|

|

|

Hi family!

940 SW Turbo 2.0L B200FT

284000 Km

I recently replaced the exhaust manifold as well as its gasket to the block.

I drove about 6000Km (almost all highway), and the car was perfect.

However, it seems I am getting into another unexpected trouble, here below the symptoms:

1. When the engine is cold, you get a rough running when you first start it. After 1 min. it runs smoothly.

2. White smoke from the exhaust all the time

3. Coolant is leaking (I have to fill-up the water tank every 2-3days). I thought it was the radiator, got a new one, it is still leaking from all the hoses, and now also under the water tank itself. This means the pressure in the system is high.

4. Engine Oil has recently blown out from the oil cap.

The good news is that the engine has never overheated, the needle is always in the middle.

I suspect a head gasket failure, the car is 25 years old and the gasket has never been replaced, but you are certainly more qualified than me to tell.

I recently replaced the following (always with your help!):

1) Exhaust Manifold

2) Exhaust Manifold gasket to block

3) Oil Cooler gasket

4) Radiator hose Water pipe - Oil cooler

5) Radiator hose Crankcase - Oil cooler

6) AC Condenser

7) Radiator

Apparently, there is only one mechanic at my local Volvo dealer who is able to diagnose my car, (and surprisingly I have been told he is the youngest!). He will be back to work in one week.

1) Is it reasonable to suspect the headgasket? I guess the symptoms are there, and after 25 years it makes sense.

2) Is there an easy way for Volvo to see this?

3) I am trying to mentally prepare myself for this job, I know it will take a long time to do it well, I have downloaded the guide in the FAQs. Is there any other good reading or video tutorial you would recommend me?

4) Wish me good luck!

Thank you!

Alessandro

|

|

|

|

|

Dear Metallo,

Hope you're well and stay so! Based on two decades of reading BB posts, the symptoms you report are consistent with a failed head-gasket. Your mechanic should be able to check for the presence of exhaust gases in the coolant.

You can do another test. Pull the oil dipstick. If the oil looks milky - like a pale chocolate milk - that's a sign of coolant in the oil. Such mixing occurs, when the headgasket fails. If the oil looks "normal" - golden or black - that suggests there is no mixing of coolant and oil.

Absent head-gasket failure, the two systems - cooling and lubrication - cannot connect, unless your oil cooler has, somehow, failed internally.

Hope this helps.

Yours faithfully,

Spook

|

|

|

|

|

Hi Spook,

I am well, thank you, I hope you are well too!

Look, I just did the test you suggested, honestly the oil doe not look bad, I would say more on the black side, which is what I would expect.

It could also be that the amount of coolant mixing is not enough to generate that type of pale chocolate milk color you refer to.

Once the engine runs smoothly after the first minute it has been turned on (which sounds like it starts with 3 cylinders instead of 4, just to give you an idea on how rough it sounds), if you drive the car, it drives perfectly.

The car is in my my garage since yesterday, engine is stone cold, I started slowly to unscrew the coolant tank cap, there is lots of pressure,

I can see coolant leaking in all the radiator hose connections, as well as the one under the tank itself.

This morning, the coolant level is still max. but I think that level of pressure should not be there when the engine is cold.

I changed one month ago the oil coolant gasket, if something was wrong in the reassembly, (I really cannot think of anything really), it would have been noticeable immediately.

How frequently should the headgasked be replaced?

Alessandro

|

|

|

|

|

Remove you coolant cap on your coolant overflow and remove the gasket seal from the cap. Save to gasket to reuse later. Replace the cap and ductape the cap with a strip of tape onto the reservoir. This will slow down the coolant loss until you can replace the haedgasket. Your rough start- up is from the headgasket leaking into one of the cylinder and shorting out the spark plug. Relieve the pressure of the coolant before you blow a coolant hose or your coolant reservoir. I had to do this to my Saab 900 until I replaced the headgasket.

|

|

|

|

|

Almost certainly a head gasket leak. One quick test you can try when you suspect it's leaking into the cooling system is to remove the expansion tank cap, start the engine and run it a good few minutes until it's warm and the thermostat starts to open. If it suddenly bubbles up into the expansion tank then you know that's the problem. A Volvo indie mechanic showed that trick to me when one of my headgaskets went and I was amazed. Red blocks are known to be able to idle almost forever with the expansion tank cap off and not boil over. I'm not sure if that's as true for 960 white blocks if that's what you have, but the coolant level should still rise slowly with the cap off and not boil up suddenly. I wouldn't go driving around with a head gasket starting to go like that into the cooling system. Your heater valve or a heater valve hose could suddenly let go, or worse still the heater core. You absolutely don't want to overstress an old heater core, a horrid job to replace.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

|

Hi Dave,

I did the test:

- Before starting the engine, the antifreeze was at min. level, cold engine.

- I removed the expansion tank cap, turned the engine on.

- Slowly I have seen the antifreeze level going up, no bubbles.

- Soon after the temperature needle reached the middle, the antifreeze overflew from the tank, but no bubbles.

- I turned the engine off.

I still think it is the head gasket because I noticed in an area between the cylinder head and the block, say, the part looking at the water pump, it is wet, so something is coming out from the gasket.

Tomorrow, the car will be at Volvo, let's see what they say.

However, I would not know how to explain the pressure and leaks from the hoses to the radiator, other than the expansion tank cap been defective.

I mean, are the two things connected someway?

Leaking hoses means high pressure in the circuit, but I do not understand how this could be connected to the blown head gasket, which instead, explains why the engine starts roughly.

Alessandro

|

|

|

|

|

Dear Metallo,

You described:

- Before starting the engine, the antifreeze was at min. level, cold engine.

- I removed the expansion tank cap, turned the engine on.

- Slowly I have seen the antifreeze level going up, no bubbles.

- Soon after the temperature needle reached the middle, the antifreeze overflew from the tank, but no bubbles.

- I turned the engine off

Same would happen if you have a jammed/stuck thermostat. But that didn't explain the rough start.

In normal engine if you start the car with coolant level at min (expansion tank cap off), the level would raise until about max, when the radiator fan kicks in, the level would back down back to above min. There wouldn't be any overflow. Of course no bubbles there.

You might have 2 issues at same time - marginally leaking headgasket and stuck thermostat. Lets see what the Volvo shop says.

I'd say marginally leaking as there is no bubbles in your coolant. The small headgasket leak had closed up during engine running as the metal expands when hot. But during engine cooldown the leaking gap would open again and some coolant would seep into the cylinders making a rough start coming morning.

Amarin

|

|

|

|

|

Hi Amarin,

Glad to have you aboard on this topic!

So, I just returned from Volvo, here a few bullet points:

- There is no water in your oil, they pulled out the dipstick and it looks clear oil

- They pressurized the cooling system at 21 psi which is operating temperature, both top rad hose on the radiator and the lower rad hose on the water pump there is a pretty steady drip of fluid coming from there.

- In order for them to say yes/no there is no water leak internal to my engine system, they need to make sure those leaks are sealed up.

Suggestion:

- Check your hoses for cracks

- New Clamps

Basically, his focus was more on the water leakage, and therefore they need first to fix that and then continue with a deeper investigation.

Now, here is my point: I could understand one hose, but in this case, all the hoses to the rad are leaking + the one under the expansion tank and the little hose on the side of the cap. So I am VERY skeptical that there is something wrong with the hoses or the clamps, and I am more prone to think the cap has an issue.

I have ordered a new one, let's see if that helps.

With regards to the rough start, he said that he did not want to say anything yet because it needs to be investigated properly, but a fist thought could be that if there is coolant bleeding into the TBC, it wouldn't get into the oil system necessarily, and it would go through the intake at first start up, resulting in white smoke and rough operation for a short time.

But again, that is just an idea that needs to be investigated.

Once the leakage has been isolated and fixed, they will put the system again under pressure and see if there is any pressure bleeding off, because if there is, it means I am losing water somewhere and if we cannot see it externally, it means it is internal and we have to look where it is.

If the water issue has been resolved, I will see whether this has affected the other issue or not.

If not, it means the rough start is a separate issue.

Now, I am still convinced that the headgasket has to be replaced, because, as you say Amarin, if could still be a very minor leak that does not get into the oil yet.

So, to summarize:

1) Tomorrow I will get the new cap, I will replace it, and see if the leakage persists.

2) If the issue is still there, then I will check the hoses (more skeptical than ever) and possibly buy new clamps (any recommendation for the clamps?)

Guys, I paid C$75:00 to have Volvo tell what I already knew, which is why I do not trust anybody to work on my car.

So far, I have always resolved the rare issues on my car with your help, I am sure I will continue this way.

I understand they have to follow protocols, which I am not saying is bad, but the dealer charges their labor C$ 150.00/h and I think I can use that money in a more efficient way on my car.

Thank you all!

Alessandro

|

|

|

|

|

Dear Metallo,

You wrote:

So, I just returned from Volvo, here a few bullet points:

- There is no water in your oil, they pulled out the dipstick and it looks clear oil

- They pressurized the cooling system at 21 psi which is operating temperature, both top rad hose on the radiator and the lower rad hose on the water pump there is a pretty steady drip of fluid coming from there.

- In order for them to say yes/no there is no water leak internal to my engine system, they need to make sure those leaks are sealed up.

Suggestion:

- Check your hoses for cracks

- New Clamps

Its good that Volvo did pressure test on the system. You're right to focus on those leaking points first. Leaking hoses wouldn't do you any good (in short or long term) regardless good headgasket or not.

Don't bother looking for cracks if your hoses are Volvo original ones (they use good rubber for their hoses). Look for double layering instead. This meant the outer layer had separated from the inner layer. You have to dismantle the hoses to examine for this. Furthermore if the hoses are bloated more than the diameter of their anchoring points (eg. radiator inlet/outlet ports) then this also becomes suspect. Replace them if you find any of these defects. Can't repair the hoses.

No need to replace the clamps unless they're spring clamps (like those in Japanese car). If you're using screw clamps just tighten them a bit more.

I think to satisfactorily answer the question about any coolant leak into your cylinder, you might need an endoscope. Consider getting a USB endoscope camera from online sources (ebay etc). They're like $20-30 IIRC. This has to be connected to your PC laptop. The camera has its own light source. Then scope your cylinder first thing in the morning thru the spark plug holes (don't start engine).

Another way is to pull out fuse#1 (this disables the ECU and fuel pump at same time). Briefly crank the engine (yes it can crank without fuse#1 - I use this as anti-theft method with dummy fuse when parking long time at airport) then dismantle the plugs to check for wetness. Do this first thing in the morning.

I prefer the endoscope method as it better represent the cylinder condition as it is. Cranking the engine to look for plug wetness may depends on the amount of water there. It also depends on which Otto cycle the engine stopped. If it stopped on exhaust stroke any residual water will be blown out with not much to wet the plug. Might have to try a few times to catch it.

I had experienced such small headgasket leak long time ago (mileage about 600k km). Engine started with a bit of hiccups. Kept on adding coolant to expansion tank every 3-5 days. Continued using the car for daily commute to work for almost 3 months while saving for headgasket job. In that sense Volvo is truly a luxury car. Can't imagine the same if it was German cars.

Amarin.

|

|

|

|

|

Hi Amarin,

Yesterday I got the new green cap for the expansion tank, so I removed the old grey one and replaced with the green cap (Volvo and both of them 150 kPa).

The engine was cold, so this morning I drove about 15Km and then parked the car back in my garage.

I checked all the hoses to the radiator, no leaks, but the level of the fluid went to the min.

This evening, after 8h the car was unused, I checked again, no leaks from the radiator hoses, however I have noticed some liquid leak from the tank, specifically from the small hose that goes to the radiator. No leak from the hose under the tank.

However, the shape of the tank itself (the side that looks at the exhaust manifold) has changed from flat to be slightly curved (like, a small belly), which has led me to think that the pressure was very high.

I started to slowly undo the cap, man the water from the min. level overflew and the pressure was huge indeed. I closed again and did the process again until the pressure was gone.

I do not know what to think at this point, but such a high pressure to warp the tank after 8h the car is unused, it is not normal.

With the old grey cap, I had leaks at the radiator hoses, and did not warp the tank.

What can generate such an anomaly?

Alessandro

|

|

|

|

|

Dear Metallo,

"I checked all the hoses to the radiator, no leaks, but the level of the fluid went to the min"

--> You noticed this when then engine has cooled down 8 hrs? With no visible leaks from the hoses this could only meant one thing - I suspect faulty headgasket.

"With the old grey cap, I had leaks at the radiator hoses, and did not warp the tank"

--> The old grey cap could be faulty and couldn't relieve excess pressure so the water had to go out somewhere ie. at the hoses (I interpret this as leaking at the clamps, not anywhere along the hoses as that would clearly indicate faulty hoses). With pressure relieved, the tank didn't warp.

New green cap has double the pressure capacity than the old grey (green cap 150 kPa, grey cap 75kPa). With excess pressure vented out, the hoses didn't leak (plus you could have tightened the clamps by this time around). But the residual pressure inside tank still doubles than what was there before, so the tank warped. I also suspect the current tank could be of aftermarket quality (thin walls). If its original tank (thicker walls) it shouldn't warp as whatever excess pressure should've been vented out by functioning cap leaving only the residual pressure which still within the design capacity of the tank. Where this excess pressure came from? I suspect faulty headgasket.

Amarin

|

|

|

|

|

Hi Amarin,

[Quote]

New green cap has double the pressure capacity than the old grey (green cap 150 kPa, grey cap 75kPa).

[/Quote]

Actually no, the grey cap is also 150kPa, it was replaced by the green one.

[Quote]

If its original tank (thicker walls) it shouldn't warp as whatever excess pressure should've been vented out by functioning cap leaving only the residual pressure which still within the design capacity of the tank.

[/Quote]

I agree with you, but this is the original Volvo tank, I never changed it, so this gives you an idea on the level of pressure I see.

[Quote]

Where this excess pressure came from? I suspect faulty headgasket.

[/Quote]

Which is my original suspect in my first post.

For sure, I will replace the gasket, but I am sure there is a leak in the water pump gasket too, when I replace it, how can I check if the water pump itself is good or not?

Thermostat: Is there a way to test it too?

Water tank: I guess now I have to replace it as well, I cannot keep it warped.

Alessandro

|

|

|

|

|

Read this like it is a comic book scream of frustration -- AAARRRGGGGHHHH!!!! -- I can understand a back yard mechanic (not meant as a slam - just not a professional) being cautious but this saga has gone on too long. Just do what needs to be done -- replace the effing headgasket. After 40+ years in the import repair field I feel your symptoms are trying to make themselves obvious and until you get to it you'll just be chasing this and that without curing the basic problem. If part of the problem is, in fact, more than the gasket you'll know soon enough or will find it when everything is dis-assembled. BTW - A thermostat can be checked with a pot of water, a stove and a thermometer. -- Dave

|

|

|

|

|

Dear Volvo from Heck,

Hope you're well and stay so. When I bought a low-mileage 940, and got service records that showed an over-heating incident, I asked a mechanic to test for exhaust gases in the coolant.

I had seen no signs of cooling system over-pressure, etc., but I wanted to be sure that there was not a latent problem. He did the test and reported that there were no exhaust gases in the coolant.

I wonder why metallo's mechanic did not do this test.

Yours faithfully,

Spook

|

|

|

|

|

Dear Spook, I am fine, thank you - and hope you are as well. I can understand your situation with a newly acquired 940 and written evidence of a previous problem. Taking the extra step of having a test performed set your mind at ease. I believe the OP is taking it too far. No matter how much testing is done there are no guarantees that every possible cause will be discovered but the symptoms - especially the misfire at cold start up and the swollen expansion tank - point directly to a head gasket issue.

I have to admit to not being particularly technically oriented. I have great respect for those Brickboard posters who are. If I have a problem with my computer beyond shutting it down and re-booting I'd have to look for a "computer guy" for guidance. When it comes to automobiles I look at the total situation and try to make some sense of it in a logical fashion but at some point you just have to get after it and tear it down. As I mentioned (in the case of the MGB) waiting to act led to unrepairable damage to the motor. Imagining possible faults with the water pump is not a productive course of action. In all my years (and hundreds of cars worked on) I've yet to ever find a water pump not pumping. Leaking seals, worn bearings, upside down thermostat -- yes -- but the first bit of damage (the HG) is what needs attention--the rest will make itself known. -- Dave

|

|

|

|

|

Dear Volvo from Heck,

Hope you're well and stay so!!! I quite agree. I long ago - in this post's history - suggested to metallo that he have the coolant tested to see if exhaust gases were present. Were exhaust gases found in the coolant, that would instantly inculpate the head gasket.

Even on a turbo-equipped engine, I doubt there's a way for the exhaust gases that drive the turbo to get into the turbo's cooling system. A coolant leak in a turbo would result in coolant loss, but not the extreme cooling system over-pressure metallo reported.

I suppose a water pump could seize-up, if a failing bearing were denied attention. That, though would first register on the temp gauge, in the form of the indicator needle to the right of center.

Yours faithfully,

Spook

|

|

|

|

|

Spook and Volvo from Heck,

First, thank you all for your valuable comments.

Yes, I will definitely do what needs to be done, headgasket and, the water pump gasket, which is leaking too. I will also check the thermostat.

It is my first head gasket, (after 25 years 'she ' deserves it), so be patient if I come up with further questions.

I will post pictures when I get to the point :)

Take care,

Alessandro

|

|

|

|

|

Alessandro - I think my words may have sounded a bit harsh - but asking questions is the way to go when doing something new. The B21,23 and 230 are pretty straight forward to work on. Be sure to soak up the studs and nuts that will need removal--especially relate to the exhaust manifold. After all these years the head is likely to be "stuck" on and difficult to lift off the block. After removing all the intake and exhaust stuff, timing belt, etc. put a sturdy steel bar into one of the intake posts and use it to lever the head separate from the block. - Dave

|

|

|

|

|

Hi Dave,

No worries, I am glad I had this kind of conversations on this forum, it is a good way to learn from those who had the same issue before me :)

I already changed the exhaust manifold two months ago, the only pain is to remove it again, also because the turbo is always in the way.

The benefit is that I know that area by heart :) including the bloody stud underneath the manifold that needs to be removed if you want to be able to completely pull it off from the block.

I will keep you posted, also because I need advice on the best way to clean the head and the block. No abrasives, CRC and plastic scraper?

Alessandro

|

|

|

|

|

Alessandro,� The method I learned may not be satisfactory to all.� After scraping off stuck on gasket material with a tool that wont gouge the head or block and using a cleaning agent like carb cleaner to soften the gasket material.� Then I "block sand" both the head and block with a piece of 2x4 cut to the correct width and wrapped with a mid-grade emery cloth and doused� with a liberal application of ATF.� Then wipe/wash it all down.� --� Dave

|

|

|

|

|

Hi there,

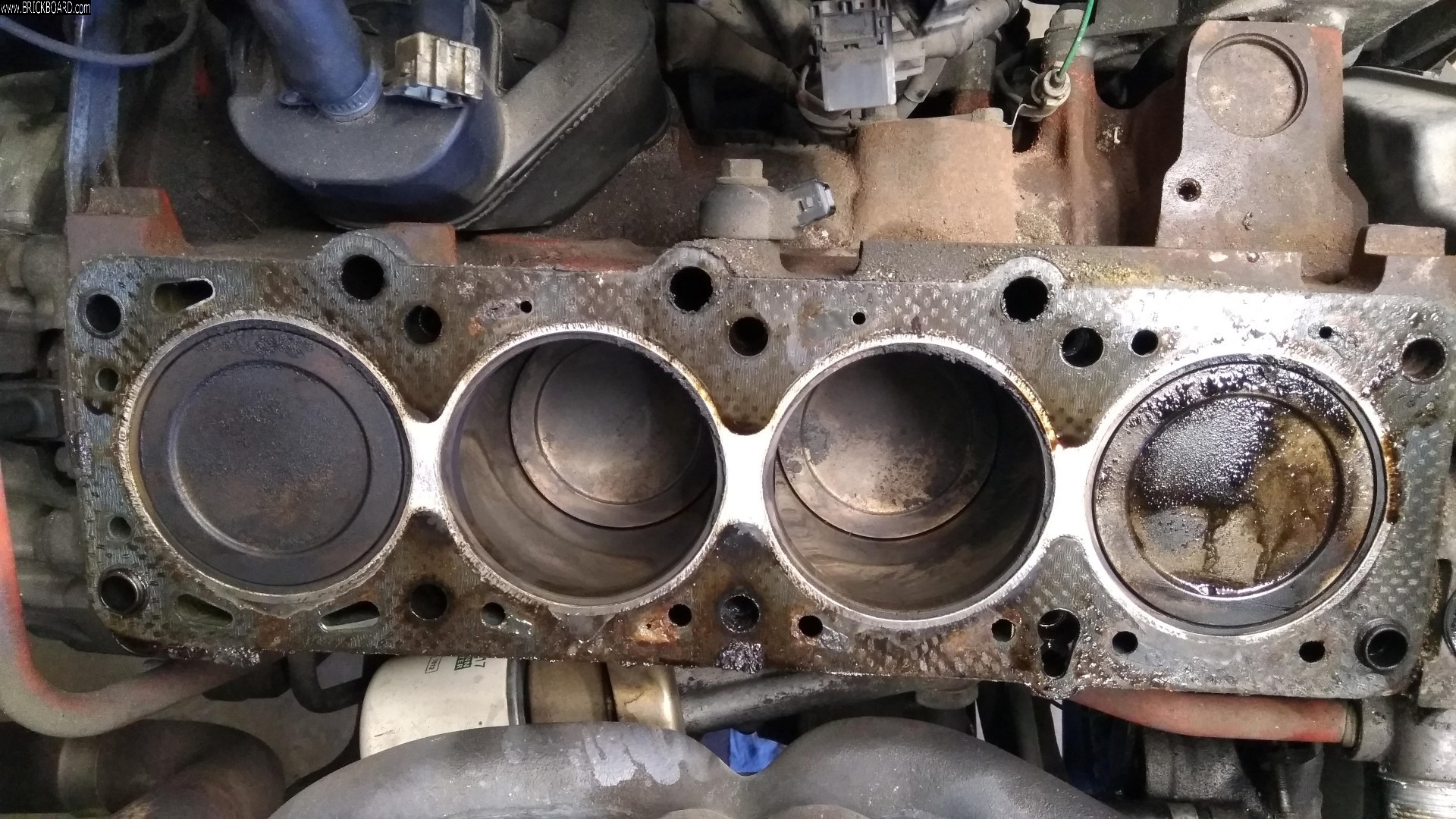

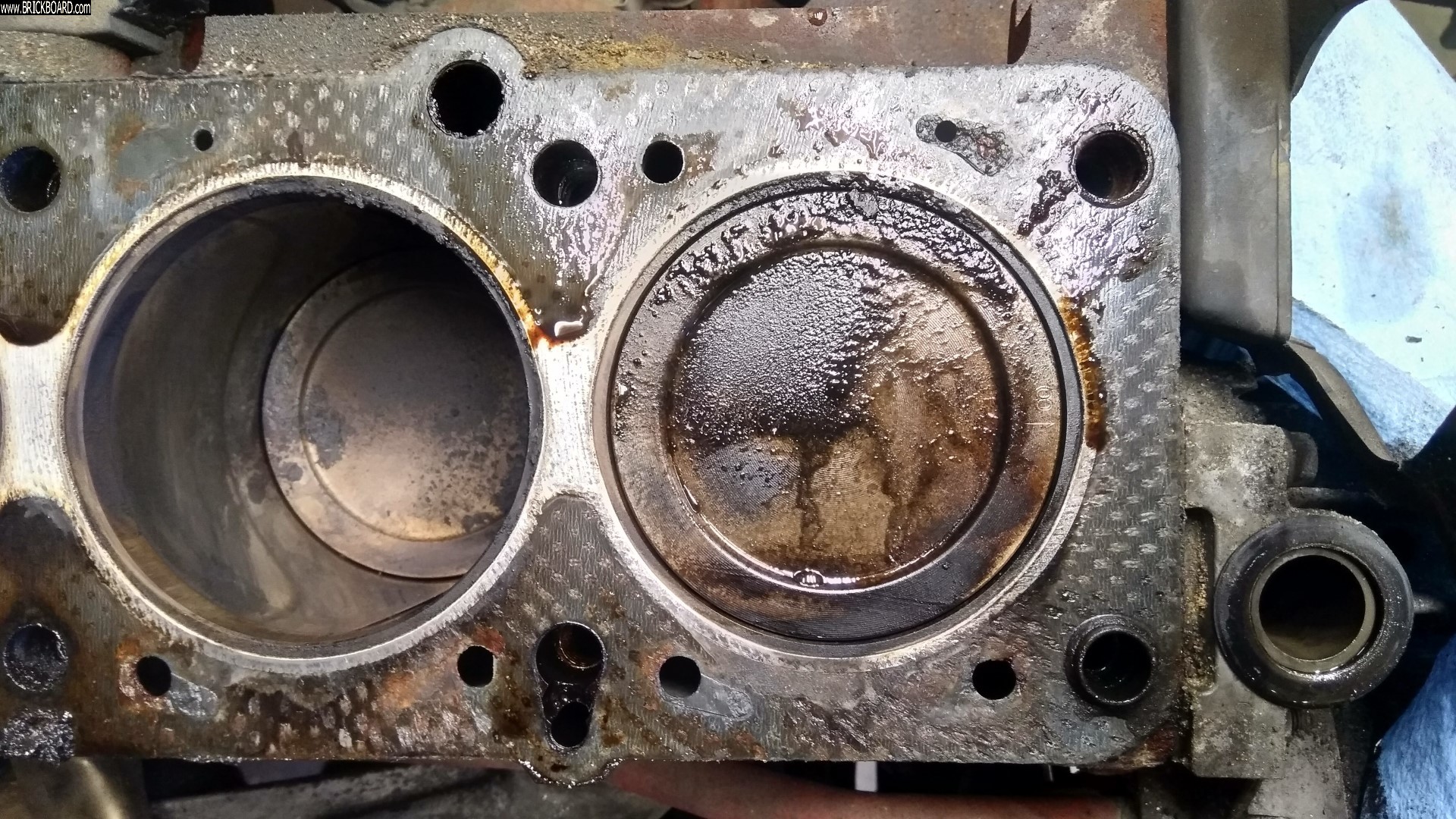

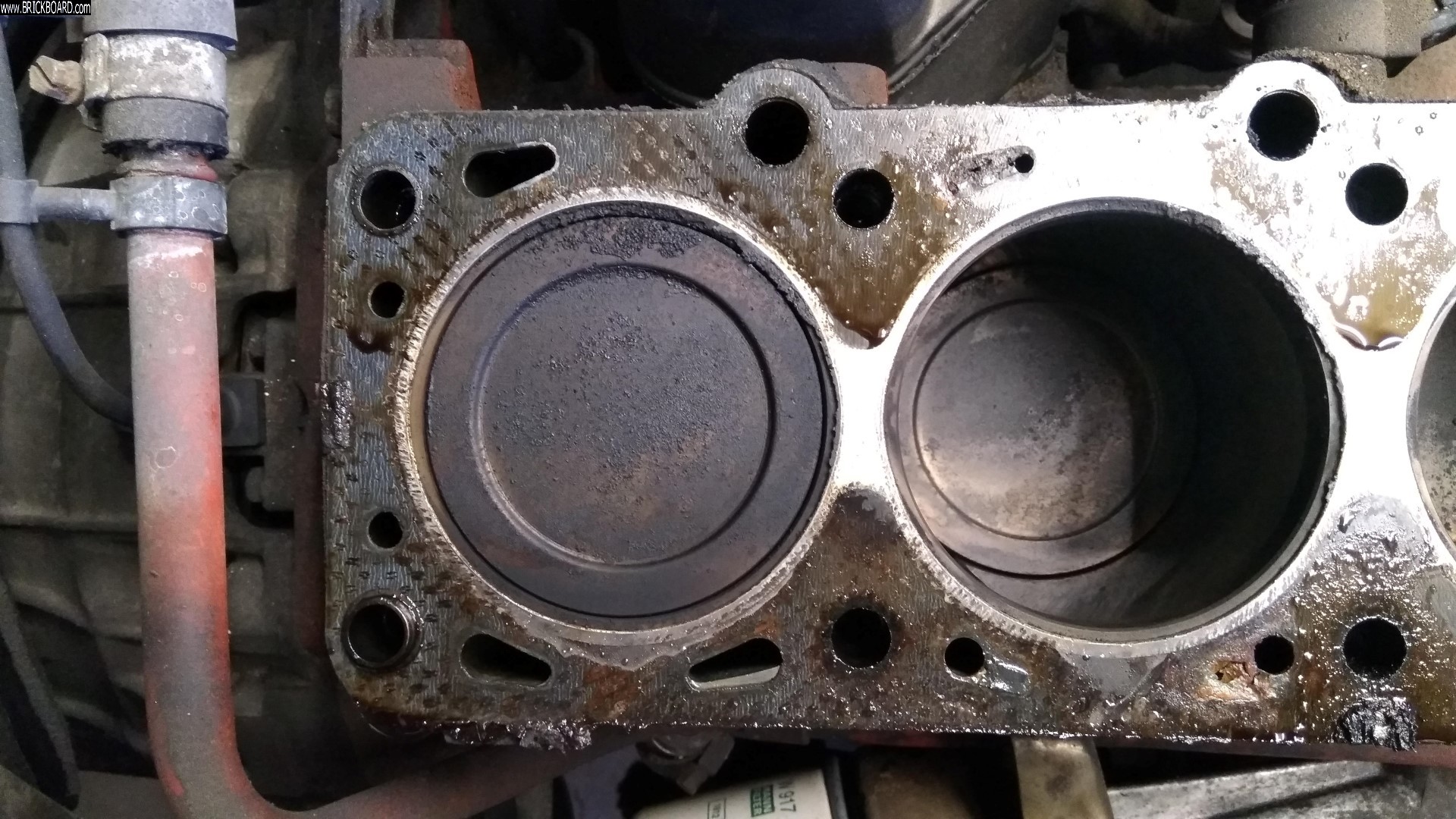

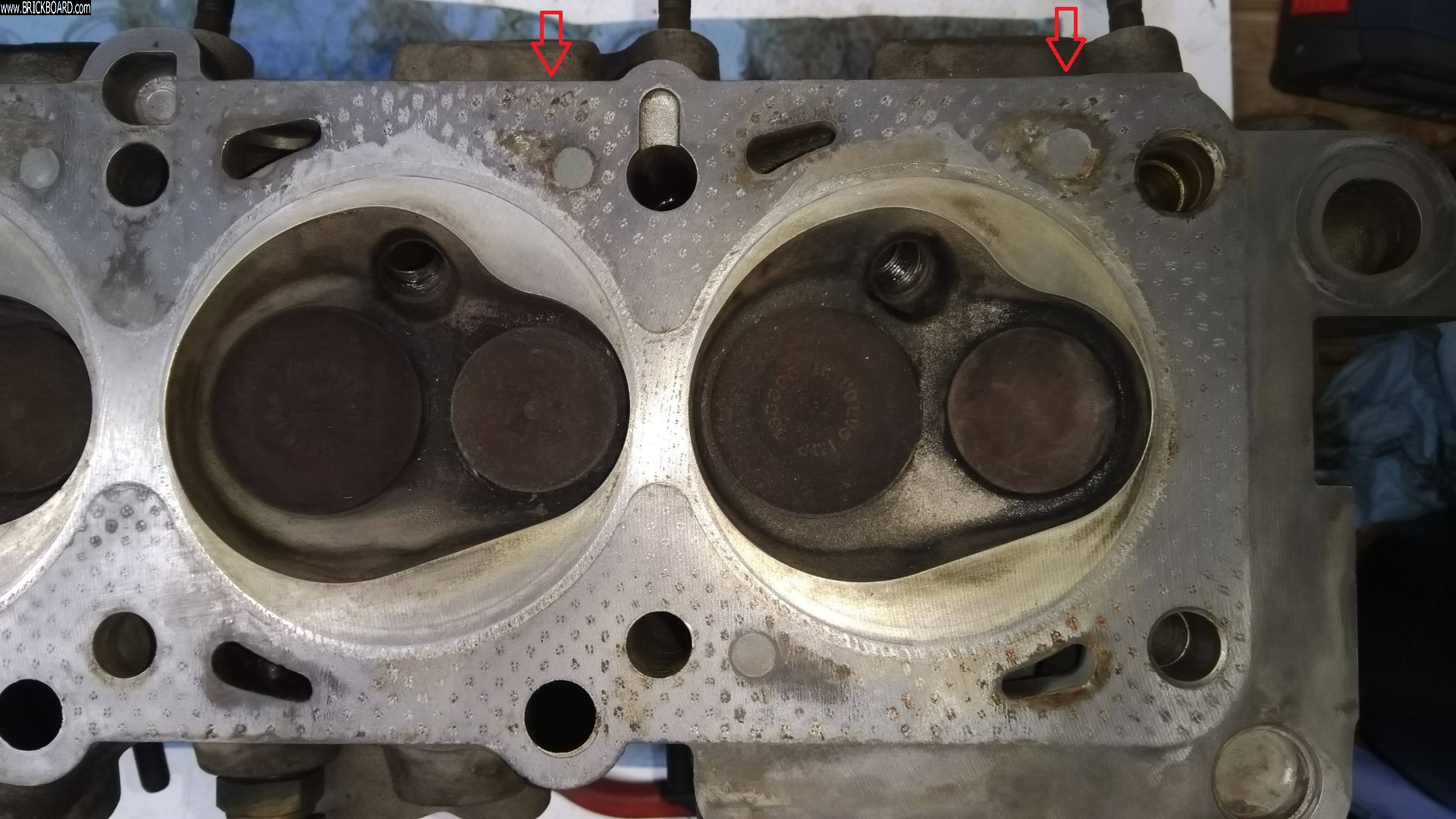

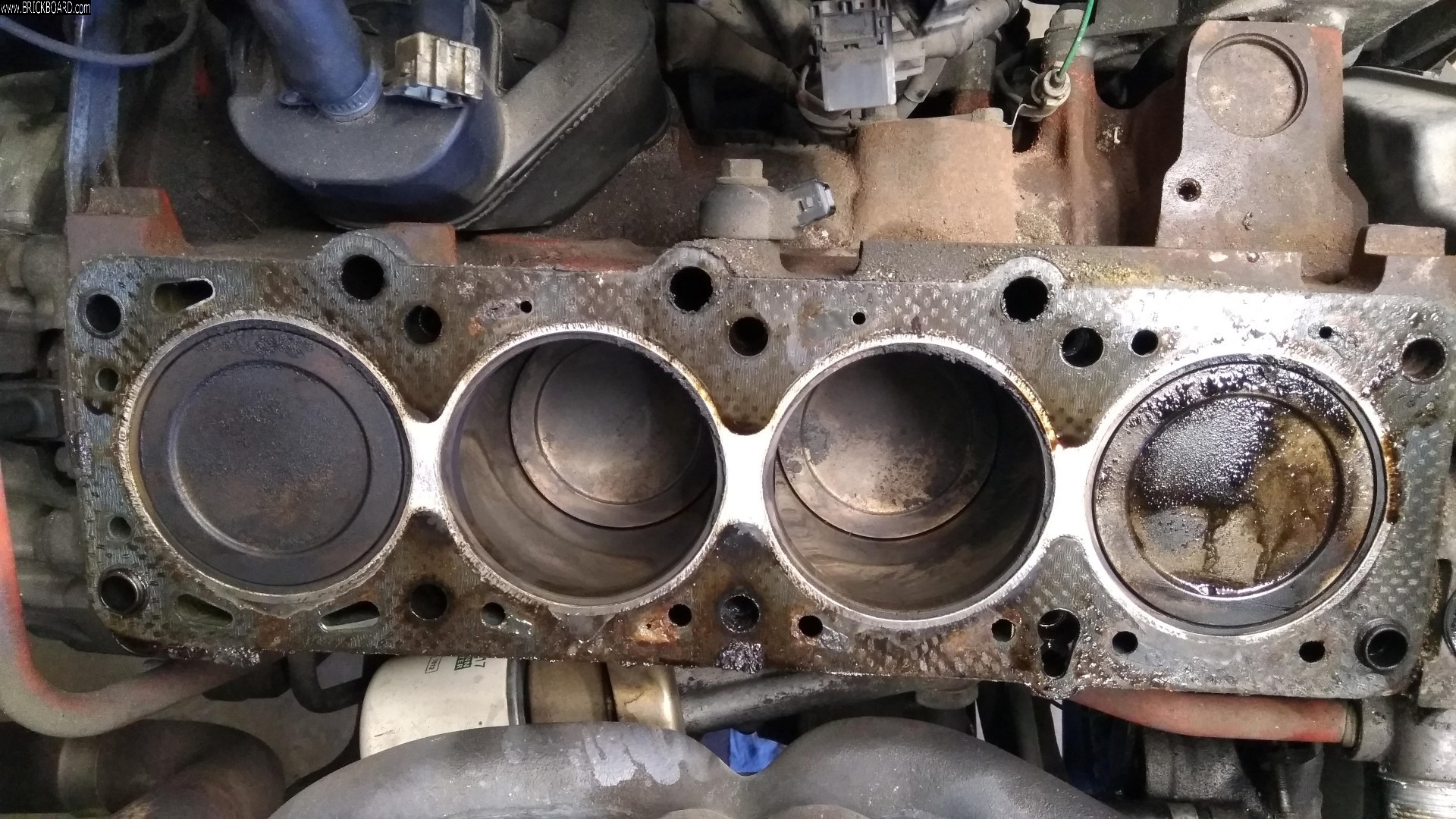

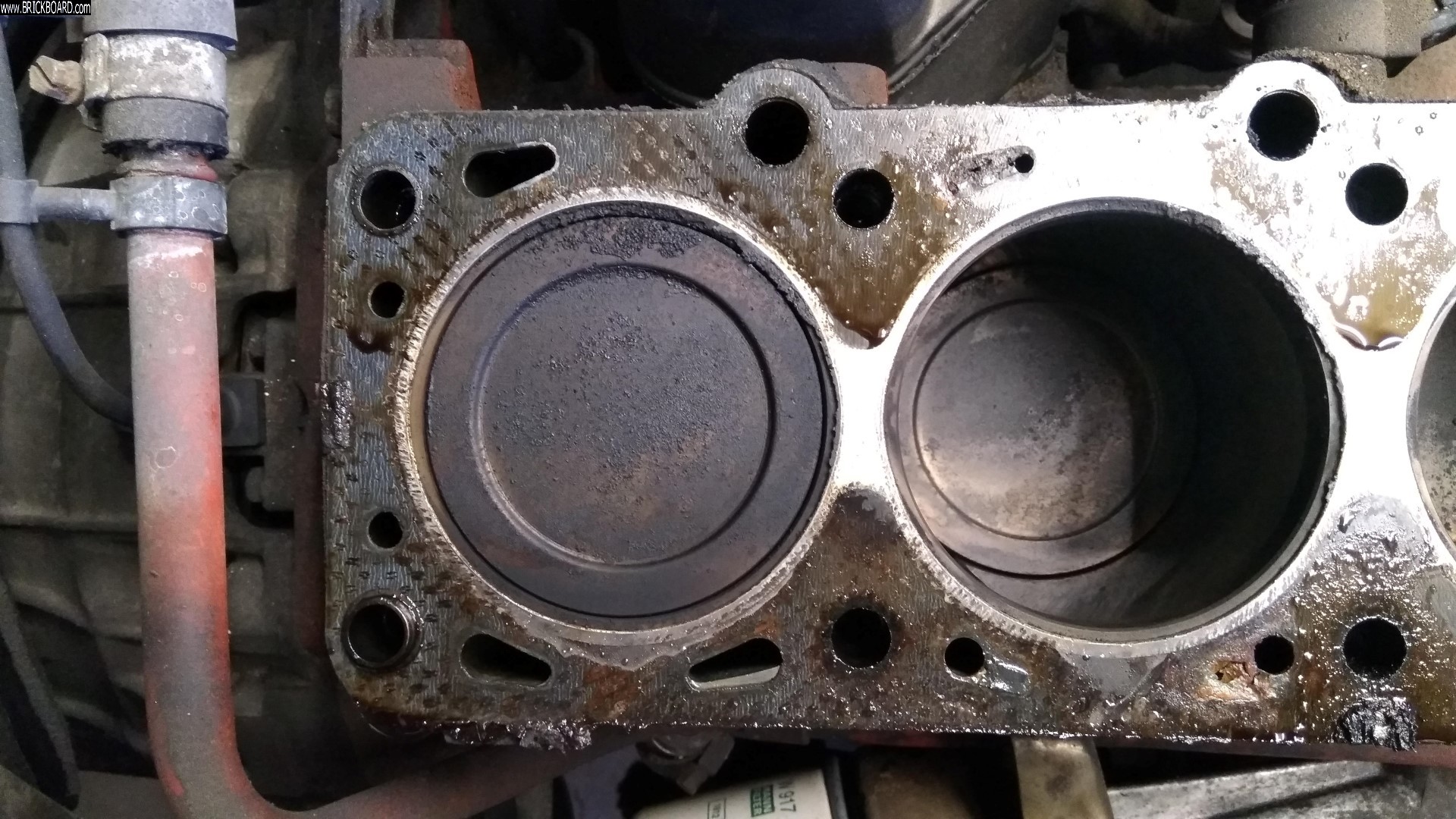

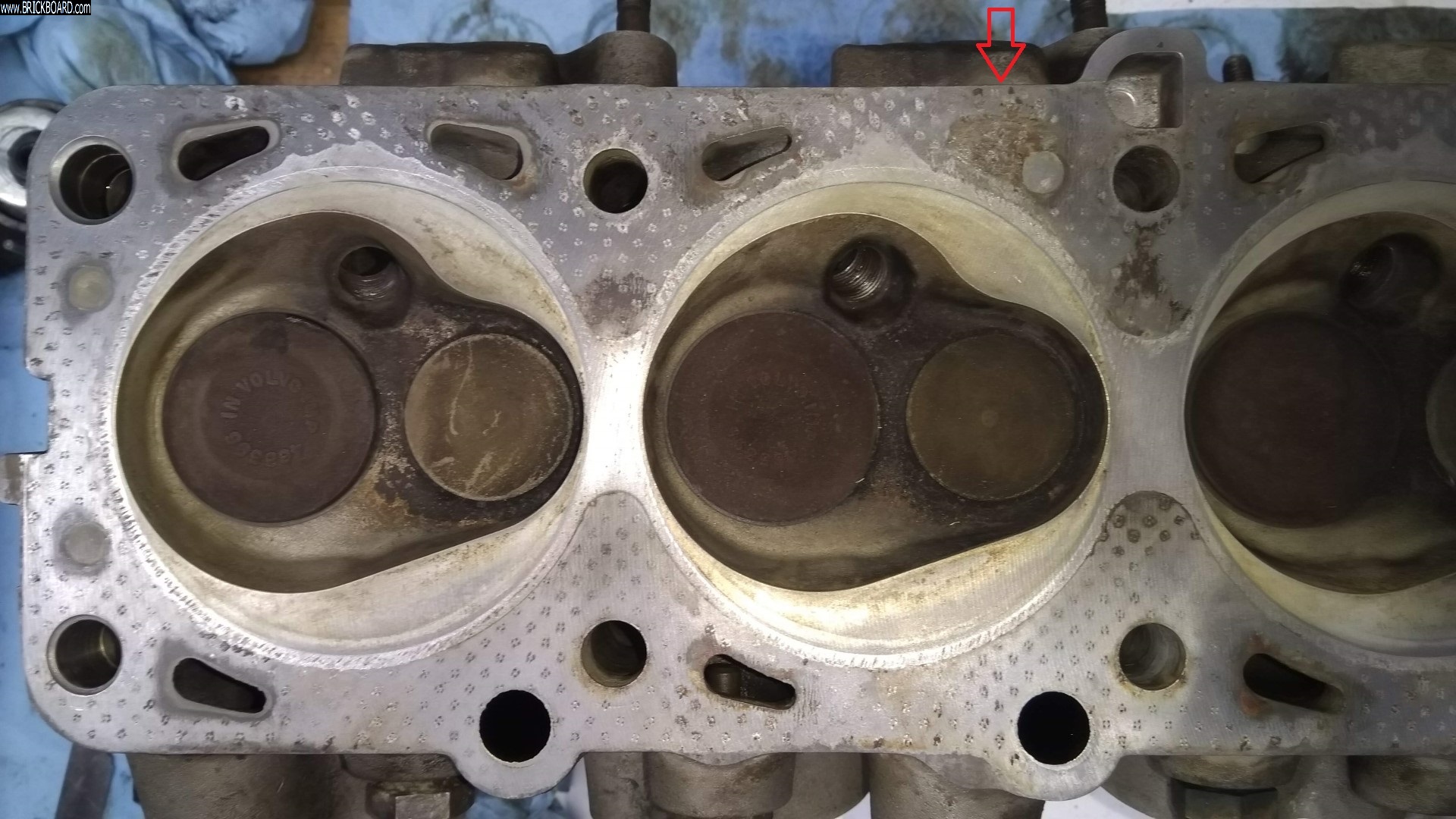

I have removed the cylinder head and here is what I see:

1) First, spark plug #1 was wet, the others all good

2) Cylinder #1 is wet

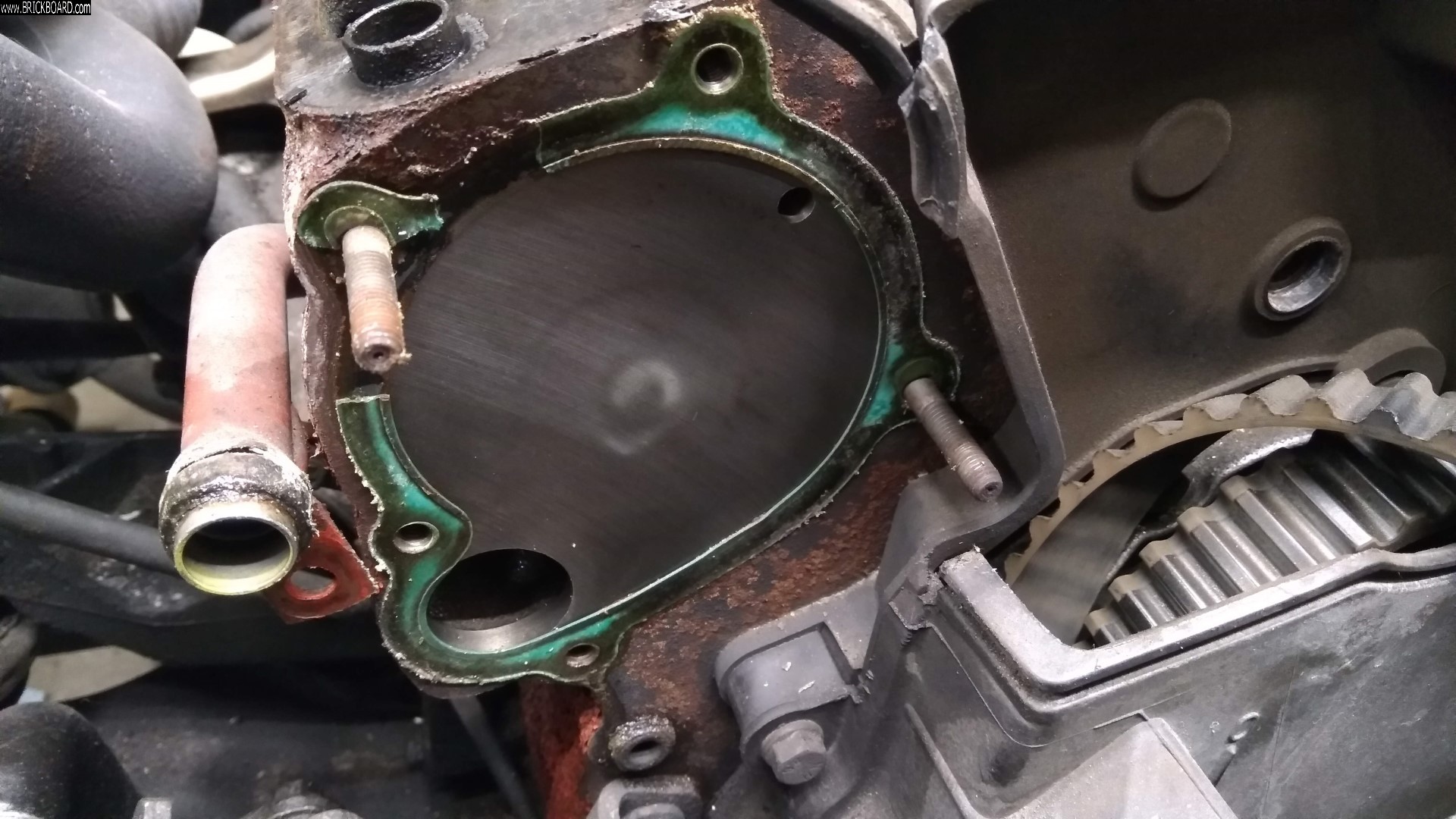

3) I am pretty sure the water pump gasket is gone, but I am going to remove it, and let's see.

It seems to me that the coolant infiltrated in cylinder #1.

Now some pictures as you will likely see more than I do, I am building experience here :)

Now have to start with the cleaning:

1) To clean up the pistons, at least the top part, shall I use a simple degreaser?

2) I guess I have to be very careful that any debris does not go between the pistons and the cylinders, to clean the cylinder #2 and #3 is likely more difficult as they are down.

3) I guess none of the various chemicals and/or debris should go into any of the holes around the cylinders, am I correct?

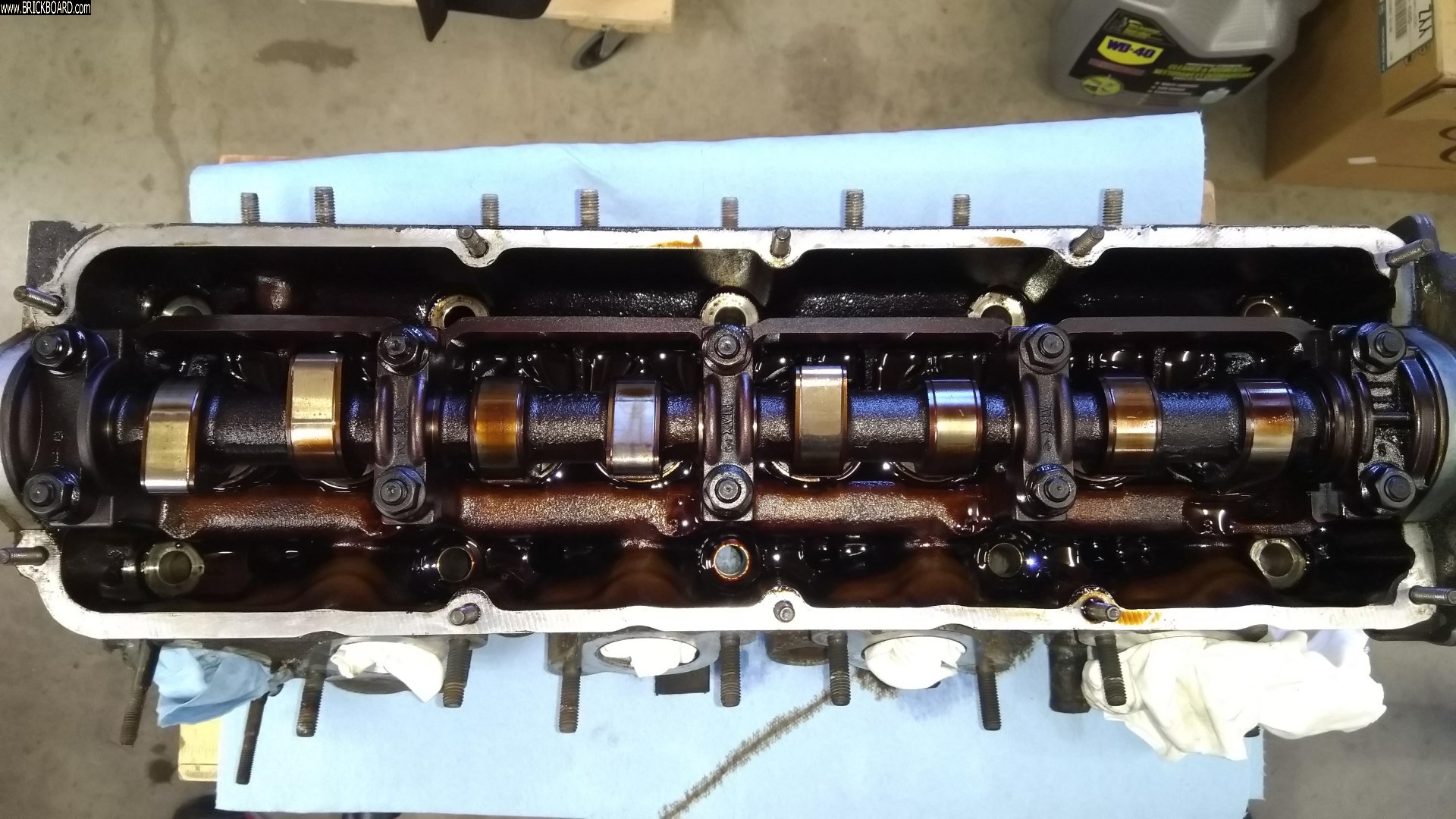

While I was there, I verified all the valves' clearance, all of them 0.35mm, not bad after 25 years!

Any observation that you have, is always very welcome!

Now, let me go to disassemble the water pump.

Thank you,

Alessandro

|

|

|

|

|

Allessandro, The piston tops need not be sparkling. Simply scraping off the loose carbon (w/plastic tool) and blow it away. If you don't have access to compressed air a can of computer "compressed gas" should suffice. I put a balled up wad of paper towel into the coolant passageways and duct tape over the oil passageways when scraping or blowing. The machined holes for the headbolts get blown out of oil and debris with air (hold a rog over the opening so you do not wind up with a face full of @#$%%). You can rotate the crankshaft to bring each set of pistons to the top. The pistons do not remember whether they were last on a compression stroke or exhaust stroke. Just set the timing marks as needed when installing the head and timing belt.

The B21-B230 are very easy on cam and valve seat wear - unlike the B18-B20 motors. Unless they've been run dry of oil they rarely need re-adjustment.

A pulled back photo showing all the cylinders would be good to have. - Dave

|

|

|

|

|

Hi Dave,

Thank you for your quick reply.

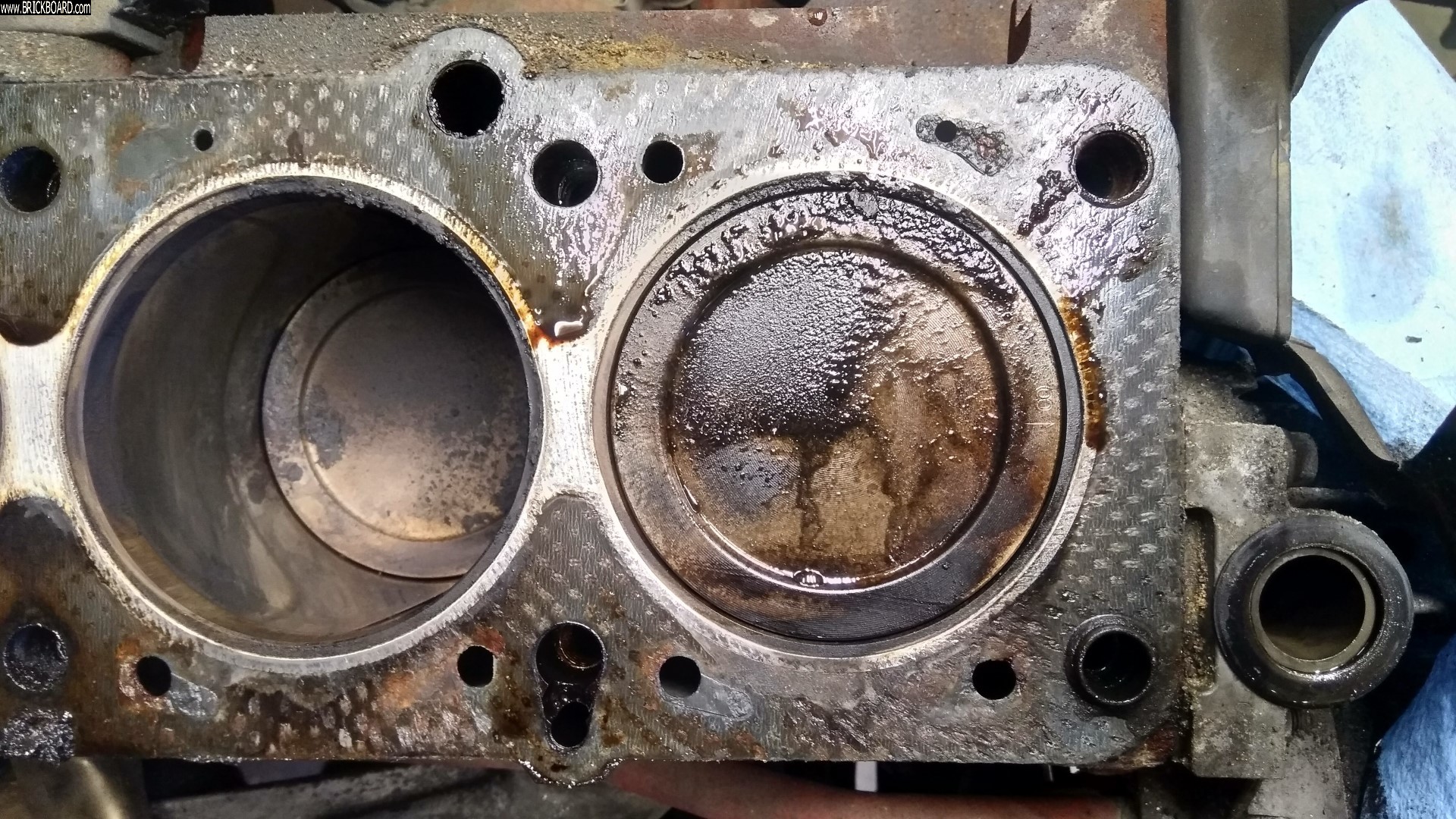

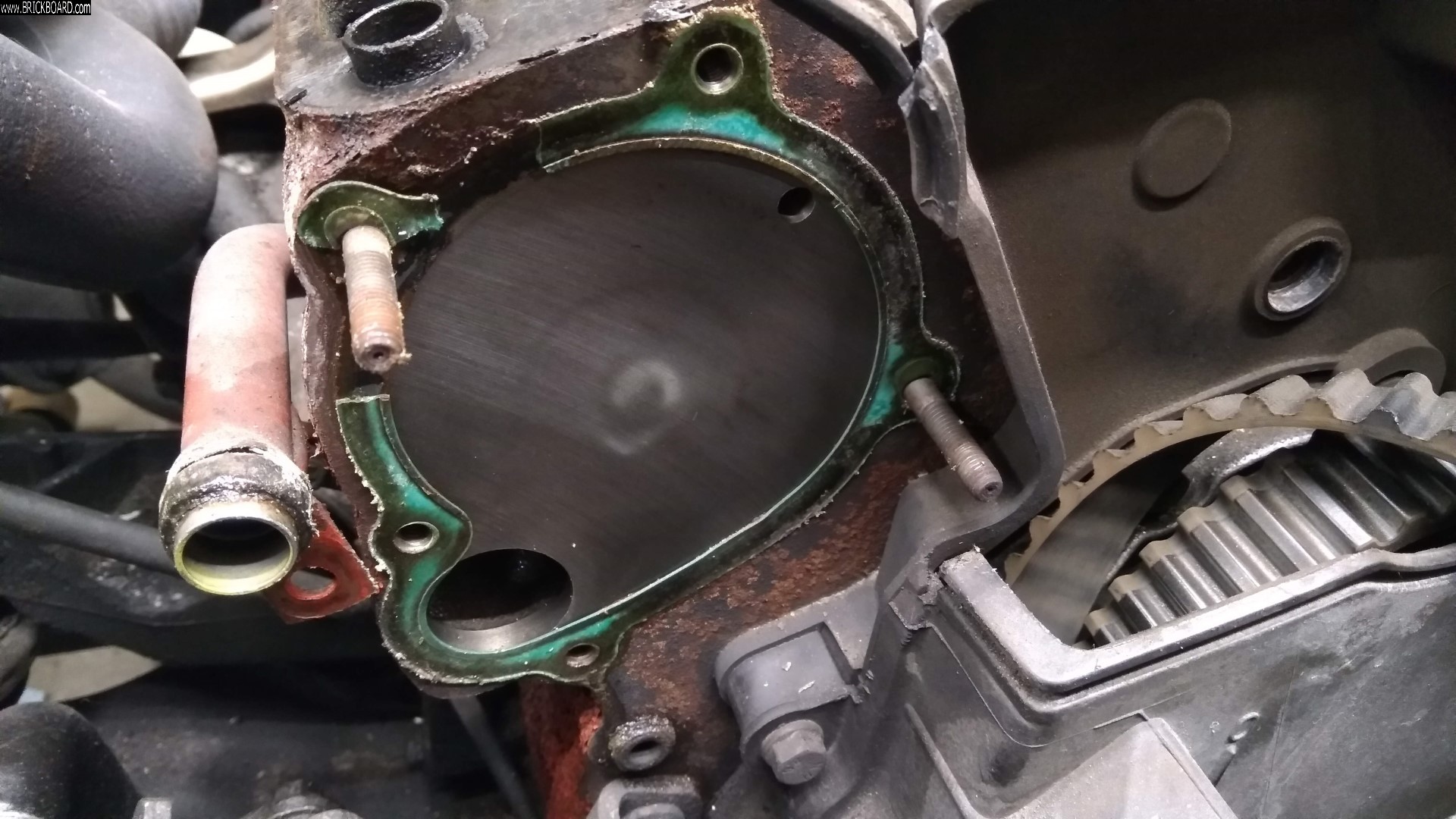

In the meantime, I was right for the water pump:

Now, could you please explain me how the cooler ended up in the piston #1?

I want to be sure to eliminate the problem, looking at the image, since the piston is wet on the upper part, is that the area the coolant was leaking in?

Also, to clean the body of the cylinder head, any arm in using diesel oil?

To me, it has always been the most effective way of cleaning gunk on anything.

My car is a B200FT which I think means a B19 engine, and those valves impressed me for lack of wear.

Thank you,

Alessandro

|

|

|

|

|

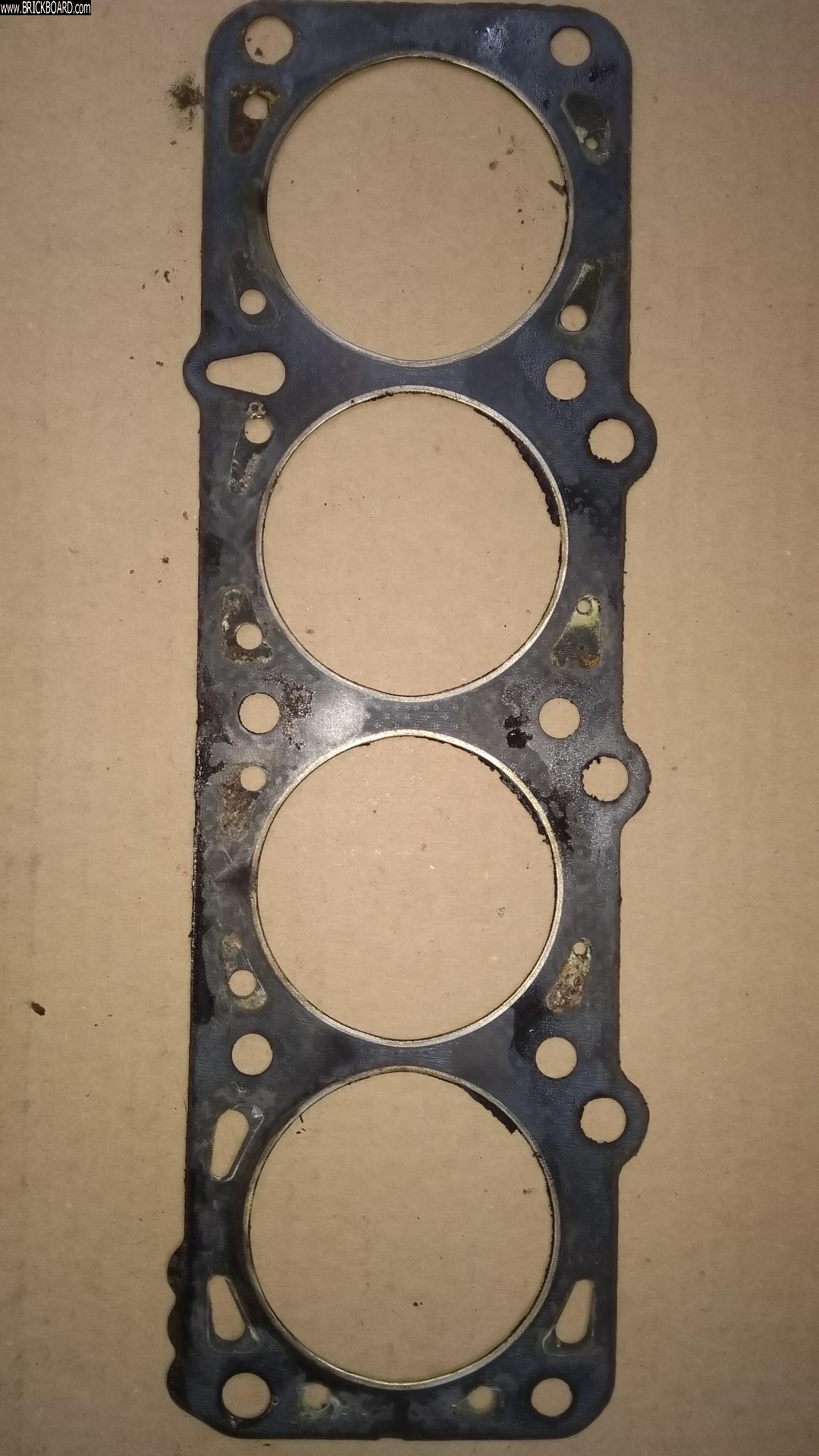

Interesting photos we don't often get to see here. Head gasket obviously failed at the front of #1 cyl. That in turn caused the water pump gasket to fail, not likely the other way around. Often times when the coolant gets sucked into the cylinder on the intake stroke you end up with a spotless, steam cleaned cylinder and plug. In your case, based on the look of the top of the piston I'm guessing it was mostly exhaust gasses going out into the coolant as the back side of the water pump is the intake suction side of the cooling system. Others may have differing thoughts. Just curious, how long do you figure this condition was present?

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

|

Hi Dave,

Actually, end of February I replaced the exhaust manifold as well as its gaskets to the block.

I drove about 2500 Km (Highway) and one morning I noticed the engine was rough when I first started it cold.

Since I was about 2500 Km from home, when I drove all the way back, I started to look into this issue.

If you read the thread, I had issues with the coolant, lots of pressure, leaking from all the radiator hoses etc.

Volvo did not find any water in the oil.

I think that the water pump gasket has failed because in 25 years it has never been changed, but I do not see how the two things could be connected, I mean, how does the coolant leak from the headgasket? How does it get there in the first place?

Thank you,

Alessandro

|

|

|

|

|

.. how does the coolant leak from the headgasket? How does it get there in the first place? ..

There are water and oil passageways between the head and block in the knockout areas of the gasket, some not that far from the cylinder wall, so when a gasket wants to fail, the narrow areas are often the easiest failure points.

Every time I see a head gasket discussion I think back to my wife's little old Mazda letting go back in the 1980s on her way to work. Before the end of our block, vapour started coming out the exhaust far more than normal. She had the smarts to pull over and stop. I decided to try limping it the five short blocks to a local service station figuring it wouldn't overheat enough to do head damage, plus it was only a crap little Mazda so I had minimal emotional attachment (if it had been my yellow peril 144GL I'd have been far more cautious). By the time I got to the station there was a mushroom cloud following me, cars were honking to get my attention and they all had their head lights on like they were driving in thick fog. One new head gasket later and the Mazda lived on to see better days, soon under a new owner after finding a nice '85 245 for her. 240 (and 140) exhaust systems are well known to collect condensation in the rear cross muffler with a lot of short trips (and why they rust out so prematurely), which makes for extra vapour when they do eventually get hot on a longer trip. It took her a while not to get nervous looking at wisps of vapour in the rear view mirror for 5-10 minutes going to work early on a cool/damp morning.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

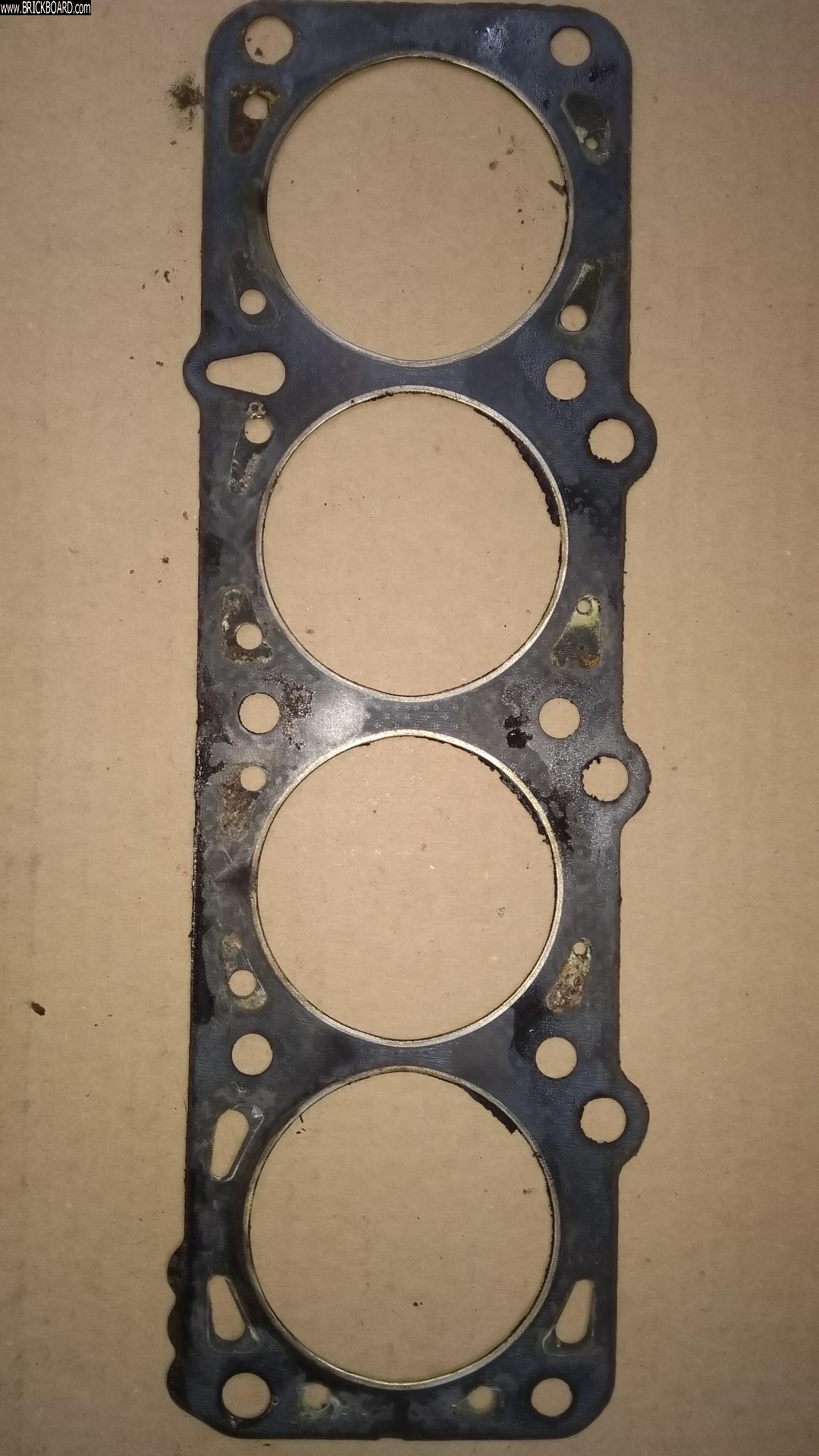

That head gasket actually looks pretty good to me. Have a closer look at the cylinder head, specifically at the block to head mating surface. Is there any corrosion visible in and around the coolant channels?

The reason I ask this is this:

I have been following this thread with some interest as I experienced a failed head gasket a couple of years ago on a B200F....or so I thought.

There was marginal loss of coolant that could not be detected externally. There was also a tiny oil leak to the outside near the oil gallery above the oil filter.

There was some evidence of overflow from the expansion reservoir's cap (if I had filled coolant up to the max. line on a cold engine).

There was also evidence that a previous owner had experienced high cooling system pressure as all hose clamps were tightened way too much, cutting into the rubber. I replaced many hoses.

Long story short: I drove like this for a year until oil started to appear in the expansion reservoir. I suspected #2 cylinder as it showed a dirty piston top on an endoscope while the other three were clean (indeed, exactly the opposite of what one would expect). I made an appointment to have a specialist replace the head gasket.

The day previous to the repair I made a long but uneventful trip. The morning of the repair I tried to start the engine but the starter motor would bog down. Water does not let itself compress like air, so I suspected over night water had seeped into cylinder #2. I removed the spark plug from that cylinder and started the engine which spewed the water out through the hole. Then I refitted the spark plug, topped up the coolant and drove to the shop.

They sent the cylinder head to be sand blasted and planed/skimmed but it turned out the water channels had corroded to the point that tiny channels had also formed in the mating area, running right under the head gasket. One found its way into #2 cylinder The head had to be replaced, as the corrosion went deeper than the head could be skimmed. This was not immediately obvious, but the sand blasting process revealed it clearly.

So hence my advice to check the cylinder head too!

By the way, yesterday I replaced my water pump because after a while after this head repair, there would be a tiny leak around the pump to head seal. This is not a unknown failure and apparently many keep driving like this slowly forming a sort of "coral reef" around it. It certainly didn't bother me and I postponed it until yesterday when I had planned to do maintenance anyway. I replaced it also because some play in the pump's bearings could be felt, which I didn't like.

You wrote:

"I think that the water pump gasket has failed because in 25 years it has never been changed, but I do not see how the two things could be connected, I mean, how does the coolant leak from the headgasket? How does it get there in the first place?"

This leak occurs on the pump to head seal, but that's not part of the head gasket but the rubber O-ring that sits in the pump.

The water pump I replaced turned out to be a Meyle branded part, which AFAIK is not a OEM pump, suggesting my 245 may be on it's third water pump now.

--

1992 245 Polar B200F M47

|

|

|

|

|

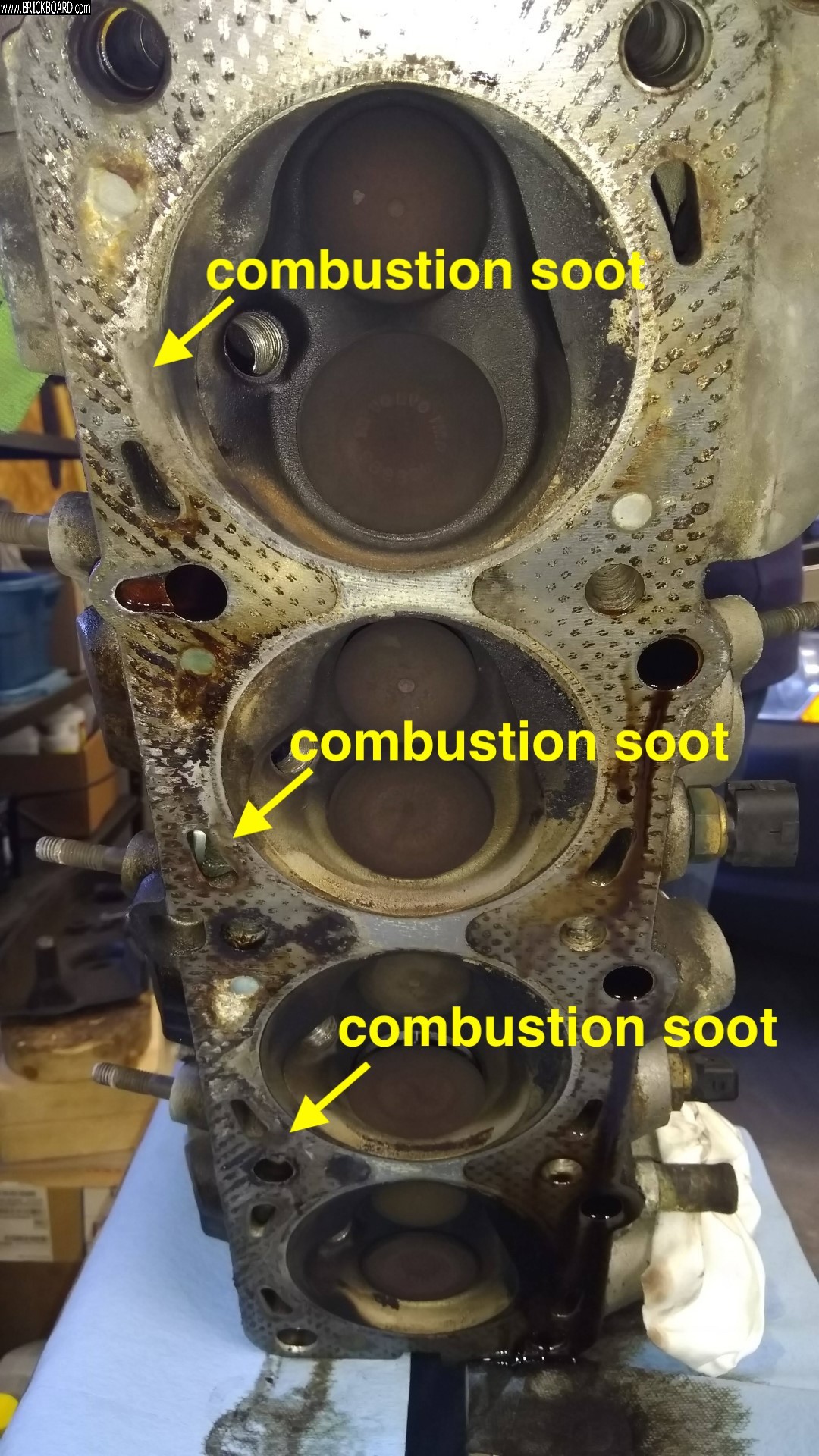

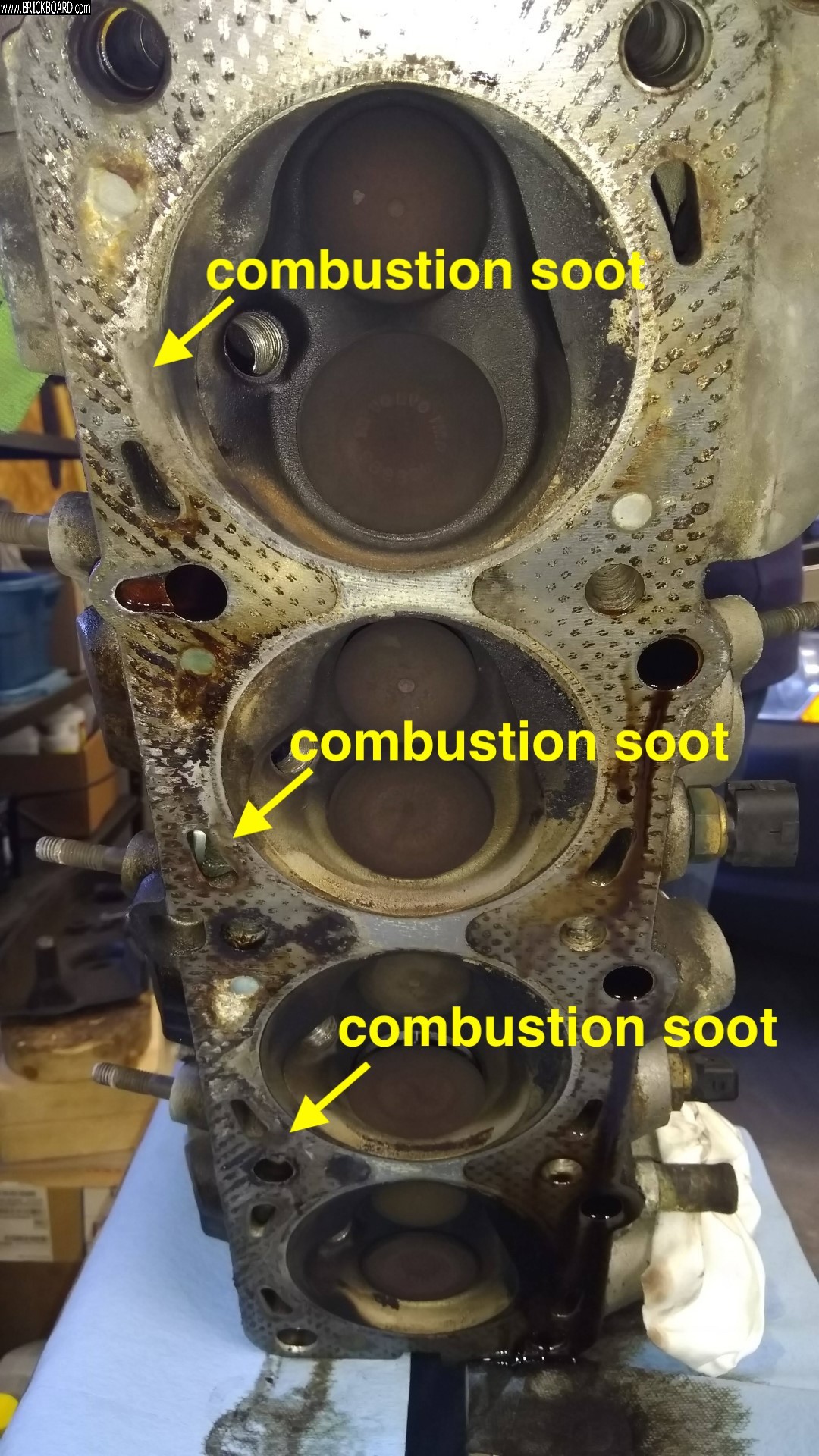

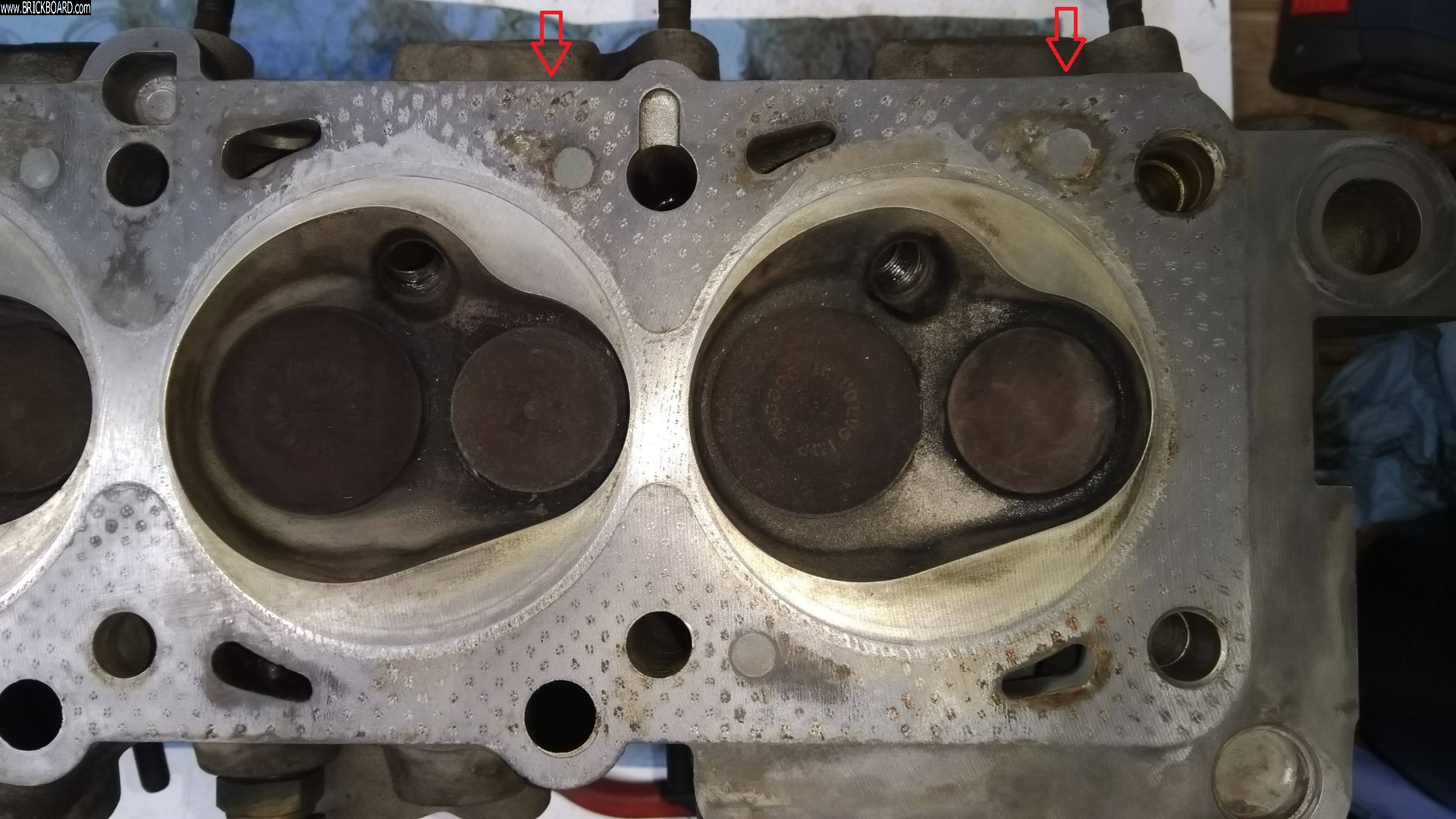

Here's what I see on your cylinder head

Those soot tracks shows points of failure on the headgasket and how exhaust gases got into the coolant channels, causing unusual high pressure within the cooling system

On the engine block, note that pistons 1, 2 and 3 are relatively clean (steam cleaned) compared to piston 4. These are consistent with the failure points on the cylinder head

The aluminium cylinder head expands faster than the iron engine block. I could see that those failure points are on the headgasket side facing (ie. rubbing against) the cylinder head.

Using a good coolant (like Volvo OE latest G64 Glysantin - better heat removal) and flooring the throttle only when engine fully warmed-up could delay these from happening. But eventually it (ie. replacing headgasket) would still happen because of the difference in expansion rate between head and engine block.

Amarin

|

|

|

|

|

Amarin,

Absolutely, but you may remember that I had two issues:

1) The rough start when the engine was cold

2) The high pressure of the coolant, leaking from all the hoses to the radiator. The pressure was so high that it warped my(genuine) coolant reservoir when I replaced the reservoir cap.

While we can see the reason for the rough start, I am still unsure about the reason behind the high pressure of the coolant.

According to Volvo, those were two separated issues.

I am concerned because if I do not understand the reason behind the high pressure of the coolant, the risk is that I am back to square one once I re-assemble everything.

Thank you,

Alessandro

|

|

|

|

|

Dear Metallo,

For issue #1 - still unanswered. Prior to dismantling the head there was no attempt to visualize for any coolant within the cylinder. Also no attempt to take out the spark plugs to look for coolant wetting the plugs.

Lets not dwell on the past. The evidence of steam cleaning for pistons 1, 2 and 3 is convincing enough to say some coolant did leak into the cylinders.

For issue#2 - the soot tracks on the cylinder head is how the combustion gases got into the coolant channels and causing high pressure. I could see no other source of high pressure for this engine (ie. not from the turbo, cracked cylinder head (I don't see any), clogged cat converter, et cetera)

Volvo could be thinking the rough start and high pressure were two separate events. With the head already dismantled you're in better position to evaluate this than Volvo. Connect the dots (ie. the two events together)

Rest assured just carry on with the job IMHO (ie. cleaning surfaces, valve lapping, new valve seals, new headgasket)

After all cleaning done, re-evaluate the cylinder head and block for any cracks (just to be sure). Check for any warp (straightness) while you're at it.

Amarin.

|

|

|

|

|

Hi Amarin,

Thank you for your thorough explanation.

The only thing I am undecided to venture in is the valve lapping, it adds lots of work for me, as I have never done this before, and I am not sure if I have all the necessary tools to do it.

On another note, I am having a hard time removing the water pump seal from the block, any recommended chemical I could use?

I tried CRC and a paint stripper, but to no avail.

It is really dry and stuck to the block.

Thank you,

Alessandro

|

|

|

|

|

Dear Metallo,

You wrote:

"The only thing I am undecided to venture in is the valve lapping, it adds lots of work for me, as I have never done this before, and I am not sure if I have all the necessary tools to do it."

At least do the test prescribed by Volvo From Heck. Before starting the test, select which pair of valves to close first by turning the camshaft manually. Pour gasoline on the closed valves to see any gasoline leak at the intake/exhause ports. Let the gasoline pool (stay) about 5 minutes or more before deciding any leak or not (common mistake most people do this rather quickly without giving some time). Lots of youtube video on this.

You wrote:

"I tried CRC and a paint stripper, but to no avail. It is really dry and stuck to the block."

You need to use a box cutter blade. Only use the blade, chuck the handle/blade-holder away. Lay the entire blade's sharp edge FLAT on the non-gasket portion at water pump area, then work the blade (at an angle not perpendicular) through the stuck gasket. You could snap the blade shorter if its too long to get into the work area.

Don't use art-knife (too pointy, might score the surface) or shaving blade (too fragile, might break causing injury)

Amarin.

|

|

|

|

|

Amarin,

[quote]

At least do the test prescribed by Volvo From Heck. Before starting the test, select which pair of valves to close first by turning the camshaft manually. Pour gasoline on the closed valves to see any gasoline leak at the intake/exhaust ports. Let the gasoline pool (stay) about 5 minutes or more before deciding any leak or not (common mistake most people do this rather quickly without giving some time). Lots of youtube video on this. [/quote]

The B200FT is an interference engine, so I wonder if rotating manually the camshaft can create any damage. Also, on the Haynes manual they recommend to not rotate the crankshaft, camshaft or auxiliary shaft with the belt removed, which is why I ask for confirmation.

If no damage occurs when rotating the camshaft, shall I do it by re-inserting its sprocket? That should make it easier to rotate.

How can I be sure the valve are closed while rotating them?

Is it when the two lobes are at TDC point like cylinder #1 in my image?

So, al I have to do is to rotate them until I get the two lobes in the same exact position for all 4 cylinders?

Sorry for asking what may sound as the obvious, but mistakes would be expensive :)

Thank you!

Alessandro

|

|

|

|

|

With the head off there's no danger in turning the camshaft or the crankshaft--all the marks just have to be set right on re-assembly. When the lobes point up-the valves are closed. Visually seeing it will make it obvious. Yes, mount the timing gear--or sometimes I've seen "flats" built into the cam for turning with a wrench. - Dave

|

|

|

|

|

Hi All,

I did not have any time to work on the car during this week, but today is cleaning day.

I cannot clean the block more than this, to the finger touch, it is all smooth.

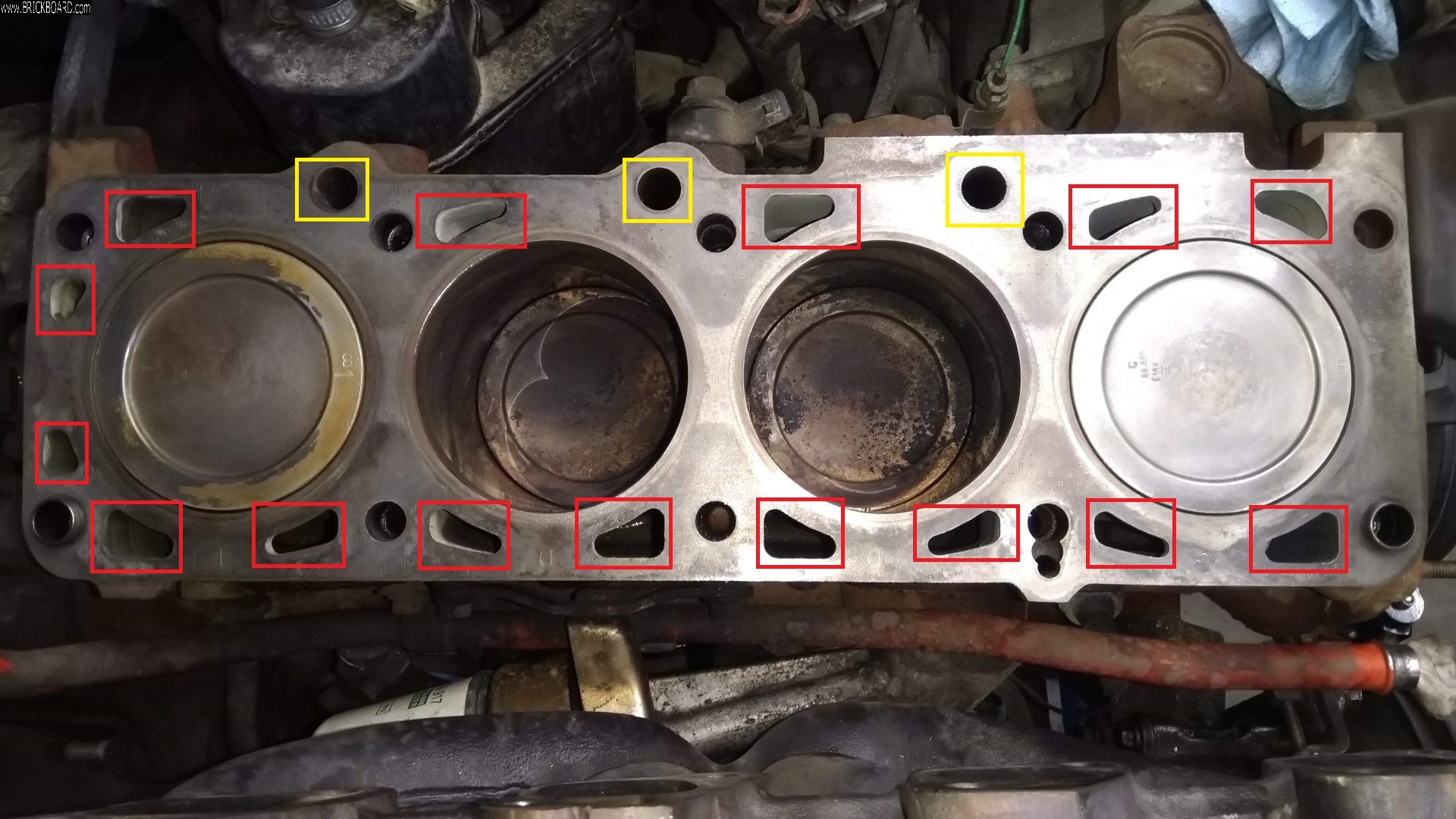

Now some questions for you:

1) Just to confirm. I can rotate the crankshaft to bring the two central pistons up and finishing the cleaning, correct? As long as I do 360° and go back to TDC, (crank notch aligned to the 0 mark), I should be good. Please confirm.

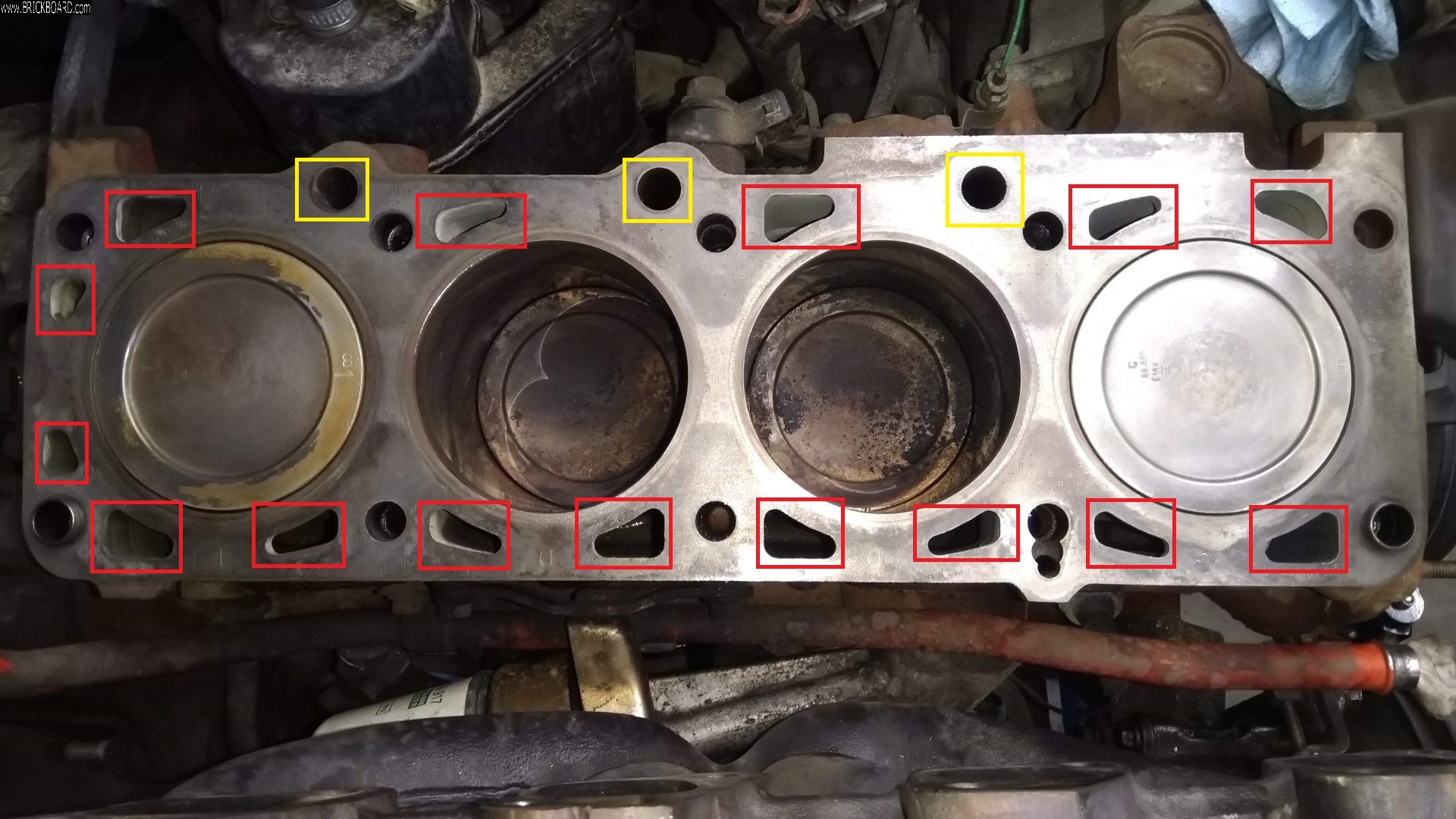

2) I marked all the coolant passageways in red, and oil ones in yellow. Am I correct in identifying them?

3) Would there be any benefit in using in blowing compressed air in the coolant passageways? How about the oil ones?

4) The car needs engine oil drain and filter replacement. I guess the best time to do this is before I start the engine after I am done with this job?

Thank you!

Alessandro

|

|

|

|

|

Dear Metallo,

Answers to your questions:

1. Yes

2. Yes

3. No benefit for either or both. Only use air for the bolt holes

4. Yes

Amarin

|

|

|

|

|

Thank you Amarin,

So I pulled off the camshaft and tested the valves by pouring some gasoline.

Left the gasoline in there for about 25 mins., and came back.

I noticed the intake valve of cylinder #4 leaked a few drops.

All the others are sealed.

Now, what would be the recommendation here? Shall I lap that valve only?

Or shall I lap them all?

The problem is that I do not have the tool to retain the spring, and if I have to do the job myself, I need to buy that.

I have already taken a quick look on the Internet, I saw multiple ones, but you guys probably can recommend one rather than the other?

I am a bit sad because this will clearly extend the time it takes to do this job, and I never see the end. :(

As always, many thanks for your advice.

Alessandro

|

|

|

|

|

Dear Metallo,

You wrote:

"Left the gasoline in there for about 25 mins., and came back. I noticed the intake valve of cylinder #4 leaked a few drops. All the others are sealed."

Actually you should have stayed and waited all the while.

Finding it leaked at end of 25 mins doesn't tell you what time it leaked. It could have leaked early, mid or late (ie the severity of leak)

In reality the valves are supposed to seal in split second during compression in a working engine. The reason to leave the gasoline for about 5 to 10 minutes during the test is because the gasoline wasn't under any pressure (only under influence of gravity) unlike in working engine.

I suggest you clean it all up with brake cleaner, let dry (use hairdryer) and REPEAT the test just to be sure.

This not to make you working harder than usual but to help you (and us) to decide.

If it leaked early (within a few minutes up to 5 minutes considered as severe leak) then lapping is a must IMHO

Amarin

|

|

|

|

|

Amarin,

I did as suggested, I cleaned the valve and re-tested, no leak!

I was surprised to see that the edge of the valve was basically clean already, it is not pitted, no gunk etc.

I cleaned the valve edge and its seat with CRC, tested again and no leak.

I mean, other valves were open and they are dirtier, but they do not leak.

Who knows why, but I am happy you told me to try again.

Thank you man, now I can start cleaning the head surface :)

Alex

|

|

|

|

|

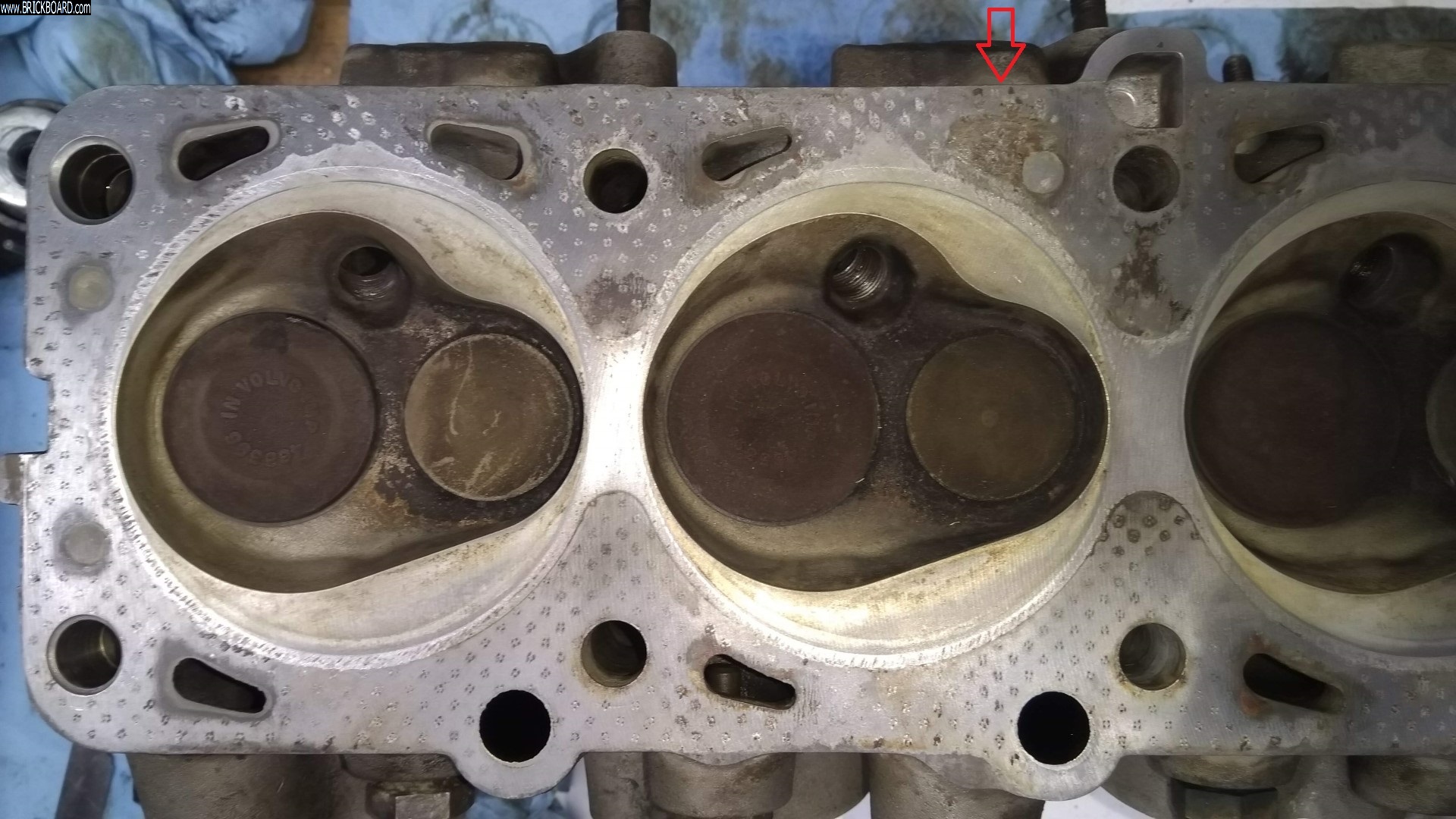

Hi there,

I cannot clean the surface better than this, and I put an arrow to show my areas of concern:

They are pitted and I can feel them with the finger.

Machine shop for resurfacing?

If so, I guess I have to inform whoever will do that of this:

Height New: 146.1mm

Min. after machining: 145.6mm

This is not a common car in my area, actually my car is the only one in NA with this engine. I doubt that the machine shop(s) in my city has ever machined one of those before, and if they did it was probably a long time ago.

Can they resurface it without removing the valves?

Any other info that you think could be useful to them?

Thank you,

Alessandro

|

|

|

|

|

Yes you need to send this to the machine shop. They know what to do and how much to shave the head. Let the valves be in their places no problem.

Amarin

|

|

|

|

|

Dear Metallo,

Firstly nothing to worry about

That cylinder head "defect" in the red box mates to a coolant passage (ie.hole) on the block. So its not important for that "defect" to be perfect flat.

Try putting the head momentarily onto the block and see what I meant

"How can I be sure that no aluminum debris ended up in any of the passageways?"

--> Blow strong air into all the passages ie. workshop air or canned air

"I assume I have to oil again the valves before I re-assembling the camshaft, correct?"

--> No if you meant to pour oil into the intake and exhaust ports to lubricate the valves

--> Yes if you meant to pour generous amount of oil onto the entire assembly ie. after putting the valve buckets + shim + camshaft. Do this ONLY after you've bolted the head onto the block. Don't want any oil spill onto the cleaned mating surfaces

Amarin

|

|

|

|

|

Hi Amarin,

Yes, I meant to pour oil onto the entire assembly.

Thank you,

Alessandro

|

|

|

|

|

Hi all,

when I started this project, I also planned to replace all the oil seals.

The issue I have is that I simply cannot succeed to remove them, neither the crank seal nor the intermediate one.

After 25 years they must be stuck in there, and I do not want to scratch the surface.

Isn't that easier if I remove the whole sealing flange?

Is there anything preventing me to unbolt that sealing flange and remove those seals? In doing that I can also replace that sealing ring.

I found an article in the FAQ with a picture, if you click this link and search for :Location of New Seal, you will see what I mean.

https://www.volvoclub.org.uk/faq/EngineSealsBeltsVent.html#VolvoCamTool

Thank you!

Alessandro

|

|

|

|

|

Dear Metallo,

Hope you're well. I've stood aside as there are many better-qualified to offer advice as to head-gasket replacements.

If you have a "heat gun", that may help you to remove rock-hard seals. The heat will cause the seal's polymer to expand faster than the surrounding steel. That could break the "bond" between the seal's edge and the surrounding metal, allowing you to extract the seal.

Heat may slightly soften the seal's polymer shell, allowing a hook tool to be inserted between the seal's lip and the shaft. The lip is the softest part of the seal.

The hook tool should be inserted with the round part of the tool "flat" against the shaft. This positioning will keep the hook's point from contacting the shaft. The hook's smooth, round sides won't damage the shaft.

The tool should then be pushed inwards, between the shaft and the seal's lip. If that can be done, turn the tool, so the hook moves towards the seal's outer edge. You may then be able to pull the seal towards you. It may take several efforts - around the circumference - to "walk" the seal out of the seal carrier.

Hope this helps.

Yours faithfully,

Spook

|

|

|

|

|

Hi All,

I managed to remove both oil seals using a drill and two screws.

Pulling in the new ones was not easy, the intermediate being the most difficult.

I used a PVC pipe and a plastic film to make sure the lip was inward for the intermediate seal. The crank one instead seems to be shaped slightly different, therefore its installation has been easier.

Now, I have to hope they are working well.

I will finish the cleaning of some of the parts, and slowly start to re-assemble everything.

Torques:

In the pocket data booklet, I read the following, which is confusing to me?

- Main Bearing Cap: 110 Nm

- Connecting Rod Cap (Stage 1): 20 Nm

(Stage 2): angle-tighten 90°

- Camshaft cap: 20 Nm

Now, to me there are 5 caps that hold the camshaft, and when I have unbolted them, I could do that with the cylinder head on the bench, without big effort, which to me is a 20 Nm.

What do they mean by 'Main Bearing Cap' and 'Connecting Rod Cap'?

I could assume that the three central caps are what they call 'Connecting Rod Cap'? So those three should have 20 + 90°, while the remaining two on the edges 20 Nm.

If my thinking is correct, what is the 'Main Bearing Cap': 110 Nm?

- Water Pump: I cannot find the torque Specs

- Thermostat: I cannot find the torque Specs

Thank you!

Alessandro

|

|

|

|

|

Dear Metallo,

Hope you're well and stay so. As to torque specs for the water pump and thermostat housing, I've always tightened until "snug". That seems to have sufficed.

Hope this helps.

Yours faithfully,

Spook

|

|

|

|

|

Hi family,

Still moving ahead with the reassembly... one question:

The two 'locating plates' (front and rear) that go with the lower timing belt sprocket, do they need to be lubricated?

I would think so, if so, with what? ordinary grease?

To be clear I refer to those P/Ns:

- 1357621

- 3531184

Thank you!

Alessandro

|

|

|

|

|

Dear Metallo,

Hope you're well and stay so. I agree 100% with Amarin!!! Under no circumstances lubricate the locating plates. The reason: oil weakens most rubber compounds.

I do not lubricate the crank bolt and have had no issues with corrosion. That said, were I concerned about corrosion, I'd apply a very thin coat nickel-based anti-seize to the smooth part of the crank bolt's shaft. This will serve as a "gasket" and keep moisture from getting to the threads. Most torque values presuppose dry (un-oiled) threads.

Nickel-based anti-seize is rated up to about 2,500°F, so will not deteriorate and become an obstacle to removal.

Hope this helps.

Yours faithfully,

Spook

|

|

|

|

|

Dearest Spook,

I hope you're well.

Oiling the crank bolt is stated in the manual.

Before I got into replacing the timing belt as DIY, I let my mechanic (ex-Volvo) did the timing belt change. He used power tools to get the bolt out, without even the need to use crank pulley holder. No sweat really, the bolt was out with a few short bursts.

When I got into the job myself my 1/2 inch 2 feet breaker bar with pole extension creaked and groaned extensively until I worried it might snap. I had to use 3/4 inch "L extension" with 15/16 hardened black socket to get it out. And I realised the bolt's threads was dry.

Recently I've done another timing belt change and it was easy. One pull with the 3/4inch extension and it was loosened. The thread was oiled last time. Yes, I use crank pulley holder.

Your idea of using nickel based lubricant as sealant is sound. I might be doing it in the future.

Stay well, stay healthy!

Amarin

|

|

|

|

|

Hi folks,

I just finished re-assembling everything, and I decided to take courage and turn the engine on.

I have recorded a video, but something does not work, there is a tic tic tic, I suspect one of the valves, but I cannot think to what I could have possibly done wrong.

https://www.mediafire.com/file/im35qryi28tgcu9/00085.mp4/file

Please ignore some of the conversation I am having in Italian with my wife.

From mid video onward you will see smoke coming from the turbo/manifold area, it did the same 3 months ago when I installed the new exhaust manifold, after two days it stopped.

In this moment I am really frustrated, as the idea to disassemble the crankshaft again, after 5 weeks I have been working on my car, (when I could during the evenings), is killing me.

If it is a valve, I changed all the the rubber absorbers, before doing that, all the gaps were within tolerance, like, 0.35, is it possible something changed after I added the new rubber rings (Volvo call them absorbers).

I guess I should measure again to see if anything has changed.

I do not know what to thing really, the alignment of the timing belt?

My other concern is that this is a interference engine.

Any help is appreciated, more than ever.

Thank you,

Alessandro

|

|

|

|

|

Dear Metallo,

Hope you're well and stay so. I could not get the video to work: an error message displayed. Does the "tic-tic" noise get louder as engine RPM increase?

The B200 engines are not - so far as I've ever heard - of the interference design.

Did you replace the valve guides?

Hope this helps.

Yours faithfully,

Spook

|

|

|

|

|

Hi Spook,

That is strange, I have no issues to download that video, I have re-uploaded it from scratch, please try the link below:

https://www.mediafire.com/file/bvq3gc4g5www17v/video.mp4/file

All the B200s are interference engines.

I did not change the guides, they were perfect before, no need to replace them.

I only changed the hushers.

In the video, there are a couple of points where I increase the RPM, the engine gets louder and the tic tic is faster.

It must be the tolerance of a valve, I measured only 4 or 5 valves before reassembling, they were all good, and kept going.

Alessandro

|

|

|

|

|

Dear Metallo,

Yes I hear the tic tic sound

I think I had experienced this before. I called this "motor boat" sound. In my case it was the exhaust gasket between manifold and downpipe (header) leaking.

In your case it could be manifold-turbo or turbo-downpipe gasket.

Amarin

|

|

|

|

|

I changed the gaskets from exhaust manifold to block 3 months ago, and there is no gasket between turbo and exhaust manifold, as well as no gasket between down pipe and turbo.

It is hard to understand were the sound comes from, but it looks coming from the cylinder head, somewhere close to the timing belt.

I can check again the valve tolerance, all of them to be sure there is nothing in there.

For the rest I am at a total loss at this point.

Alessandro

|

|

|

|

|

Dear Metallo,

I've done a sound waveform analysis of those ticking noises from your video on my laptop comparing to valve ticking sounds I got from some youtube videos. What I get is that they have similar waveforms. So you might be right in thinking those are valve noises.

Exhaust leak noise usually becomes louder during acceleration and not loud during idle. Its could be that the microphone that captured your sound amplified it a bit in that it sounded like "chug-chug" to me thus made me say its like a "motor boat" sound.

So yes, check your valve clearances. Did you organize the valve buckets with their respective shims according to their original placing in the head and replace them back into their respective places as before? Because the buckets could have different wear at their valve stem contact points (have a look inside the buckets) and if you got them mixed up during reinstallation you might get increased valve clearances thus producing the noises.

If this happened you need to readjust the clearances. Don't bother doing this on a hot engine, its unpleasant to work with. Suffice to read clearances on cold engine, replace the shims with thinner or thicker ones bearing in mind the clearances will increase 0.05mm when hot (eg. 0.40mm clearance will be 0.45mm when hot). Aim for all having 0.40mm clearances (cold) if you can with the available shims by switching them around. Otherwise you need to order one or two shims with new thickness.

Amarin

|

|

|

|

|

Amarin.

You were right about the exhaust manifold, I found one of the gaskets (the one to the front) was placed in the wrong way. What happened is that during the re-assemble, it fell, so when I put it back, I was probably betrayed by the light or simply I was tired, and put it back quickly the other way round.

So yesterday I did the job again, put brand new Elring gaskets again, and the engine sounds very good now.

I will post a video later.

I drove the car for about 10Km, no issues, still leveling the coolant, but I noticed a line of oil that comes out the oil filler cap, and clearly goes down the valve cover etc.

I think this is only the filler cap that needs to be replaced.

Does it happen frequently that the filler cap fails?

Thank you,

Alessandro

|

|

|

|

|

Dear Metallo,

Hope you're well and stay so. Glad that the problem was not with the valves!

The oil filler cap has a rubber gasket. The gasket slowly hardens as the rubber is "cooked" by engine heat. A hard gasket likely does not seal properly. So, before getting a new oil filler cap, replace the gasket.

This is Volvo Part #940096. At a U.S.-based Volvo dealer it costs about $8. It should be readily available elsewhere.

As your engine is a Turbo, it likely does not have a "flame-trap". On non-turbo engines, if that part - a plastic insert with a number of small holes - is plugged with "gunk", the blockage can cause crankcase over-pressure. Oil is forced past seals, etc.

I presume your car does have an oil breather box - mounted on the right side of the engine, as you face it, below the intake manifold - where oil vapor from the head (where hot oil circulates) is condensed and returned to the oil pan. If the oil breather box is clogged, that, too can lead to elevated crankcase pressure.

Hope this helps.

Yours faithfully,

Spook

|

|

|

|

|

Hi All,

So I managed to resolve the last issue, and yes, it was the return oil rubber o-ring to the block that was broken in two parts.

I replaced it and no more leaks anywhere.

The car drives wonderfully.

I only have one question left: Why do I have so much condensation in the cooling tank?

Thank you!

Alessandro

|

|

|

|

|

Dear Metallo,

Hope you're well and stay so!

Heartiest congratulations on completing a tough job!!!

Do you notice this "excess" condensation every day, or only on days when the ambient temperature has dropped markedly (versus the day before).

"Excess" condensation could be due to cooling reservoir tank lid failure to vent properly. After driving, allow the system to cool. Then remove tank cap, count to 10, and replace cap. That should allow any water vapor to escape.

It may be that a drop in ambient temperature after you park, causes water vapor to condense. If so, that's normal.

Hope this helps.

Yours faithfully,

Spook

|

|

|

|

|

Hi Spook,

Thank you very much, I couldn't have done this myself without your help, Amarin's and anyone else who dedicated their own time to help me. You are awesome!

With regards to the condensation, both tank and cap are genuine brand new.

I see this every day, regardless of the weather.

I will try first to open the cap as you suggested, and see if that helps.

I still have the old cap, which after 25 years, proved to be good, given that the issue was the head gasket.

Every day I drive the car, and I still do not believe I finished the job.

Once I reverse from the garage to leave, I always check is there is any leak of oil or coolant.

In a few weeks I will drive 5000 Km to see my son, I hope the car passes the test :)

The only thing I miss now, is the wiring to the coolant sensor, I just got the metal pin that goes in the flat connector behind the dashboard, so I should have everything I need... but I will take it easy :)

Alessandro

|

|

|

|

|

Dear Metallo,

CONGRATULATIONS! 🤩🤩👏👏

Just back from holiday trip to Chiang Mai, Thailand.

What more can I say, just enjoy the car!

Amarin

|

|

|

|

|

Dear Metallo,

Hope you're well and stay so!!!

I'd not worry about the condensation, if it is a daily phenomenon.

As flying is far safer than driving, if I had to travel 5,000 Km, I'd certainly fly and rent a car on arrival.

Best of luck with your journey: I hope it is boring!

Yours faithfully,

Spook

|

|

|

|

|

LOL, it's just economics... flying 4 people and renting a car it would cost me 4 940s :)

...without considering the pleasure of driving my Volvo!

|

|

|

|

|

Certainly sounds like a leaky oil cap gasket. Has happened to me a number of times on my Volvos. Regular maintenance item.

Spook is correct. Turbos do not have flame traps. If replacing the oil cap gasket doesn’t solve your oil leak issue then do the positive crankcase pressure test that Amarin suggested to determine if the PCV system is clogged somewhere. Could be the breather box hose (to breather/PCV box on engine block) is clogged. That hose clogged a few times on me.

--

Will I buy another Volvo??? We'll see....

|

|

|

|

|

Hi Spook,

I do have a PCV box, and I cleaned it already a couple of years back, and I remember I wasted my time because if was not dirty.

With regards to the gasket P/N 940096, yesterday while I was browsing my little Volvo garage stock :) I found a genuine Volvo gasket , still sealed, and I wondered myself what was that for.

When I read your post, I went to my garage, and it is indeed P/N 940096, which is an easy fix for me :)

Who knows why I bought that part in the past, and never used it.

I will come back and see if that fixes the issue.

Thank you,

Alessandro

|

|

|

|

|

Dear Metallo,

Glad that you've solved the issue!

"I think this is only the filler cap that needs to be replaced"

--> No. Just replace the rubber gasket at filler cap. Volvo part #940096 (only 6 numbers not 7 as usual). A few bucks only.

Also check that your crankcase pressure is normal. Put a piece of paper or rubber glove on the oil fill hole with engine running at idle. The testing item should stick to filler hole.

Amarin

|

|

|

|

|

Hi all,

It's not over :(

The engine is leaking oil, badly, from the back.

I have inspected the engine, all the front is clean, so the 3 seals I replaced are all good.

What do I see wet?

1) The filter, the bottom part is wet (if I look standing over the engine with a mirror)

2) I see a drop of oil under the distributor.

I have no idea if the oil is leaking from the distributor and goes down to the filter or if they are both bad.

I just drove 60KM and I have lost at lest half a liter of oil if not more.

Today, my wife, while driving back home, left at least 8 big spots of oil on the driveway, just to enter in the garage, so I am talking about few seconds.

So, the oil must be leaking a lot while driving (which is logical) as it runs even down to the central part of the muffler, as well as the cross bar right under the transmission, plenty of oil in there too.

Since I wanted to change both filter and oil after 1000KM (as it is good practice after having milled the cylinder head), I opted to buy a FRAM filter (PH7328), and keep the MANN I always use for the next change.

I am aware that only Volvo or MANN filters should be used, and I have been doing this for 25 years, but I cannot believe that so much can come out from the filter?? Unless you tell me that it is well possible.

Keep in mind that in January, I changed the oil cooler gasket, so that's new.

The only O-rings I did not replace are the ones of the distributor because they were not leaking before.

Regardless, I will replace them, at least the two that are easy, as I do not have the tool to replace the housing seal.

In the meantime, I did the PCV test:

https://www.mediafire.com/file/g6ij3p60hgucb9z/00090.mp4/file

Any thoughts?

Thank you,

Alessandro

|

|

|

|

|

Dear Metallo,

Out of the two possible leak sites (distributor vs filter) the filter's site has higher pressure. So logically if the leaked oil has reached the muffler it must be from filter site. Oil leaked from distributor usually goes down around the transmission bellhousing.

I also have oil leaking from my distributor all this while (waiting to find time to replace O ring) but my oil level haven't went down at dipstick.

For starters, just re-tighten your oil filter more. I can't comment on the quality of FRAM filter (haven't use them). It may just have loosened a bit or the filter's sealing ring not that good.

Then wipe the filter clean of any oil or just spray clean it with brake cleaner.

Do your test drive again and inspect the filter's site afterwards.

I hope it may be just a case of loosened oil filter. Or replace it with MANN.

Your PCV test looks ok to me. The glove didn't stand up during engine running.

Nice sounding engine by the way :)

Amarin.

|

|

|

|

|

The filter for sure is tight, I checked it multiple times.

I will go down and change it, but I am skeptical, too much oil.

Last night I was looking at the garage floor, every foot there is a drop of oil along the muffler, as if the oil is in the pipe and drops from there.

Mind, the car drives nicely, no more coolant leaking and everything sounds great.

BTW, I noticed a lot of condensation in the expansion tank, I never saw that before, I mean the old tank, why's that?

Should the filter be the problem, that means that while driving the pressure is huge, and sprays out everywhere.

Let me change it to Mr. MANN and see if that resolves.

I will keep you posted.

Thank you,

Alessandro

|

|

|

|

|

Check for a leak from your oil pressure sensor/switch. Should be located just above the oil filter. Usually they don’t leak profusely but worth checking. Also suggest thoroughly cleaning the filter and oil pressure sensor area to help locate the source of the leak.

--

Will I buy another Volvo??? We'll see....

|

|

|

|

|

Guys,

I am getting mad with this oil leak, so to recap:

1) The oil cooler gasket has been replaced in January, genuine Volvo, the squared one.

2) I change the oil filter and installed the MANN, hand tight as it should.

3) I checked the thread of the cooler, it is perfect, also because I never over-tightened it.

4) I turned the engine on, idle for 15 min. everything sounds good, but here is what happens:

Damn it!

Is this the oil cooler itself?? Or possibly that side of the adapter?

There is only a gasket in that area, how is it possible that the cooler leaks?

As always, I am totally at your mercy for help.

Thank you guys,

Alessandro

|

|

|

|

|

Dear Metallo,

The oil cooler setup looks simple enough not to suspect anything could gone terribly wrong. Just a square gasket and a big hollow bolt to mount the cooler to its engine adaptor.

I suggest unscrewing the MANN filter out and use a deep socket or wrench to tighten MORE the cooler's big hollow bolt (size 27mm IIRC)

Then reuse the MANN filter (yes the filter still new, its O ring would still seal).

Start engine and recheck. Just a short run.

If the above still leaks then you might have to dismantle all out to inspect the sealing surfaces.

Amarin.

|

|

|

|

|

I had already tightened that nut, and also checked once again the squared gasket, all good.

Today a drove a few kilometers, but since I see oil dripping from the joints along the muffler line, just a few drops, that would lead to think to a turbo failure, right?

However, I would not see the connection with the oil coming out from the filter.

Since the turbo sounds and appears to run well, how do I check if there is a failure in it?

I resolved the coolant leakage, which proves the head gasket was creating it, and now I get oil everywhere.

After 6 weeks, I am exhausted, and I need the car, so I think I am going to see a mechanic, put the car on the hoist and see if they can better see where the oil leaks.

Sad but true.

Alessandro

|

|

|

|

|

Dear Metallo,

Valve noise is usually not that loud as there is valve cover/rocker cover on top of them. But do check anyway. Stone cold clearance is 0.35mm, hot is 0.40 (0.05 increase when hot).

But with the new rubber hushers (absorber) you'd have to force a bit on the feeler blade to slid them in.

The proper way is to dismantle the timing belt and camshaft again, lift all valve buckets with magnet, remove all those rubber hushers, install all back and do your clearance checking.

I still think its leaking exhaust. You may need a smoke machine to introduce smoke from tailpipe or use smoke producing product ie. Marvel mystery oil or Seafoam to visualize smoke coming around the exhaust area.

Amarin

|

|

|

|

|

Dear Amarin,

Hope you're well and stay so!!! I've not had to contend with a crank pulley bolt so tight, that I was worried about breakage. I, too, use a crank-hold tool.

The bolt is pretty "beefy", so I'm not too worried about snapping it. I, too, use a 1/2" (12.7 mm) square-drive breaker-bar with a 24" (approx. 600 mm) handle.

While I have air-powered impact wrenches, I've not needed one such to remove a crank pulley.

I've seen on websites, aftermarket crank pulleys (also-known-as harmonic balancers) with slots too narrow - about 6mm wide - to accept the standard crank-hold tool. On Volvo-supplied crank pulleys, the slots are closer to 8mm wide. I do not know why any after-market supplier would use a narrower slot.

Hope this helps.

Yours faithfully,

Spook

|

|

|

|

|

Dear Metallo,

Both NO lubrication. These install dry. They would guide the rubber timing belt. Don't want any oil or grease gets on timing belt.

Need to lubricate the threads of crank bolt with engine oil. Or it would be very hard to remove on next timing belt change.

Amarin

|

|

|

|

|

Dear Metallo,

"What do they mean by 'Main Bearing Cap' and 'Connecting Rod Cap'?"

--> Main bearing cap - the cap that hold the crankshaft's main bearing. These are located below the engine's block. You didn't take out the oil sump so disregard this.

--> Connecting rod cap - the cap at the lower end of connecting rod (the upper end is at piston). You didn't take out the oil sump so disregard this.

Your should only concern about:

1) Cylinder head - Stage 1 (20Nm), Stage 2 (60Nm) and Stage 3 (angle-tighten 90 deg) - tighten from centre to outwards

2) Camshaft cap - 20Nm (yes its not that high)

3) Crankshaft centre bolt (damper pulley) - Stage 1 (60Nm) and Stage 2 (angle-tighten 60 deg)

4) Camshaft & intermediate pulleys bolts - 50Nm

Note: You might not be able to tighten the cap nuts (with camshaft already in) all at once because some of the cam lobes might be pressing against the valve buckets. Start with those nuts which you could thread in first (usually at cam caps 4 and 3). Then slowly work your way thru to caps 2 and 1. Finally torque all caps bolts when the camshaft is fully in.

Amarin

|

|

|

|

|

Hi Amarin,

Thank you very much for clarifying all of the Newton's stuff :)

While cleaning...I keep on finding new things that need to be checked:

Engine Coolant Temperature Sensor: In the Pocket Book they say that at 20° its resistance should be 2280 - 2720 Ohms. I have: 5.328 kOhms (currently I have an interior temperature of 19° in my garage).

Gauge Temperature Sensor: I cannot find the resistance values anywhere, but mine measures 2.900 kOhms

The gauge has always worked fine, I mean, always steady at 90°.

My concern is the Engine Coolant Temperature Sensor value I found.

Thank you,

Alessandro

|

|

|

|

|

Dear Metallo,

That engine coolant temp sensor (ECT) has TWO thermistors (temperature sensitive resistors) electrically grounded to its metal body. You shouldn't measure across those two terminal within the connector. You should measure between one terminal within the connector to its metal body. Do the same for the other terminal. Your ohms reading should be about half of what you posted. I think your ECT is ok.

Why two thermistors? One for the fuel computer, the other for ignition computer.

Amarin.

|

|

|

|

|

Dear Metallo,

For the smaller seals at the camshaft and intermediate shaft, they're easy. A small jeweller's screwdriver with a flat head (ie. not the philips head) might do the job picking out the seals. For the camshaft the seal its easily out once you remove the no.1 camshaft caps.

For the main crank seal there's nothing to prevent you to take out the sealing flange with the seal in it. But for me it will complicate the job in removing the oil pan bolts (the ones that holding the flange, not other oil pan bolts) and ensuring leak free installation later. In short I'm not that sure.

So I prefer to pick out the crank seal with a small screwdriver (not jewellers type) with a sharp flat head (honed on sharpening stone) in order to bite into the seal to pick it out. Usually this works. The hard part was to start the seal moving out from its place. Same like trying to unscrew a tight oil filter out.

Lets hear from other members who had removed the sealing flange.

Amarin

|

|

|

|

|

Hi Amarin,

I already tried the flat screw on both intermediate and crank seals.

They are hard like concrete.

With a flat screwdriver, are you going in from the outer edge and then you pull up?

Doing that, you force on the edge, and I do not want to notch it.

I also tried the tool below, but I do not want to scratch the interior surface, so I gave up.

https://www.canadiantire.ca/en/pdp/oemtools-o-ring-pick-0251168p.html

I wonder how this may work better:

https://www.canadiantire.ca/en/pdp/oemtools-seal-puller-0251207p.html#plp

I know, unbolting the 6 studs and 1 nut is not ideal, but if they are that hard.

I also tried with a screw, as suggested in the FAQs, but man, it looks like the genuine one is made out of metal, you really cannot put a screw in there.

In fact, the genuine crank seal, is beige and not gray as the spare one you buy from Volvo.

Thank you,

Alessandro

|

|

|

|

|

Dear Metallo,

Watch this youtube video, try the nail method as shown (at 3.20 minute) then use your canadian tire hook (tool 1) (I'm not sure what to call it) to pull the seal further out:

https://www.youtube.com/watch?v=OLG3SuZ70uM

Hope this helps,

Amarin.

|

|

|

|

|

Those seal picks (Cdn Tire or Princess Auto) are useful for getting the seal spring and much of the bulk out, but will only get you so far with a baked on seal. I have a well worn, very cheap quality little slot screwdriver that I use for the next step as a chisel, run around by hand or lightly taped with a mallet. The aluminum alloy of the cheap screwdriver does minimal damage if I happen to get carried away. No great problem if you slightly damage the seal seat, you can use a suitable gasket sealer if needed. What matters most is not scratching or scuffing the shaft contact area. Well, that and not having too many seal fragments get into the block, but still not the end of the world if a little gets in. I’ll even use some fresh coarse steel wool (rock wool) to polish the seal seats, just being careful to wipe out stray fibres. Others may try to be more purist than that, but it’s really not all that critical as long as you get a nice clean seal on the shaft, even setting the seal in a little deeper if that gives you a better surface.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

|

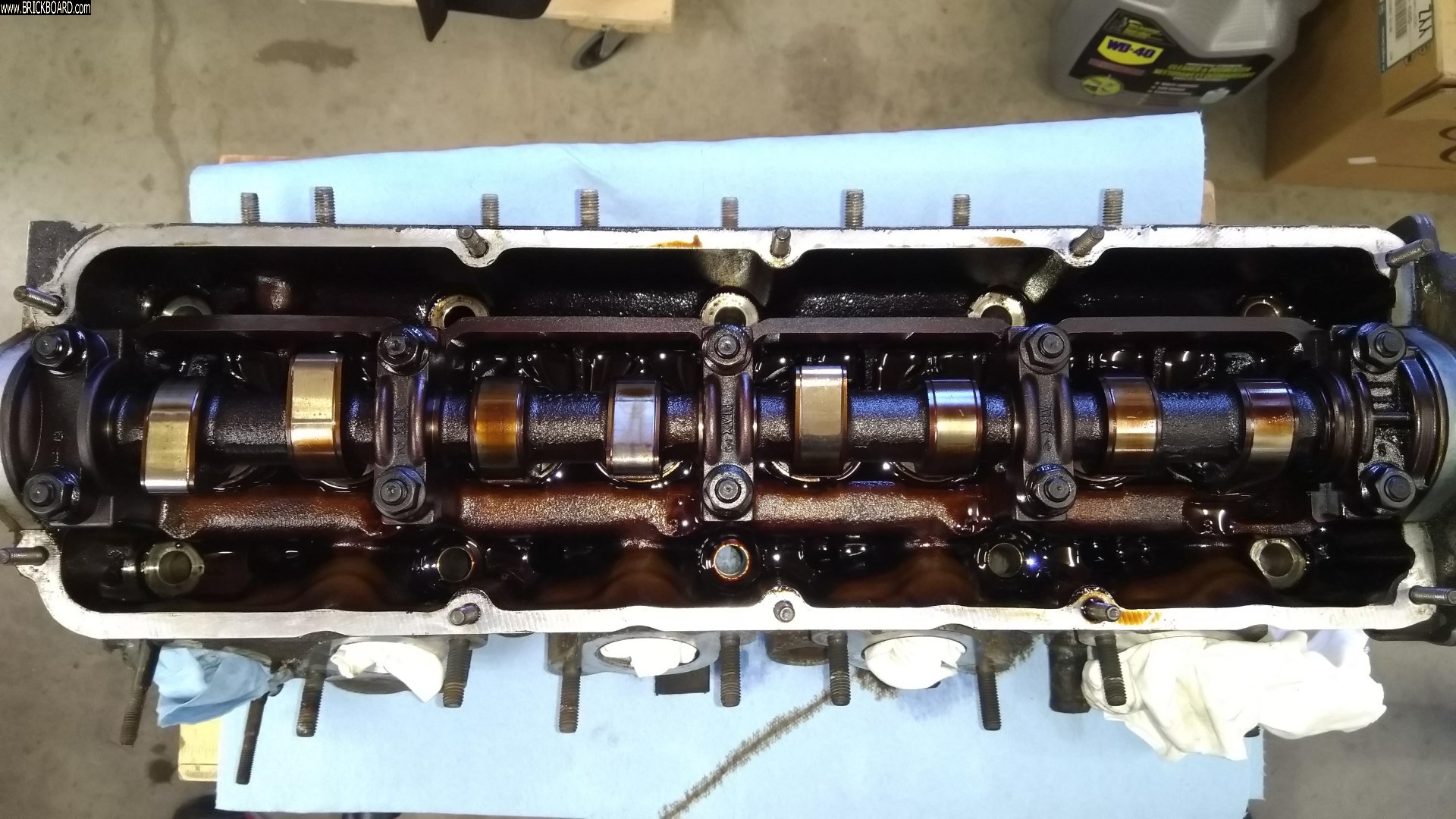

Hello to Amarin and the Malaysia brick drivers in general.

You bring up an interesting point PAST the discoloration mark on the head and it’s about the camshafts reinstallation.

I would apply “engine assembly lubrication grease” to the cam and journals upon reassembly. Covering with oil after the head is on doesn’t hurt either.

I would want the camshaft supported on a stable lubrication film right off.

His head or the engines is now fitting a lot better with your help.

Now you can help me with mine. 🤪

I’m not an automotive machinist and have very little knowledge about their specialized one of a kind equipment. I just know it expedites things like every special made tool does.

I have only changed five head gaskets in my lifetime and with only one being on a red block. So all these heads had an overhead camshaft.

On that one, I didn’t have to resurface the head either.

On this consideration of camshafts, I went with the belief that it was “best” to not to even remove the camshaft.

I measured the head for flatness, cam in place, as it was in specification. This after 220+K miles on it.

I just cleaned the surface and remounted the head with a new gasket and the same bolts again.

That was over 100K back and many years ago on my 1978 GT.

My problem was a slight oil seepage problem with the head gasket right above the oil filter. There is an oil passage right there.

I’m sure a coolant passage was going to be next.

Since I have never resurfaced one of these overhead cam heads before and a question was brought up about if the valves if could be left in.

I agreed it would not make any difference as long as the valves were not up.

So to resurface it the cam had to be removed or at least on a cylinder or two but why not remove it all together?

From the looks of his pictures that’s what was done. It’s out.

So my questions are lurking to follow below.

Apparently this head was not warped or if it was what would they do then?