|

This might be totally irrelevant, but on the later 240 wagons, the tail lamp and brake lamp are shared by the same bulb. It has three electrical contacts; ground, tail, and brake, and the holder has three tabs to lock it in the housing, one larger than the other two, to prevent it from being clocked wrong.

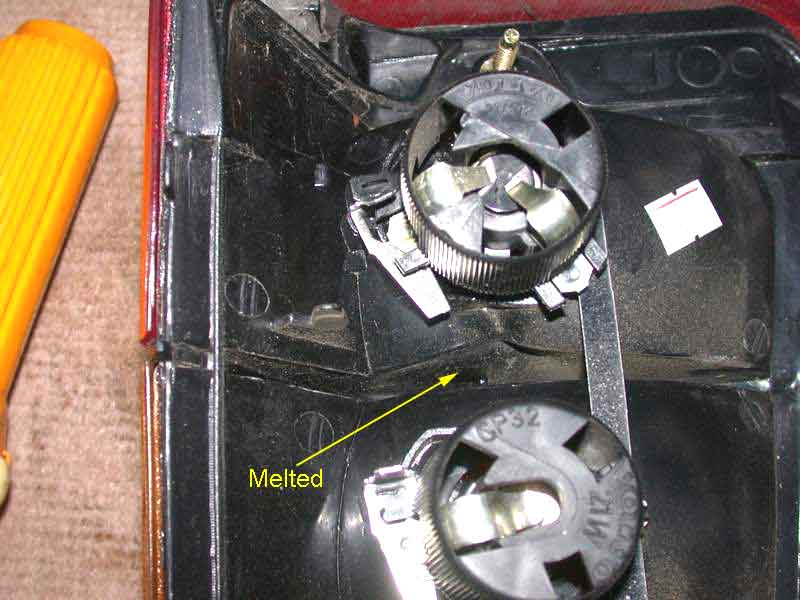

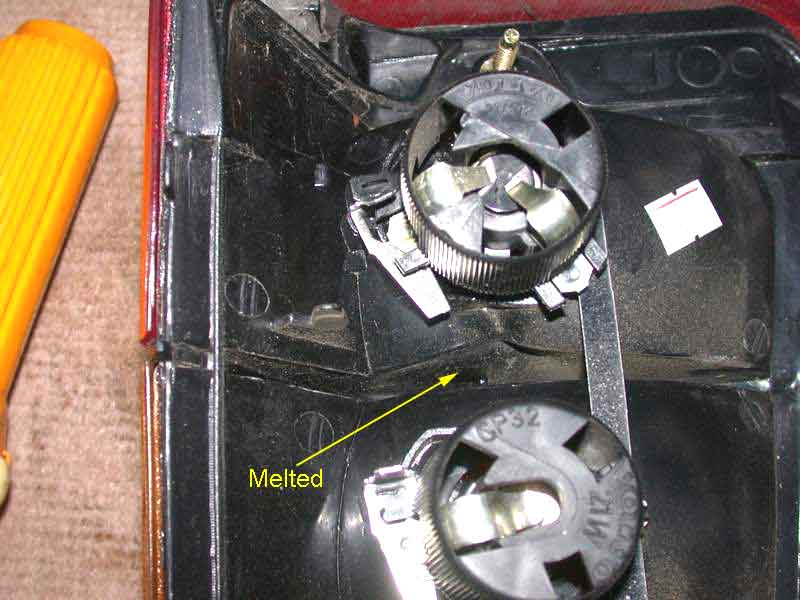

When the lamp assembly ages, cracks develop letting moisture in which eventually cause oxidation of the spring contacts on the holder where they take the current from the plated metal fixed to the body of the lamp housing.

As the oxidation increases the contact resistance, heat develops, especially while you are waiting for a long light to change with your foot on the brake pedal. With more heat, more resistance. More resistance, more heat. The plastic lamp housing softens, the spring tension of the contacts relaxes, and now the resistance increases further.

Then the bulb failure lamp lights, so you go around back to investigate what needs fixing and find the lamp housing so distorted you can't even get the bulb out of the hole, much less get the holder to make good contact again cleaning the metal. You blame the whole mess on obsolete incandescent lamps invented in the 19th century so you can justify converting it to LED, completely missing the oxidation/corrosion/leaky lens issue, and now you find the bulb failure feature is useless.

Could it be the fit is tighter because it is on the way to this 245 symptom?

--

Art Benstein near Baltimore

We're going on a class trip to the Coca-Cola factory. I hope there's no pop quiz.

|