|

|

|

It's been and still is a hot summer and my daughters 245 didn't make it back to me yesterday. The engine ran fine for about 75 miles but quit with 25 miles to go. Temperatures have been in the mid 90's for the last several months.

She was able to get about 10 miles further by letting it cool off, but we had to rent a truck and car dolly to get it home. After letting it sit we were able to drive it on and off the dolly to make the rest of the trip.

I'm thinking the heat may have caused power stage/ignition module by the battery to fail and once cooled off continue to work temporarily. It started fine and idled this morning.

The heat sink paste was dried out,so I replaced the module with a like new Bosch unit I have and applied fresh heat sink paste.

Does this sound like a plausible fix?

Any suggestions as to what else may have caused this are appreciated!

Thanks

Dan

|

|

|

|

|

me, i'm a hard ass. i'd rather diagnose it before throwing parts and watching what sticks. betting it's the crank sensor-here's how-

when it cranks and doesn't start, does it have spark? hear the fuel injectors click?

if no to both, it's the crank sensor.

if yes to spark but no to injectors, probably the fuel pump relay. needs further diagnosis to confirm.

if yes to injectors but no spark, then it could be the amp you replaced or the coil, cap, etc. again needs further looking.

if yes to both, then i suspect again the fuel pump relay. it can run the injectors without running the pumps OR 1 of the pumps has died, tank pump or main pump. again , more testing.

now classic crank sensor failure is gets hot, shuts off, cools off and starts. the other items mentioned are USUALLY fail completely, no start again. if i have to use the dartboard for an lh 2.4 no start, crank sensor wins. good luck, chuck.

|

|

|

|

|

Thanks for the reply! I replaced that a year or so back but I will keep it in mind.

Dan

|

|

|

|

Hi Dan,

I didn't see how you pegged the issue to ignition. Are you sure the tank pump is working?

--

Art Benstein near Baltimore

"We can evade reality, but we cannot evade the consequences of evading reality."

|

|

|

|

|

Well I haven't pegged it or confirmed anything yet, I would have to drive for 2 hours to see if it runs as normal

I feel the main pump working and tested the tank punp a few months ago. I will check it out tomorrow

|

|

|

|

Dan, my experience as a non-pro with a small family fleet of daily drivers yet, is when the tank pump quits (brushes short, commutator worn, doesn't matter) the car can be driven locally without any symptom. It may even work part time in the case of short brushes. But the main pump will suck fuel from the tank past a stalled pre-pump.

But take it on the interstate, in the heat, and the fuel warms up as you drive, gradually heated on its trip through the rail and back down the return line, until the main pump can no longer overcome the vapor lock formed by the heated fuel in the tank-to-main pump line. The motor doesn't just quit, it runs on a quickly increasingly lean mixture, and loses power before it dies. Getting up a hill is tough, although I don't know of any in Florida.

Since the experience helping my daughter through such an occurrence on a trip through Yellowstone, I've added to the oil change routine a simple check to see the tank pump is drawing current through fuse 4, hoping to catch a failed tank pump before it requires a tow. She nursed it along by doing what you describe -- allowing time for the fuel to cool between trip segments until finding a shop in Wyoming to do the tank pump replacement.

None of our cars have had a temperature-related failure in the EZK ignition system, either from a power stage or crank sensor. In any case, none of those parts ever failed "temporarily" to regain performance when cooled - yet. But, I would expect the motor would die without any warning should it happen.

It is hard to gather the facts from another driver, especially one as precious to us as our daughters out there on the side of the highway.

--

Art Benstein near Baltimore

Children seldom misquote you. In fact, they usually repeat word for word what you shouldn't have said.

|

|

|

|

|

Art

Thanks you may be on to something, one question does the pre pump run any time the key is in the run position? It is not running just now but was running a few months ago when I had the fuel tank pressure problem.

Dan

|

|

|

|

|

Art I get the spark and the pump does run, what Amp reading should I get that would indicate it is pumping fuel

Thanks

Dan.

|

|

|

|

Hi Dan,

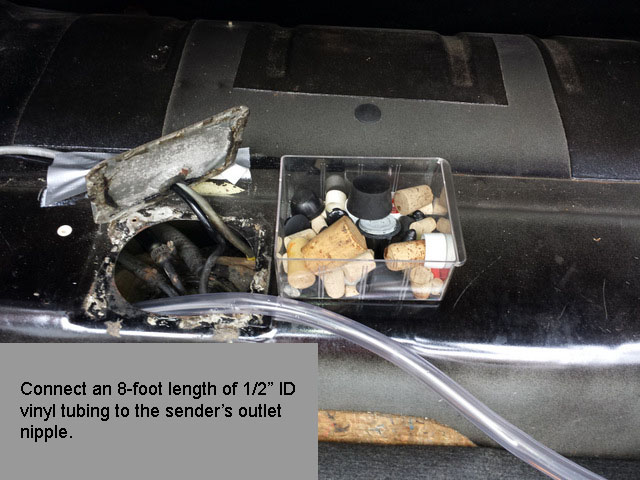

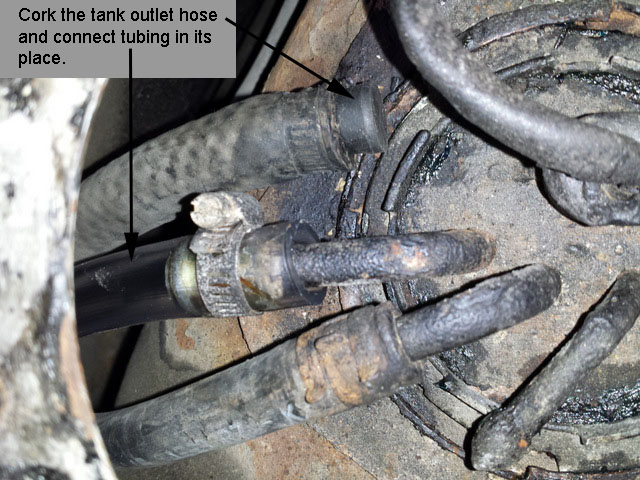

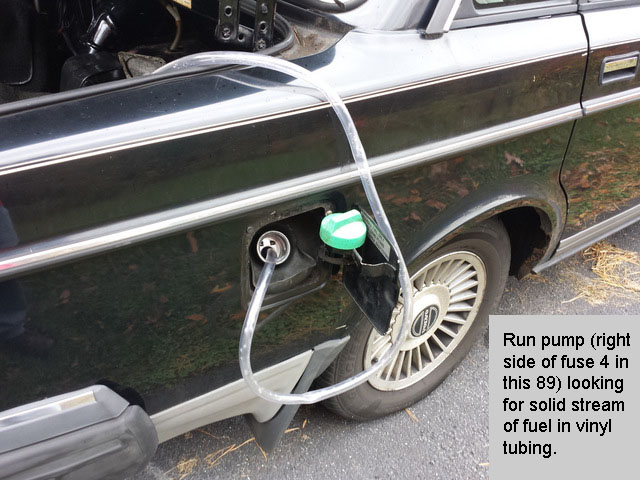

If you hear it running and you're sure it is the tank pump you hear, checking the current won't help you to know whether it is getting fuel to the main pump. For example, if the rubber hose inside the tank has ruptured, it may be pumping fuel but most is falling back into the tank.

To answer your question, I think these lift pumps draw a little more than an amp, not much really. For a closer number I'd have to assume the brand I am using is typical and measure it again, rather than depend on my memory. Along with the oxygen sensor heater, fuse 4 may be seeing 2+ amps.

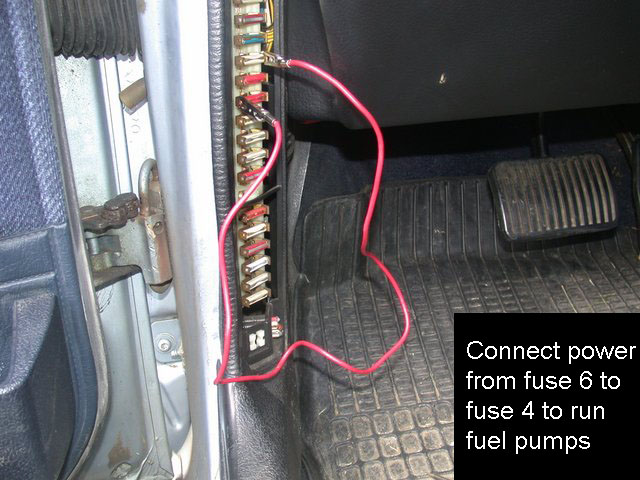

Either way, the symptoms of this sort of vapor lock can have other causes. One in particular is specific to the 91-92 and early-year 93 cars. These model years run the whole fuel management system through fuse 6, and with just a tad of salt air or leaky windshield corrosion can cause local overheating. I've got some pictures of that here: http://cleanflametrap.com/emfuse.html

And, depending on what symptoms you've related, we still don't have a firm call on ignition or fuel.

It's tough when you can't reproduce the trouble, and it is someone else who drives the car.

--

Art Benstein near Baltimore

"I been in the right trip but I must have used the wrong car." -Dr John

|

|

|

|

|

Thanks Art, I guess I need to look at the in tank pump and rubber connector.

I may also replace fuse 6 with an external fuse holder, I did this bypass to a 91 wagon years ago.

Thanks again

Dan

|

|

|

|

|

Well the the in tank pump and Volvo rubber hose appear to be in good working order, I will replace the pump and pre filter because I have them.

Next I will bypass fuse 6 and hope it works, only time will tell;

Dan

|

|

|

|

Looks like you're doing a "cover all bases" play. An act of love, surely.

1. Fuel pump relay

2. Ignition Power Stage

3. CPS

4. Tank Pump

5. Fuse and terminal connections.

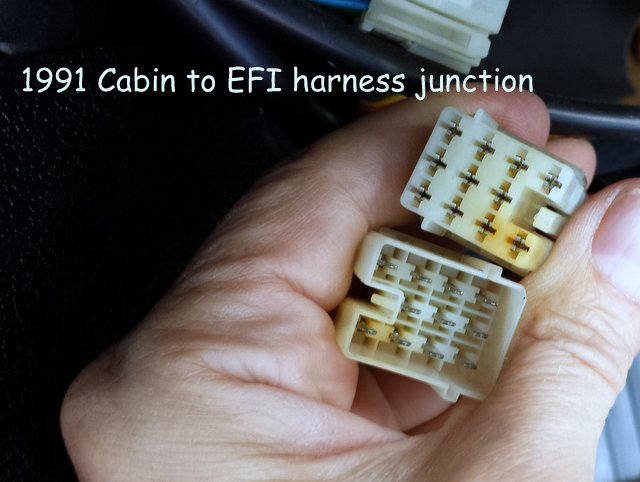

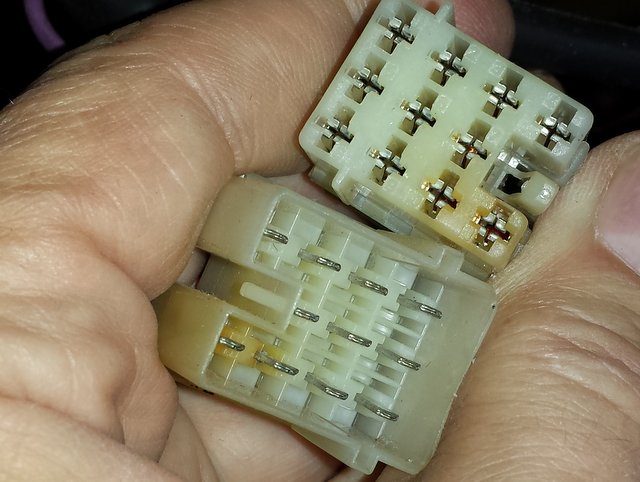

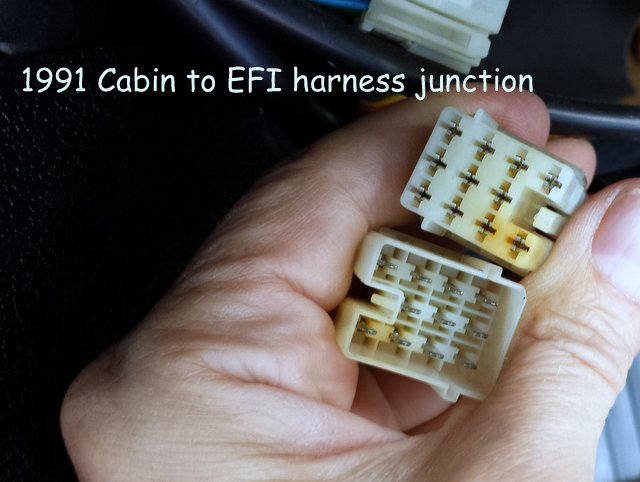

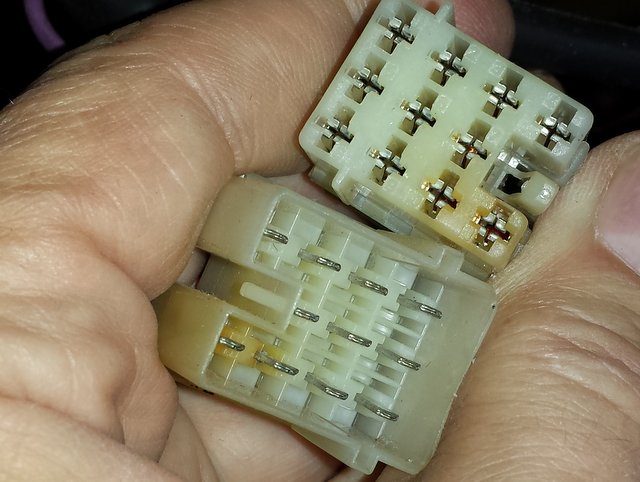

I can think of one other weak point in the path taken by 12-volt power to the engine management system. At least, one I've had trouble with in a '91 and believe still is present in the '92 harness. Behind the glove box:

Overheated connections. Check it out. My "trouble" was not confirmed, only seen as a suspect, so I just bypassed the harness connector to be rid of the possibility. The red wires are sharing the current to the EFI system most likely because one single wire would certainly be too much for the capability of this connector.

So far, I've not ever had a problem with an ignition coil, another item that can be trouble in the heat, as Chuck mentioned. But remember, my experience is with a small family fleet, much like yours, not enough to really evaluate likelihood.

--

Art Benstein near Baltimore

“Always code as if the guy who ends up maintaining your code will be a violent psychopath who knows where you live.” - John F. Woods

|

|

|

|

|

Thanks Art, I was disappointed the rubber tube was fine as my daughter did say when the engine stalled it was loosing power gradually before it quit. So your vapor lock description was making a lot of sense. I didn't know vapor lock was a thing in FI engines!

Getting the intank pump out is a PITA and I don't really know how old it is so I'm going to use it.

Did you just by pass the heated looking wires or all of them in the connector.

I replaced the CPS a couple of years ago, I will take a look at it.

Dan

|

|

|

|

I had a feeling that symptom of losing power might have been remembered. Yes, if the pumps are working, vapor lock is not a thing in our injected cars.

The rest of the connections, those not carrying all the current to run the injectors, AMM, idle valve and computer looked in great shape. I just bypassed the two red wires by cutting them and stuffing them into butt splices. Kinda feels lousy doing that sort of thing to a harness, but the odds I'd ever need to replace either of those harnesses in entirety are not worth consideration.

You know, I've found fuse 4 with corrosion. It may be obvious that would do the same as a failed tank pump, but worth mentioning, as I don't recall touching on that here. At least give it a copper fuse.

--

Art Benstein near Baltimore

"The world is full of specialists that only think about one small aspect of a problem. To be a good systems engineer you have to look at the whole picture, all while keeping cost, service, and reliability in mind." - Paul Rako

|

|

|

|

|

I do use copper fuses and periodically spin them or clean them by rubbing them on my blue jeans.

I have a spare good coil so will give it a try.

What is the correct orientation if the pre pump filter?

Dan

|

|

|

|

|

In tank pump and filter replaced, fuse 6 bypassed with a fuse holder & 15 amp blade fuse, and swapped out a good bosch coil.

I checked the ignition connector and there is no sign of over heated pins.

I found and repaired a couple of other issues not related to engine operation

|

|

|

|

|

Thanks Art, I should have figured that one out on my own!

I'll check it out tomorrow, when it is supposed to be less humid and ever so slightly cooler.

Dan

|

|

|

|

|

I have a 940t that would shut down after driving for awhile and then start up and drive some more until it would once again stall and refuse to start. Once it cooled down it would start again and drive before repeating the behavior.

I had a spare power stage and I renewed the thermal paste before installing it. I haven't had any trouble since. Hopefully she won't either.

Randy

--

Any twenty minute job is just a broken bolt away from a three day ordeal

|

|

|

|

|

Thanks Randy it seems to be a reasonable conclusion I just want to have some confirmation!

Dan

|

|

|

|

|