|

|

|

Hi everyone, it has been awhile since I've posted here. I have a 1983 244 Turbo that has a problem that I'm having some difficulty solving.

The car has 321,000 miles. I have rebuilt the engine, replaced the steering components, all suspension components, brake components, etc.

two weeks ago everything was fine. car ran very well. Then the temperature gauge (coolant) started going high. about 3/4 of the way up and stayed there. It slowly rises while the car idles.

Here is what I did.

1. replaced thermostat (first thing done). no change

2. replaced temperature sending unit (for gauge). no change

3. Replaced fan and fan clutch. no change. This is getting old.

4. Replaced water pump. No change.

5. removed intake manifold (again) and checked the wiring from the temperature sending unit to the gauge. continuity is there.

6. Grounded the yellow wire from the sending unit and the gauge went all the way up.

7. Replaced temperature sending unit for ECM. no change. (didn't expect a change there).

8. Removed radiator and flushed it excessively. Some rust and bits. Added CLR Just in case. let it sit awhile and flushed again.

9. Removed hoses from heater core and flushed excessively. Some rusty water but after awhile it came out clean.

10. REmoved hose from engine to heater core, forced pressured water through hose through heater core and back out engine. no change.

11. Flushed engine. (drained from petcock in rear and flushed.) clean water

12. Rechecked engine timing. Spot on at 12 degrees BTC.

13. Rechecked RPM at idle. Spot on.

Engine idles all day and doesn't overheat, but gauge goes to 3/4. Hmmmmm

14. Checked temperature on hoses. Bottom hose at 58 degrees C, Top hose at 68-71 degrees C. I used a infrared temp gun. I have to admit, the top hose is very hot to touch. I wondered many times was the brand new thermostat not opening? I replaced it with another spare I had and no change I also placed all of them in water, brought it to boil and kept tabs on the temperature and they all opened at 88 degrees C like they were suppose to. Hmmmmm?

15. Checked for air in system. let it run with no cap and got all air out.

16. Removed instrument cluster and checked board. Okay.

17. Replaced gauge regulator transistor (had one handy so why not?) no change.

I ordered a new radiator, it should arrive next week from IPD. However, I'm now at a loss. what am I missing? Could I have mistimed it? It did take quite awhile to get the timing right. I had made the mistake of removing the distributor and that didn't help at all. Got all timing marks spot on (several times). Had to remove and reinstall the distributor according to the manual many times. But I got it (I believe). It fired right up. The other times it did not. You could tell the timing was way off. Adjusted it to 12 degrees BTC and it runs great. But the temperature gauge????

Any thoughts? I'll let you know what happens when I get the new radiator. But this sucks.

Thanks,

1983 Volvo 244 Turbo 321,000 miles

1995 Volvo 850 T5R (fully restored) 298,000 miles

1970 Plymouth Barracuda, 340 4 speed pistol grip (Cuda), in-violet purple 5 year restoration.

2011 Mercedes CL65 36,000 miles

|

|

|

|

|

Hi,

What a revolt in’ development this is? Are you having a “Life Of Riley” moment? 😳

Shame you didn’t try the heater/blower trick before ordering a radiator.

The clean spark plug and low compression is kinda of a late check up. I was thinking you said you did that along with lots of other possibles.

Within that you are saying that you had no clues for it.

Like the little thicker or wetter accumulation behind the tailpipe is can be a definite tell. Yet no noticeable loss of coolant or Rusty water?

I would not be so concerned about machining the head but look out for corrosion.

On it or the engine block as it probably got under the head gasket a tiny bit. You mentioned a rust condition.

I will be surprised if you need to flatten the head or work on the valves since it appears you have caught this early.

The valves should be OK as it was running fine just before.

Once you get the head off turn it upside down and fill the combustion chambers with water.

Cover the valves tulips to see results out the ports on either side.

If you lose water right away then you may have a warped valve but it’s very early in the game for that to happen.

Even a burnt valve takes a lot of time to develop.

You never overheated so what I’m hearing you only steam cleaned that #2 cylinder temporarily.

How many miles are on the rings as the compression just seems normal too me. You just need a head gaskets all around.

In old days… redoing the valves only prompted a myth, that it adds more pressure onto the rings and then the rings get worse and it will use more oil.

I don’t know if I even believe that.

It was more an excuse to get a person to do a total rebuild or later. to be use as a scapegoat out of any warranty for the engine work.

Blow by is blow by and there just might be a little more of it if the valves were truly leaking.

The Volvo head is a nice piece of precision and that they run as long as they do.

Seldom do you hear about bad valves unless the engine had deteriorated from the lack of some good maintenance.

No Tuneups or abusive driving make bad valves.

Turbo boosting is another story.

You might want to for go the head work altogether, if it’s less than .020 out from corner to corner.

It may be half of that as being normal.

There is going to be some but it’s usually minimal and the reason for the specification.

Anything less is what the head gasket is for.

You have to remember that you are checking for flatness while the head is in a relaxed state.

The heating and cooling of the head over the years cause internal stresses to appear. They are usually minimal because the casted head is annealed before final machining.

So, at this point it’s will be stress affecting the cam journals alignments.

If you have it machined they will have to be aware of the cams journals alignment and ask about what they do about it. I’d like to know!

Just a precautionary thought, I have on my own, about resurfacing a head of aluminum or iron.

I have never read this about anyplace but then again, I don’t claim to be an automotive machinist.

Maybe that’s why they read for flatness corner to corner. It’s the hump or valley in the middle I’m concerned about. They do not use Babbitt inserts to exchange out using Plastigage, like on crankshafts.

If it gets decked there is a minimum dimension, from the journals to the deck called out in the specifications sections of manuals.

Why I don’t know exactly since the cam turning is done by a belt. So it must be valve clearances down to the top of the pistons as they will be lower overall.

In the case you must scrap the head or dish the pistons out slightly and that would be questionable as having to allow for carbon deposits I bet! 🫣

As I remember the specifications are only for the amount of warpage allowed plus ???

Don’t do it unless you have too.

It’s similar to brake rotors, except the thinner they get, the more often they will warp again sooner.

There, you change stopping habits or keep good coolant in the engine block for the head.

It was proven that Metal to metal seams never work but designing helps more.

I heard that the British tried the experiment with Rolls Royce’s or Bentley’s in their early years to make a gasket-less engine.

Maybe it was around the thirties or fifties?

Maybe other another brands of British, I don’t really know.

But they wanted certain retail customers to begin with.

Everything was totally hand lapped and fitted so precisely that it created other problems.

It was touted in sales on production models to have the hoods sealed or wired down so that only their technicians worked on them or void the warranty.

Some elite road service that would be.

If these vehicles ever got to venture out on the open roads from a pampered home life of Europe.

So if it is true, nobody would know but those in-house mechanics.

Maybe it’s all fictitious?

I’ll write this up as American or German propaganda to old and some younger rich men to buy domestic.

My economics had me give up on Ford and Chevy P 30s. 70’s and 80’s were junk.

The Volvo 240s rescued me. Beat car payments or lasting 11 to 17 years was an understatement.

So, Just saying be careful with whom you let do the resurfacing.

I have heard the term “broaching” before in one automotive machine shop that made me question their skills.🤔

It is a term they used for their head resurfacing machine.

I didn’t get to look at it so I walked away.

For me, a broach is a tool used to cut internal slotted keyways in a through hole using an arbor or hydraulic press with sized sleeves with shims.

Examples of internal cuts are a hub of a gear, sprocket or crankshaft pulley.

A broach or the Broaching term is the movement of a single edge cutter but edges in multiple successions with graduated feed or depth control.

So rotating many cutters on a rotating head might qualify technically as the same thing. 🤔

I had better leave that one alone on a forum.

I need to ask if you ever saw a lot of oil sweating above the oil filter from under the head.

Hard to see on a turbo but that is a sign of a head gasket leak too.

There is a pressurized oil galley right up to the head there.

So is Number Two Cylinder?

Phil

|

|

|

|

|

I didn't observe any of the issues you mentioned and I check regularly with this car. I completely restored it (interior, exterior, engine, etc) and although most of my family wants this car (and quite a few neighbors), they can't have it.

Some of the water passways on the head gasket were blocked. I saw no evidence of a blown gasket. But may some blockages were just enough???

The machine shop technician looked at the head and saw nothing immediately wrong. But, they will deck it correctly, do a valve job, etc.

the Block looked fine. Each cylinder looked great. NO scoring in the cylinder walls, no lip at top. Not even much carbon on top of the pistons.

I'm going to take the turbo and get it rebuilt while it is off the car. The bearings are tight, but since it's off I might as well.

On thing I noticed, is that my older radiator is much thicker than the new one from IPD. I might just take it to my friendly neighborhood radiator shop and get it checked out. I prefer to use the three core vs the two core radiator.

So lets see:

1. Timing was spot on. All timing marks lined up perfectly and when running was at 12 degrees BTC.

2. New thermostat Mahler

3. New temperature sending units (both)

4. Gauge checked ok

5. New radiator

6. New fan and fan clutch

7. New water pump

8. New timing belt

9. Compression test, cylinder #2 was 115 psi. not close to the other cylinders

10. Spark plug for #2 cylinder was much cleaner than the others

11. Slight (you had to really be looking for it to see it) milky film on the oil filler cap and also where the flame trap device hose connection was.

This would have been stupidly expensive if I didn't do the work myself.

So, I'm hoping that the head gasket water ways were just clogged enough to cause this.

I'll let you know in a week or so.

Thanks,

|

|

|

|

|

Hi,

Glad to hear back from you.

I gather that you never saw any oil sweating from under the head.

The head gasket itself will not necessarily show signs of how it failed but having one cylinder seemed cleaned is enough evidence that something is a miss.

I hoping it is the head gasket and not a crack above number two cylinder.

A crack can go three ways. Across either of the two port and connect to the coolant passages.

Good thing to get an evaluation of the three row radiator since this is a turbocharged engine.

I suspect that it was a Volvo upgrade and would be considered a standard.

Or someone before you changed it.

Im sure IPD must have asked or offers an upgrade.

That is what they do, get into modifying stuff in a narrow field for interested customers.

Does your car have an intercooler? I don’t know what years that all got started.

As far as cylinder wear that too sound very normal but the partially clogged passages coming up from the engine block is interesting. I can only imagine what the radiator has to tell.

I understand your statement about doing the work with enormous savings.

Just finished watching Scott Kilmer talk about the newest cars out.

He said you have to reset computer codes for putting in a new battery because it charges an old battery differently as it ages.

It won’t make your new battery last as long as the original OEM special

It smells of some sophisticated consumer entrapment technology after the sale of a new car.

The batteries have codes and you have to tell the car what it has either way.

He also said to watch out for a battery monitor that talks to the cars computer.

It is out of sight down on the negative cable.

It can get messed up if you jump start yourself or someone else.

I’m thinking, 🤔 It must be more sensitive than chapped lips! 🫢

You have to Always use the engine block as a ground and not the negative terminal on the battery to help prevent an issue.

Imagine the future battery conundrums we are going to get with EV vehicles?

I’m a fuel cell and loads of capacitors man in that arena.

Been sick with the fiasco of cordless tool batteries and differences with wall chargers of the past.

He also threw in comments throughout his presentations that mechanics or shops charge up to $100 an hour to reprogram and diagnose many things. Data type Scan tools are $3800 is part of it.

I just learned, from a mobile installer, about a car’s windshield.

Programing them is Up to $400 to get that done.

He specifically said BMW cars or those with cameras and driver assistance.

I got two 240 windshields for $580 completely and installed.

Also an extra glass, in hand, for only $90.

They are rare to locate, at the moment, in California.

I’ve got it wrapped in foam carpet padding vertically in the back of a closet. Nice and safe.

I guess when you own a new car you have to buy a seat for the drivers helper and for your mechanic has one with the servicing installments plans.

Called extended warranties? Some start @ $1000+ a year. All service bulletins and for oil changes

Luckily that starts after you take the depreciation bite from driving it off the showroom floor.

I’m glad to hear that you are one of those people that keeps a gleaming eye out for anomalies.

The neighbors know you have a gemstone around the present system.

I can wait a week if you can? 🤗

Phil

|

|

|

|

|

I've owned this 83 240 turbo since new. I am the one that "upgraded" the radiator. I did it years ago when I was having AC issues. My AC shop (been using them since the 80s) installed a three row radiator and a electric fan also.

I took the turbo to get rebuilt today. Still waiting for the Cylinder head to be returned.

Cleaned and repainted the engine (volvo red), cam cover, and upper heat shield.

I'm debating on pulling the block and getting it rebuilt.

I'll keep you informed.

Thanks,

|

|

|

|

|

Hi,

Original owner, wow!

I never read about how many miles are on this critter anyways?

Compression seemed good to me because they were even. But I’m a NA guy.

New rings might gain you 10% better numbers. That’s like 160 tops and more combustion efficiency will not be so noticeable. IMHO.

Did the turbos come with a lot higher compression ratios but got it added with boost?

That’s the variable.

Is it a clutch or slush box with the same mileage.

You are only a couple hours to lift it with or without the transmission.

You can check big end rod inserts if they sound suspicious?

You might need a crankshaft seal and does the oil pan sweat?

Its truly is a 🎲roll.

Rebuilding the turbo is whispering in the background here.

I think you’re the only one hearing it’s soul and after this many years, you are it!

In all honesty, how much more do you, a caring someone else or a soulful family, want out of this car?

It the same question running throughout the BRICKBOARD.

Enjoying the posts, thanks.

Phil

|

|

|

|

|

320,000 miles.

I rebuilt the engine back in 2007/2008 (another head gasket issue), and I decided to pull the engine and get it rebuilt anyway. It had about 160,000 on it then.

engine rebuilder said it looked great internally.

As far as compression was concerned, It read 115 psi on cylinder #2, and 137 to 145 psi on the other cylinders. So low on cylinder #2. Since I couldn't find anything else wrong with it, thermostat, temp sending unit, gauge, gauge wiring, fan, fan shroud, water pump, radiator, etc. I looked at the head and head gasket.

I like my three row radiator as opposed to the new two row radiator that I bought, so I took it to my neighborhood radiator shop and they rodded it out, found a small leak, repaired it, painted it and it is good to go.

I had to order new exhaust valve guides for my cylinder head job so I'm waiting for those to arrive before the head can be completed.

They haven't yet quoted me a price to rebuild the engine, so I may not at this time. I remember pulling my engine and delivering it to the machine shop/rebuilder in 2007/2008. Fairly easy to pull the engine/transmission. gave away my engine hoist, so if I decide to do it, I will go to harbor freight and buy an inexpensive one.

However, I do remember that it was a serious PITA to get that engine/transmission back in the car. it took three of us. One to remove it and three to get it back in.

I may do it anyway, since pretty much everything is off the car right now.

I'll let you know.

|

|

|

|

|

On my '81 NA I found that not installing the head till the engine is in the car allows more tilting of the engine/trans assembly before hitting the fire wall.

|

|

|

|

|

Hi,

Been thinking about you!

As far as putting the engine and transmission back in, using a leveling rail is the ticket to work alone.

You crank it to a move the hook between the chains to shift weight.

It allows you to tip it very steeply to miss the front bracing in one fell swoop.

It helps for the car to be up off the ground some.

In a junkyard they use car rims and a gantry on tires that roll.

A “cherry picker” hoist is what I have and I think that’s what you are referring to.

You might rent one of those but that depends on how much versus buying for a fleet of vehicles.

@312,000 miles that’s a lot of ups and downs on the rings.

Even though they are sealing now a person might want to give them another thought.

Rings do wear and a thinning occurs between diameters.

This causes upper ring chamfering to disappear some.

It lends to direct ring pressure that by now does have less effectiveness. They do expand during compressions and firings.

A loss of ring tension means even the oil scraper rings are also doing less of that.

You say the valve guides were not salvageable as in getting them knurled and fitted again.

So that fits with the high mileage and getting new ones is very admirable for longevity.

You will have to pull the head again as the bores have to be scuffed to seat the rings.

This only if the bores are in tolerance.

Bores come can be Oversized or tapered.

The right on size works if in an allowable tolerance.

That can be tolerated, up to a certain point?

Not doing anything is rolling the dice with this mileage.

IMO for a difference of a few hundred bucks comes some peace of mind.

Boring the cylinders, was in my day was about $30 a hole and that included the cross hatching honed surface. Everything is fitted to the pistons provided.

Even piston knurling can be done as it only affects the skirt. For example, If you cannot get pistons for an engine it’s an option.

It is what rings and an Oiled piston skirt do.

These make up a floating bearing all supporting the connecting rods alignment.

Besides possible newer pistons a lower end should be a relatively an inexpensive outlay.

If the crankshaft journals and the throws are not wiped, as it appears, then grinding the crankshaft for connecting rods will be minimal or not needed. There is an allowance for taper and insert sizing.

It will be up to the setup mechanic as from there he is just torquing bolts to finish up a total rebuild.

Those parts mentioned above can make him a profitable enough.

There are Markups are hidden everywhere.

So, if he if honest to his trade he will be happy getting you there.

He should do it for an additional reputation as a go to man!

In the 1800’s it was important to hang a “shingle.” It represents a town’s offerings of trade for miles around.

I think you said for twenty years now.

There it is!

Phil

|

|

|

|

|

Well, I screwed up twice.

1st I stripped an Cylinder head bolt hole for the exhaust manifold. Got the Cylinder head back from the machine shop, installed it with a new head gasket, torqued it to spec per the manual, checked the timing, added new oil and filter and new coolant and it fired up right off.

However, exhaust leak. Bolt hole stripped. Oh boy!

So I checked for leaks and found coolant on the clutch bell housing. How the heck did that get there? Nothing on passenger side. Oh boy! Since there was an exhaust leak I purchased a time-sert thread repair kit.

I removed the cylinder head today and didn't see any issues. But there was coolant showing on the passenger side at the gasket when I removed the intake manifold and looked at the head when connected to the block.

Interesting. did I not torque it down correctly? I'm pretty sure I did. not my first rodeo. I checked the block for warpage and it was straight and level. Same for the head. Hmmmmm?

Well I drained the coolant and it was clean. Curious, I drained the new oil and it was entirely milky. What the @@>>>###?

I guess that I didn't torque the cylinder head down correctly or enough.

I chased all the bolt holes before installing. So that wasn't it.

Well, once I repair the bolt hole threads, I will install a new head gasket and try again.

not fun..

|

|

|

|

|

Hi,

I have been out of state and now I’m wondering about the outcome of you getting the head back on the engine.

I doubt the tightness sequence would create enough gap to cause a space for leakage.

Chasing the treads out of any crusts of the block or head is always advised.

Sorry to hear about the exhaust bolt but since you will have the head off again it will be easier to access.

When it comes to removing a locked up bolt or spark plug “Patience” is required.

Most any penetrant helps but most importantly is how to strain the stud or spark plug back and forth or in and out is what works for me.

When you twist a length of thread you are stretching the material slightly and those stretch and rotation combinations are what helps the penetrant work. Vibrations will jiggle the crusts that developed within the clearances at the top and in the root spaces of each set of threads.

Heat and cooling is nearly the same thing but aluminum is fast in drawing off the heat and besides it evaporates the fluids. The PATIENCE is your best friend.

I also was wondering if the head gasket was the wrong one. The 2.1 liter engine may have gotten a B-23 gasket or by chance the rear freeze plug was removed?

The B-21 in the late seventies was the first cross flow design and it’s why it’s was call a B21 F engine.

Since cross flow was not such a big deal later on the engines dropped the F.

B-23 and B-230 moved in along with the turbos and LH change up away from K-Jets by 1984.

With that, said study the gaskets carefully for elongated gasket holes or bigger ones for more coolant flows in places.

I only have ever changed two head gaskets in my lifetime.

Once on my B-21F for an oil sweating right above the oil filter.

In the early eighties a Datsun’s 280Z. It had two or three different head gaskets.

So, I too was surprised as the engine rebuilder paid me to replace the wrong one after I had put my sister-in-laws engine back in the car and it leaked.

I took the engine to a rebuilder where a coworker of mine did, part time engine cylinder boring for $10 a hole.

Since it was during a recession of 1982 and I was laid off, it turn out to be a handy thing.

It was my first head job but they had confidence fir me since I pulled the engine in the first place, plus, it was a twenty mile trip for them to deal with it.

They bought the new oil and antifreeze as soon as they saw the gasket.

So wrong head gaskets can happen more than you think!

Hope to hear from you.

Phil

|

|

|

|

|

I checked the new head gasket vs the old one and they matched. I didn't notice any leaking from the freeze plugs. But it can't hurt to check again.

I put the head back on and it still showed high on the temp gauge.

So, I rechecked the circuit board components (all good). I retested the gauge shorting the wire to the gauge to ground (went full), then inserting a 68 ohm resistor (series) to ground on the wire and it went 3/4 up. I bought a used cluster and inserted it and it still went to almost red after heating up.

I was stumped, so I took it to my Volvo/Saab Swedish auto shop in West LA. They checked it out said it wasn't overheating and said it needed a resistor in the circuit. They added it and it goes 1/4 up now. That makes no sense to me.

However, the car now runs like crap. Like the timing is waaaaay off. I rechecked it and the marks were spot on. I checked each spark plug, cleaned them and reinserted them and it still ran off.

I will bet it is something simple.

I am going to place all timing marks on, then remove the pully from the crank, and cam and make sure they are placed on correctly.

The oil is clean and there is no oil in the coolant either.

I will also check compression one more time to see if maybe the head gasket isn't on correctly.

I will also remove each injector (remember they were cleaned and tested a short time ago) and see if they spray consistently into small containers.

I will find this bad running issue now.

|

|

|

|

|

Hi Lawren,

I was wondering what had happened to you on the Brickboard and with the head work you procured.

I sure would not like to see you pull that head off again for this high or lower temperature gauge symptoms.

If they put in a higher resistance to any circuitry, that doesn’t make sense to me, will only appease your anxiety.

Having the timing marks right on has nothing to do with it running like crap unless it’s not jumping farther around when the engine is raced up.

Adding resistance to an engine coolant temperature circuit surely would affect the mixtures but only on a LH system.

I think we determined that you have a K jet mechanical system so all of that goes out the window.

I need to tell you about my 1978 GT B-2.1 F with a K jet system, that I still have.

What you are describing has happen to me.

It turn out to be a wire from the temperature sensor inside the harness on the firewall side to the gauge. It lost most of its insulation against another wire, maybe a ground somewhere else down below.

I pulled the sensor wire out of the harness with another twisted/soldered to it. Pulled it from the top down to the sensor end and put on another terminal.

I guess you could go either way.

I don’t remember replacing the upper half going to the instrument cluster.

I blame a lot bad wiring a lot on engine cleaners harming wiring.

In the next few years Volvo made a lot of bad engine harnesses referred to as “biodegradable.” So I could be all wrong here.

Your issue is a similar episode. Mine was in or about 200,000+ miles on the engine.

I too worried that this might affect the engine if it kept being high somewhat regularly.

I had also notice some excessive oil sweating just above the oil filter from the head, so then maybe, I’m having a head gasket issue too.

So I yanked the gasket out and put it all back together.

This is why I suggested leaving the head alone and no reworking.

Fired that mother up and there it was again the gauge went back up despite a new thermostat change earlier.

I change it only because the Wahler thermostat was still working accurately after 17 years.

Sure I change coolants but hoses and working thermostats get used more and than a couple years.

Now coolants are touted to last longer so will hoses treated like a Timex too.

How far can you drive on empty is a bothersome question, OK?

Volvo hoses, of which use to be made in Australia, are a long ongoing experiment on my part. Very few changes but I have them in stock.

I cannot recommend any domestically makers of hoses, since I have owned Volvos.

I became sold on this Wahler because it comes from the manufacturer dated and made of a brass frame with a copper cased wax motor.

As far as I know no one else does all that.

Both are Compatible materials in my thinking of metallurgy.

Other brands are cheaper for many many other reasons.

I’m evaluating the new owners, Borg Warner, if they’ll keep it that way?

I still have the old one it in is replacements box.

I keep good things around me.

You could say I’m becoming “dated” for doing that as well.🥴

Anyway, after that miserable diagnosis of possible overheating, the oil sweating did go away permanently.

I took noticed that all the pressurized oil going up to the head is right there.

There’s not much gasket space for sealing and it’s close to the outer edge.

So this wasn’t something that was ever going to go away and a head gasket was the fix.

The B-23 and the B-230 might be different but I’m not one to want to find out until …?

So Now, I was back to the temperature gauge “conundrum” that you are having it seems.

I suggest you locate the wire in the harness and replace the engine side half like I did.

Do you have just a plain harness and no connector through the firewall?

Mine curled up high enough to access it from the top to open.

On My 1984’s wires were put in a split loom by the previous owners mechanic.

This was from the LH gray connector back downward.

It’s Not a factory looking repair so yours might be really bad inside if it’s solid.

On my 1986 I wrapped the joint it with emergency silicone tape at the time.

It’s still holding up just fine and both remind me about Volvo harnesses.

Good luck using my thoughts, I hope it helps.

The 1978 has about 350K now.

I say about, because the car wore out the odometer’s shafts or the journals, made out of the aluminum frame.

I had peened them over to tighten them up once before.

VDO never expected them to last long anyway.

The MPH still works and the center clock is intermittent but I have a replacement.

I intermittently ask myself if I’ll ever replace it.😊

I quit looking about ten years ago.

I don’t drive it as much as use too, so it’s all guess.🤔

Phil

|

|

|

|

|

Hey Phil; Thanks for the information.

I agree that added a resistor (haven't checked where yet) on the circuit board shouldn't have been a fix. I checked the circuit board and all resistors, traces, components and diodes and they all checked okay. So, I don't understand this yet.

I repaired the bad running issue. I put the car's timing marks back on, removed all pullies, made sure they were all installed on correctly, in case they may have slipped, checked top dead center with both the timing marks and also a screwdriver in the #1 spark plug hole. made sure everything was spot on.

I did compression tests again. Both dry and wet. Dry was between 135 and 142 psi on the cylinders. Remember, I had the head and valves redone.

Wet was between 165 and 178 psi on the cylinders. not too bad.

I then did a leak down test and I found:

1. 10%

2. 20%

3. 20%

4. 20%

I used the timing marks and screwdriver for #1 and screwdriver only for 2, 3, & 4.

No air bubbles in the coolant reservoir each time.

removed the oil filler cap and heard air (not much) each time.

Heard a very low ghostly wind noise (barely could hear it) in the tail pipe each time.

Found one of the wires completely off on my oil pressure sending unit right next to the oil filter/alternator. This explains why the oil pressure light was blinking when I drove the car? and maybe this sent a signal to the ECU and the car ran badly?

Don't know, but, when I put everything back together and started the car, it fired right up, timing was spot on at 12 DBTDC and the engine ran really smoothly.

I'm going to check that instrument cluster circuit board one more time and also the wiring.

Thanks,

Lawren

|

|

|

|

|

Hi Lawren,

Glad to hear from you about your car.

A little conveyance goes along ways to moving things along.🤓

I would say the compression numbers are good enough to say everything is fine with the engine.

I don’t know what those percentage numbers mean on a leak down test.

Variances in numbers is to be expected with mileages of any kind with how the rings are sealing.

Cranking speeds vary from engine to same engine in relation it tightness IMO.

MANY VARIABLES come with everything it seems.

I would guess if they put a resistance in why not at the sensor?

OR … the wires have been wiggled enough to create more resistance or less conductance and therefore a lower reading. Maybe they took what they could get and gave up.

How the timing got moved must have been some other intervention?

I believe you are on to resolving this issue shortly, as there isn’t much left to ponder.

It must be wiring from what I’m gathering here.

Keep plucking the at harness and the keyboard as inquiring minds would like to know.

Phil

|

|

|

|

|

actually I misspoke. They put the resistor at the sensor not at the circuit board.

I installed a new Bosch temperature gauge. However, the sending unit adaptor doesn't fit into the cylinder head threads. So, I ordered their metric adaptors. They should arrive shortly. This will tell me clearly what the actual temperature is.

In the interim, I used the existing sending unit and took out the series resistor.

So the original Volvo gauge reads 3/4 again when up to operating temperature and the Bosch gauge reads about 170 degrees F. However, since the sending unit isn't the one for the Bosch gauge, I can't really trust that reading yet. I'll let you know what it reads when I get the sending unit adaptors shortly.

One thing I may not have mentioned is that back in January, 2022 I got my turbo upgraded to a higher performing turbo.

I'm not exactly sure when this gauge issue started, but I don't think it was that long ago.

Another thing I noticed is that the existing tachometer was reading very low. A regular timing light showed the RPMs to be 850-900 at idle, but the gauge tachometer read really low. I can't explain that one. May have something to do with this?

So, I opened it up and adjusted the tachometer trimpot so that it read correctly.

But, this is suspicious along with the temperature gauge issue no?

See you.

|

|

|

|

|

Well here is the latest. last night my new radiator was delivered so this morning I installed it.

Temp gauge still goes high. and steam coming from the exhaust. The car was on front ramps only. It went away but that was not normal. It never did this before, and I always check when I start he car. So, I did a compression test.

Cylinder #1: 137 psi

Cylinder #2: 115 psi (darn)

Cylinder #3: 140 psi

Cylinder #4: 145 psi

I removed the spark plugs.

#1: looks good but dirty (normal)

#2: clean (not normal)

#3: looks good but dirty (normal)

#4: looks good but dirty (normal)

Then I lifted the oil filler cap and there was a very little white substance there. you could only see it if you were looking for it. I removed the intake manifold and looked at the flame trap mechanism. There was white substance there also.

I'm thinking head gasket. I started removing everything. Checked timing. Spot on.

removed intake manifold.

removed fan

removed shroud

removed radiator

will remove turbo tomorrow and then cylinder head.

I will take the cylinder head to a machine shop, get it decked, valve job, new valve seals, etc.

will install new head gasket shortly.

I will let you know shortly.

If you think I'm going down the wrong road, let me know.

Thanks,

|

|

|

|

|

Haven't received the new radiator yet. I'm really hoping that it is the problem (since i've replaced just about everything else sigh!!!).

I've removed the thermostat and back flushed the entire system many times.

Question, could a clogged heater core cause this issue? I removed the hoses and blew water through the core front and back and after getting some rust out it flows okay. I'm just checking.

The heater works well by the way.

Thanks,

|

|

|

|

"Question, could a clogged heater core cause this issue?"

I believe not. In fact you proved it wasn't clogged anyhow.

If you close the heat control, you simulate the effect of a clogged core and that's how you drive normally all summer. I'm pulling for the radiator too!

--

Art Benstein near Baltimore

“How much does a chimney cost?”

“Nothing, it’s on the house…” or "It's gone through the roof..."

|

|

|

|

|

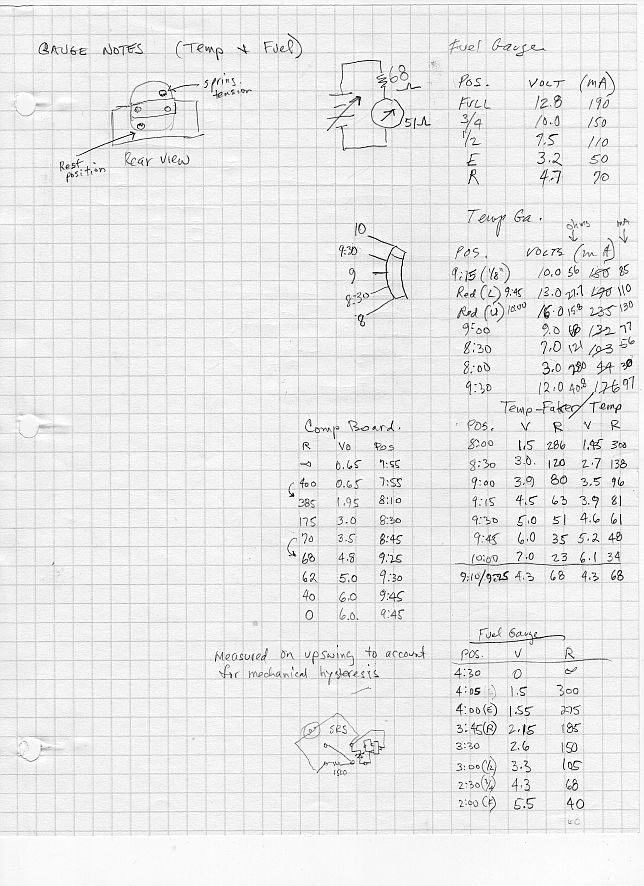

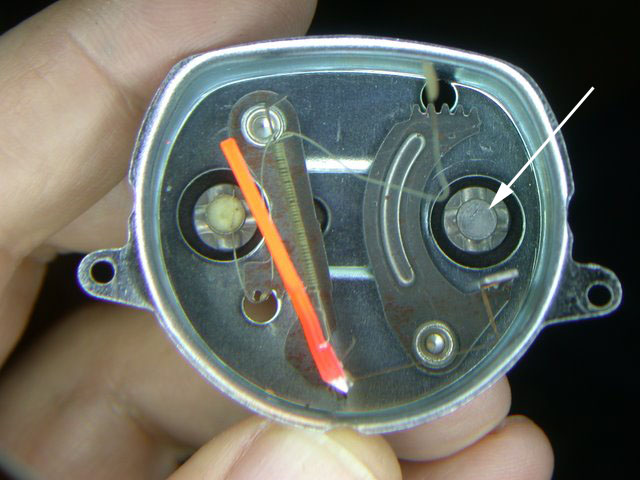

A failed/failing temp compensation board (voltage stabilization circuitry) that piggybacks on the main instrument cluster circuit board is well known for such problems in 240s of your vintage. Although I see some notes they weren't introduced until 1986, yours may still have it. A quick feel up behind the cluster will soon tell you. Do a search here and on other sites for more on that, including how to simply bypass it. Art Benstein's page on this is excellent with lots of pics

https://cleanflametrap.com/tempFaker.html

You wouldn't be the first to replace half your cooling system when it's just that troublesome little board. Rather than throwing parts at a problem like this, an infrared temp gauge would be useful to monitor block temp during and after warmup to see if gauge movement matches actual block temp change. Also to see how uniform the rad core is in case there are significant blockages. Basic ones aren't that expensive. Even a cheapie in some barbecue parts sections would be useful..

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

|

If there is a voltage stabilizer involved, it may also power the fuel gauge. Is the fuel gauge still reading accurately?

Also, while the radiator is out, you might want to remove the thermostat, reattach the hose neck, and then back flush - forward flush - back flush - forward flush the engine with a garden hose to assure a good flow rate and to clear out any debris.

|

|

|

|

The 240 didn't have that "feature" in 1983 production.

--

Art Benstein near Baltimore

"Never trust the work of the last guy, even if you're the last guy"

|

|

|

|

|

Hi,

Just off the top I think you have a low flow rate through the radiator or from the engine.

The radiator shouldn’t have had rusty water in it.

If you just rebuilt the engine was there an inspection of the cooling jackets especially the ports up and through the head?

Maybe some sediments broke loose.

If you used a cleaner that stuff just put rust into the radiator. Radiator shops love it for selling radiators.

You should have it flow tested and it could be rodded out but most want to pop in a new one when the radiator fails flowing capacity.

It’s sad that people don’t use antifreeze or rust inhibitors, even like plain ole’ soluble oils before modern coolants. Todays chemistry prevents this action.

Heated water gains more strength through that extra energy being present.

It makes it a more aggressive solvent solution for removing iron by oxidation in less time.

The top hose is not hot enough as 160 degrees Fahrenheit is too cold.

I like 92 degree thermostats.

Being closer to 200+ degrees helps improves combustion efficiency. With a pressure cap it going to be even higher before it exits the head.

Since you have a infrared thermometer use it the top part of the radiator where the tubes are.

The thick rubber hoses are not as accurate for passing or showing true radiated heat signatures.

Measure downward and seek for the hottest horizontal tubes.

They might be scattered or not evenly dropping in temperature as you go down which means a stagnant flow or set of restricted tubes and fins. Fins do rot away on the tubes.

Overall the air temperature, from front to backside, should change only up to 30 degrees Fahrenheit maximum. Rule of thumb. That is a normal design outline but Most of the time, it’s less as that is a maximum capacity.

If that air isn’t then it’s the radiator isn’t working.

Poor circulation or it’s not getting the greatest amount of heat into that flow.

That’s why it’s confusing.

Your engine is running colder @ 88 C so the gauge needle should show opposite or lower down.

Normal just below half way and straight across for @ 92 C.

This cars instrument cluster shouldn’t have a digitally stepped compensation board that will lie to you from 1985 on.

I will say a new radiator cannot hurt anything but the wallet that will not feel lumpy anymore.🫤

Phil

|

|

|

|

|

Thanks, I will definitely install the new radiator when it arrives.

I'll let you know next week.

Thanks,

|

|

|

|

|

Hi,

Thanks for the reply.

I thought of something you can do in the interim.

Try using the heater core and fan to bring down the temperature.

It is like adding on an extra radiator.

It’s something you can do to avoid an overheating problem while climbing mountains or extremely hot days.

Out west it’s a common knowledge thing for us old timers that uses the 255 air conditioner system.

That’s two windows down and 55 miles per hour. 🤗

It should make the temperature drop and it will prove that the gauge and sensor system has not run a foul electrically.

I hope this will lead you to an answer to what’s going on.

Phil

|

|

|

|

Phil, first thing I thought when reading the subject line, before opening the detailed post, was a dirty intercooler. But then I read the story. No mention of intercooler. And thorough attention to the radiator, which was the trouble when I had a similar symptom.

It is scary when you're well away from home and that gauge starts climbing above 9:00. I borrowed my daughter's car that day, because the AC worked and the trip was to be a tour of Smithsonian exhibits, five of us in the car on a hot July day in traffic on the DC Beltway.

We tried the 440 AC substitute, and running the heater (it helped), but besides my anxiety about possibly needing a long tow and ruining the day, we were all sweating.

Best part of the story was seeing all the crap come off from between the fins when I got her car home and turned the hose on the radiator and condenser. Didn't need to replace the rad, just clean it outside. I know this thread has a different outcome -- I'm hoping the fresh rad will be the trick, but Phil, you had me there with 255 AC. Out here the humidity and traffic congestion suggests 440 AC.

--

Art Benstein near Baltimore

"...people will always choose a simple lie over a complicated truth, because the lie has one unbeatable advantage: the truth always has to stick to what actually happened, whereas the lie just has to be easy to believe" - Fredrik Backman

|

|

|

|

|