|

|

|

Driver rear brake hose leaking. It seems to be leaking thru the threads where the hose screws into the caliper. I slid the caliper off and it's clearly leaking with foot on the brake. There is a slight leak even when no pressure is applied to the brake pedal. The hose itself shows no leaking, rather thru the threads.

I unscrewed the hose off the caliper and inspected the threads. I put in a used caliper and tightened the hose to it. I noticed there is no washer at the bottom of the brake hose going into the caliper, though there is room for one

I would just go with another brake hose if I could get the old one off at the brake line fitting, but I can't.

Am I to conclude that the threads on the decades old hose have failed? Could I use Teflon tape on the threads? What about the absence of a washer?

Please offer your help

--

89 240 wagon, 94 940, 300K, 94 940, 141K

|

|

|

|

|

replace the copper seal,,get it straight in!! & maybe thats all you need otherwise I would replace the hose !!& maybe the caliprer!

|

|

|

|

|

"I would just go with another brake hose if I could get the old one off at the brake line fitting, but I can't. "

The trick with undoing old brake hose off its hard line fitting is first to get a firm grip on the hex fittings

To get more grip you have to free the entire fitting off the car body by undoing its mounting bracket

Next is to clean the fitting off any dirt with wire brush (preferably brass not steel) so that any sprayed penetrant could get into the threads

With the cleaned fitting dangling free off the body, choose your 2 biggest crescent wrench (over 1 foot length) and grip the hex-head on the hard-line side and brake-hose side. Arrange the wrenches in "V configuration" and break open the tight fitting. The leverage should do the trick.

Avoid using flare-nut/brake-line wrenches for this job. I find that these specialised wrenches only useful for non-heavy duty brake jobs such as replacing master cylinder, proportional valves and bleeding brake nipples.

Amarin.

|

|

|

|

|

I'm gratified that so many heavies have come to offer help...

I've had limited success doing these fittings but I have alot of confidence I know what to do. I like the idea of removing the mount from the car; I'll try it. Cleaning, spraying and leverage is understood. Using "Cresent" wrenches is different. Never would have thought. I think you mean adjustable wrenches. I have two big ones so I will be able to do as suggested.

--

89 240 wagon, 94 940, 300K, 94 940, 141K

|

|

|

|

|

Yes I meant adjustable wrench.

My reason to avoid using flare-nut/brake wrench is because you'll seldom find such wrench that could grip tightly around the brake hex fitting ie. there is still some "free play" eventhough you had picked a suitable sized wrench

This "free play" is the one thing thats going to round up the edges of the hex later. It could also slip thus damaging the fitting.

Using adjustable wrench, you could adjust until the jaws fit tightly around the hex fitting. Eventhough the jaws only in contact 2 out of 6 surfaces of the hex, the grip is firmer (than flare wrench) and it won't slip.

Amarin

|

|

|

|

|

Dear j.pelchat,

Hope you're well and stay so. Having read all replies, I don't understand how this leak began. The brake hose has served for "decades". Suddenly it starts to leak, where the hose enters the caliper: the hose itself is "dry".

The discussion about a missing "washer" - between the hose end and the threaded recess in the caliper, into which the hose is screwed - mystifies me. If there always was a washer present, to seal the hose end to the caliper, what happened to that washer? Brake fluid is not likely to dissolve a copper washer.

If there was no factory-installed washer present - and I don't recall having seen such a washer and don't see it on a parts diagram in Volvo VADIS (a superseded dealer parts/service database) diagram, then fully tightening the hose's caliper end should suffice to stop any leak.

I'd guess that after decades of service, the hose's rubber has deteriorated. Fluid escapes where the hose's rubber sheath joints the brass fitting.

I've always relied on PB Blaster - a penetrating oil - to break corrosion bonds and so to ease removal of bolts, etc. Especially on a fine-threaded fitting, it can take a few days for PB to work its way through micro-channels in the corrosion.

If all fails, and the hose can't be separated from the brake fluid pipe, I seem to recall a post that described splicing a section of brake tube onto the factory-installed pipe, after the new section's end had been flared properly and the factory-installed threaded cap re-used.

The brake fluid pipes to the rear wheels may still be available from Volvo. But separating the factory-installed pipe from the "T" junction may be as hard as separating that pipe's end, from the hose.

Hope this helps.

Yours faithfully,

Spook

|

|

|

|

|

While replacing the radiator in my 740 the lower transmission cooling line

fitting spun off the radiator but was frozen to the steel tubing that cracked off at the fitting.

This is why it's a good idea to soak the fittings with Mystery oil on both ends

while you're waiting for UPS to deliver a new radiator.

It was easy to splice in a new end to the steel tubing using a short piece of steel brake line,

some straight coupling fittings and the old fitting to the radiator.

I used a standard flare tool and there was plenty of room.

There are other flare tools that might work better in tight places.

Check with the parts stores for free loaner tools.

Cut the old mangled fitting off close to the back of the existing flare ie:

Cut through the fitting to lose only the flare on the tubing to get it apart.

Maybe you wont need to splice in some new line if you cut it short enough?

Get a new fitting and put a new flare on the end you cut.

Don't forget to put the fitting on BEFORE flaring to avoid embarrassment.

Good luck, Bill

|

|

|

|

|

Spook

Thanks for the thoughtful reply and thanks for taking the time to try and understand the issue. Great questions and since you asked:

The leak at the rear brake hose took me by surprise. The pedal was noticeably soft on a short drive and by the time I got home, most of the fluid in the reservoir was gone. There was a very obvious leak at the rear wheel. Upon inspect I noticed fluid leaking down the back side of the caliper but couldn't identify its source. The hose looked completely dry, and the only fluid was on the caliper.

My first thought was the caliper had a crack in it; luckily, I had a spare used one. That was a quick change as the male end of the brake hose came right off the caliper. I didn't notice a washer and there was no sign of one. When I screwed the hose back into the caliper, I notice a gap between its shoulder and the caliper. I bled the rears and the problem continued. Logic brought me back to the hose which was still dry.

I began soaking the line-to-hose fitting with Blaster and applying gentle pressure with the wrenches.

The situation with the dry hose was very curious. I removed the caliper and with a foot on the brake noticed fluid seeping at the threads of the hose. Perhaps there is something wrong with the hose under the crimped end (which isn't brass), But I don't think so. My best guess is the fluid is sneaking past the threads.

I have reinstalled the hose using teflon tape on the threads (I know, I know). It has stopped the leaking and after test drives, it seems like a temporary solution.

Subsequent attempts to remove the hose at the line fitting have failed and the brass flare fitting has been buggered up. I guess I will need to get some new tools and learn how to make those fittings.

Thanks again

--

89 240 wagon, 94 940, 300K, 94 940, 141K

|

|

|

|

|

Dear j.pelchat,

Hope you're well and stay so. As the teflon tape has stopped the leak, I think you have a permanent fix. Plumbers routinely use teflon tape on threaded pipes and fittings for water and gas. These are "low-pressure" uses.

Heat degrades teflon, but at temperatures far higher than those reached during normal braking, e.g., at 326°C (618.8°F). A long descent (e.g., from atop a mountain or a mountain pass) in ambient temperatures above 90°F (32°C) might so heat-saturate the caliper. But at 600°F, the rubber seal between the caliper piston and the caliper body likely would melt.

Thus, I'd leave alone the hose-to-pipe connection, unless the hose itself fails. I don't recall many posts reporting such a failure. Rear brake hoses are much less stressed than are front brake hoses, which accommodate a wide range of wheel movements.

If, after a month, there's no more leakage, I think you've got a permanent fix.

Hope this helps.

Yours faithfully,

Spook

|

|

|

|

|

Flex brake lines don't last forever.

Why cant you get the old one apart from the brake line?

Use a little mystery oil on the fittings and

it should bust apart easily with a pair of wrenches.

Heat it with MAPP gas if you get desperate.

I'd stick with OEM quality rubber flex lines and avoid stainless.

Good luck, Bill

|

|

|

|

|

I have a quality 14mm on the hose and a 11mm flare on the brass fitting and have sprayed it for a few days. I have gone as far as vice-grips and still can't get it to move.

The gas tank is 8 inches from the fitting and I promised my wife I wouldn't use the flame

--

89 240 wagon, 94 940, 300K, 94 940, 141K

|

|

|

|

|

>The gas tank is 8 inches from the fitting and I promised my wife I wouldn't use >the flame

I know you promised your wife you wouldn't use flame, but I would renegotiate. How about using a floor fan to push any vapors away from the hose/line junction?

Old brake line fittings are stubborn to say the least. Before things get torn up and misshapen I would clean up the site with a small wire brush. Really clean it up, especially the threaded portion on the male side.

Heat the area with the tip of the flame on the female portion. While it is still hot spray it with PB Blaster. Yes, it will smoke and possibly ignite momentarily. The penetrant will cool it and I believe it actually draws it in.

I would repeat the heating and spraying at least three time before I put wrenches to it and I would eventually try the wrenches immediately after spraying while it is still hot.

Good luck.

--

Any twenty minute job is just a broken bolt away from a three day ordeal

|

|

|

|

|

Hi Joe,

Can you use a longer handle open end instead of the flare wrench?

Longer lever arms work better. (Vise grips might deform the fitting)

What did you spray it with? I vouch for MMO.

What if you cut off the fitting?

Do you have room to get a flare tool on the the brake line in place?

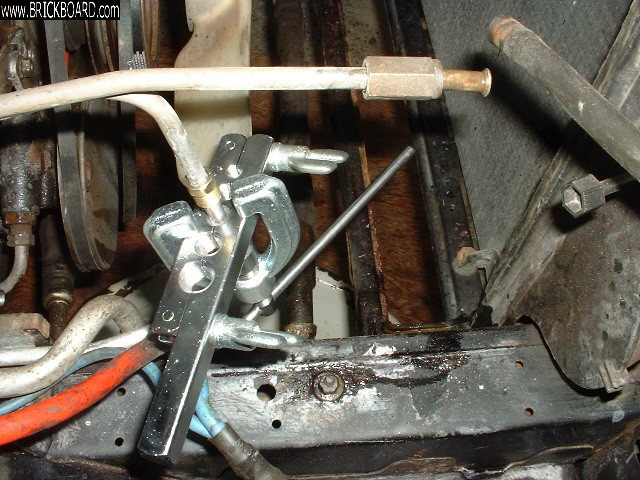

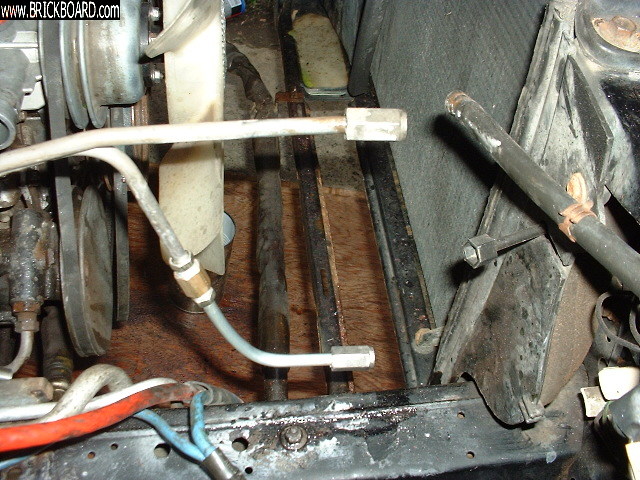

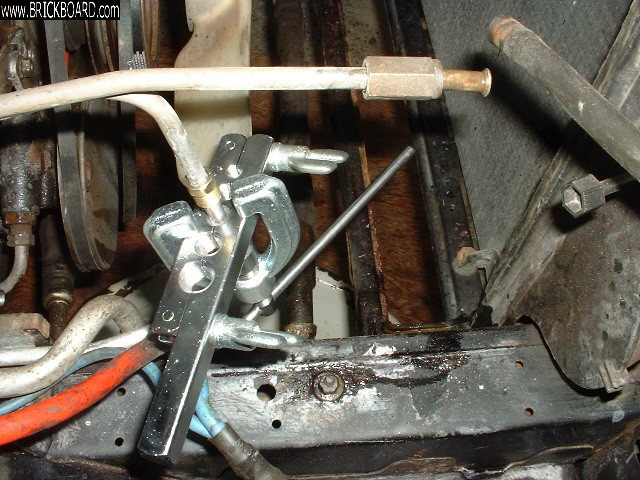

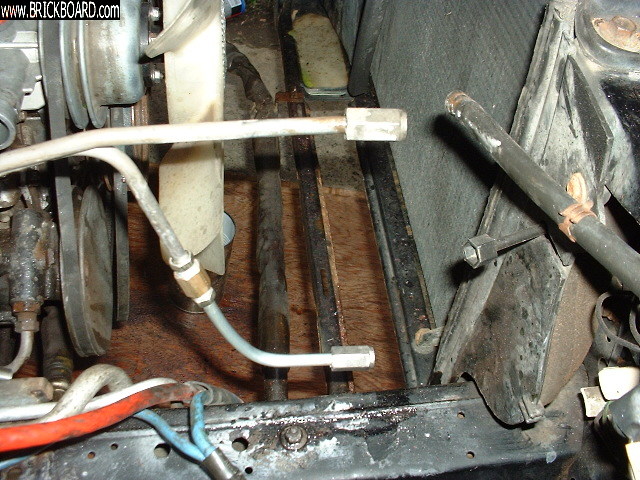

Send a photo.

Bill

|

|

|

|

|

As for leverage--it would be better to continue with the flare nut wrench as it affords a better grip - but another wrench can be "hooked" over it for more leverage (box end of a wrench hooked over the other end of the flare nut wrench). Dave

|

|

|

|

|

If a copper washer was used to begin with -- it is of absolute importance. Without one the fitting can leak through the threads--as you've found. - Dave

|

|

|

|

|

There is room for a washer but there is no evidence that there ever was one. There is about a 2mm gap between the shoulder of the hose end and the seat on the caliper. Perhaps I could add one

--

89 240 wagon, 94 940, 300K, 94 940, 141K

|

|

|

|

|