|

|

|

Forgive me if this topic has been beaten to death...

I purchased and installed a rebuilt alternator to replace the original 24 year-old Bosch alternator. That one had little trouble handling heavy simultaneous electrical demands (according to my volt meter) such as headlights, blower, brake lights and heated seats while the engine was idling.

The newer alternator shows a significant voltage drop under the same load at idle, with the volt meter near the lower red zone. The dash lights do not come on or glow. Revving the engine pushes the voltage back to healthier levels.

The voltage also drops quite a bit when reverse is engaged. (It's the M46 manual tranny.) Do those filament reverse lights use that much power?

The voltage level is just fine under normal driving conditions under light or moderate electrical loads.

I also replaced the battery at the same time with one that has a lower CCA rating and reserve voltage as well. Would that make a difference while the car was running?

New battery cables were also installed. All connections were cleaned and had dielectric grease applied. A new Bosch regulator was placed on the rebuilt alternator as well.

Is the rebuilt alternator a lower amperage than the original Bosch?

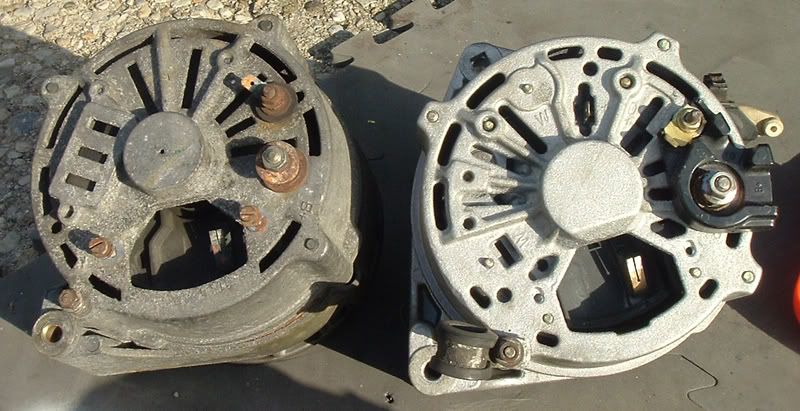

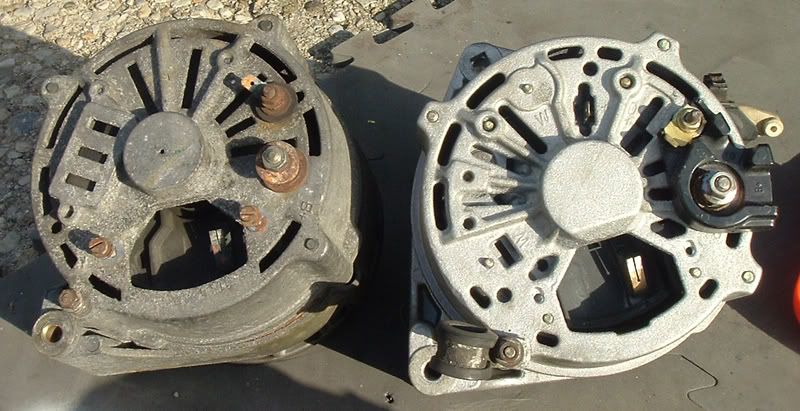

Any info would be appreciated since winter is coming and I want to know if I have enough juice to get me through the cold. Below is a pic of the original Bosch alternator on the left, with the rebuilt one on the right:

--

Mike F - 1984 244 DL - 265,000 miles

Original engine, transmission, drive train, alternator, starter

Undergoing reconstructive surgery with POR-15

|

|

-

|

|

|

As long as the battery is in good condition, the alternator should perform normally. Your alternator is not I think.

After a start, the alternator replaces amps drawn from the battery, and provides amps(current) for the loads in the vehicle. As the battery achieves full charge and if the loads are light, the battery voltage will climb to a max of about 14.3 volts. Charged batteries have MORE resistance, and the voltage goes UP. Low voltage indicates high current being produced, OR, what I suspect in this case, a failure of one or more of the diodes.

From your description the alternator is not capable at low speeds of providing sufficient current. To check, turn on the headlights high beam, the rear window defogger, and the heater fan. The voltage will obviously drop, but should attain mid 13's with the engine at about 2000 rpm. If the alternator can produce 13's under this load at slightly above idle speed, then all is well. Use a voltmeter at the battery to check properly.

There is a chance that the new brushes are not "seated" on the commutator, but even that should take only a few minutes. As well the regulator in the brush assembly may also be faulty, and/or the brushes have insufficient spring tension, or are worn.

I've seen lots of crappy "rebuilt" alternators.

|

|

-

|

|

|

Thanks for the info. I bought the alternator on eBay so I know nothing of its history.

I think I'll try to have my old Bosch alternator rebuilt by a reputable person and reinstall it. Then, I'll have the one I'm currently using rebuilt as well so I have a reliable spare on hand. There's an automotive shop in town that specializes in rebuilding starters and alternators; they claim to be a Bosch shop, so I'll give them a shot.

--

Mike F - 1984 244 DL - 265,000 miles

Original engine, transmission, drive train, alternator, starter

Undergoing reconstructive surgery with POR-15

|

|

-

|

|

|

I guess you got my idea that I was trying to paint as a example of.

Quality matching parts and repair reputation has to be shopped for!

|

|

-

|

|

|

I love the responses from on the board. Most are right on target.

Paul of Inga has it the closest that the battery is a ballast. Its the big absorber of shifting currents.

A battery has a lot going on inside. Temperature is a big thing for the specific gravity of the electrolyte and the overall conductivity of plate materials.

I have read on another post that the alternator has to warm up. AH yeah but..its not a muscle..?

Exciter diodes outputs a current that is controlled by the regulator control range specification. The middle man. It changes the force field to the outer windings. That changes the ampere output because there are more or less stronger magnetic lines to be broken as the rotor turns.

The diodes are coarse made check valves. These route the current in one direction. DIRECT CURRENT. If they are of poor quality and have leakage you can hear them buzz on a AM radio. Spikes of AC. The term "Alternator"

Manufacture tolerance and quality of the electronic components vary. A BATTERY for sure! A alternator rebuild, for sure.

Transistor circuits (regulators,ECU,and AMM's) are more stable than the rest because there are designed with temperature change in mind. The other stuff well I rest my case that there are more variables than just a alternator warming up!

Speed of the rotor has to cut those lines to get current flow. Self feeding current flow but regulated by speed and the regulator to within tenths of a volt change.

Pulley diameters and surrounding connections, you bet.

|

|

-

|

|

That looks like a 100 amp Alt out of a 740.

Couple of things to check, since it is related to speed and not load it seems.

What kind of shape are your accessory bushings in. After years of oil and age they can deform and allow the Alternator housing to be off line. That can lead to belt slippage at slow speeds. The one that gets missed and also the worst of it is under the adjustment arm held in by a 13mm nut. If replacing a bit more pricey but worth it go Blue and get Poly ones from one of the two online places.

Check and make sure your belts are tight enough, they can stretch over time a bit.

Make sure the Ground wire from the block to the frame of the Alternator housing is in good shape on both ends. The one in the grease under the housing gets missed. And if that is an 100 amp you have to find a good spot to tie the ground anyway.

After my recent no charge incident with a corroded ground wire, I added a backup ground from the firewall to engine strap down the side of the engine and tied that to a separate point on the Alt Chassis. That one is not going to bite me but once dang it.

Good Luck,

Paul

|

|

-

|

|

|

I believe that I replaced all three bushings (two for the alternator itself and the third for the adjusting bracket) with new rubber bushings. Maybe I should replace the bracket's rubber bushing with a poly one.

The belts were loose when I first installed the alternator. I tightened it since then, but would the belt start slipping again when there's more demand placed upon the alternator? If so, maybe the belt is still too loose or should be replaced with new ones. The current belts seemed like they were still in good shape even though they have perhaps a few ten-thousand miles on them. It would be wise of me to do so and keep the old belts in the trunk as a spare.

I didn't replace the ground wire because it seemed to be in good shape. I cleaned and greased all connectors.

--

Mike F - 1984 244 DL - 265,000 miles

Original engine, transmission, drive train, alternator, starter

Undergoing reconstructive surgery with POR-15

|

|

-

|

|

Another thought, as I am sometimes want to have,

What is on the fuse where you are getting the voltage reading? You may be seeing the drop as the current increases from motors, lights, or whatever else is on the line. A lot of add on Voltmeters get added to the first switched terminal on the fuse box that you can plug into.

And as a battery gets fully charged up and that current load drops lower, you will see the voltage in the entire system ease lower. Nothing bad going on, just needs less current. Automobile charging systems do not use regulated current(there is for voltage). So you will see variations in voltage was the current load changes and that is true for load increases and decreases. Like when you idle the car for instance, slower speed, lower current, and a voltage drop. Watch it... yes, but unless you see the dreaded 12 Volts when you start the car and it is still there as you accelerate away (cool feeling). I would watch it but not worry about it. Now if you see the voltage continue to drop over time, you may need a set o brushes pretty soon.

Regards,

Paul

|

|

-

|

|

|

My then-Volvo dealer installed the voltmeter but I don't know from where in the car's circuit it is monitoring. I would have to trace the wire.

My assumption was that the 100-amp alternator could handle any factory accessory that my 240 could throw at it, certainly much better than the previous non-100 amp alternator ever did.

I also assumed that the battery was merely a vat of energy that was used to start the car; otherwise it was nothing more than an odd-looking wire that completed the car's circuitry while it was running.

Maybe I'm more ignorant about this matter than I thought. Oh, well. That's why I'm here!

--

Mike F - 1984 244 DL - 265,000 miles

Original engine, transmission, drive train, alternator, starter

Undergoing reconstructive surgery with POR-15

|

|

-

|

|

Just read your posting, and saw you are also doing floor pan por repair. The part where they say if you let it dry on your skin, you will be wearing it off, they mean that. Day two of the silver finger tip, got some of it off but that was with a brillo pad.

Back to your issue, how do you tighten the belts? I ask because I did it wrong for several years myself.

If I can figure out where I stuck my green books I would tell you where Volvo puts the voltmeter. I hooked my first one up the same fuse as the turn signal. Good for knowing the blinker worked, not that good for voltage ref. It got moved very soon after that.

Have you compared your VOM output to a good DVM? I had a VOM slowly fall in voltage reading, and it was the VOM. A new one resulted in a back to normal reading.

I would watch it, but not worry too much about it.

Good Luck,

Paul

|

|

-

|

|

|

I wear those yellow dishwashing gloves when I use POR-15, but I seem to end up with the stuff on my elbows. Hitting it right away with some solvent or even alcohol gets rid of it, but once it cures, it's there for the duration. I use the clear paint instead of the silver or black which is more forgiving if I make a mess of the car or myself.

I'm probably not tightening the belts properly - I use a crowbar to push down on the alternator but I try not to brace the tip on anything other than the engine itself. There's something else in the way that prevents me from getting a good leverage on the crowbar - I try to avoid it but I can't think of it right now. What's the best way of tightening the belt; I'll try that when the weather breaks.

I do have a nice digital multimeter. I'll compare it to the VDO voltmeter in my car one of these days.

--

Mike F - 1984 244 DL - 265,000 miles

Original engine, transmission, drive train, alternator, starter

Undergoing reconstructive surgery with POR-15

|

|

-

|

|

Yep, you learned to tighten belts the same place I did, pry it over and tighten it up. The AC belt squealed so bad after me placing the Alt/Water Pump belts I paid my pro to tighten them all.

Here is the secret to belt tightening on a 240. First put the crowbar/pry bar away you will not be needing either. You just need two 13mm wrenches (or a 13mm socket and a wrench), and a 10mm socket. Take two 13mm's and loosen the lower nut on the bolt that runs through the accessory bushings, just loosen do not remove. Now take the 13mm wrenches and looses the bolt that holds the adjustment nut the alternator body. Now you will need a 10mm socket to tighten the belts. To tighten a 240 belt you crank on the the 10mm nut. As you tighten the bolt the the body of the alternator moves away from the engine block. Crank on the bolt until you see the belts starting to get tight. You do not have to pry on or tighten any of the 13mm's yet. Tighten until you are sure that the belts are snug but not over tight. No need to hurry that 10mm nut will hold it tight until you snug up the two nuts and bolts. And you are done. Same thing on the power steering and the AC compressor with one caveat. There is a hidden bolt on the AC compressor on the top back side you need to loosen. If you run your finger along the top of the back mounting bracket you will feel a dome headed bolt. You have to reach in on the other side and loosen that also. But after learning all that here on the BB. Fan belts have gone from an issue to a breeze.

Hope this helps,

Paul

|

|

-

|

|

|

Thanks for the tip. I'll give that a shot soon when I get my hopefully-properly-rebuilt alternator back from the shop. I'm always paranoid that either I'll tighten the belts too much or not enough.

--

Mike F - 1984 244 DL - 265,000 miles

Original engine, transmission, drive train, alternator, starter

Undergoing reconstructive surgery with POR-15

|

|

-

|

|

Not the most scientific method, I use the thumb test. There is a Volvo Tool for checking belt tension listed in the green books. I have the Por 15 coated silver thumb(almost worn off). Should have just a little give when pushing in on a belt. To tight back off the 10mm a couple of turns and check it. The bolt on that Alternator is a long crank on the racket by the way, at least on my 86 it is. I keep pushing on the belt and cranking on the nut until the belts are nice and tight and then back it off until I am happy with the tension. Then and only then do I worry about the other bolts.

You see a lot of bent 10mm bolts at the PUP. And the reason I know, yeah... needed a couple after "Learning from my mistakes". And the parts stash may also be well stocked with extra bolts and the ends they screw into.

Good luck,

Paul

|

|

-

|

|

|

What is the capacity of the battery that you installed? The battery also acts as a ballast with the engine running, which keeps the voltage from fluctuating wildly. I have noticed on my 85, that when I'm at idle and the A/C compressor kicks in, and the condensor fan comes on, at idle, my voltmeter drops as well. Using a digital voltmeter and testing, I find that with the headlights on, the voltage is 14.2 volts (this is after starting the engine and giving the alternator time to replace the juice that starting robbed from the battery). when the compressor and fan kick in, the voltage drops to 13.4 volts. So, yes, loads do affect the reading on your dashboard voltmeter.

Again, I don't know how many cold cranking amps your new battery delivers, but if it has sufficient reserve to start the engine, then you should be okay. It sounds as if you have a normal condition.

|

|

-

|

|

|

The new battery is the OEM-type battery recommended for this car (the one that has the positive terminal near the fender). I asked my mechanic for that specific type of battery thinking that the car's electrical system would work best with it. It's an Interstate battery.

It hasn't had to start the car after sitting overnight in temps far below freezing; I suppose that that's the ultimate test.

--

Mike F - 1984 244 DL - 265,000 miles

Original engine, transmission, drive train, alternator, starter

Undergoing reconstructive surgery with POR-15

|

|

|

|

|