|

|

|

I need to service my wheel bearings on my 91 240 sedan but to do so I must remove the brake caliper. It has two 15mm bolts that are on there like a mother.... I was able to loosen the lower ones on each side but the upper one on either side is so stuck on I'm not sure what to do. I do not own air tools and I don't intend on buying any. I need ideas becase my 12 point socket started to strip one of the bolt heads...I can probably salvage it with a 6 point socket but damn...what is holding it on? I'm a big man and can exhert some serious pressure but my toughness is no match for these bolts (plus they haven't been serviced in years)

If you guys can offer me a tip or two to remove the stubborn bolts I'm all ears..

|

|

|

|

|

I got them both this afternoon with map gas and one of my "new" six point sockets on a 15" breaker bar.

Now....next adventure.........front bearing replacement.

|

|

|

|

|

FWIW,two problems exist with this set of bolts other than the corrosion and torque, that is threadlocker holding them in and threadlocker to keep them from coming loose. To degrade the threadlocker, using some heat on the head of the bolt works also to help break rust as it moves radially in the hole from the heat. The calipers normally get hot from brake heat, however just direct heat away from cylinder. To help the PB Blater or Kroil applied around the head and the threads if you can reach them, hit the head of the bolt squarely and flat with a ballpein hammer. Instead of an impact, try a six point impact socket with flex handle augmented by at least four feet of pipe. Good feel of the bolt and good control of the torque-this has worked many times the impact just chattered. Once it moves, any wrench or ratchet will remove the bolt. And remember the treadlocker on the cleaned bolts when you reassemble it as these bolts will come loose.

|

|

|

|

|

OK, I have a love for "forum crosstalk" and in this thread we have quite a range of different experiences, which I won't refer to as levels, because they cannot be arranged in any quality order.

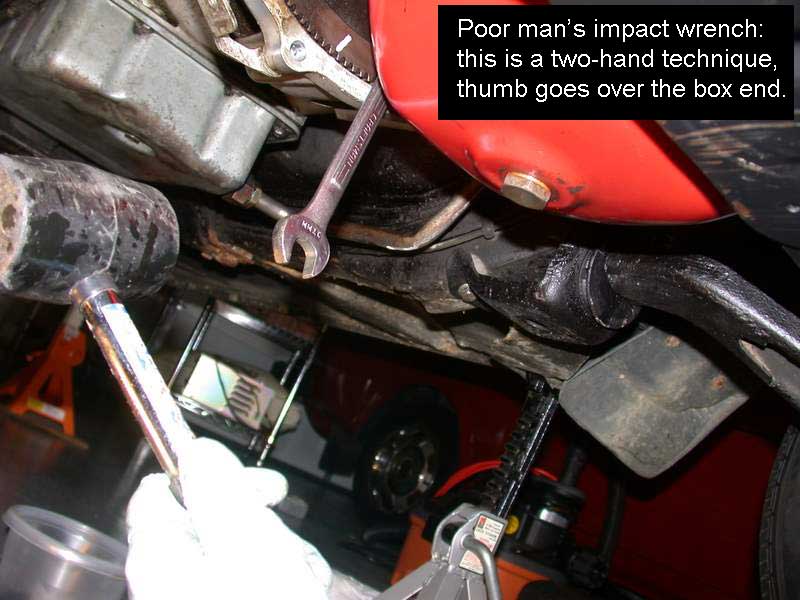

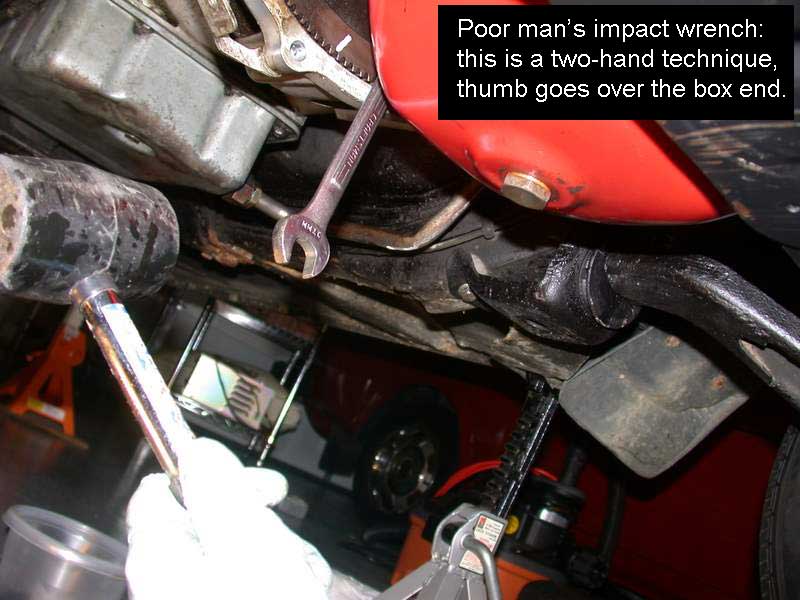

My suggestion: Use impact. Not necessarily an air or electric impact gun, but simply, impact. The way I do this every time with caliper bolts is with a combination wrench. I use the (necessarily 12-point) box end on the bolt head, held squarely on it with the fingers of the left hand, while my right hand swings a rubber mallet at the end of the wrench.

No busted knuckles. No rounded bolts. No broken bolts. Works every time.

To join the "crosstalk" I will gladly offer my own opinions. Onkel Udo will eventually dig his air wrench out of the basement, because he will see why it is my tool of choice to take the lug nuts off. And deal with suspension hardware. To me, it is the only tool for changing a fuel filter. But I let it lay beside me, unused, when removing caliper bolts.

Now, the only reason I don't bother with air for the caliper bolts is I work from the outside of the wheel, close to the ground, not on a lift. It is just awkward, from that position, to wield the rattle gun. I have done it, but learned not to.

And that the feel of a bolt beginning to shear is lost with air tools, I will disagree, understanding that experience with air tools includes learning which ones to use, what settings, how to observe the socket's rotation in correlation with resulting torque, and how to listen to clues the wrench gives you in relation to the particular air pressure and volume being fed it.

As with all experience, certain mistakes are needed to find limits. Ask any pilot.

Like Art (the pro) mentions, I always wondered why 12-point sockets were ever so popular, given my only use for them is on 12-point bolt heads (turbo) or if attached to a fixed (not ratchet) handle. Or sometimes pounded over a corrosion-shrunk exhaust fastener, shortly before resorting to the flame wrench or abrasive wheel.

--

Art Benstein near Baltimore

Acupuncture is a jab well done.

|

|

|

|

|

I used a C clamp to hold the 15 mm in place, propane heat and small sledge hammer.

Have done this job several times but this was the first time for "factory installed" bolts. I could see traces of red "lock tight" compound once I got em out.

Gaylord Smith

1992 240 105K

1993 240 110K

|

|

|

|

|

Betcha a dollar it was made in ........

China.

Warranteed? What's that?

|

|

|

|

|

"Onkel Udo will eventually dig his air wrench out of the basement, because he will see why it is my tool of choice to take the lug nuts off. And deal with suspension hardware. To me, it is the only tool for changing a fuel filter."

Anything is possible.

I have yet to find the impact wrench the right tool for removing lug nuts (I prefer a 4-way) but I am willing to learn different.

I have yet to use an impact for suspension work but I would have liked it the one time I did struts on the '82. I suspect that the bushing replacements I would rather pay for than do myself are what you are mentioning in particular. I have been lucky enough to always have access to a Volvo indy to do the things I just dislike doing.

I am in the camp of rarely (if ever) replacing the fuel filter. This may change if I ever get a fuel starvation symptom.

I still own a hammer actuated impact driver from working on motorcycles and find myself using that on the Saturn race car occasionally when the owner's wimpy CH impact wrench cannot do the job on the bigger torx bolts.

Funny, I remember now why I have two of my three bolt turning air tools...deck construction! I am a sadistic SOB but even I wish driving 60+ 1/2" x 3 1/2" lag bolts on no man! Then there are the 5" ledger lag bolts! I also remember why I want concrete patios from now on! Two things I do not do anymore...roofing and deck frame construction.

|

|

|

|

|

I have done the poor mans impact. I hold my thumb over the wrench to keep it in place but after so many hits the wrench will start to move on me no matter how hard I try to hold the box end over the bolt head. I guess I'll try mapp gas heat but I worry about too much will damage something else?

So, basically, the bolts have not been removed since its birth? Whick could mean the bearings and the grease are original....what about the brake pads? Don't you have to remove the caliper to install new pads? Wow....300,000 miles on original pads and bearings.....I'm impressed.

My biggest fear here is breaking the bolt....then I'm screwed since there are no pick and pulls within a 200 mile radius of where I live.

Another question, someone mentioned replacing the 15mm bolts with 17mm....where do I get those given I have success removing these?

Thanks everyone...

|

|

|

|

|

"I guess I'll try mapp gas heat but I worry about too much will damage something else?"

Aim at the bolt and away from the pistons which have rubber dust boots. I applied heat, counted to 30, didn't work. Next try to 40, didn't work. Next try to 50, worked.

"Don't you have to remove the caliper to install new pads?"

No! Squeeze the brake pads against the caliper (away from the rotor) using something like vise grips. Remove the small hairpins from the pins (threadless bolts) that pass through the "ears" of the brake pads. From the front, knock the pins out with something pointy and then, from behind, grab them by their heads and pull them out. Expect the retaining springs to go flying. Slide out pads.

http://www.fcpgroton.com/product-exec/product_id/9452/nm/1985_1993_Volvo_240_Front_Brake_Hardware_Kit_Vented_Rotors_/category_id/48

"someone mentioned replacing the 15mm bolts with 17mm."

I think I used 19mm bolts. Match the thread, diameter and length and get the hardest.

--

1980 245 Canadian B21A with SU carb, M46 trans, 3:31 dif, in Brampton, Ont.

|

|

|

|

|

Check IPD's site for front and rear caliper bolts. Pretty sure I recently saw them on there. You could even use the part # from there and look up the part # on Tasca's site or from another Volvo dealer as the price might be quite a bit different.

If you choose to use any kind of flame/heat treatment, please be cautious and have an extinguisher near by.

Travis

|

|

|

|

|

They have been apart in the past 300,000 miles, pads won't last that long. It depends on who put them together the last time. I don't want the caliper to fall off, but the bolts don't have to be torqued to 150 lb. ft. either. As tight as I can get tehm with a 3/8" ratchet is plenty.

If you do break them, you can find replacements at any decent hardware store. You may not get your choice of grades, but get the best you can.

Heat, vibration, patience, and a little penetrating oil will get them loose. I like a mixture of 1/2 ATF and 1/2 acetone as penetrating fluid.

Greg

|

|

|

|

|

I had the same problem recently. 2 15 mm bolts, one on each side. Broke two 6 point sockets (didn't have a 15mm impact socket). One was a "Grab-it" that I bought since the head started to round. Even though I had used PB Blaster and waited days between tries.

With a better socket, the right side cracked loose using a jack to raise the extension put over the wrench handle and tapping socket/bolt with a hammer.

Left side refused.

Finally took out the MAPP gas and applied, tried, applied, tried, applied, tried, cracked loose.

Replaced the 15mm bolts with 19mm ones as is used in older 240s.

And I replaced the 13mm bolts on the rear calipers with 17mm.

--

1980 245 Canadian B21A with SU carb, M46 trans, 3:31 dif, in Brampton, Ont.

|

|

|

|

|

NEVER USE 12 POINT SOCKETS ON ANYTHING OTHER THAN 12 POINT BOLTS.

the only time i use that kind of socket is on my wifes range rover which has absurd 12 point bolts.

bear in mind if you snap one of those caliper bolts you are looking at drilling it outs or replacing the entire knee assembly, been there done that. not fun!!

so go easy on the removal and do not use air tools since you will lose the feel for the moment the bolt starts to stretch rather than turn out.

|

|

|

|

|

"do not use air tools since you will lose the feel for the moment the bolt starts to stretch rather than turn out."

Come on guys this is just misinformation!

Impact drivers don't stretch bolts, breaker bars stretch (and break) bolts. If you want to lose the feel for a bolt put a 3' cheater on a breaker bar and watch it shear bolts like cheese.

I don't usually get involved in forum cross talk but greener mechanics need good info.

--

Patrick, '68 220 , '53 GMC 4104, '97 VW Transporter.

|

|

|

|

|

with all due respect you could not be more in error.

air tools at least the serious kind of impact gun capable of 600-1000 lbs of torque will snap a bolt in a heart beat with no forewarning.

hand removal even using a cheater bar will always give a feel for a weakening bolt before it snaps unless you use the cheater bar like a gorilla with no sense of proportion to your loosening.

|

|

posted by

someone claiming to be patrick of montreal

on

Wed Jan 9 13:01 CST 2013 [ RELATED]

|

|

"with all due respect you could not be more in error."

bit heavy on the hyperbole.....impacts have been around for a long time for good reason. Anyone who uses a 600-1000 ft/lb impact at 90+ psi on a small bolt deserves the trouble they get into. I have 3 impacts from 1/2" to 1" drive (1/2" goes to 450ft/lb. 1" is 1,600 ft/lb) and the appropriate sockets to go with them. All my guns have a dial to adjust pressure and if I really need to power down I turn the main air pressure down and slowly raise it while impacting. I fixed cars and stuff for 15 years before I got air tools......I know every trick in the book for loosening bolts, not one suggestion in this thread is new to me, I have used all of them and still do on occasion. Most of the suggestions using hand tools and hammers are just mimicking what an impact driver does FWIW these days I also use my 18V impact screw driver with a socket adapter for small fittings.....got into that work on the electrical panel of my 60 year old bus, fastest way to spin off the brass nuts on the connectors and in the right hands no worries re breakage. Also good at loosening 60 years stuck Philips head machine screws.

What it all comes down to is the right tool for the right job.....Impact drivers aren't a bad tool unless you do not know how to use them. They are an awesome tool if you know what you are doing and much safer than reefing on breaker bars. BTDT.

Don't really expect to change anyone's mind here, just passing on 35 years of experience fixing stuff.

|

|

|

|

|

Heat will help! But first, you ABSOLUTELY need a decent set of six point sockets. No need to spend tons of cash, but get a decent Craftman/Husky/Stanley set or something like that. Then, get a Mapp gas torch, and heat up the stuck bolts. Be careful around anything rubber or plastic that you could destroy with the heat.

The heat makes the bolt expand, which breaks the stuckness that's holding it in place now. After that you should be able to break it loose. You may still need a big breaker bar, or to slip a pipe over the one you've got, but that should do the trick.

|

|

|

|

|

Hi,

Having you tried spraying it and letting it soak for a while with PBlaster? I would try that and use 6 point sockets. It may take a couple applications. Hit the ratchet handle with a hammer might do the trick. I have even applied the method of trying to tighten a fastener that is stuck and then loosen it.

Travis

|

|

|

|

|

"Hit the ratchet handle with a hammer might do the trick."

Never hit a ratchet! Although we all do it, a ratcht should never be used to try and break/undo a bolt/nut from it's tightened position. All of the force is taken by the small ratchet gears inside the head and they aren't designed for that. If it doesn't undo straight away, use a bar.

Blaster/Kroil a good idea (neither available in the UK) and Loctite softens with heat so even a mini-butane torch should work on small jobs like this.

|

|

|

|

|

If you are going to fix old cars you are going to need air tools, and while a cheap compressor with a decent sized tank will do, you need to spend a bit more on the impact driver (at least 400 ft/lbs) to do what needs to be done. If you insist on staying manual you will spend more in broken bolt/extractors/drill bits/time etc as nothing loosens fasteners as well as impact drivers

However if you must here are some clues.....

1: Don't pull/push hard on the ratchet etc,better off hitting a breaker bar with a hammer, this will stop the bolt from stretching and breaking (why impact driver are so excellent).

2. Try hitting the bolt head hard with heavy shot (via drift and small sledge) to break free corrosion in thread hole etc....

3. Heat and lots of can help but you really need to heat it. Propane will rarely do it, mapp gas may get you there, oxy/acetylene will always get you there but the chances of adjacent damage rise with the heat so often you lose as you gain.

Good luck and consider air tools, changed my life as a shade tree mechanic and I almost never break any fasteners any more (would have said never but some small dia steel bolts in an aluminum holes stymied me last fall, broke all three, then once the starter was removed, I could get enough heat on the block to twist out the stubs (Eurovan has some dumb bits)).

--

Patrick, '68 220 , '53 GMC 4104, '97 VW Transporter.

|

|

|

|

|

"If you are going to fix old cars you are going to need air tools"

I respectfully disagree. Air tools are REALLY nice to have for certain things but I almost never use them even though I have a pretty good compressor and collection of impact wrenches somewhere in the basement (have not even unpacked them in 6 years). We use them on the Saturn race car but not on my Volvo's.

Those same bolts, I used a lot of penetrating oil for multiple days (since I was using it on the brake line connections and bleeders anyway) then a 1/2" 6 pt on a 2' breaker with a 3' cheater. Broke loose without even resorting to using my feet or a bottle jack.

In the wrong hands, air tools do more damage than good. In the right hands, they are the right tool for the right job. When in doubt, split the difference and get a decent electric impact wrench.

|

|

|

|

|

If you lived in Quebec you would have cracked out your air tools years ago. Salt and slush seize up stuff so bad I have on occasion had to use my 3/4" impact on the wheel bolts of my work van....I bought that 3/4 for my bus but was glad to have that day.

It is all about time and effort (and breakage) air tools get it done fast and safe and with minimum breakage. Pretty sure I could do all the maintenance on my 220( (dry weather light duty work car) with hand tools, but time is at a premium in the summer so I don't. Also important to home mechanics is the safety factor, reefing on breaker bars etc is a good way to pull a car off it's jack stands etc....(not that a car should be hoisted in an unstable manner but it happens) and skin knuckles etc.... I have never worked on my rides and regretted cracking out the air tools, sometimes I don't but even then my 18V impact screw driver seems to get used.

Impact drivers are the #1 mechanics tool.

--

Patrick, '68 220 , '53 GMC 4104, '97 VW Transporter.

|

|

posted by

someone claiming to be volvo

on

Fri Mar 22 22:09 CST 2013 [ RELATED]

|

|

Wtf?!! the bolts he is talking about are on the back side of the caliper bracket. You can't get a impact on ther or im sure he would have done that. sheesh.

|

|

|

|

|

I still respectfully disagree as I do now live in the land where most of the city's road budget is used for salt. I do not change my position. Both my cars lived their entire live is heavy salt environments.

Impact tools are less likely to round off bolts than a 12 pt wrench. Impact tools are faster for many jobs. Impact tools are almost never "necessary".

This being said, I am the same guy who would rather pre-drill, hand nail and hand set trim nails than use an air nailer on 100 year old wood. 99% of the time the air nailer is faster and just as good or better, but one blow-out can ruin your whole day/week/project. My advice is only as good as my experience.

|

|

|

|

|

Use a 6 point socket, a breaker bar and slip a 12 to 15 inch pipe over the breaker bar and lever down on it. It should break the bond. Volvo used lock-tite on these bolts that is why it is hard to remove. You just need better leverage.

|

|

|

|

|

Try using a metal extension of some sort and a hammer to hit, really hard, the head of the bolt. This will ''shake'' and loosen the threads. Try not to damage the bolt head. I work in the auto repair trade and would recommend never using 12point sockets. Stick with 6 point as they are less likely to let go and strip bolt heads and they will save your knuckles also. Hope this helps and good luck!

-Art

--

Teach a man to fish and he will never go hungry. Teach a man to rob a bank, he will never go fishing again.

|

|

|

|

|