|

Hi there,

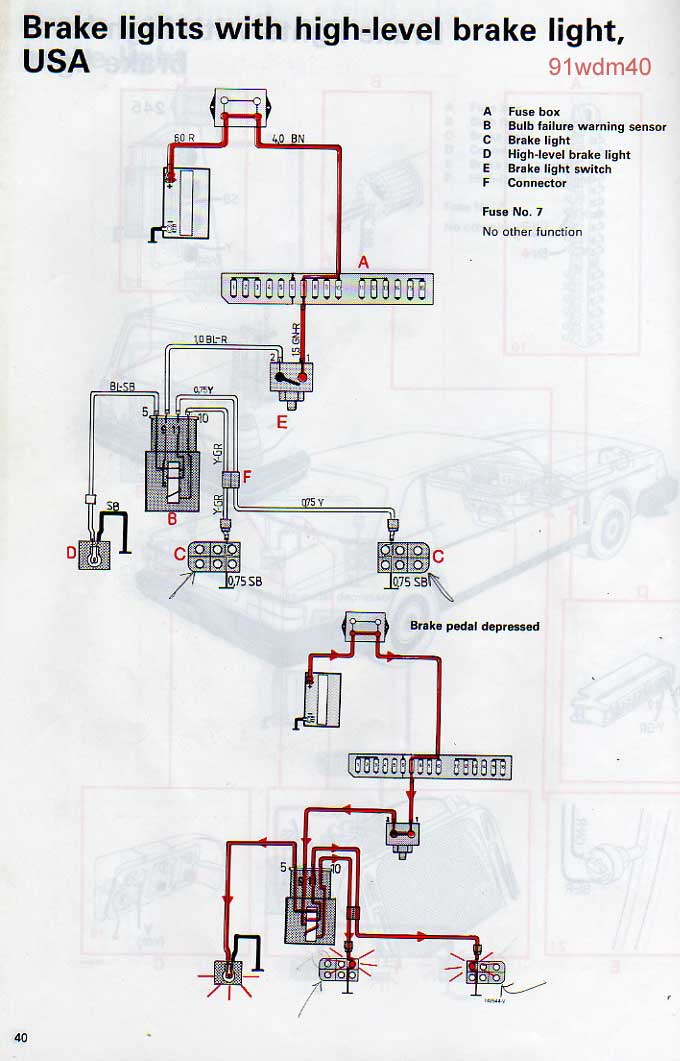

Thanks to Arts instant graphics you can see the power goes to the switch first.

If the switch does not close upon pressure applied no power leaves. The switch is spring load to close by pushing the plunger outwards as the pedal lever goes down away from the switch.

It also can be mounted on the opposite way on the lever and moves away from a cross brace.

In either case they cannot not mash the switch as the brake lever cannot have an obstruction for full operational reasons.

An old switch might do strange things but most of the time this does not happen.

My answer was given, to help to with your original question and to break you into the basics.

Now that Art's expertise is getting mixed in, you may need more information from him. He is our resident guru.

The bulb out relay, I originally thought, used a "shunted circuitry" so it would not carry the total current that makes it operate.

In another word, it is "tapped" in parallel as to mimic or monitor the sides. Left or right or front to rear, and compare a current balance between them.

I looked at them as having two windings coiled in two different directions with a third coil winding inside with the warning light is attached.

Each winding cancels each other with their flow until one side was greater than the other. When out of balance an electric field would transfer power into the third winding causing the warning light to light. I thought no moving parts!

I have learned differently from Art, because does "in depth" research, He has written they use magnetic reed switches at their cores.

Those contacts turn on a separate powered circuit.

Apparently to ground through the bulb powered by the cluster.

Maybe that circuits windings shorts internally by overheating somehow? The relay wires burns something else to cause taillight failures?

Or a possible short outside. Like in the trunk or under the seats wiring that causes the overheating.

We just know that they do fail, out of the blue!

Lucky me, I have not had one do it. I have a spare or two in a box but I cannot say I have done any DEEP research. (:-) Maybe I will after a melt down!

My idea might makes sense, to me only but may not create enough power to make the light bright enough.

I got my idea from the way a solder guns works that powers focused lamps fo light to solder by. A Weller brand pistol type gun.

By the way they, they quit just as easily!

I will watch this thread to get diagnosed by Art.

I am sure I still have a wrong thought in here somewhere!

?:-)

Phil

|