|

|

|

Can anyone tell me the proper size and pitch of the screw used on the original puller tool?

I would like to see if I can source the proper bolt/rod to build another puller that can exert more force.

Background:

Got another stubborn hub.

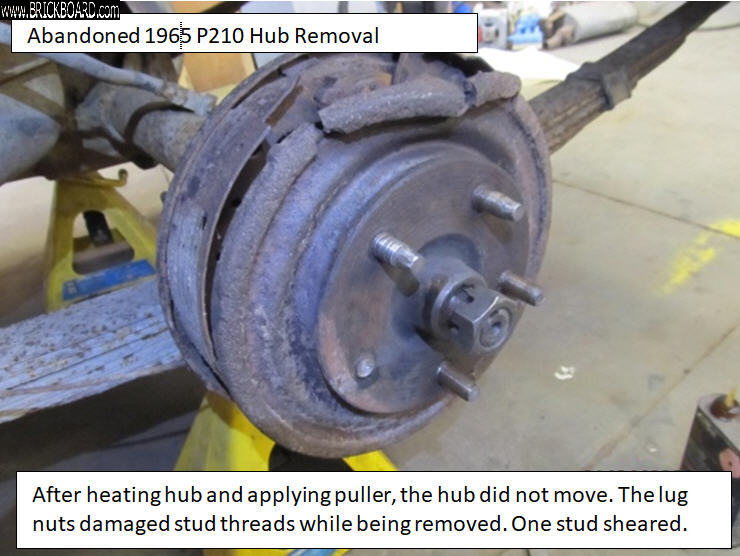

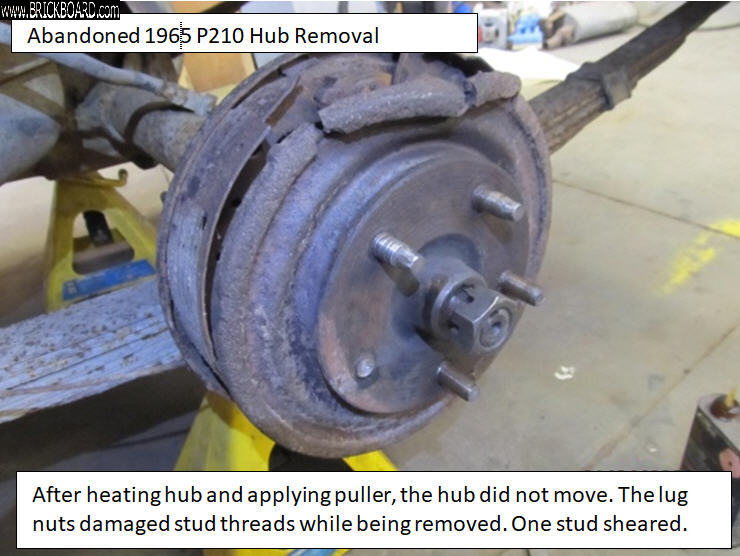

Tried removing with a hub puller. No go.

Left it on overnight. Tried again. No go.

Heated hub with oxy/acetylene torch. Applied puller. No go

Taking lug nuts off resulted in damaged threads and one broken stud.

Chased remaining thread with a die and cleaned lug nuts with a tap

(lesson never learned, always do a good job of restoring rusty old nut and bolt threads before use)

Tapped the broken stud so that puller load will spread equally.

Plan is to heat again and leave puller on overnight and keep trying before cutting off.

My puller is homemade and uses a 1” UNC bolt, 8 threads per inch. It may not be sufficient for this job, but it did work on my PV.

|

|

-

|

|

|

Hi,

Did you let it fully cool before applying the puller ? The damaged and sheared studs suggests you may not have done that, because they start to lose strength above 300F.

The heat transferred to the axel shaft will cause it to expand. The hole in the hub may expand less than the shaft, making the unit actually tighter when hot.

Pulling after the shaft is cold and has shrunk away from the hub is necessary.

Sometimes more than one cycle of heating, cooling, oiling and tapping with a hammer are required.

Just a thought,

Peter

|

|

-

|

|

|

Yes, I attempted to pull the hub right after I heated it. Your explanation makes sense, since the lug nuts went on fine. I will definitely thermal cycle it and only pull it again when its cold.

I've also sourced a national fine, one inch bolt and nut to modify my puller or build a new one that should increase the pull. Unfortunately I have to wait for the nut and bolt to be ready for curbside pickup. We are in Covid lock down, and everything now takes a very long time, even when parts are in stock.

I was able to re-thread the studs and mount new lug nuts. I tapped the broken stud and bolted it to the puller. I'm hoping the studs will hold.

Thank you.

|

|

-

|

|

|

Have you tried a large impact driver on the puller?

As a sort of last resort I would guess that there is a Duett (leaf springs) axle lying around somewhere that wouldn't be too expensive.

|

|

-

|

|

|

I did not use an impact gun on it as the puller is set up for hammering. I used a 10 lbs hammer (bearings must be damaged).

I'm not worried just yet, as I Have another two rust pile P210s I have to disassemble in an attempt to piece together one, hopefully.

I'll mess with the puller later, as I'm attempting to lift of the frame now. Not as easy as I thought. Right now I think I'm stuck on the last item holding me back, the hand brake and linkages (nice and rusty).

I've also sourced a one inch fine thread bolt and nut to build another puller. Still waiting on the supply to call me on cub side pickup. I will not put a T-handle on the new puller and try it first with the impact gun. In the meantime, hopefully I will be successful in liberating the body from the frame.

|

|

-

|

|

|

I have 2 of the genuine Volvo pullers. One has a T bar for hammering and the other a nut type end. You can get short heavy spanners with an end on them made for hammering. They have to be pretty tough so worth paying a little extra for a good one. I have just used a good flat ring spanner, longer, and the hammer end is sort of sacrificial. I've never had a drum that has been really obstinate.

|

|

-

|

|

|

Here is picture of the body

|

|

-

|

|

|

Your fortitude is admirable, long may it continue!

|

|

-

|

|

|

Thanks for the feedback Derek and Ron.

I’ve made some progress and separated the body from the frame. I also now have the fine pitch one inch bolt and nut for building another puller without a T-handle.

Since I have two other axels, probably time-fused as this axel is, I’m going to get a lot of practice.

I think I’ll take your advice with the graphite. I pulled my PV544 axel off a couple of months ago and my puller took it off no problem, but I greased it when I put it back together a couple of years ago.

Here are a few pictures of what I’m struggling with.

|

|

-

|

|

|

jk;

"bearings must be damaged" I can't agree, sorry...because the pulling force is ONLY exerted between Hub and Axle, and NONE of the force, including impact, of a properly installed hub puller acts upon the bearing.

Cheers

|

|

-

|

|

|

Using a 10 sledge hammer created a lot of shock. Normally, this causes brinelling. If a bearing is brinelled,the failure will not be obvious. May go a few thousand miles before bearing failure is noticed. But, you can never be sure when it will fail.

|

|

-

|

|

|

JK;

INDEED, a 10Lb hammer applies a LOT of impact (and sometimes, it is STILL not enough(!!) with further tricks and techniques, like time-under-tension and thermal being necessary...), but it applies this to the Puller directly, and only incidentally to everything else the Puller is connected to...and I would hope that the bearing (with its grease-film) can take this without being damaged.

Sure I would dearly love to spare the Axle and Bearing, and everything else involved, the application of such horrendous forces (and that is why I advocate the use of graphite filled grease on the joint during assembly, which keeps the required separating forces somewhat under control!), but that is the design and implementation we must live and deal with...

Cheers

|

|

-

|

|

|

“... My puller is homemade and uses a 1” UNC bolt, 8 threads per inch...”

8 TPI may be too coarse to give you the adequate mechanical advantage. I’m thinking any puller I ever had had rather fine pitch threads.

|

|

-

|

|

|

Versions of the proper Volvo tool are available. They might seem expensive for what is usually a now and then job but they will always be your best option. About $120 when compared to UK pricing. If you are having to farm out the manufacture of of one I'd think that a proper one would be cheaper and could be with you in a few days.

https://www.classicvolvoparts.co.uk/parts.asp?carID=3&cID=49&scID=327&page=E_Rear_Brakes_With_Front_Discs_Single_and_Twin_Circuit

The one from Mike Dudek looks less substantial than that one and isn't a copy of the original. The one from VP is likely the same as the Brookhouse one but I haven't checked. Try Eric at hiperformanceautoservice.com

|

|

-

|

|

|

Thanks Derek. I fabricate a lot of special tools to get the job done easier. I would not consider farming out the job. I have spent other people’s funds on specialty items and I know it’s the most expensive way to go.

When I built my first puller, I just grabbed whatever I could and it happens to be a 1 inch coarse bolt and nut. It worked on my PV544.

I doubled up on the parts during the first build, so I have another plate and tube, but did not find large diameter UNF nuts in bolts in the scrap bin. I’m looking into sourcing UNF threaded rod and nut around 1 inch diameter. Looks like it should be available in 1-14. Just need to follow up with local suppliers.

I’m in no hurry to pull the hub, as I’m disassembling the P210 for frame off resto and I still need to disassemble my other spare parts vehicles. Actually, since I have the drive shaft out I cannot apply enough force to the puller. I need to lock the other wheel and differential. So I will fabricate something for that. I’m sure my other hubs are also stuck on the axel.

This tapered shaft seems to be the major maintenance problems on these vehicle. Has anyone come up with a better solution, or different axel?

|

|

|

|

|