|

|

|

The newbie guy here again, the one working on getting the 87 that sat for at least ten years back on the road. I've got the car running and have an exhaust on it. Not driven yet because it's still on jack stands until I go through the brakes (at least the front ones).

After I got the exhaust on it I was able to idle it in the garage for a longer period of time. The temperature gauge would get up to about a half a millimeter to the red and I would shut it off. Heater was not working. No leaks anywhere in the cooling system, so I immediately thought of the thermostat, that it wasn't opening properly and not circulating enough. I picked up a quickie replacement "Carquest Premium Thermostat" at Advanced, put it on and started it. It ran for about ten minutes and same thing on the gauge, didn't drop. I let the motor cool down and went back and started it again. This time the heater came on and I stuck it out for a while longer and the gauge dropped. I'm assuming the thermostat fixed the problem. I'm also happy to see that the heater core seems to be ok--that had me worried. Also, this engine is running very smooth, exhaust has no smoke of any color, no indication of coolant in the oil or vice versa so I'm also happy that the head gasket seems to be OK.

I have not done a radiator flush yet but that is coming.

My question is do these B230 engines typically get that close to the red zone on the temperature gauge before the temp drops? Is that just their nature?

|

|

-

|

|

|

I have not done the flush yet because I've been busy and it's been cold but should get it done on Thursday. Plan is to drain old coolant, backflush with a garden hose, then flush (I'm using Prestone) with distilled water, then flush again with distilled water at least two more times until it's as clean as I can get it. I'm filling with the Prestone "European Car" antifreeze, it is HOAT and it's what the auto parts store had enough of.

Then brakes (calipers, rotors and pads all around), then tires, then I'm going to look into MacGuyvering the temperature gauge. I'm thinking I'll have this thing road ready by spring.

|

|

-

|

|

|

Hi,

If you still have an issue after you have done the threads options as they are Definitely the things to look into first, I have thought of something else to consider.

The early eighties LH systems did have engine wiring harness issues. By 1988 and later cars a better wire vendor was used.

On the old ones the yellow wire to the temperature sensor and back up to the firewall connector had what was considered biodegradable insulation. This'd was on at least a couple wires, in the sleeve that crumbed away. Same for the drivers door lock switch wiring crumbled!

I changed a head gasket on the 1978 due to wrong heat signal and a slight oil seepage problem above the oil filter at 200k. I convinced myself that age and miles was worrying enough. Wrong!

To my dismay the wire was more the gauge problem and not a head gasket.

That yellow wire rubs into another powered circuit or to ground and messed up the gauge reading.

I had this problem on both my 1978 and 1986 wagon. I spliced on another wire to one end and pulled a new up through the sleeve.

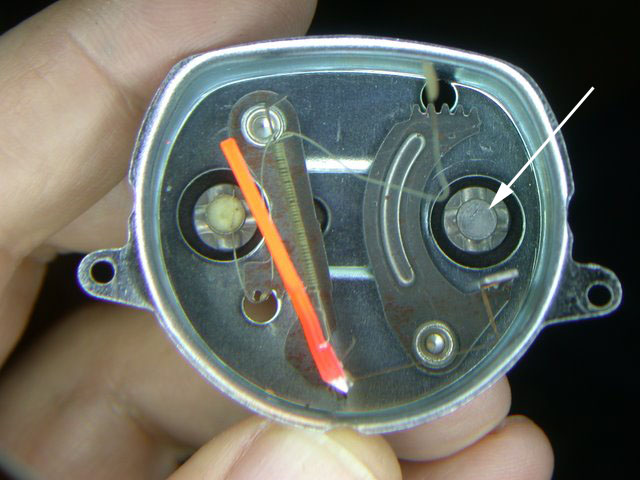

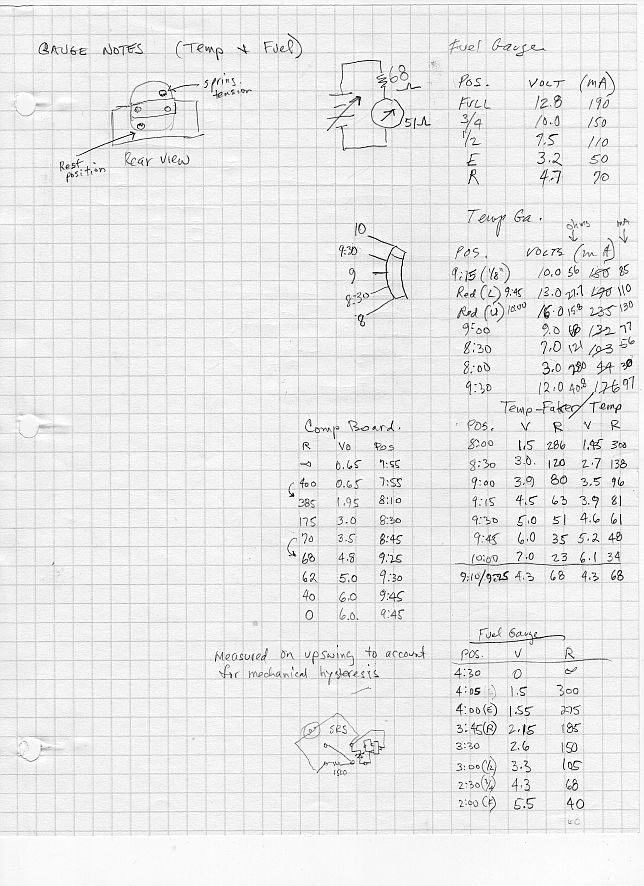

I too, get rid of all those temperature compensation boards.

It's a matter of due course, for me, as they will eventually give you a problem of going wacko!

Soldering or clipping on a jumper is a cheap project to eliminate the worries of ... Is it real or not!

The 1978 car is strictly an analog gauge.

The later 1985- electronic speedo's use a digital stepping compensation board to raise a reading at a certain heat levels.

I feel that "normal" threshold step gets out of calibration with age.

Probably due to the resistors or the capacitors dry out or oxidize internally.

Small clocks and maybe tachometers can too?

I suspect the compensation board must have another step for the red hot zone left?

I have never tested the yellow wire to a "direct ground" and hope I never see that reading!

Yes, if an engine is truly overheating, you will hear all kinds of gurgling and popping going on when the engine is shut down.

The engine coolant will even get hotter after a shut down because all circulation from the pump stops. Heat that was just created hasn't moved out from the cylinders and is headed into stopped coolant!

Heated water has densities or currents and are fighting their way around and up from the those cylinder jackets through smaller head space channels. If space was sufficient we wouldn't need pumps and engine blocks would be a lot larger!

I was told or read that it's not good on the instrument gauges to "short" the wire to ground using a fixed resistance. If they get too much current and heated too far up it can warp the needle mechanism.

The instrument clusters have better regulation today, so I, might be all wet with old school testing procedures.

With electronics you got to know what you are grounding or putting power onto.

The fuel sender gauge can be trouble shot with more information but it also relies on voltage regulation as well! At least those are solid state today!

You need to check the movement of the new sender out of the tank against its swing limiting stops.

The float arm might be stuck or turned wrong slightly? It's tight down there even with the right one!

Sometimes the float ball pops off! Zero reading!

Phil

|

|

-

|

|

I changed a head gasket on the 1978 due to wrong heat signal and a slight oil seepage problem above the oil filter at 200k. I convinced myself that age and miles was worrying enough. Wrong!

To my dismay the wire was more the gauge problem and not a head gasket.

Don't beat yourself up about this too hard, it might not have been neccessary right there and then but who knows what was in the making.

In the photos below is the very cylinder head I mentioned in my previous post that needed to be replaced because of corrosion of the water channels.

This was right after cleaning the area above the oil filter with brake cleaner.

And subsequently after running the engine. You mentioning this exact spot rang a bell.

I kept on running the engine in this state for over a year and lot of distance, and just kept topping up the coolant regularly.

I now wonder, because of Dave's explanation on deionized water, CO2 and the formation of carboxylic acids, if my procrastination may have led to the early demise of the head.

The 1978 car is strictly an analog gauge.

The later 1985- electronic speedo's use a digital stepping compensation board to raise a reading at a certain heat levels.

Strictly speaking, the temp comp board is a fully analogue device based around a quad opamp. And around opamps, quite a few different circuits can be constructed.

Probably due to the resistors or the capacitors dry out or oxidize internally.

Small clocks and maybe tachometers can too?

At this age, electrolytic caps would be the usual suspects as they do literally dry out. Resistors, diodes, and ceramic or film capacitors would probably be good for another few decades or so. Solder joints can crack and connectors oxidize.

Shorting the lead of the temp sensor to ground wouldn't really bother me as long as it's being done just long enough to see what the meter does.

|

|

-

|

|

|

Hi Phil,

I could be wrong, but I'm not sure the fuel gauge behaves the same when the key is off as it does when the swing arm is bottomed out. In other words, if I'm correct the gauge has a zero point for no gas, and another zero point for no power.

When checking the operation with the sender out of the car, I seem to recall that when the key is on, the gauge reads just a little below the red with the arm fully extended, and then reads quite a bit lower when the key is off.

Seeing as both fuel and temp gauges depend on power from the voltage regulator plugged into the back of the cluster, and the OP is having trouble with both gauges, I can't help but wonder if perhaps the regulator or it's connections are flakey.

Before pulling the sender, it might be useful to check that 10 volts are being supplied to the gray wire when the key is on.

Peter

|

|

-

|

|

|

Hi,

Hmm, I don't know if you are making a statement or a question but you are on the right track of possibilities of it all!

I think I understand what you are trying to say about the fuel gauge having a cold resting zone when the key is off.

As a matter of fact both gauges work the same way because both are a linkage system and use heater attached to a bi metal strip in them.

When heating a bi metal strip, one side expands in length faster than the other and thus imparts a bending movement of a needle within the linkage.

When turning the key on, this completes a circuit through sensors that have minimum amount of resistance that may heat each gauge slightly.

This is either a cold coolant reading or a low fuel reading.

Even though it can heat the gauge a tiny bit but is not part of the gauges calibration.

As both conditions change the resistance of either type sensor changes and therefore a change in the location of the needles.

A voltage regulator is made with the idea to be below any higher voltage in the system in order to stop fluctuations of the heating element electrically.

Now there can be some slight variations of calibration due to ambient temperature around the gauge that will effect readings of these type of gauges.

If you will notice on these there are not any exact numerical notations on the face but a band region that we mark off in "our minds" as being half full or closer to one end or the other.

On gauges that provide an actual numerical numbers for precise readings, these gauges work with a closer tolerance type of linkages or digital displays.

There are always a different mechanism and demands but for sure are definitely more expensive when any exactness is needed.

To the average motoring consumer they don't need to know, or would they care, to contemplate one degree Celsius or a couple tenths of a gallon consumption in the last twenty minutes!

They are not aviation or navigation engineers!

Lots of people have no idea what goes on past turning the key pushing a button or which way a nut turns to loosen.

Most only want to know from a display that you are almost out of gas or that you are not overheating. Some have to be reminded and asked it that its normal range of a reading?

They were called warning or "idiot lights" before needle gauges!

You still see both and a buzzer!

I ask, are we getting more dumber or more complicated in our lives than necessary?

This might be the decade or two, to be known for being a "reevaluation of mankinds purposes" just like the differences in gauges!

Phil

|

|

-

-

|

|

|

Hi Art,

Oh my gosh, you confirmed everything I said in with your normal outstanding details.

What attention you have in taking notes and keeping it all organized!

I would have never thought of Lentil beans and salt water as a medium to surround a sensor!

Did you eat the beans without an adverse reaction because of the salt? (:-)

I have had people tell me you can take the snap out of beans, but they didn’t or wouldn’t disclose their method.

It must have worked or you ate the beans well after the experiment! (:-)

I use vegetable oil to check coolant thermostats, capillary tubes on heater valves or most anything else as it has density.

I can go higher that the 212 F and it’s more stable to control heat input than the surface of the water allows.

I keep the oil out in the garage and labeled for its use.

I could use old engine oil but that stuff stinks, as we all know!

I have to also say,

You are like our own ASME consultant for 240 Volvos! Your set the standards!

Thanks

Phil

|

|

-

|

|

|

the Roman Army: each soldier was supposed to carry three days worth of rations (6-8 lbs of food) and water (“Marching Pack”). Rations that would be carried on a march would include preserved food, such as bucellatum (a type of hardtack), bacon, salted meat, flour, and dried lentils.

https://i.pinimg.com/originals/49/92/6b/49926b9340931c52321eedcfdf182444.jpg

|

|

-

|

|

|

Hi,

Ok, I guess there is some “rational” in your thinking about Art’s lentils and the temperature of them cooking?

I gather that there are two gauges, one for coolant and the other for GAS!

You must have a point to explain to me about the Romans relationships to this thread someplace, other than keeping themselves space far enough apart? (:-)

Sorry that I didn’t get it, even with my imagination.

Phil

|

|

-

|

|

From experience, it takes three to four days for the system to become used to a diet with legumes and then the GAS is history. Of all those other ingredients, I enjoy adding bits of bacon. That photo was taken many years ago as an immediate answer to a question put on this board with words to the effect "How many ohms does the sensor read when the engine is hot?" The coolant in a 240 under black-cap pressure might easily be over 200 degrees.

--

Art Benstein near Baltimore

"I have you know I was not the slowest car on the road either!

I passed nine other newer cars and one truck on the grades.

It just so happens that the nine cars were on that truck!" -machine man

|

|

-

|

|

|

so phil do you have that problem with Art closing all his post with some quip???

Art Benstein near Baltimore

"Good cheekbones are the brassiere of old age." -Barbara de Portago

|

|

-

|

|

|

One of my favorite tools is an infrared temp gun. I picked mine up at NAPA but everybody carries them. Measure at the thermostat housing and compare to the gauge in the car.

Greg

|

|

-

|

|

|

I had one in my hand not too long ago at Northern Tool but didn't get it, would be a nice addition to the toolbox.

|

|

-

|

|

|

Here's the latest. I let the car run for about 35 minutes, that's the longest I've had it running. Gauge went to about 46 minutes, then dropped after about ten minutes, then climbed almost to the red again after about another ten minutes, and stayed there for about 12 minutes. I got out of the car to take a closer look at the engine and also check if anything weird was going on at the tailpipe. Fan running, top and bottom coolant hoses were hot to the touch but engine did not show signs of being close to overheating, it actually was radiating no more than what I would expect to be normal heat. This took no more than about two or three minutes to do the check. When I was done with the check, the temperature gauge was back almost to the bottom line. I let it run for a couple more minutes, it stayed where it was, and I shut it down.

I went back about two hours later and started it again. The gauge went up to almost red very quickly then came almost all the way down to about 46 or 47 minutes and then gradually fluctuated up and down.

Bottom line, the gauge is fluctuating more than I'm used to, but this car is absolutely not overheating. I am beginning to think Gray245 might have nailed it on the compensation board.

I also think it's cooling better because the more I circulate the coolant the more the 10 or 15 years of gunk in the radiator is getting broken up. The flush should do it good.

|

|

-

|

|

Flushing the cooling system in your engine seems like a must do to me if there's rusty water coming out of it now. Include the radiator and interior heater core.

On my current 245 a neglected cooling system caused damage to the water channels in the cylinder head at the head to gasket surface. What seemed like a head gasket failure was actually corrosion of the head's water channels. Presumably of standing for long periods of time or running coolant with depleted corrosion inhibitors, or maybe even straight water.

It happened when a PO owned the car, so I have no way of knowing for sure what caused the damage or why.

Not until after the head had been sand blasted became the damage apparent and was it time to source a replacement for the cylinder head.

So, after recommissioning your B230, keep an eye on the coolant level and surface in the reservoir.

I was suggesting that the lack of a temp comp board causes the fluctuations, but after looking at Art's site, I'd imagine it might still be in there but it may be that the flimsy connections between main and temp comp board are contributing to the erratic behaviour. In a car that has been sitting somewhere for that long, it would actually be the first thing I'd check for. Perhaps taking it out and reseating it a few times scrapes away the oxide layer.

|

|

-

|

|

|

""The flush should do it good.""

If you don't know this procedure.

To 'back flush' a Volvo Red block:

1.Remove the thermostat and re-attach the upper radiator hose to the engine but leave it disconnected from the radiator.

****I have an old thermostat that I have 'gutted' but with the rubber gasket still on the ring. I put this in place so the thermostat housing seals and the back-flush water dosen't leak over the engine block*****

2. attach a hose to the Draincock on the engine block---it's under the exhaust manifold under #4. A cheap garden hose with the connector cut off works---the cheap ones usually have a smaller inner diameter for a tighter fit on that draincock.

3. devise a way to channel the water that will come out of that disconnected top radiator hose to keep it from splashing the engine compartment----a length of 2" PVC works.

3. turn on the hose and run the water until it runs clear out of that top Rad hose.

|

|

-

|

|

|

I finally got a day that was warm enough to do a thorough flush of the cooling system and refill everything. Doing the backflush through the block was really good advice. I filled three 3 gallon buckets before it started running clear and it was shocking the amount of rust and other gunk that came out.

After draining, flushing with solvent, backflushing, and flushing two more times and refilling the system with coolant I ran the car for about a half hour. The temp gauge is behaving normally now, go figure.

Thanks all for the info and suggestions. The car is almost roadworthy, still got to go through the brakes and put tires on it.

|

|

-

|

|

|

Hi,

I think I need to ask this question about coolant systems, as I wondering, what exactly is a “solvent” to be used between flushing.

The term solvent is a very broad term as water is a solvent.

Did you use a caustic or acidic cleaner of some sort and it needed a neutralizer follow up?

Phil

|

|

-

|

|

|

Maybe solvent wasn't the best word, I had a quart of Blue Devil and a quart of Prestone radiator flush, I used one each time I flushed and then flushed with just plain distilled water. Anything that I use to break stuff up and clear it out I call a solvent.

It worked though, I was on that engine for about six and a half hours. When I was done I had a very clean cooling system and very wet feet.

|

|

-

|

|

|

You will want to read Art's post about replacing the temperature compensation board. Doing that usually results in the temperature gauge giving more accurate indications of the coolant temperature.

http://cleanflametrap.com/tempFaker.html

--

Any twenty minute job is just a broken bolt away from a three day ordeal

|

|

-

|

|

"My question is do these B230 engines typically get that close to the red zone on the temperature gauge before the temp drops? Is that just their nature?"

No, it is not their nature. Mine rises slowly until the "43 minutes" position and stays there. My previous 245's temp gauge behaved exactly the same.

However, I still have the compensation board in the instrument cluster. What this does is smooth out normal variations to prevent causing unjustified fear of overheating. Only if the temperature rises above the normal window will the needle start to rise again.

On instrument clusters that had this compensation board removed, I would not be surprised to see a lot more variation of the temp. Enough to let you see when the thermostat opens.

Search this forum for "temperature compensation board" and familiarize yourself with it so you know what to look for.

|

|

-

|

|

|

Gray245 thanks, I had not even heard of the compensation board. I'll read up on this but why would the board be removed, unless some of the cars had it and others didn't.

On a 35 year old car a lot of stuff is going to be quirky. My instrument cluster seems to be ok--my gas gauge isn't working but I put an aftermarket sending unit in and I'm pretty sure that's the problem. The strange thing is, when the car is that close to the red zone it doesn't act like an engine that is close to overheating--It doesn't radiate high heat off the engine and I don't hear hissing or ticking on the engine or see any steam coming off it. That makes me wonder if part of the problem isn't instrumentation.

|

|

-

|

|

|

Hi,

A gauge doing funny things is typical of a bad compensation board. I remove them as a matter of course because I want a straight gauge that just reads the temperature. It's very easy to do.

Every 240 I've ever had goes steadily up to about 9 o'clock. If you watch it very closely, you might see a small dip when the thermostat opens, but they never go anywhere near the red. If it did I would suspect a sticky t-stat.

I would use any potable water to flush the system. I don't see any reason to use distilled water for that.

Go to clean flame trap.com to troubleshoot your fuel gauge. I think you'll find info on the comp board there as well.

Peter

|

|

-

|

|

|

Art's write up w/pics

His site

Clean Flame Trap

240 Volvo Temperature Compensation Circuit

Here is a quick path to the truth in temperature.

http://cleanflametrap.com/tempFaker.html

_____________________________________________________________________

Temperature Gauge Failure in 86-93 240 Models

2011-03-09 - IPD Staff

If your coolant gauge is reading erratic or the needle doesn’t move at all, locate the coolant temp sender near the center of the engine block on the driver side under the intake manifold. The wire is yellow, and the connector is a female spade type. Disconnect the wire and touch it to ground and the needle should go to the hot range of the gauge when the key is in the run position. If it doesn’t, then the temp compensator board is most likely the cause.

We offer new replacement compensator boards or our money-saving bypass kit as well. Either repair will require that the instrument cluster be removed and disassembled. This is about a one-hour job that can be accomplished easily with common hand tools and a good service manual. Our bypass kit includes detailed instructions.

https://www.ipdusa.com/products/5670/Temperature-Board-Bypass-Kit-for-Volvo-Ipd-1363117-108262?

Pix ---the Jumper----

https://s3.us-east-2.amazonaws.com/prod.mm.com/uploads/2019/07/19/1563580027_dscn1801c_mmthumb.JPG

|

|

-

|

|

|

It is possible your compensation board was removed allowing for the needle to rise higher. Compensation boards were usually bypassed because they gave faulty temperature readings. With the age of your car I’d also take a good look at your radiator fins. If they are clogged, the engine will run hotter. My 90 had that problem. (I also bypassed the comp. board due to the needle hardly moving.) Although in my case it was a more extreme situation as the car would run borderline red in traffic but was okay when moving. Can’t complain though. The car still had its OEM Blackstone radiator at 300k…:)

--

Will I buy another Volvo??? We'll see....

|

|

-

|

|

|

Just a comment on Grey245's excellent post about the temp gauge compensation board. I've owned every RWD model Volvo since a 1965 544. It was common for the temp needle to react swiftly, racing up to the HOT zone during the warm-up period and it was actually reassuring to see the drop when the thermostat opened. - Dave

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

A slight rise above the mid-point before dropping to a steady reading when the thermostat opens is fairly normal, but getting within a mm of the red zone is a bit higher than normal. If it still keeps doing it then some people might suggest a faulty/sticky/broken thermostat for that symptom, but in your case that's been replaced. It's much more likely to be something like an air lock around the thermostat housing.

There's a little weep hole in the rim of most thermostats. That should be at the top (high point) when installed. Also, the thermostat needs to be installed in the correct orientation with the plunger pointed down.

If the needle is going back down to normal then not to worry too much. Depending on the rated thermostat temperature you've chosen (there are a couple of Volvo standard temperatures for B230s) then the needle may or may not be perfectly straight at the mid-point.

Do a thorough flush and top it up well, making sure warm coolant is once again flowing through the rad hose once the engine is warm (I like to massage the upper and lower rad hoses to hasten air removal).

If you do a water flush (as you should) then a fair bit of water will still be left in the system after the final drain. Rather than topping it up with 50/50 premix coolant, I prefer to fill it with concentrate coolant measured to half the system capacity and then top up with water to get a true 50/50 concentration. Concentrate coolant usually works out cheaper anyway even when not on sale. Preferably use distilled water to avoid mineralization, with de-mineralized treated water being next best (some say better), even softer tap water (surface water from a rain fed source) will do fine, but avoid hard well water (ground water source) which will be heavier on the minerals and won't be as pH balanced, and definitely don't use deionized water which will quickly exhaust the buffering capacity of the coolant and start stripping metals.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Dave thanks for the suggestion. I have read a lot of stuff on air and "burping" the system and when I flush it I will certainly pay attention to that. I've heard that the best and easiest way to do it is to run it with the reservoir cap off and let it bubble off.

The thermostat did not have a weep hole, which did concern me but it was what I had available nearby. It is the 195 degree thermostat, also what they had available. I'll keep that in mind if I keep having an issue, maybe get by until I can find the OEM thermostat.

This system absolutely needs to be flushed, and I'm anticipating I'll have to run distilled water through it about three or four times to get all the gunk out. When it runs it I'm getting a lot of fine rust particles in the coolant reservoir. After sitting for ten years (at least) I'm sure the radiator is pretty crusty inside. That can only help.

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

"and definitely don't use deionized water which will quickly exhaust the buffering capacity of the coolant and start stripping metals."

Could you elaborate on this a little?

I looked it up and found that deionized water is obtained by running water through a charged resin bed. That is the way house water softeners work. The resin bed attracts the ions (both positive and negative) leaving only water.

It is said by the manufacturers that the water is suitable for use in cooling systems, both industrial and car radiators.

Demineralized water had the the ions removed by filtering.

Distilled water had the the ions removed by evaporating and condensing the water, leaving the minerals (ions) behind.

My question: why would this water react with the coolant differently from demineralized or distilled water?

|

|

-

posted by

someone claiming to be

on

Wed Dec 31 18:00 CST 1969 [ RELATED]

|

|

Re. using deionized vs distilled water in cooling systems

I used to have free access to deionized water and knew from the chemists not to use it. I forgot the reasons so had to do a little research here. DI water is more conductive than distilled, thus allowing electrolytic corrosion of the cooling system metals to more easily happen.

Distilled has been exposed to the atmosphere, already absorbing CO2, while DI has not, and as DI slowly absorbs CO2 (abundant in the atmosphere) it makes a weal carbolic acid, the pH slowly going from a neutral 7 to a more acidic 5-6, thus DI has a greater tendency to galvanic corrosion as well. With the increased pressure in cooling systems this more readily happens. Although it's a closed system, there is air in the expansion tank as well as trapped air in the system.

There are different qualities of DI depending on the resin bed and time spent recirculating. In my chem lab it was on the high pure side, more so than in treated potable water systems. There appears to be a fair bit of lore about which is better to use in cooling systems among auto people. There may be more to the chemistry in auto cooling system applications than I’ve mentioned, but I do note that Prestone variously says distilled or demineralized on their website depending on where you’re reading. The main thing is avoiding heavily mineralized hard water, i.e. well water, to avoid deposits and scaling that may restrict flow.

--

Dave -still with 940's, prev 740/240/140/120 You'd think I'd have learned by now

|

|

|

|

|