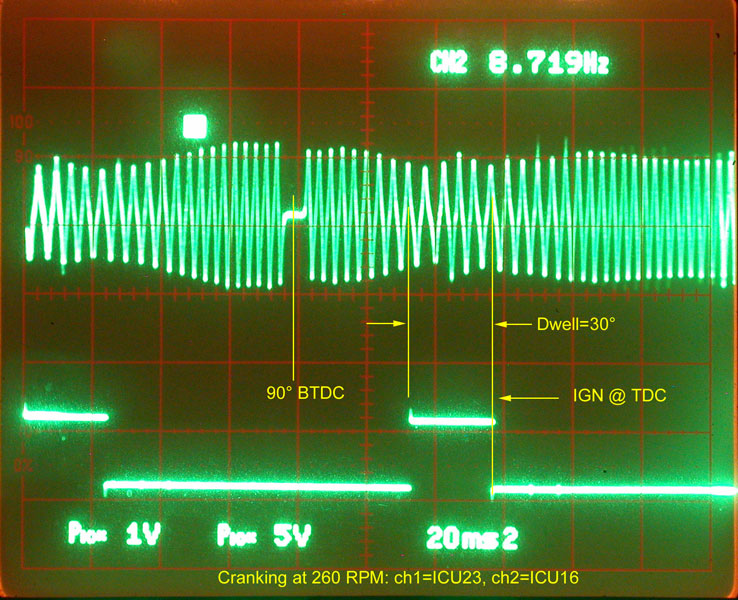

Art has stated that his oscilloscope shows the starter motor turning the engine is around 260 rpm. This seems a lot more logical that, Having those dents that bad, then you would have trouble getting a 90 rpm tick off from the CPS.

I’m glad you stuck it out and got the plate more true!

It proves that the gap is thin under the CPS!

I see you have lots of projects to keep the BRICKBOARD busy!

Phil

|

|

-

-

|

|

|

I’m so messed up I don’t know whom to read first!

I even double posted.

I don’t even want to try the math let alone read an oscilloscope!

Phil

|

|

-

posted by

someone claiming to be amazonphil

on

Tue Aug 17 12:04 CST 2021 [ RELATED]

|

|

the cause was just due to inexperience. My wife got in it to move it and I was nearby. she turned the key but didn't release it and gave it gas. of course the starter gear stayed engaged and when she reved it up it made the gear go way faster than it was ever intended to. the gear basically shattered and I found 7 of the 8 teeth all separated. It probably broke in half , rolled around between the case and the ring gear until it smashed to smaller bits. this wouldn't happen to most people because they would know to release the key, It was just an accident obviously no harm was meant and no regrets but I was happy to solve it as it took some time and now I have the car back in working order.

I put my meter on ohms with the sensor removed and on the bench. and found two wires with some resistance so I guess that was the coil. the resistance was lower on the bad one, maybe some coils shorted part way through the coil of the sensor and weakened the signal but it still had some resistance through what wire wasn't shorted.

I tried putting it on volts and wagging it near a wrench and I did see the meter jump to a volt or two. I'll plan to get a new one when I order parts and I'll try comparing them again with the new one.

I assume it was putting out a pulse but the pulse wasn't strong enough to satisfy the ECU.

when I found that it fired and also lit the test lamp across the coil primary but only momentarily when I began cranking and that this only happened after I returned the key to off, that made me think the issue was not things like issues with the secondary or the distributor or the cap or plug wires because issues like that would not have anything to do with whether or not the key was returned to off. The fact it gave up "trying" after each key return to start but fired when it was returned to off made me think the computer wasn't getting the pulse.

it was not happy with the pulse and so it gave up trying after the first rotation. during the first rotation it must give some sparks and probably fires the injectors, but maybe at a somewhat random timing so that the motor can fire before completing a revolution. The electronics cant' know where the engine is until it sees the segment with no holes. at that moment it probably sort of initializes, but prior to the completion of 1 revolution it is still designed to fire. It seems to be designed to fire even for that moment when it is still "lost" because otherwise it would never fire at all until it completed it's first revolution.

I'm just a self trained backyard car mechanic, I am a millwright by trade, so I have to troubleshoot machinery and it's common for other machines to need to see the zero position during initialization and they will often give up if they are lost. I was recently fixing a samsung washing machine , Even that has sensors on its motor and I had an issue where one sensor wire broke and it would just turn a little, then error out. The error was cryptic but it was basically the same issue.

with things like CNC machines, they often count the pulses to stepper motors and remember this pulse count and that is related to the position of a part. Its common for a machine to need to go hunting for a switch or sensor so that the electronics know where the parts are. often this is part of the machines initialization sequence. In some machines there is some memory on the board so it can remember where it was if turned off.

in a closed loop system the machine may know where the part is at all times as there is constant reporting, but other open loop systems, they just initialize and go find a home sensor to know where the part is and then assume the parts are moving properly. there are often calibration or offset tables so they can be adjusted and fine tuned electronically. if a part moves 10 inches that may equate to 1252 pulses of the stepper motor, if it moves back 626 pulses then the part moved 5 inches. sometimes as part of a machine sequence a machine may keep returning to its home sensor and count pulses. if the pulses used to return to the home sensor position differ from what is expected, then the electronics know something is wrong. that may produce an error saying the part is "lost" or similar. that can happen for example if a bearing seizes so the pulses don't move the part the correct distance. sometimes the drivers which supply the pulses go bad due to failing capacitors etc. I assume the volvo gets this feedback of the number of pulses and if things stop making sense it produces an error, in this case it's a critical error and that shuts it down. It probably also remembers the code for a bad CPS sensor. turning the key to off allows the computer to try again. I assume that code is stored in memory unless a certain number of trips are completed or the battery is disconnected. The ICU probably has both active and stored codes. the stored code helps the technician find the issue after the fact, and the active code probably stops the engine from firing until the electronics are reset by switching it to off.

I'm not all that familiar with the volvo codes but I was just fixing my 88 ford van and it has a code reader that works in a similar way. Its bosch as well.

in my 88 van I opened up the ECU and had a look. what I found was that the ECU board has about 3 small capacitors on the board. I could see that on the board and near these capacitors , the board was sort of stained. what was happening is that these electrolytic caps were leaking their oil onto the board and stained it. it had not failed when I began working on it. ( but I fixed that:)

I attempted to replace the three capacitors, for reliability, but when I was trying to cut one free I accidentally took a chunk out of a transistor. I figure I can change the transistor but I just ordered a "rebuilt" ecu from rock auto. the original ECU did not fail but I dont try it again after I damaged the transistor. I'd be willing to bet that the volvo ECU's and ICU's suffer the same issue and they can probably be made more reliable at this age by replacing the caps. they cost about a dollar. I found that I did not need to take the board out of the aluminum heat sink that it is mounted to. just remove the cover..

I could instead just clip the caps off and remove them about 1-2mm above the board and that left stubs to solder to . then I wrap the new leads on the new caps around a pin about 3 turns and so then soldering the looped end around the little 1mm lead on top of the board is possible. The bosch board in my van was coated with a green rubbery substance but alcohol turns it to goo so it can be removed in the solder locations. the caps have a band indicating which side is ground. its important to note that before clipping them out , electrolytic caps have a polarity and it must be adhered to when you put the new cap in.

newer cars will have smaller components and some may not be so easy to work on but I think the caps can be changed fairly easily during the 88-90 era.

I have a side hobby of restoring old tube radios, mostly from the 30's to the 50's. with those I often dont even try to test the caps I usually just change them all , the shotgun method ;-) after a few decades, they commonly fail but other parts like resistors can last and not degrade. I dont work on transistor radios but the ones that I have pulled out that were 50 years old usually still work so I wouldn't expect the transistors to degrade with age, but the caps do. Old radios have a lot of paper caps but the volvo wont use them , they will have more reliable and more modern non electrolytic capacitors so I'd leave those alone. the electrolytic ones look like tiny tin cans and will have a value like 16Mfd and a voltage rating like 16 volts or something like that. if you replace them you can check and replace each one with the same value.

If you have an ECU or ICU that failed it might be worth trying to just change those caps or some may want to change them for reliability. the replacement ICU I got from rock auto was rebuilt and that's probably all they do. they might have a test bed to check that they function. The one for my van was around 200.00 or so.

there is a list somewhere of what Volvo ECU's and ICUs can be interchanged. The ICU is different depending if it's a hall sensor or CPS sensor. I found I can swap the ECUs between my 240s and 740's. The ICU's seem to interchange as long as they are using the same type of hall or CPS sensor. the connector is different. all my cars are about 88 to 90 ( except my 66) so maybe other years differ but these years are very common here. we had a lot of immigration during those years and they loved buying new Volvo's

Turbos have different boards and I cant' say whether they will work or not if you interchange those. if you dig into that the ECU's and ICU's will have a bunch of different versions and revisions. i haven't worried much about mine failing but if I go on a long trip I'll throw one in the spare parts kit just in case.

I don't know if they are are any symptoms for when ECU's fail or if they go intermittent or just cause non starting issues but I do think the caps are a thing that may fail due to age at this point in time. Ive only seen one instance where mine had an issue and it was a circumstance where the car would not start, due to inconvenience I just had it towed in and the mechanic charged me a thousand or so for a new ECU. that was at least 20 years ago..

I blew up an ECU once by hooking my battery charger up backwards but you guys wont do that ;-)

|

|

-

|

|

I linked in this page mainly because of the pinout diagram, but there's also a description of the workings of the ICU. If I had read that sooner, it would have saved me from some calculus as it's simply written there, including the identification mark I called 'glitch':

"Ignition systems supplied by Bosch for Volvo 4-cylinder engines feature a type 60-1 toothed profile. This means that the profile is provided with 60 drilled holes and with one 'long' tooth of twice the length of a 'short' tooth. In other words, the profile is provided with 58 (60-1x2) short teeth and one long tooth which represents the crankshaft position reference point. The angular pitch between two adjacent short teeths is 6.0" (360 deg/60)."

A mistake I made was assuming that the ICU doesn't know the number of cylinders of the engine and simply keeps repeating a single step.

However this passage shows otherwise:

"This retard is only carried out on the cylinder(s) that have detonation. The EZK can differentiate which cylinder is knocking, as long as the knock and Hall sensor signals are present. "

|

|

-

|

|

Great news. This is the first time I've heard of starter parts being the cause of a bent tone ring. Normally it is one of the oil seal carrier screws backing out that is blamed for that.

The sensor is "powered" by a magnet. The third wire is just a connection to the foil shield in the cable. It's just a coil of very fine wire wrapped around a magnetic core, so that the movement of nearby ferrous metal causes the coil to generate a small amount of voltage which is amplified and counted in the ICU. Your speedometer pickup in the differential works the same way.

--

Art Benstein near Baltimore

It's always darkest before dawn. So if you're going to steal your neighbor's newspaper, that's the time to do it.

|

|

-

|

|

The manual I linked in because it's a good document for everyone with the LH2.4 Jetronic to have. The FAQs are probably easier to use, though.

For now, I would just read the diagnostic codes, if any, from the #6 socket and see if there's a 2-1-4 among them. The complete list of ICU (aka EZK) error codes is here.

If the same procedure on socket #2 yields a 1-3-1, then it's pretty certain the signal from the CPS isn't right. ECU codes here.

Note the subtle difference in description between a 2-1-4 on #6 and a 1-3-1 on #2.

With "older system", do you mean the one that has the rpm sensor inside the distributor?

|

|

-

|

|

|

yes i was pondering the idea of reverting backwards a year to a distributor with a hall sensor but its likely too complicated

i spoke to my brother, he has a 244 thats also 1989 and it has a better body and a bad head gasket. it's essentially identical. He said i can have it if i'd like.

im considering just pulling the engine and some of the other good parts from this car , scrapping it,and then i might feel like I'm moving forward.

i did have this car sorted out with suspension fuel pumps, good heater blower etc. it drove like new but the body is rough.

im sort of in a similar position with 3 740's. i had a 88 wagon i liked and bought a 89 and a 1990 sedan for parts. the 1988 sedan had a rough body so im taking the parts worth saving and i think theoter, the 89 740 is worth saving.

if im up againt pulling the engine or tranny to fix this issue i might be best off to fix one with a nicer body. ill try reading codes first but i know that disk is a little distorted.

|

|

-

|

|

|

Hi Phil,

Something unexpected happened to me yesterday for my 1994 940 - it won't start. This happened at the office parking. It cranked well but still no start. A small crowd started to gather to look - told me its time to get a new car! Now this is a well maintained (no pun intended) car so I thought what went wrong? No OBD codes!

Long story short, I suspected the ignition cables. Air, spark, fuel and timing are the basic things. Luckily I got a spare set in the boot. Replaced all and it started! Went home well. At home tested the old cables for continuity with multimeter. 2 out 4 failed! The damaged cables were Bougicord as per OE standard. Installed it about 2 years ago. Parts nowdays not as good as long time ago.

So there, check your cables.

Amarin.

|

|

-

|

|

That may not have been the actual cause of your no-start condition.

2 out of 4 cables "wrong" (according to the multimeter) didn't bother my redblock very much a few years ago. The multimeter may have measured a break in continuity, the high tension of the sparks had no problems jumping over the small gap there must have been. After replacing the HT leads, the engine ran smoother, though, but only very slightly.

|

|

-

|

|

|

I tend to agree with you. The spark should be able to jump when just 2 failed out of 4. During that early morning drive to office all was well. I'll just continue on my own and report if any positive finding. Lets just concentrate on helping the OP on his no start situation. I don't want to hijack the thread.

I just want to let the idea across for the OP to check his ignition cables. If my 2 years old cables could have premature failure then what about owners who have long unattended ones.

Regards,

Amarin.

|

|

-

|

|

Hmm, I am not familiar with this particular fault, but after glancing through the thread I would agree to check for the possibility that the CPS is no longer giving a steady pulse to the ECU.

This pulse is the basis for the ECU to operate the fuel pumps and igntion.

A very interesting document to have for everyone here with the LH2.4 Jetronic (easily identified by the presence of the diagnostic unit in the engine bay hanging on the left strut tower) is TP31361/1 and can be found here.

I previously replaced the starter motor after someone froze on the key , she held it in crank position,gave it gas and that broke up the gear on the starter.

I might have done something during that process, I undid one motor mount a bit to get to the 19mm bolt on top. It's in a tight spot. wires along firewall may have gotten pulled on etc.

If I turn the key off then try to start it fires a few times, but won't start.

If i keep the key on then retry it does not fire at all.

If i return the key to off , then try,it fires a bit more.

This would suggest to me that the ECU operates the fuel pumps at power up (which it should do for about two seconds after turning the ignition on) and then waits for the cranking signal from the CPS.

TP31361/1 simply states about the signal provided by the CPS that "If this information is not forthcoming, the fuel system control unit will not function.".

I put the fuel line to fuel rail in a jar, it fills, so its pumping gas.

I tried quick start, in the throttle body, no difference.

When I start cranking the tachometer jumps for an instant so i think it is getting a pulse from the crankshaft position sensor. at least initially.

That would suggest that the CPS is providing a signal which is then lost, disabling the ECU until a reset.

I tried swapping the fuel pump relay, under the drivers feet carpet, no difference.

If i put the key on and then connect battery it seems to charge the fuel rail for a moment

This sounds correct for powering up the ECU by turning on the ignition but not yet cranking the starter motor. From this moment on, the ECU needs the rpm signal supplied by the ICU which is the unit that receives the signal from the sensor and reworks it in both frequency and amplitude for the ECU.

I'm trying to remember how to check the codes, it has the little box with LED and a jumper wire

Take the cover off the diagnostic socket, insert the bullit connector in #2 port, turn on ignition, press the button on the diagnostic unit for more than 1 but less than 3 seconds and look for the flashing pattern of the LED.

1-1-1 means no errors. If there IS an error code, write it down and push the button again to see if there are more codes stored (up to three possible, perhaps more in some markets).

#2 port covers the ECU, the same procedure in port #6 covers the ICU (aka EZK) codes.

If you look in TP31361/1, this procedure is called "Control function 1".

You have two more "control functions" available to enable you to check the correct operation of the TPS (control function 2) and injectors+IAC (control function 3) without the need af extra equipment.

Then there's a whole section on fault tracing.

Right now I'm leaning towards a CPS signal that is not steady, for whatever reason. You already swapped it out with a known good one, and so you did with the ECU and ICU. So I understand why you would want to check the flex plate, and I would do the same.

If you cannot visually check the flex plate, you could hook up your scope to pin #1 of the ECU. This is where it gets the rpm signal from the ICU.

More info on the signals on the pins of the ECU here and of the ICU here.

Good luck!

|

|

-

|

|

|

Does a 1989 240 have OBD? If so what codes (both fuel and ignition sides) are present?

|

|

-

-

|

|

|

Art!!!!!

So great to see you still posting and active on this board.

I no longer have my 245, but miss it dearly.

I hope all is well with you and your family. All that you have done over the years to help rear wheel drive Volvos stay on the road is much appreciated!

Tom

|

|

-

|

|

Tom, we're well so far thanks. Good knowing you are. Most of the RWD forum is 900 stuff these days, so not much for me to go on about. Never heard anyone say they were glad to put 240s behind them. Surely ours will be missed when they turn to rust. I washed both 89's yesterday and sure enough, it rained soon after.

Nice to see your kind words!

--

Art Benstein near Baltimore

A thief broke into the local police station and stole all the

toilets and urinals, leaving no clues. A spokesperson was quoted as

saying, "We have absolutely nothing to go on."

|

|

-

|

|

|

Hey Art! Like Tom says, always great to know you're lurking here and doing fine.

I hear you about not being in any hurry to leave the world of 240s, the ultimate classic brick. Maybe though it's high time to get yourself a few more 700s or 900s in your family for you to maintain so you can feel more like commenting on the later models as your expertise and talents here are always in demand. There are so many commonalities with their 240 cousins of the same vintage. You simply know too much about our RWD beasts to let your talents go to waste. Also, this forum always lacks in pics worth a thousand words and no one does them better than you.

As for your comment about no one every being happy about leaving 240s behind, well as much as I miss a bit of the fun of driving a well running 240 and the pride that goes along with keeping it running, I wouldn't at all go back from the easy driveability, creature comforts, added safety features, similar hauling practicality and, surprisingly, even the build quality of the later 940s. If I long for anything in the way of old Volvos, it's missing the fun times I had in my younger days with my first car, a '66 122S Sport Canadian bought off a Volvo dealer's son way back in 1969, next best thing to the '68 123GT one of my friends later had. That was the start of my disease for which there is apparently no cure.

Continued best wishes, my old online friend!

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

|

|

|

Hi,

It’s getting late for me but I will touch a couple points.

The AMM stands for Air Mass Meter. It right behind the air cleaner filter box.

It’s purpose is to measure the mass of air flow only. It does this with watching a heated wire change in temperature, of which, takes into account temperature, moisture and density.

The orange wire that powers the AMM also powers the injector solenoids with positive polarity current. That is all it does! It does not have any pluses on the wire what so ever!

The other side of the injector coil is grounded on and off by the ECU.

It does this in various pulse lengths of time or widths!

If you are familiar with an oscilloscope you know what I mean.

They make a thing called a “noid” light. It’s a LED (light emitting diode) encapsulated in clear plastic.

It plugs in between the injector clips and the injector body.

As far as ”O” rings on those injector bodies, they are for making an air tight seal into the intake manifold. As a test for function of those some mechanics squirt some oil around the crevices.

As the oil gets sucked and it shouldn’t go in, or if changes the idle roughness then you know you have a problem of a hard cracked one.

A intake manifold gasket is a far worse problem to catch, because temperatures of the manifolds mass change and that shifts open the gasket seams.

I have no experience with a starter gear blowing up flywheel teeth.

So this is an automatic in order to have an inspection plate.

The sensor is on the other side, like up on top.

This idea sounds like a very remote possibility, to me, but it’s your time, that’s far away from the issue of burning some fuel for a start up?

It appears you have a lot going on. Must be a “timeshare life” at the moment?

You are a long ways from worrying about a couple things I mentioned on here.

Your engine is not even running!

Keep plugging away at the car and the keyboard though!

(:)

Phil

|

|

-

|

|

|

Pull the distributor cap off and make sure everything is clean and tight. I once had unexplained problems, and when I pulled the cap. The rotor had cracked, and was floating free.

--

Bruce S. near D.C.

|

|

-

|

|

|

Thanks Bruce. I did clean the cap and rotor.

the thing is it fires at first then it seems to stop giving the low side of the coil the pulse. I realize that the test lamp cant; keep up to the pulse frequency but it goes out after about one second or so and firing stops. right now I think the sensor flex plate may have gotten mangled by the pinion gear coming apart. that would make sense because the no start problem ensued immediately after that starter was replaced and I did find gear teeth floating around in that area. I think that after a rotation or so the computer cant see the pulse and quits trying to give the signal to the coil, via the fender transistor/ amplifier thing.. but i could be incorrect. I have a spare transistor and a good comment was made to renew the heat putty.

I can swap the coil or the cap or the leads jsut to prove that inst the issue, that shoudl be easy. maybe I can compare resistance of other coils, I have heard they can go sort of weak maybe the two windings can short part way through the bundle and still sort of work.

|

|

-

|

|

|

Hi, Another Phil here! (:)

Just off the top it appears you have an ignition spark problem, since starting fluid didn’t work.

You have to spray quite a bit through a vacuum port if you want the engine to hit several times. It won’t run long but you want to hear a few hits!

Another thing to check into, for a complete no start, is the timing belt to see if it is spinning the cam!

That starting fluid is a quick check I use to check for spark.

I set up the coil wire, from off the distributor cap end over very close to a strut bolt on the strut tower. This checks the coil wire!

I usually can see it from peeking under the hood and reaching in to the key. A white or blue spark should be about 1/4 inch long.

A bad rotor button can kill spark into the plugs.

There are several things that controls getting a spark going!

If no coil sparkling, check the connector on the electronic relay, that fires the coil per instructions, from the ECU.

Its really reliable but cleaning contacts and replacing it’s heat sink paste keeps it that way!

It Usually never gets maintenance and is nice to do every five to ten years or so depending on your locality. But of course, It’s hidden behind the battery on the inner fender.

Of course the ECU needs a signal from the Crank Position Sensor. They are known to go bad within in the wiring sheathing.

How old is yours?

Located down behind the cylinder head in front of the firewall. Another Well hidden but very important gadget! (:)

The key on and off “completely” fires the fuel pump each time for about one second. It’s a program to charge the fuel rail for quicker startups.

This does not confirm that the CPS is working!

The fuel rail program might be the only reason it hits a little!

Consider the CPS, as it the first thing, that tells everything else.

Wakes up the engine it is now turning!

Hope this helps you get a grip on your thinking cap as it’s solvable!

Phil

|

|

-

|

|

|

thank you Phil (machine man )

i clipped a test lamp across the coill and did the following things, none made any diference. the coil seems to have power wih key on but ground is intermittent.

the test lamp stays lit ,but of pulsating when I turn the key off and then to on and start cranking. it fires a few times but if I continue cranking the test lamp goes out and so does any firing. If i do not turn the key off, and then try cranking more times , no firing and no test lamp. Its repeatable, if I turn to off then I get a few more cylinder fires but not enough to run and the test lamp coincides with it firing in the same way.

I took all the fuses out unhooked battery and scrubbed the fuseholder well put new fuses in if they looked oxydised and put some electrolytic grease on them. they are ok now. made no difference.

I tried my old cranksaft position sensor. no different , put it back

I found a relay up near the ECU and ICU, looks like a fuel pump relay, I tried swapping it out, no change.

I swapped out the ECU and got the same result.

i swapped out the ICU , no difference.

I put the old parts back..

maybe if I could follow that ground path back from the coil, I think it goes to red and white wiresa and one goes to the module near the battery box,, I can swap that out too.

there is a fuse near the coil and mass meter, it's ok..

I thinking maybe a key switch problem or perhaps I damaged a wire while changing the starter motor, there is a big plug up near the firewall that was sort of in the way of the wrench for the top nut..

I have a 740 Im parting out so \i could take the keyswitch and see if that's the same..

I have a scope if that will help.. I know the test lamp shouldn't go out so I must be close. the problem seems related to the coil not getting a comsistent pulsating ground signal if that makes sense..

I think I ruled out bad fuses, bad ECU or ICU, crank sensor.. ill chack tha the timing belt isnt; broken nut cranking sounds normal, I can check the spark but I think its interrupted before the coil low tension leads, and not a high tension fault, bad distributor, wires plugs etc..

the starter has a couple of red leads and a push on connector, I think its a yellow wire, they seem ok..

Phil

Phil

Phil

|

|

-

|

|

|

Hi Phil (:)

Jeez, it’s almost like I’m writing to my self! Maybe I am, in a sense, thinking about how I would check things out at the same time? (:)

The test light will show power to a ground only when power is present.

That means the coil gets charged on the primary side but the actual firing of the coil doesn’t happen, until the power is “cut off” each time! The fender relay does that per instructions of the ICU.

The ICU talks to the ECU and gets information back from the ECU. it’s all very fast!

The light bulb only has time to just flicker off or get dimmer between firings. I wouldn’t trust it to tell you much.

The coils HV side needs confirmation.

The collapsing magnetic field of the primary winding leaves no place for the built up current to go.

It has to go into the next winding, that has many more turns and that winding has the coil wire attached distributor cap and spark plugs.

All is on the end of that High Tension or voltage circuit.

The term “tension” is relevant to a high voltage “potential” as is came prominence with the advent of AC power and higher current levels.

It’s a descriptive term used with distribution towers and consequently the power grid.

I suggest you go to CleanFlameTrap.com and see a picture of a test light being used to confirm that injector power and to AMM are happening.

This is provided that the CPS is signaling the ECU.

This power will be coming on from that relay, you found, installed by the ECU and ICU under the passenger side dash.

He picks up an orange wire on the backside of the AMM connector that links two systems. Fuel and air mixture control.

If it’s on, then most likely, the ignition circuit ICU will come on.

The orange wire is sort of in the middle and indirectly connected.

Art’s web sight has lots of information on various areas of the 200 series. It’s worth a study for other fixes that have invariably transpired over the years of the 240 series.

Keep posting we will get you running!

Phil

|

|

-

|

|

|

I will keep trying. on a similar thread someone suggested that the problem is likely in the area where the starter pinion gear shattered and I did find a little ding in the plastic case of the sensor, that got me to thinking I should remove the bottom alunimum reinforement plate near the oilpan and see if I can inspect the flex plate. it has holes for the sensor to read and I might find it mangled.

I giggled at the cleanflametrap.com name , I have a 88 740 that I bought for parts and drove home and the dipstick pushed itself out along wihtn some oil , I suspect a plugged flame trap , It didn;t seem to have blown the seals out so it has hope. I salvaged a windshiled for it ont he weekend which made it a bit more worthwhile to ressurect. i seem to remember somethign about a rubber hose that is inside the engine and that it can degrade,, but im off topic now..

i dind't find the reference to checking the pulse of the injectors. I just had them all out and used old rubber orings overand then found the ones I had ordered , I can try to change that stuff later. last thing I need is a fuel leak because of an o ring.

im trying to think what the acronym AMM means? Im probably missing the obvious here..

thanks for ID;ing that solenoid. I shoudl write on it what it is, I found that a fuel pump relay fit in there but i\ wasn't sure if it's the same part. I thought that's weird.. I already found the pump solenoid to the left of the drivers feet but couldnt remember the last time I had issues with one , I know I have in the past on a few 240s

in industrial hydraulic systems some of the 24V solenoids now have LED's on them which is nice for troubleshooting, I thought maybe LED's might be added to the injectors at the connectors if such a part exists.

I do have an oscilloscope so maybe i can find the sensor wire and look for the pulse. I dont use it tooo often but can. I could probably put a 1 meg resistor on the probe and probe with that without harming the electronics or loading anything down much.

I remember getting into some volvo factory troubleshooting on a similar issue with my 88 740 wagon, but I got to the point where the wiring was a bit different , it was telling me to check for ground at the connector to the ECU but went on to troubleshoot the signal I think..

that car had the hall sensor so maybe its right for this car. the electrical is very similar but there were changes with the hall sensor or CPS sensor. I have had the hall sensors fail on other cars.

Ill check if the sensor plate is mangled first It might take a few days Im back to work now. if that doesn;t get me there I'll dig in further

I appreciate the help Phil and all who replied. it helps. Ill try to answer some other posts and help where I can. Ive owned lots of volvos and have had most things apart. the worst is the blower in the 240 ;-) That site has some good info worth reading.

Phil

|

|

-

|

|

|

Have you tried swapping in a different (known good) coil?

|

|

-

|

|

|

how about a simple thing like the ground cable from the chassis to the motor

|

|

|

|

|