|

|

|

I recently replaced the primary pump and sender unit on my 1992 245 as the former had failed, or so I thought.

The actual cause turned out to be a break in the black wire somewhere in the sealed part of the feedthrough. The continuity measured fine from connector right up to the feedthrough (stuck a needle through the wire insulation), but inside the tank, right at the solder point, there was no longer continuity.

Normally you see failed pumps, but it doesn't always have to be the case.

Oh, and I probably drove around with just a functioning injector pump doing both jobs without apparent symptoms (other than a slight humming with a near empty fuel tank)... for the better part of 11 years... oops...

Thought I'd share this and was also wondering if this is a common problem, or that I was just unlucky...

Is there a way to assess the health of the old primary pump without destructive "surgery"?

|

|

|

|

|

Hi Grey,

It is a common problem. Current wisdom is that rust gets under the knob connector and disturbs the connection. Usually by the time this happens the pipes are corroded to the point that it's best to replace the whole unit.

I bought a 245 last spring as a project that had the same issue with the black wire as yours. It was unusual in that there was very little rust on the top. The pipes were in perfect condition with most of the cadmium still there.

As a temporary fix I drilled a 1/8" hole right beside the knob and ran a new wire through the top. I put a couple of layers of heat shrink on the wire when it went through the hole, lashed it to the knob, and coated the whole mess with epoxy inside and out. I then covered the top with a couple of layers of tar based undercoating.

I know I should replace it, but I'm curious about how long it will last. I've kept an eye on it and expect to see some gummy undercoating if it begins to weep. I recall a reference here about a hard-to-find replacement connector for the unit. Perhaps someone else can recall what that is, for the odd case that would warrant it.

I can't help you with repairing your pump. So far I've gotten by on salvaged spares.

Peter

|

|

|

|

|

Thanks for your reply.

Mine had a fair share of rust, but not as bad as on Art Benstein's site. Especially the return connection was rather flaky with rust falling off, and it was that that made me decide to buy a new sender unit (this one: http://www.skandix.de/en/spare-parts/engine/fuel-mixture-formation/fuel-supply-system/fuellines-and-ventilation/sender-unit-fuel-tank/1018107/). It comes complete with connector, of course without the primary pump and its rubber hose and bracket.

But to be fair, had I known it was just a wiring problem, I might have gone for your solution as well.

|

|

|

|

The tank pump may not have had much life left by the time the feedthrough corrodes in two. Not that the two processes are related, but the time for the salt to work on the latter is roughly equivalent to the mileage on the former's brushes, in my experience. Some pics in here: In The Tank

To assess the pump nondestructively, once out of the car, is actually a worthy goal, as the same inspection of a new, unused pump, is. Too many of us have experienced the pain of replacement with an inferior product, only to repeat the labor and have no assurance we are not repeating the mistake. In the end, the only nondestructive assessment we can make is that it is performing at the moment.

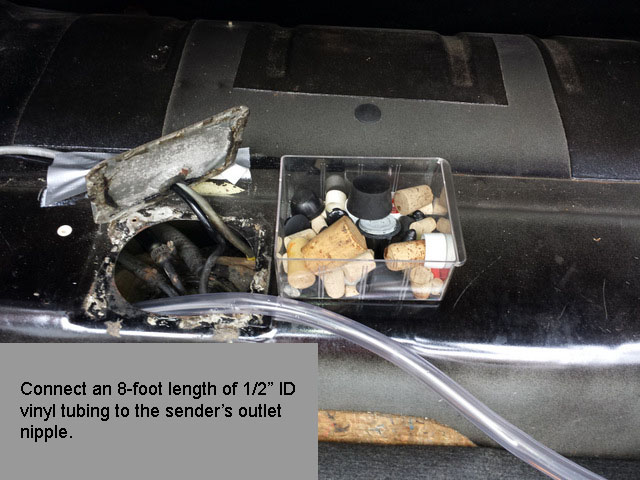

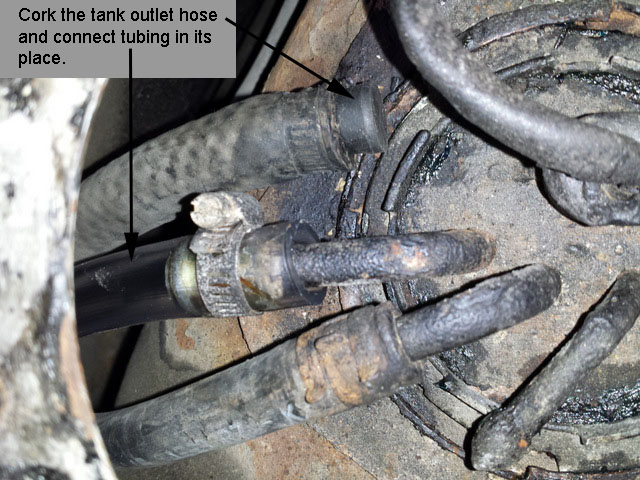

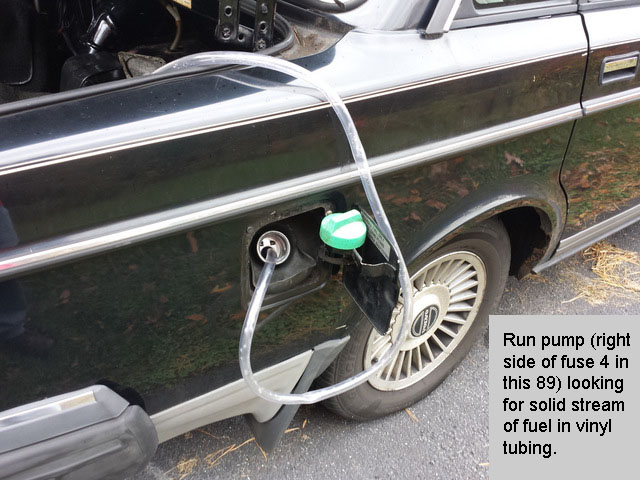

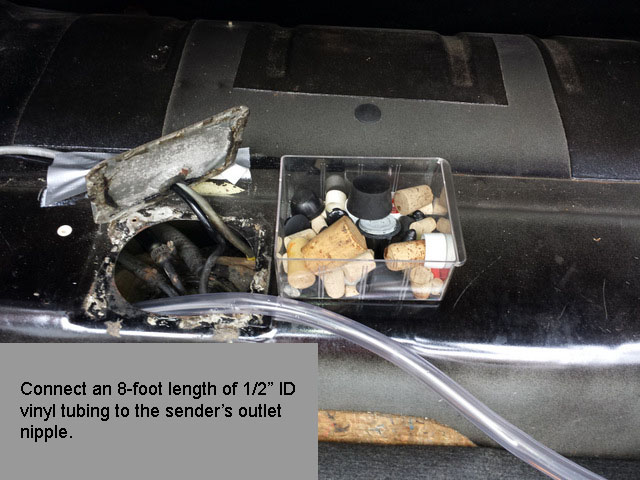

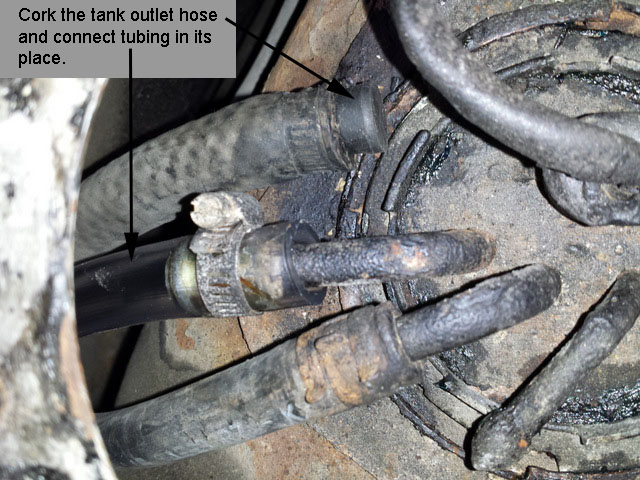

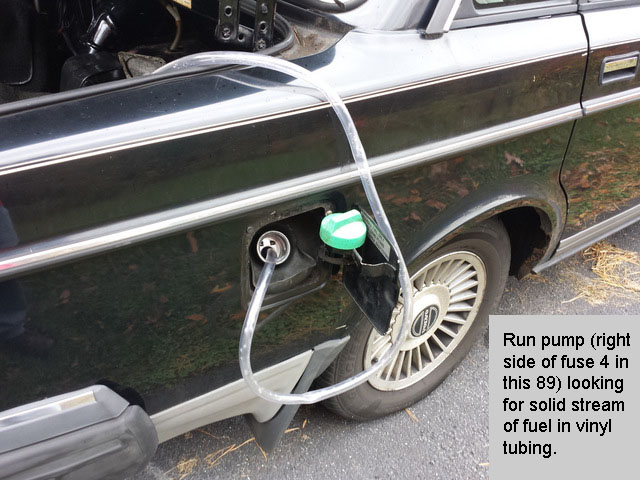

In US 1992 and 1993 245s, there is a Schrader valve tap for checking fuel pressure both at the rail and between the tank pump and injector pump, so we do have a method to determine tank pump operation. Normally, without those features, we would guess at its performance by hearing it run, but there are cases where the hose is perforated or impeller cracked such that sound is not clue enough. Here's a method I used recently to verify tank pump performance:

--

Art Benstein near Baltimore

Those who jump off a Paris bridge are in Seine.

|

|

|

|

|

Thanks for your reply.

So, corrosion gets to those wires after all. I thought that the feedthrough would shield them from it and that maybe it was a dry solder joint under all that sealant, or something. I might try to pry out that stuff and see what I find underneath.

After I had made sure that the primary pump was getting voltage, but not drawing any current, I googled for the replacement procedure and your site was one of the first to turn up, so I was aware of it already. What I saw made me decide to have a go myself. Thanks for posting that stuff, it's really helpful.

First I had a look under the panel and found that - though not as rusty as the photos on your site - there was enough flaking to warrant the replacement of the sender unit. At that time I was still under the impression of just a pump failure as the fuel gauge was working fine. The rust made me decide to buy "the lot", i.e. everything new, including the lock ring.

On your site I saw the differences in length between pumps, but the German supplier I ordered the parts from (Skandix) was good enough to have both types available and indicated what type was used in which VIN number range.

That meant that for me it was just a simple swap of the moulded rubber hose and plastic pump bracket from the old unit to the new.

The new pump is an Airtex, which your site gave me the piece of mind of being of decent quality (weeks before I had replaced the main fuel pump and I chose to use the original Bosch item despite the 65 Euro higher cost).

Both Schrader valves are in the European model as well, but I have no fuel pressure meter. That's an interesting way to check for the working of the pump, nice colour car too (same as mine ;-) ).

I know that the new pump works as I ran it dry for a couple of seconds to make sure the wiring was okay. And when I heard the pumps priming the first time after the replacement, I could hear the sound of an empty hose being filled by the primary pump. Now I can can hear it whirring away when idling (the estate has tha "advantage" of extra noise from the rear), something I haven't heard for a very long time.

|

|

|

|

|

Hi Art,

That's indeed some serious rust you have there... Why does all that stuff look so shiny?

I was going to have a closer look at my sender unit sometime soon, but your post got me so curious, I decided to do it now.

When I first inspected the top of the tank sender unit, I was greeted by a common site of dirt and rust, though the amount of rust wasn't too bad (1).

Only the return line was rather flaky, and it was what decided me to buy a new sender unit too (2).

At the time I didn't know the actual cause, so I'm glad I did.

A closer look at the old sender unit revealed there was no rust under the feedthrough (3).

But on the side of the feedthrough plastic cup there was some white stuff I could scrape off with a knife. Also on the bottom, the plastic was not nice and straight, it looked a bit brittle and broken, with that white stuff in the crevices (4).

I put a saw in the plastic and removed it to get access to the innards and the photo reveals the cause (5).

There's that white stuff again, and now I'm thinking that maybe it's some kind of corrosion product, but it's not green. I cut the wires right above the epoxy, and they all showed shiny copper strands. Also notice that the sealant has been pushed out of the pastic cup a little (6).

Here's what I think happened: the sealant and the plastic got separated over time and moisture could creep in and reach the tabs onto which the wires are soldered. It was just a matter of time until the pump connection corroded through as this seems to have gotten most of the moisture, leaving the fuel level sender signal and ground connection intact.

(1) http://i.imgur.com/hAgNa4W.jpg

(2) http://i.imgur.com/xczftlZ.jpg

(3) http://i.imgur.com/BNaUeFL.jpg

(4) http://i.imgur.com/ZDGuCM4.jpg

(5) http://i.imgur.com/5ykAP2x.jpg

(6) http://i.imgur.com/NhzvT0Y.jpg

|

|

|

|

|

hello arty b- two questions . back in 11 i replaced the sender and tank pump in my newly acquired 92 245 following your erudite advice. hardest parts actually were taking out the wagon deck cover and 3d seat to access the sender pump hole under the plate and fitting the float arm back in the hole. has worked fine since(now about 25k miles since). what is all that black crud on surface of your old unit in your before picture(undercoating or permatex goop)? with the new unit in is the aerosal undercoating effective against rust and moisture intrusion? your instruction was a work saver since i bought a length of expensive gates special hose for the pump to upper pipe b/c the hose that came with the unit was fuel injection hose the outside of which was not suitable for immersion in gas. catching that saved a repeat job. my last question is medical. if a man spills ketchup on his eyes does that make his heinz sight 20/20? sorry. thanks tons oldduke

|

|

|

|

Hey oldduke, I have at least one answer for you. Yes that black crud was undercoating; at least it was a tarry substance that cleaned up with kerosene. It wasn't uniformly distributed over the surface, and I'm pretty certain I was the first into that tank since the car was built. Pretty certain. Unless a previous invader was meticulous about not scratching things, using Volvo parts, and not losing any fasteners. :}

Whether the spray job I gave it will be effective is a question for 2027. Will get back to you on that then. Meanwhile on the medical advice, we understand tomato is a fruit, so ketchup must be a healthy smoothie, but for the benefit, I think it should be ingested orally.

I'd have been glad to do this tank pump on a wagon yesterday instead of leaning over the trunk's lips. My back is killing me today.

--

Art Benstein near Baltimore

No joke!

|

|

|

|

|

Art wrote--"I'd have been glad to do this tank pump on a wagon yesterday instead of leaning over the trunk's lips. My back is killing me today."

I'm not so sure you'd say that if you've ever taken out or installed a 3rd seat in a 245. Not as simple as you'd think--and HEAVY. -- Dave

|

|

|

|

|

very true art and heck- if no 3d seat in 245, just a deck panel, then it would be easy. taking out that seat can lead to 3 f sharps maybe even a mofo. no shortcut though if you want to get to the intank pump and sender. so do you advocate epoxy cover on new connective electrics instead of undercoating spray? implication seems to be that it insulates from moisture better. thanks tons oldduke

|

|

|

|

You have a 3rd row in that 245? Yikes, yes. Might even consider dropping the tank, given that situation?!

My advocacy ends with my experience. In 2027, when I expect I might be revisiting that tarred-up tank bung, I'll let you know whether epoxy should have been poured. You'd need more than a special tool to turn that locking ring.

Thoughts are water, and especially water with dissolved salts, is a very powerful agent. And the terrain of the tank's top provides no drainage whatever. Maybe Plasti Dip? Or build an umbrella dome over the whole shebang. No, these thoughts are a waste of time, except for the trade-offs an automotive designer might have to consider in DeLorean spirit. Those slant-six Dodges never got old enough to exhibit troubles like this?

--

Art Benstein near Baltimore

Sometimes I wake up grumpy; other times I let her sleep.

|

|

|

|

|

hi arty b- from what i have found out the 3d foldup seat facing backwards in my 245 wagon is a rare and highly desirable option in the wagons . the only other tank i saw in the last 60 years like this was the 60 valiant station wagon. actually this seat doesnt seem a very safe thing in either the 245 or the valiant. the volvo 245 i rate a close 2d among the 25 or so cars i have had since 65. the top would be my 77 sl6 dodge aspen. what killed that was rusting at 360k. easiest car i have ever had to work on . did 90% of the repair and maintenance. when i replaced the tank pump and sender unit in the 245 back in 11 i had to buy a bung nut tool to remove the ring holding the unit. that job went smoothly but took a long time. did cuss. does one get kicked out of the brick board forum for using profane language? guess im on my way out. pump was a delco and sender was a vdo. so far no problems with that job. regards oldduke

|

|

|

|

|

Hi Art,

Thanks. I take photos with a normal camera to get good results, I want to share what I find so that others may benefit...

I'm thinking our problems with the feedthrough might actually have more in common than it may seem at first. My 245 has done a "mere" 313,000 km (~195,000 mi), so it would have a little less wear and tear.

When I was removing the feedthrough, I exerted force with a screwdriver in the same places where rust would, and all it did was pull it from the sender unit (1).

But the white stuff and ragged edges may mean that mine was also in the process of breaking up, it was just that the corrosion got to the pump connection first.

Also, if I'm looking at the first picture of your daughter's car's unit, I can't help but think I'm seeing the same slight raising of the epoxy filler. Would you be willing to explore a little more?

I also made some cross sections to see how this thing is constructed (2).

The wires feed in from the top and are soldered onto the three tabs, two of which run into the tank and the remaining one is spot welded to the top of the sender unit.

These solder connections are fixed and shielded from the elements by the grey epoxy filler. But that epoxy doesn't seal the tank.

The actual sealing happens by the tight fit of that plastic cylindrical protrusion into the tank, carrying through the tabs onto which the intank wiring is soldered. The verdigris you saw was from these tabs, not from wires.

The discolouration of the plastic shows exactly what part sticks into the tank, and is hence exposed to the fumes, and what sits in the metal or above. I think your's broke roughly where I sawed through mine.

(1) http://i.imgur.com/gKjc5l2.jpg

(2) http://i.imgur.com/6qBDfJd.jpg

|

|

|

|

|

Don't worry about the photos, they're more than good enough to get across the message.

So that fault with the sender unit was there probably quite a bit longer. Given the amount of verdigris, that would not be a surprise.

Once you get to the epoxy, my bet is that the break will be there, just like with mine. The epoxy did a good job of keeping out corrosion within it as the slice I made from that side was also about 3 mm thick. That short distance down into the epoxy, there was no trace of corrosion to be seen.

The problems really start as soon as water finds it way between the epoxy and the plastic.

At work we use epoxy too to pot electronics. Any spillage would have gone over the edge and left clear evidence. Overfilling would have led to a rounded top that would have set like that for eternity. But you can see on my photo that where the visible part of the epoxy touched the plastic, capillary forces pulled it up to form a slight slope. This can only mean that it was pushed out of the plastic (much) later.

I'm still curious about the white stuff and jagged edges on the bottom side of my feedthrough.

A bit of theorizing later:

I'm thinking that having a relatively heavy top part held into place by a relatively small piece of plastic at the bottom may, over time, have led to cracks caused by vibration. That would allow water in from the bottom, rather than from the top. The expansion of the corrosion then pushes things apart.

I wonder what you will find when you expose the epoxy where the tabs stick out.

And of course what the actual cause of the problem is...

|

|

|

|

Hi Grey,

I've never been able to set the camera right for white plastic. It is worth pursuing so this is my opportunity.

So that fault with the sender unit was there probably quite a bit longer.

Yes, I agree. This "new" car she's had since her '91 became part of the Jones Falls River in April of '14. Wow it isn't that new, is it? Time is really getting away from me, but on her initial oil change visit, I did my tank pump check routine and noted it wasn't operating.

Speaking of photography, gotta give my #1 daughter credit for braving the rising water for this shot. The car was inundated completely soon after this.

Once you get to the epoxy, my bet is that the break will be there, just like with mine.

Yes again. The feedthrough is still in the vise awaiting its next 3mm slice. Meanwhile I got the '93 figured out and immediately 3 more of our LH2.4 Volvos demand immediate attention. Well, they're well past their 17.9 year life expectancy in Sweden.

But you can see on my photo that where the visible part of the epoxy touched the plastic, capillary forces pulled it up to form a slight slope. This can only mean that it was pushed out of the plastic (much) later.

Once again, yes, you're right. Because I'm of the 'never throw anything away' clan, I may be able to dredge up some more samples after sawing this one up. I only wish I'd looked carefully at the new unit before smothering it with tar.

And of course what the actual cause of the problem is...

Root cause... Made me instantly cite my Drip Loop Theory. We've learned so much about the power of water and time, working together. The geography of Norway and a car's design are both challenges in that respect. So much goes into the body design to keep water moving, yet a few flaws remain for the next iteration (we hope).

Anything that gets wired from the top seems to die when exposed to the elements. The time-honored distributor cap is pretty well protected, but the crank position sensor is an early design which fails just like this sending unit from being vertically wired. The 240 fuse panel is a magnet for all the water leaks which end up in the wiring harness. And I think water is getting more powerful (acidic).

I'll be back here with some more slices.

--

Art Benstein near Baltimore

A famous Viking explorer returned home from a voyage and found his name missing from the town register. His wife insisted on complaining to the local civic official who apologized profusely saying, "I must have taken Leif off my census."

|

|

|

|

|

That's a sad sight... luckily your daughter is okay!

I patiently await your discoveries...

I'm wondering, now that my sender unit needed replacement, would it be wise to replace the CPS preventatively?

|

|

|

|

|

Hi Art,

To me it looks like in your case the connection broke slightly deeper down into the epoxy than mine. Looking at how much conductor is left below the bend, I'd say there must have been quite some space between the epoxy and the pot on mine.

So position and cause are more or less the same, but I agree now on the remark you made earlier that water could have found another way in.

Looking at the rust around the ground conductor, and the crack in the plastic around it probably points towards that as the entry point on your unit.

Unfortunately, I was less than subtle while removing the plastic. I just put the saw in it on four sides and pried with a screwdriver. This action destroyed the plastic in such a way that I could not tell for sure wether the ragged edges in the bottom were actually cracks letting in water.

I just found this pic which shows rust near the ground conductor on a place where there should be plastic. So, that must indeed have cracked. And a bit further to the right, it looks quite thin, as if the plastic had been "eaten" away.

I'm still puzzled by the white stuff. Verdigris is green, rust is brown... and then I noticed something in my pics again that I had already noticed but not given much thought, until now.

See how there's air around the pump supply conductor, and that the hole is coated inside with some stuff? Again, looks like the plastic has dissolved. I would have expected the conductor to be the same as the other one, to sit tightly in the plastic. And is that broken down plastic the white stuff?

Why that one... slight heating of this conductor caused by the current draw of the pump?

You might take another slice, but I think you'll find something like this:

Could you also separate the plastic from the epoxy and see if there's the same residue between the two?

|

|

|

|

|

Hi Art,

The parts of this puzzle are piecing together, but I just found something that may make us have to rethink an assumption.

It sure does look like the plastic was eaten somehow. I have no guess for that. Sure there's about an amp and a half being pulled through that connection, but I can't imagine that would result in more than a degree or two of heat -- until the connection broke and started arcing, or got so thin as to be a high resistance point.

I would expect the plastic to just melt when it gets too hot, but I hadn't considered the arcing of a freshly separated conductor, especially on an inductive load like a motor. I went over the forensic "evidence" again and found this photo:

Do I see faint black stuff, like there were indeed sparks? The brown spot in the foreground looks like it may indeed have melted.

This had me thinking, and then I realised that the fuel pump conductor carries a positive voltage while the adjacent ground conductor is at 0 V. If water gets in between the two, electrolisys is going to occur.

Electrolisys turns water into oxygen and hydrogen, add a spark... and you have a little Hindenburg going on...

Two closeups made with a cheap USB microscope:

Corrosion of the conductor wouldn't have attacked the epoxy like that, would it?

To me it looks like there was indeed arcing.

What has me baffled is this: despite brown traces running all the way up to the conductor of the fuel level sender, meaning moisture would have reached it too, there's no apparent corrosion, not even a hint of verdigris.

The pot came off of the epoxy very easily, with just a few light taps. That tells me the gap you saw and the push-out is a good indicator corrosion is expanding things at the bottom of the pot. And the residue on the epoxy next to the plastic looks like yours.

That's the assumption we may need to reconsider.

On my unit, there was no rust pushing at the feedthrough from the outside. Also, when I look at where exactly there was corrosion, it was at the join between the expoxy and the plastic. There didn't seem to be any buildup of anything big enough to force the epoxy out.

I think that the seal between plastic and epoxy is not a strong one. Once it's broken, vribration may result in it moving the direction it can go in: upwards, as far as the conductors will allow.

This photo may support my reasoning:

The left side, where there are no conductors, has moved up noticeably more than the right side. However on that side there was absolutely nothing between the plastic and the epoxy to force it up.

The right side is held in by the two remaining conductors.

Folks on this board are gonna wanna know just what conclusion to make.

I don't think that a definitive conclusion can be drawn based on just two post mortems.

Based on what I discovered by reexamining my photos, I'd say that things go like this:

After many years, the seal between the epoxy and the pastic breaks. Maybe due to vibration, maybe due to ageing plastic, or a combination. The rust in that area suggests that it's not particularly a dry place.

So, the cracking feedthrough gets moist and corrosion sets in, the electrical current to the pump might be the reason why that particular conductor gets attacked much more than the others.

Vibrations continue to attack the plastic until it finally shears off completely.

The common question is whether to buy aftermarket or VDO. Suspicion exists the two are made on the same line. The price difference always drives me to the no-name product, and I cannot tell the difference except where the assembly mistakes arose. Someone with more cajones could order both, examine, and return one or the other, or spend some time with the retailer asking questions.

I too went for the aftermarket replacement. The price differential was just too big to ignore (€79 vs €210!). Next to eachoter, I could not point out any obvious reasons why one would be inferior or superior to the other. I threw the old one away, but I decided to keep the float ball and -arm and the resistive element, just in case.

|

|

|

|

|