posted by

someone claiming to be macs245

on

Mon Sep 7 09:45 CST 2020 [ RELATED]

|

|

I've been chasing a low idle-stall issue on my daughter's 89' 240. Maintenance has been neglected while she lived away at college, so I'm playing catch up...

It still has some hesitation at idle, typically sitting at stop lights foot on the brake, it is an automatic. I have not tried to find vacuum leaks (never had much success at finding those). I have cleaned the flame trap (brass insert from IPD), cleaned the IAC valve, cleaned the Throttle Body - serious Thick oily residue in there - engine intake side. Probably 1/32" thick stuff - I made a couple plastic scrapers to get it out... It did throw an AMM code at one point so I reset & have swapped in a different AMM.

Unrelated (I think?) there may be an electrical issue that causes stalls where speedo needle jerks before engine cuts out. I believe this is the ignition switch because the door open chime is intermittent. Have a replacement switch already to put in.

My question is - what would be the best way to clean this same thickness of build up out of the Intake Manifold? I don't have a chamber/box whatever it's called for blasting - like shot peening/sand blasting... I did find YouTube videos of burning out Diesel intake manifolds. Makes for a cool video but not convinced I want to try a "hold my beer, watch this!" type of show...

Any thoughts? I'm considering getting one from a pick-n-pull and just swap it out.

Thanks folks

Mike

Currently 89' 244 (daughter), 93' 244 (son); my DD 03' Audi allroad 2.7T (Fritz)

I miss these - 88' 245 (Lars); 98' S70GLT (Son of Lars); 95' 945T

I don't miss this one - 98' V70GLT (Bane of my Volvo experience)

|

|

-

posted by

someone claiming to be macs245

on

Tue Sep 8 17:36 CST 2020 [ RELATED]

|

|

Thanks for the responses, I'll tackle a few points here:

I did pull the accordion hose and confirmed no leaks.

Spark plugs look ok, plan to replace shortly - I pulled them to do the compression test: varies 155 to 172 psi (not bad for 250K miles)

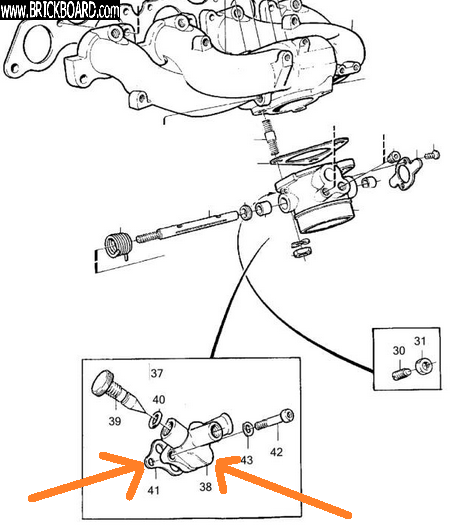

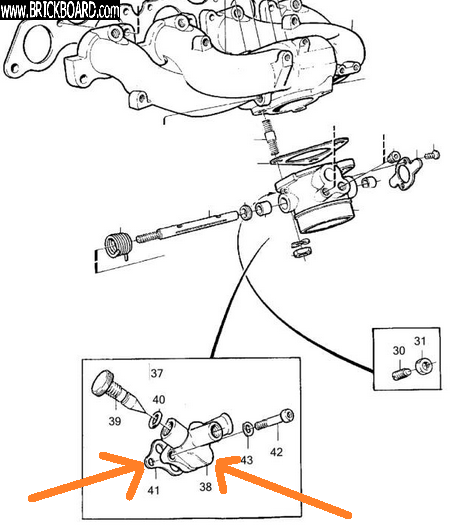

I'm not sure what the idle air bypass housing is, I did clean the IAC valve. This is an 89' so LH 2.4 with no idle speed adjustment

Yes I will be removing the intake manifold & disassembly to clean - saw another YouTube on using Purple Power so figure I'll give that a try along with scrapers & brushes

Ok Phil - I'll have to read through your post a time or 2, thanks for the details - good stuff. You make me wonder about the IAC spring, the valve resistance measurements are correct reading at the ECU (using Bentley), but if the spring isn't fully closing it then...

I will get on the fuses - that's just a good and easy thing to do for preventative maintenance & cheap too! (forgot to mention I am Scotish)

Lastly on the ignition, part of my suspicion is due to my daughter's key chain - she has a metal prancing moose and an emergency tool for braking the window hanging off her key. The spare I use is only a key so I figure the additional weight may tweak the switch innerds a bit.

Thanks All for the replies, I'll add another post if I make additional discoveries. My daughter did drive it to work last night and told me it's running better so I've got that going for me, which is nice.

Mike

|

|

-

|

|

|

Hi Mike,

Glad you got some ideas but you are right my post was a little bit thick, like gunk inside an intake.

You seem concerned about it so it must be really bad around this area.

These biodegradable cleaners are the things to use against engine oil deposits because they at least make the job smell better! (:-)

If you are going to do this, changing the gasket under there will always be good maintenance to help justify the efforts.

I’m sure any work in the zone will be appreciated in nothing else but piece of mind.

The compression sound good and these engines are well designed and earned the name bullet proof.

Even with that said, a “sniff” under the hood is good insurance and assurance to keep away surprises.

Glad to know you ruled out the plastic bellows.

As far as the IAC working it would have to be funky with gunk and closed to cause the low idle and if it was the other way it would probably idle to high.

When I pull them, I test them with a good Nine volt battery just to see it move smooth at the near recovery cranking voltage. But that’s just me, trying to justify my extra efforts! (:)

The idea I was trying to convey was to pay attention to the initial start up mode.

Get use to listening for it, as it will tell if it’s working.

If it is good at being quickly responsive you should notice it as normal get up and go without shuddering.

Happy motoring to your daughter too!

Good that she checks the oil and things!

I have heard of how the opposite happens, within some questionable “excuses” stories, when they want newer fashionable rides!

The 240 is a lot more solid and repairable with inexpensive parts. Scottish or not!

They’re not like Clip on plastics and styrofoam dent mobiles!

Phil

|

|

-

|

|

|

Re idle air bypass...

My mistake. Didn't realize it does not apply to your '89 LH2.4. For future reference, it's mounted on the bottom of a LH 2.2 throttle body.

|

|

-

|

|

|

Hi,

Well, after reading your post I will agree that you are digging around in the right place to find things to cause idle issues.

1/32” of crap in or around the throttle plate sealing edge affects tiny ports or bleed air holes for emissions functions.

As far as the rest of the intake manifold, it doesn’t mean all that much because this is a self tuning fuel management system.

Sure, if it got really, really bad down its whole length, it can affect overall performance at high volume draws.

At the throttle body, variations are more noticeable as a split vacuum hose wiggling on them.

These are calculated air amounts allowed for in the ECU emissions program.

Crankcase ventilations and fuel tank vapor canister evacuation are to flow at idle only or at higher vacuum than it would Under a load of driving.

There is vacuum hose port just for activating a valve on the canister under the bumper.

Sometimes they get dirty to plug up or stay open all the time.

Just a thought.

Make sure the flexible accordion hose has no cracks and the clamps seal well.

The AMM and oxygen sensor system are needing all the air to all come through the engine unburned and then a burned mixture.

When the pedal is opened all of these get less draw and the “throttle switch” says to the ECU, to shift programs.

The switch and the throttle plates circumference are crucial to repetitive idle speeds.

So when achieving IDLE smoothness, things are balanced “on a thin edge” with constant adjustments to match the program.

This is including timing of which you have no control over due to the CPS item!

But the rpm signal does and the knock sensor is waiting within that perimeter.

The ECU/ICU are going to try to stay right on top of that!

During this time the IAC is suppose to pass the majority of air to control idle speed.

On your car, it has a return spring for auto shut down.

It sits there and it awaits ECU signals to open it up.

It might be dead dirty or have a connection issue.

To know if it’s working, at all, listen for it to race the engine above idle and bring it back down “immediately” after first starting the car up.

This is Each and every time without assistance from the foot pedal.

Turn key and start, rev and idle to 750 rpm. No foot on the brake to hold back the engines pull but some cars can creep at times on automatics.

As far as the speedometer needle jumping up?

I see mine do that when starting the engine and I have suspected it’s spikes of voltage on and off as it cranks.

Yes it could have something to do with the ignition switch as it does a whole of things through it.

Current is being sham boozed from everywhere in the car or an indication of a old battery?

Of course, This is an electronic speedometer with its associated sensitivities!

But for me, I would get into that fuse panel, on the drivers door hinge and clean fuses!

Use some anti-corrosive salve on every fuse in there!

Even a light dose LPS One all over everything up and down keeps gremlins away for a couple years!

Moisture from wet shoes migrates from the floorboard, right up there, as it’s a cold spot inside.

Any-who, those are my thoughts on this subject.

I have written about this before in so many ways, I think I have run out of fingers!

Except unfortunately, I still count on one, to hunt and peck with!

(:-)

Phil

|

|

-

|

|

|

Hi Mike,

re rough idle...

In addition to what you have done already, I have had success in correcting rough idle by doing the following (in no particular order).

1) Check / replace spark plugs (if they haven't been replaced for a while)

2) Check the air intake accordion hose between the TB and AMM for holes / tears. Repair or replace if needed.

3) Clean the idle air bypass housing and adjust the screw to correct idle (assuming this has not been done when cleaning the TB). Also, be sure to use new gaskets on the TB and idle air bypass when reassembling.

Hope this helps and I'll defer to others on how best to clean an intake manifold.

-Ihor

|

|

-

|

|

|

If you have the manifold off the car, and completely stripped down, you should be able to get the carbon deposits off by using a wire brush on a flexible extension. This is what I would use on other vehicles and I can't see why it wouldn't do the job on a Volvo.

Happy to be corrected, as always,

Ian F

|

|

|

|

|