|

|

|

I followed FAQs

https://www.brickboard.com/FAQ/700-900/EngineSealsBeltsVent.htm#VolvoCamTool

to insert my Viton/gray crankshaft oil seal. On my 1988 240 DL N/A, a 2" wide ABS pipe with cap, like this

https://www.lowes.com/pd/NIBCO-2-in-dia-ABS-Cleanout-Adapter-Fitting/1000221933

and rubber hammer (mallet?) worked after 30 minutes.

On the 1980 DL N/A, after about 1-1.5 hours, I got the seal aligned only to the outer lip; per the FAQs, I took several breaks to ensure that the lip didn't invert (or spring twist?).

However, on the inside surface of the crankshaft oil seal housing, there's a tapering area and the tip of the original seal was mounted at the base of the tapering, about 5 mm inside the lip. I couldn't get the seal in any further past the tapered area.

I then used the FAQ's suggestion of using 22 mm crankshaft bolt and drilled a hole in the center of the ABS end cap, per the FAQs. It was very easy and I was able to get half of the crankshaft oil seal flush with the flat part of the inner lip and past the tapering part. However, it's misaligned on about the other side. I removed the ABS cap/22 mm bolt and tried hitting just the side that sticks out, to no avail. I'm stopping for the evening and would like advice on how to align this.

|

|

|

|

|

I ensured that the timing belt tensioner assembly was snug against the hole in the cylinder block (I cleaned the hole the other day) and pushed the assembly against and into the stud on the left. It didn't fit snugly againt the left stud, so I held it in place while removing the nail that holds the spring in place. It's loose upon releasing the nail.

However, before releasing the nail, the tensioner assembly was a bit off-center to the left. I was unable to center it despite several attempts before releasing the nail.

It looks this this photo, though the nail is still installed in my situation:

https://c1.staticflickr.com/8/7204/6906930807_3f3775e8e3_b.jpg

Upon releasing the nail, the tensioner moved too far to the right off-center, pointing toward 9 O'clock. The washer outside of the tensioner is off-center.

The timing belt is centers with all sprockets and the tensioner.

My situation looks exactly like this:

http://www.volvoadventures.com/240cambeltjob2.jpg

I removed and reinstalled the tensioner assembly several times, but can't get the washer aligned. Same is true when torquing down the tensioner nut.

|

|

|

|

|

Hi,

I don’t see anything wrong with the tensioner being held in place by the stud and the washer under the nut on top of the cam bearing. All of it looks squarely pushing on the belt.

The nut and washer setup will look off center to the center of the bearing and that is the normal position.

If you want to, you can remove the nut and washer from the stud of the assembly, as it will just sit there, applying pressure on the belt.

You then can check to see if there is still some gap around the stud especially on the left side.

If the belt is of proper length there should be some. Not a big bunch of room but enough left so it can shift later.

The gap is to be there for further adjustment, after the belt stretches after a run-in period.

You should do this, During later intervals, like with oil changes or even two oil changes. Depending how long you go between them. The owner manual say up to 7,500 miles for oil. It might say, but I think it eludes too meaning, about 15,000 for the belt maintenance. Can you tell I’m vague! (:)

It is advised to just loosen the nut one turn and then retorque it back through the hole with rubber plug in the timing belt cover. You do not turn the engine or anything but loosen and tighten it back.

This will maintain proper tension on the belt to keep the timing precise to the crankshaft.

I’m glad to see the pieces are coming back together!

Phil

|

|

|

|

|

Thanks for your comment and reassurance.

Just to be clear, the left stud that holds the base of the tensioner, i.e. to the left of the spring, doesn't go flush against the cylinder head. In other words, I can push it in a bit, and it pops back out the same bit. I don't recall checking for this with the timing belt job I did a couple months back on my 1988. It does not move left to right.

I removed the timing belt tensioner nut and washer and the assembly moved to the left. Am I correct that this is due only to the timing belt pushing on the tensioner and is perfectly normal?

I read the rope trick several times and am confused. I removed the rope in the middle of the timing belt change and after removing the crankshaft but before I reinstall it. When I want to immobilize the crankshaft to install the crankshaft bolt, do I rotate the crankshaft clockwise until I'm 90 degrees BTDC then reinstall the rope, or just rotate the crankshaft a little bit backwards, then reinstall the rope?

Finally, this car is a project/storage car. I just changed the water pump and continued to use the old-school green coolant which came witht he car. I'd like to switch to the HOAT, but don't want to start the engine to flush the old coolant out. Can I flush the system without starting the engine?

Thanks!

|

|

|

|

|

Hi,

You are talking about the shirt pin sticking out that the sleeve with the spring on it is moving around.

I would say that is normal also.

It must be a slip fit but tight enough to trap air under it.

When you tap it it compresses the air inside the bore and bounces back out.

That's a good fit in my opinion. It's not going anywhere.

But if you wanted to stop that, you will have to remove that pin and take a file and draw file a flat down its length to break the surface contact in the bore.

Personally, I would leave it that way forever! Nothing is going to wiggle it out under spring pressure as the assembly is locked down.

As far as the rope trick in the piston cylinder you roll the engine to hit the rope in before one turn.

That turn is always to the right pulling the belt clockwise over the top and down.

To get the rope out you might have to back up, ONLY A TINY BIT, to release any pressure on the tip that long rope. You don't put the whole rope in. You only need a few inches to lay across the piston top. The space in there gets squeezed down to less than a half inch to the top of the dome. That's why it's a non interference engine.

Easing it up slightly backwards will not hurt anything.

As far as pumping out coolant it cannot be done! As soon as half the fluid drops pump outs it will all stop! Maybe even sooner than that!

You have to drain, flush and drain again!

I have used lots of compressed air to push out the heater cores water but I'm not totally sure that it evens gets it all out, to be like in essence, " dry as a bone!"

All you can do is the best you can. I have only used OAT. The newer HOAT is new to me but I would think the two should be backward compatible to some extent!

As far as going from green ethylene glycol to either Hybird or plain Organic there is going to be some residual pockets someplace. You just can't worry about it as all of the fluids were not supposed to hurt your car, right!

I'm no chemist but I do live in the real world!

Trust me, it tries to get too real at times and all you can do is go with the flow!

In reality sometimes, you have to be fluid!

Pun intended on this subject!

(:)

Phil

|

|

|

|

|

When I did the rope trick to help loosen the crankshaft bolt, everything moved one notch to the right, i.e. clock-wise. Before installing the timing belt, I ensured that the cam and intermediate sprockets were one notch clock-wise.

I tried the new timing belt, a Beck-Arnley both ways. The way that fit aligned the cam and intermediate shaft and the white marks. However, the double white marks for the crankshaft are hard to see if I aligned them properly with the crankshaft. I triple-checked and the crankshaft is still one tooth to the right/clock-wise. Can I stop obsessing about counting teeth and gaps and be sure that everything is aligned if one tooth to the right?

Thanks

|

|

|

|

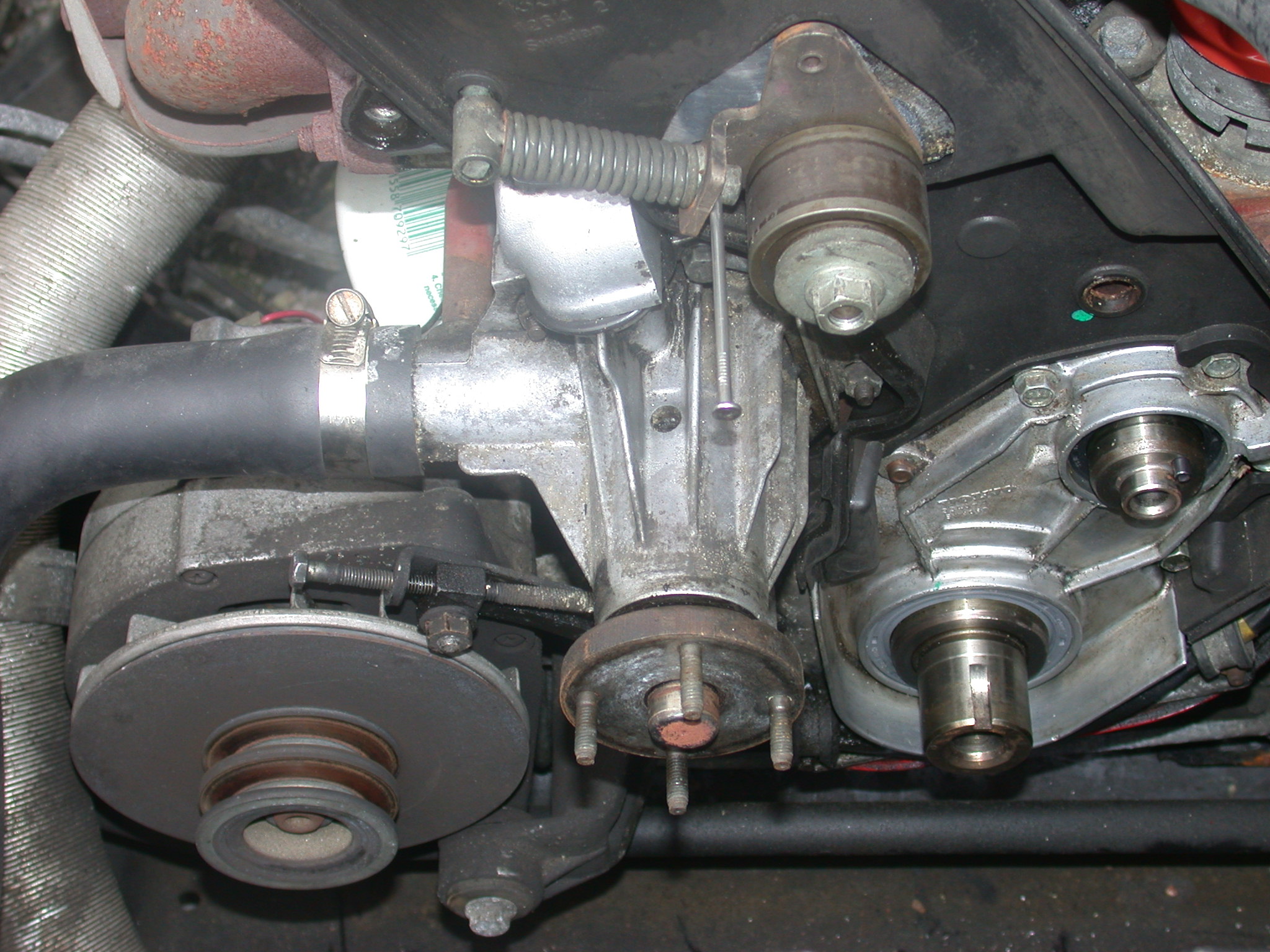

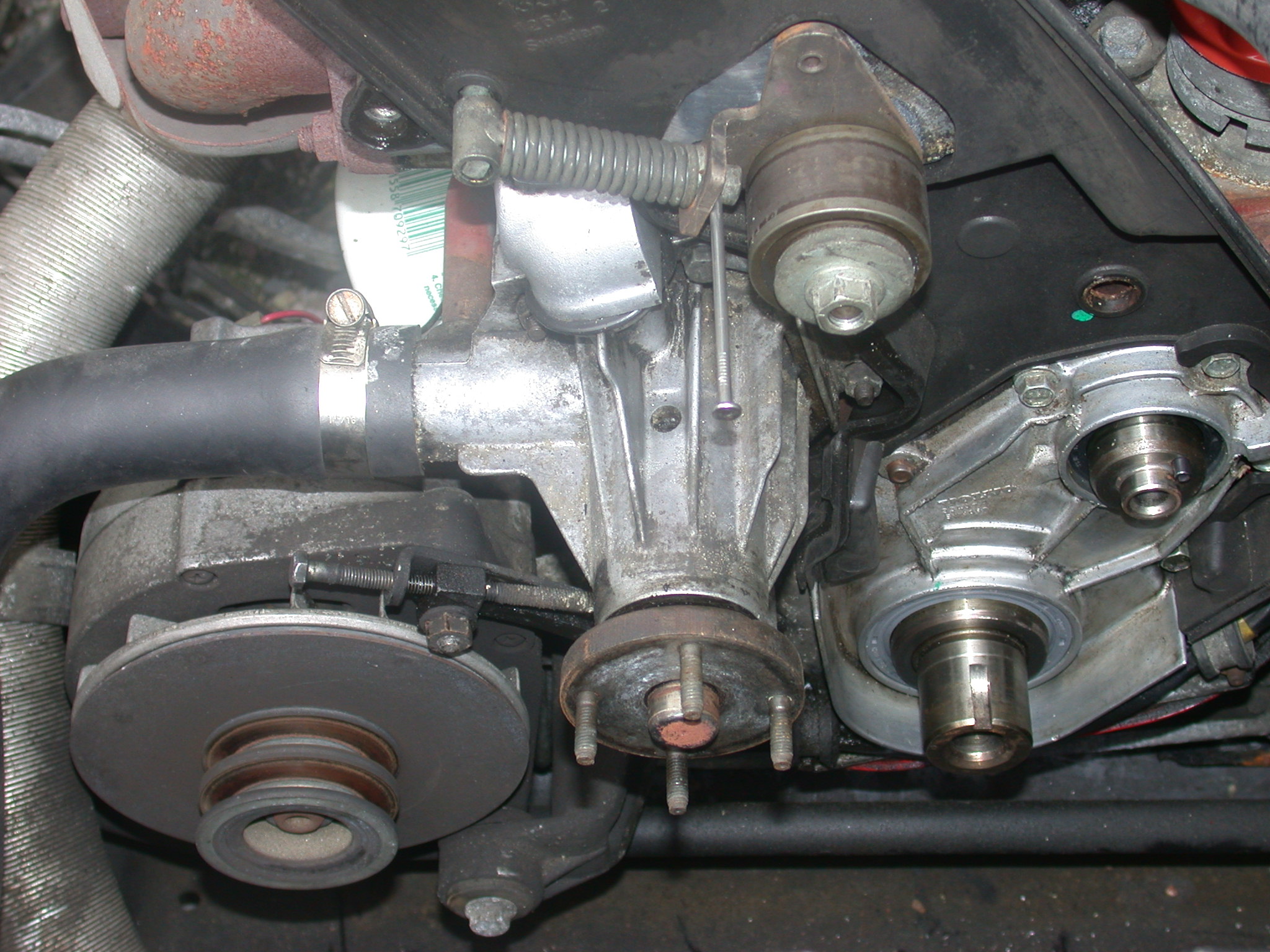

Different motor, but it helps me visualize...

--

Art Benstein near Baltimore

A cowboy from Texas was pulled over by an Arizona DPS Trooper for speeding.

The trooper started to lecture the cowboy about his speeding, and in general began to throw his weight around to try to make the cowboy feel uncomfortable.

Finally, the trooper got around to writing out the ticket. As he was doing that, he kept swatting at some flies that were buzzing around his head. The cowboy said, "Y'all havin' some problem with circle flies?"

The trooper stopped writing the ticket and said, "Well yeah, if that's what they're called. But I never heard of no circle flies.

"Well, sir," the cowboy replied, "circle flies hang around ranches. They're called circle flies because they're almost always found circling around the back end of a horse."

The trooper said, "Oh," and went back to writing the ticket. But, a moment later he stopped and said, "Are you calling me a horse's ass?"

"No, sir," the cowboy replied, "I have too much respect for law enforcement to call y'all a horse's ass."

"That's a good thing," the trooper said and went back to writing the ticket.

After a long pause, the cowboy, in his best Texas drawl said, "Hard to fool them flies though."

|

|

|

|

|

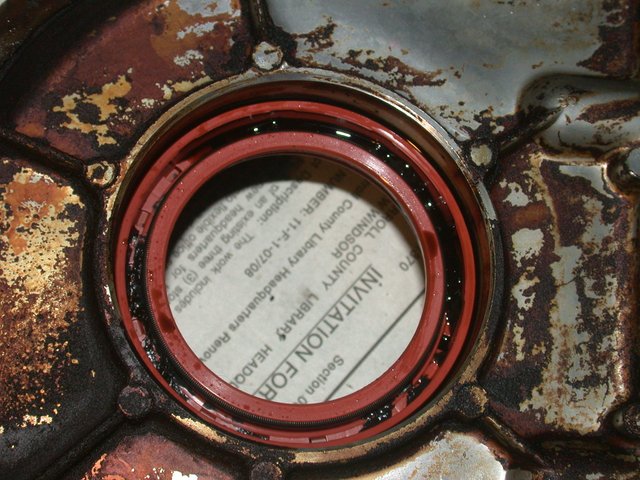

I finally aligned the crankshaft oil seal.

Here's how.

I continued to use the hex shank portion of an impact socket adapter and drove it in. It took all of 3 minutes.

|

|

|

|

|

I just installed the crankshaft oil seal further in.

About 1/2-3/4 of the outside surface of the seal is aligned with the outer edges of the housing just as the housing begins to taper outwards toward the exterior. It's hard to see, but it appears that 1/4 is about 2 mm too deep as to the outer seal position; in other words, I can see the non-tapered part of the seal housing. This situation is consistent with the misalignment of the seal as I posted above.

I'm installing a gray Elring seal. I don't know how thick the new seal is but the old, orange one is 9 mm thick. If they're the same, I have 7 mm of seal coverage over the outer seal housing.

To prevent leaks, do I need to realign the seal, or am I okay?

|

|

|

|

|

FAQs said that installing the seal up to 1/8" (3 mm) deeper than the original seal is okay and might even give the seal a new gripping surface.

https://www.brickboard.com/FAQ/700-900/EngineSealsBeltsVent.htm#Replacing_Oil_Seals

So I worked a bit more on the seal. The portion of the crankshaft seal that was misaligned is now 1 mm past the tapered part, meaning there's only about 1-2 mm of uneven-ness with the seal's position. In other words, the rest of the oil seal is about 1-2 mm further in the seal housing.

Is this okay or do I risk oil leaks?

Thanks

|

|

|

|

|

Hi,

I would not prefer that you leave it leaning as the lip of the seal is stretched tighter not being in a complete circle around the shaft.

The lip is stretching to a larger diameter and back to the size it was made for.

These sets up a fast wiggle at speed that might creep the seal loose and the oil travels with the shaft in a straight line and will dam up on one side.

Depending on velocity it will eventually seep under the lip more than it was designed to hold back. The wiggle is a flutter up and down and back and forth.

In other words, it’s life will be shortened, let along where the oil goes and touches.

In lots of cases I have seen that there is enough space to the rear to put in two seals on lots of equipment.

Like on the red block, the front lowest crankshaft area can hold two seals in there. You can move that one pretty far back if need be to clear a worn in groove or scratches. Just be careful not to hit the crankshaft shoulder.

I’m not sure about the upper two front seals if their deep enough.

Anyway, pulling it is the best and try to use that old one to help you push in a new one.

Reverse the old one so you get more surface area to push in with!

You will be able to see how straight you are moving in as it will stick out farther.

If need be, You can tap the old one and not damage the new seal.

Live and learn or why would have I know this!

It happens!

(:))

Phil

|

|

|

|

|

"FAQs said that installing the seal up to 1/8" (3 mm) deeper than the original seal is okay and might even give the seal a new gripping surface"

-> The FAQ is correct in that installing the seal deeper might give a new sealing surface. But nowhere in FAQ says its ok to install the seal crooked or misaligned.

Misaligned seal have uneven sealing forces acting on the crank surface prone to early oil leak.

Amarin.

|

|

|

|

|

Some goofing about but serious stuff underneath. Your grey seal in part 2. Use some seal fitting lube. They seem to have so little trouble with it that there is no actual fitting shown.

https://www.youtube.com/watch?v=-OCr7aBYfkY

https://www.youtube.com/watch?v=jg97Yc_A6Wc

|

|

|

|

|

Thanks.

I watched both videos. I saw them remove the crankshaft oil seal and reinstall the camshaft oil seal, but I did not see how they reinstalled the crankshaft oil seal. Have you an exact location, e.g. 2:30, for where they did it?

I checked the ABS pipe/end cap and it was smooth, even, and symmetrical. I installed it flush with the oil seal (I think), which I know was straight. I still don't understand why the seal is misaligned after using the crankshaft bolt over the ABS pipe/end cap to install it.

|

|

|

|

|

In my post, I did say "They seem to have so little trouble with it that there is no actual fitting shown." I'll make a comment about it on the video, maybe they will reply to it.

|

|

|

|

|

David has replied to my comment, go and have a look.

|

|

|

|

|

Thanks. I looked at both links and didn't see your response or his.

|

|

|

|

|

Check under Deluk and the reply to my comment. It's right at the top of the comments.

|

|

|

|

|

I found your comment and his comment.

Unfortunately, the crankshaft seal is misaligned despite his suggestions. Specifically, I cleaned both the cranshaft and the housing well. I used an ABS pipe and evenly inserted the crankshaft bolt through a hole in the cap of the pipe. I then rotated the crankshaft bolt slowly and evenly.

I'm wondering about using a small diameter wooden dowel to put pressure only on the area still sticking out?

That said, it's off by 2 mm or so. If I can't get it perfectly aligned, what's the risk of a leak?

|

|

|

|

|

You need to align the seal properly inside. Several options here:

1. Take a small rubber hammer and hit the protuded part of the seal slowly to sink it in.

2. If you don't have a rubber hammer, put a thin wood on the protuded seal and hit with normal hammer

3. Reinstall the seal. First you must be able to remove it without damaging the sealing lips. Use a specialised tool with a "spoon-like" tip such as below:

https://www.ebay.com/itm/Automotive-Tool-4pc-Spoon-Tip-Seal-Remover-Set-Shop-Tools-for-Removal-O-rings-/310878587484

4. Remove the seal destructively (consider this as a lesson) and install a new seal. This time be more careful. A new seal doesn't cost that much.

This is why some old timers lubricate (thin engine oil woud suffice) the outer sealing edge that mates to the engine to facilitate installation. And just use their experienced fingers to push the seal in. Yes I've seen that. The seal was designed to be compatible with engine oil so its ok.

If this was the camshaft seal you could just remove the end cam bearing cap, take the misaligned seal out, reinstall the cap and start over.

Amarin.

|

|

|

|

|

Thanks.

I'm reluctant to remove the seal carrier.

So this issue involves a gray Elring #1276425 crankshaft oil seal:

https://www.fcpeuro.com/products/volvo-engine-crankshaft-seal-front-940-740-760-780-240-244-245-242

Is it seal-safe and leak-safe to install oil on the outer lips?

The FAQs said that a Volvo tech told someone NOT to lubricate the outer seals, suggesting risk of leak. In the future, should I go ahead and lubricate the outer seals with oil to facilitate install? My 1988 crankshaft oil seal went on without too much difficulty and without oil on the outer lips.

|

|

|

|

|