|

|

Sure enough, the parts fiche identifies the 1993's compressor and mounting bracket as R134 parts, with distinct part numbers. Learn something every day!

--

Art Benstein near Baltimore

"No news is good news until you need to know the news" -Tonya Stevens

|

|

|

|

Did you just fiche, as in "micro"????

I thought those things were long gone!

I too learned something new today!

Matt

|

|

|

|

|

The rear bracket on your compressor needs to be moved to the outboard side of the mounting ears

|

|

|

|

If I do what you suggest, then there is no room to tighten or loosen the nuts for the R134a compressor.

I will post more pictures tomorrow once I pull the bracket out.

I will be able to show that a R134a compressor will fit fine with its OEM bracket and that a R12 compressor will fit fine with its OEM bracket, but not vice versa.

Matt

--

1989 - 245, 1990 - 245, 1991 - 245, and 1993 - 245

|

|

|

|

|

Mounting brackets are on the back side of the front A/C tabs front side of the rear tabs on my 93.

Dan

|

|

|

|

|

HI,

As Michael says you might have the wrong bolt in hand.

You may need a longer regular hex head bolt if that one in your hand is too short. You will also need to use a flat washer under the hex head to fill in across the slot for a better surface contact.

The rear bracket can be knocked down a bit lower it as it swivels like the front adjuster one.

Since this one is shorter than the rear bolt that goes there, it's not the right bolt.

Does it have a smooth, oval round head as the front bolt does?

If it does, you have the one for the front of the other compressor. It's missing from that adjuster bracket.

It will have a low profile head with a square neck on the body underneath.

This type bolt is called a "carriage bolt" in our hardware stores and usually has a coarse thread count per inch. It was used to pull down into wood of a carriage bed or truck bed to let cargo slide over. The square also fits square holes in metal or in this a case a slot of a bracket. Some of the alternator's housings have square holes.

The front bolt needs to be a carriage bolt, so it clears in the space underneath the adjustment screw.

The square neck fits into the slot so you only have to use one wrench to loosen or tighten the bolts nut up is another advantage.

FYI

Fords were made of wood in many places. He recycled his vendors oak pallets and machinery crates.

Back in the day of Fords assembly lines, one man laid under the carriages bolting on the wood boards. Bet he had a "speed wrench!

Like ones we have now that have a bend in the middle tool of which I seldom used anymore due to air tools. You know the one that looks like a carpenters auger's bit brace! It's good for the bolts for the plastic belly pan.

Just thinking again!

Probably where the idea of "rolling creepers," that we use in our nice driveways, "really" did come from the 1910's.

It was later, just before World War Two, that an employee or relative of either place worked for the Dodge Brothers too! The Dodge brothers were original parts suppliers to many of the car manufacturers.

Yep ... That's were we got that term "Jeepers Creepers."

Yep ... I remember the "Little Rascals" and "Our Gang" episodes using those words!

Hmm, after all these innovations, we still think we have horses powering our (car)riages around!

Remind me again, How far away are we from that apple tree that started all this, anyhow? (:-)

Hope you can find all your pieces! I end up finding the right box ... eventually? (:-)

Phil

|

|

|

|

|

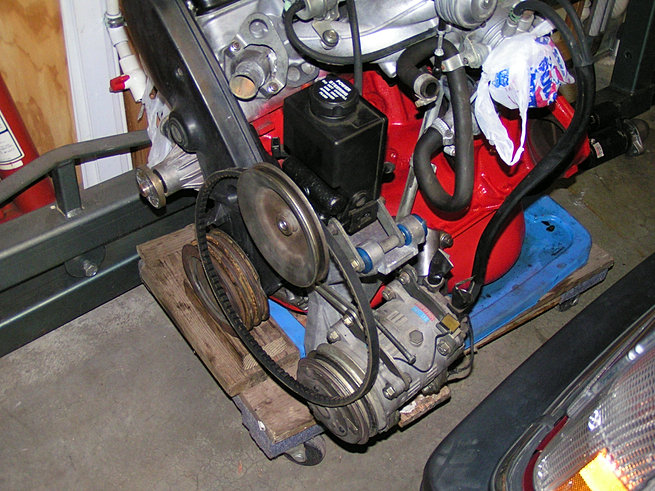

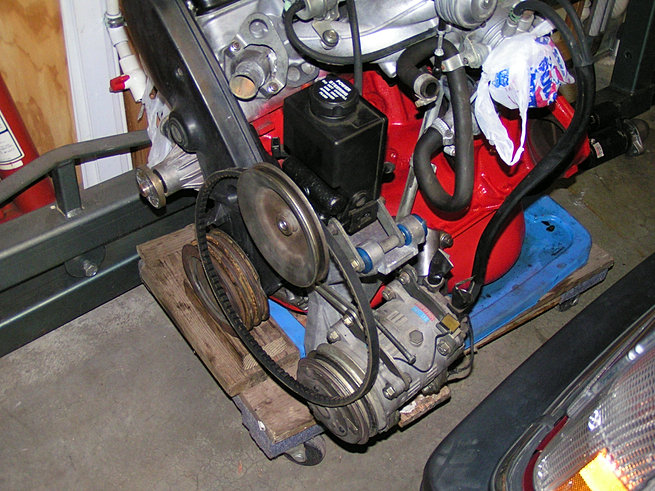

I found this picture which shows the rear A/C bracket mounted on the rearward facing side of the 2 mounting ears.

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

|

|

|

|

|

Hi Eric,

I agree that it looks like he could move the bracket plate to the outside as long at it clears that big nut on the suction side line.

It seems we are looking at two different compressor photos.

Maybe they vary by an inch or something or none. It is hard to tell length and depth or the thickness of the rear head or manifold.

Is there distance between the brackets now? They look to almost touch to me but the slot is too high.

I see the newer style magnetic clutch showing on his. The two compressors must have different oil fill ports as his is not showing.

I want to say yours is a Diesel Kiki of a more recent year. While his looks to have the newer style clutch system the compressor looks older and Volvo. Still both could be a Diesel Kiki.

I think the placement of the mounting plates is going to be set by the main engine bracket width and which way the lines have to attach.

The 2,7 and 9 series were kissing cousins over the years in this area. One side of the engine or the other side and then there was the turbo error, I mean era!

It's possible that this car is suffering from a mix and match week of socks during laundry cycles!

(:-)

All said, it should fit with the displacement of the compressor being equal in stroke length. Even if the stroke moved longer it can move more to the rear. It's the ear spacing that is fixed and centered to the front plate and the pulleys that count.

The number of cylinders is another story. I have read about the use of six and seven cylinders compressors. Volumetric efficiency can change a little that way too, just ask Honda Racing.

I don't know anything on what Volvo used or when they changed for what or even their reasoning, except they could!

Phil

|

|

|

|

That's an R12 compressor, not a R134a compressor, and yes they are different.

--

1989 - 245, 1990 - 245, 1991 - 245, and 1993 - 245

|

|

|

|

|

Try moving the rear bracket mounted on the compresser to the other side of the mounting ears.

--

Eric

Hi Performance Automotive Service (formerly OVO or Old Volvos Only)

Torrance, CA 90502

hiperformanceautoservice.com or oldvolvosonly.com

|

|

|

|

|

It's really hard to see anything in some of your pics! I can tell you are missing a nut and bolt on the back top of the A/C bracket.

You need to make sure the pulley on the A/C compressor is parallel to the harmonic balancer and directly in line with it.

Dan

|

|

|

|

Pageda,

Yeah, I know I missing a bolt and a nut. The one that goes there is not long enough to cover the distance between the bracket and the compressor.

The distance is close to 3/4".

As far the compressor pulley being in line with the harmonic balancer, that is unknown at the moment as it is currently off the engine.

If know can give me a solid answer, then Monday the bracket comes off and the old one goes back on with new bushings, but not before taking pictures and measurement.

Ugh!

Matt

--

1989 - 245, 1990 - 245, 1991 - 245, and 1993 - 245

|

|

|

|

|

I'd try to measure the bracket spacing on the one you put in and compare it to the spacing on the one that came out. If the bolt isn't long enough -- that's a pretty good sign that either 1) you're using the wrong bolt or 2) the new compressor is different from the old one.

|

|

|

|

Ok, so no feedback yet, but I have a question.

Are the brackets that held the R12 compressors and different from the ones that hold the R134a compressors?

I ask this as I had one lying around that came out of a 1990 240 with R12 and instead of cleaning up the one from the 93, I cleaned up the 90 instead so that my job would be easier. It appears in my haste to get this hatefully job done I may have screwed the proverbial pooch on this one.

If anyone out there knows the answer before I spend the time pulling this thing back again just confirm, I would greatly appreciate it.

Thanks in advance,

Matt

--

1989 - 245, 1990 - 245, 1991 - 245, and 1993 - 245

|

|

|

|

|

Just a WAG, shouldn’t there be a long bolt through the mounts instead of 2 short (or one) bolts and nuts?

|

|

|

|

|