|

|

|

My wife reported a strong gas smell. For her to notice it must be bad. Sure enough the fuel sprays (about 3 ft!) out of the larger of the rubber lines in front to the fuel filter/pump when running. I assume this is the high pressure feed to the fuel rail. I've had a replacement fuel filter in my garage for a couple of years so i guess now is the time to install it.

Regarding the fuel line that obviously needs replacement. Looks like the original part is unavailable so I'll have to make my own from pipe and the original fittings? Done some searches and haven't found much. Questions:

1) Am I correct that the complete fuel line assembly is unavailable?

2) Assuming I do have to fabricate my own does anyone has links to instructions

3) What size/type of fuel line (OD/ID) do I need and what is a source - FCPGroton seems to have several sizes. What length is needed from the fuel filter to fuel rail?

4) Do I just press in (with heat?) the two fittings into the tubing?

5) Could I just splice in a small section using a barbed fitting or is this considered too much of a 'kluge' - I'm guessing it is since we're dealing with gasoline.

Any other pointers?

Thanks

|

|

-

|

|

|

Just wanted to close out my original post.

Took a while (due to vacations and other interruptions to schedule) but I ended up following some of the advice in reply to my post in order to successfully replace the whole fuel line and filter.

I bought the 25ft 8mm nylon tube from McMaster. I pressed the banjo fittings in using a caulk gun - drilled out a slug of wood to the the correct diameter (2 1/2"?), drilled it with a 5/16" drill. Cut it in half. Then wrapped it around the tube and squeezed it together with a gear pipe clamp.I wrapped the pipe in tape first to protect it and to provide some more grip. Placed the resulting assembly in the caulk gun. Lubed the fitting slightly with Vaseline and slowly pushed in using the caulk gun. It wants to squeeze off to the side so use your other hand/fingers to keep it pushing straight. After the discussion on here and elsewhere on the internet I thought this was going to be hard but in the end it was pretty easy. Hardest part of the job other than all of the rusted bolts, working under the car etc was undoing the pipe nut attaching the fuel pipe fitting to the fuel rail. That was on tight and I ended up bending the fuel rail pipe a little getting enough leverage with the flare nut wrench. Luckily it survived intact.

No leaks so far. Thanks to everyone for the pointers.

|

|

-

|

|

|

Nice work identifying the caulking gun as the lever you needed. I'll remember that because it is brilliant.

--

Art Benstein near Baltimore

People who live on that "New Car Smell" and have their Credit Score memorized better than their own birthday will ALWAYS say you're Crazy. -punk240 Tim

|

|

-

|

|

|

Anybody try polyurethane covered with stainless steel cover? Thousand psi, probably rugged? Might eliminate a lot of fooling around with tubing return connected to rubber, nylon swagged, connected to whatever, and related worries? I got the same dripping problem on rusting return line now, '88 240. thanx for any opinion.

|

|

-

|

|

|

Sounds expensive. Can you show your work?

--

Art Benstein near Baltimore

"Freedom of speech gives you the absolute right to pose any question you like based on whatever unsubstantiated assertion you care to make."

|

|

-

|

|

|

Haven't repaired yet. Rusted through return line going up to the rubber line to tank. Was gonna drop the whole line from the pressure regulator, lay it out on the floor, bend some brake line to match, attach rubber lines, and re-install. But now I'm thinking there may be an easier way. A single line return properly installed, one shot, two clamps, low pressure anyway. Probably won't rust ever again in my lifetime. I'll be in touch.

|

|

-

|

|

|

You can use the stuff Volvo used, available cheaply as Bundyweld. Not stainless, but yes, it will hold up for the majority of our future expectations, and it fits the car perfectly -- no surprises. Easy to bend and flare.

--

Art Benstein near Baltimore

Always keep several get well cards on the mantel. If unexpected guests arrive, they'll think you've been sick and unable to clean.

|

|

-

|

|

|

Wait, if it's this line, it's absolutely available:

http://www.eeuroparts.com/Parts/84757/Fuel-Line-Filter-To-Injector-Rail-3547865/

I just had to replace mine.

If it's the short line from the main pump to the filter, that's also available from eeuro.

|

|

-

|

|

|

great find.

geewhiz what a hosing for a bit of nylon and two fittings.

|

|

-

|

|

|

Yes Ted, I agree in that it is valuable knowledge for a person in a pinch!

Past that pinch and the hosing though, for whom is that a reasonable price?

The cars total length is what 16 ft. Long! That's what about $10+ a foot?

I can buy a one inch X a foot long, solid nylon round bar, in many various flavors for less. Material volume or weight wise, it does not compute.

Regular fuel line, is what, a $1.25 from those department store, "MACY's like," parts houses.

I looked up your specification and its minimum burst pressure is 175 psi.

It must be the clamping/sealing techniques used that making these a special but not exclusive!

This might be a "on the shelf item" or made up on a "placed order basis."

Some nice paying job, if you can get steady work doing it at that price. I bet it's not working that way, even in China!

Still ... Just where does the retail pricing blend into being a your-tail pricing?

To me there is no reasoning to justify it except the need for greed.

Plain silly huh?

From what I can tell, you don't think like outrageous parts in your business.

I picked up several Ford O2 sensors, for about $10, on your advice off the internet.

You spotted them.... Great deal!

Like we know they use the same principle of operation. I bet Bosch licensed it until all the patents wore away. It works and spark plug type housings are simple. It has become the "wheel" in emissions control world!

Of course, a different wire connecting game is still being played! A.H.'s

Cheap tricks that make me everyone mad or drives us mad!

I think you would agree that any reasonably price in labor or items, will always bring in more business!

Wake Up America!

One of the latest thoughts and there are many around the world, are "Show it to the Americans, they will buy anything!"

Love my wife, like my Volvos but money, it's too cheap to hold on to, apparently!

Phil

|

|

-

|

|

|

It's expensive, but it is nylon fitted to two banjo fittings, and it has various heat shields along it. You could probably make one for cheaper, but how much is your time worth?

I had to replace mine because the surfaces of the banjo fitting at the filter had corroded, and when I tried to put it back on after replacing the fuel filter, I had a massive fuel leak. The banjo fitting surfaces wouldn't mate no matter what. I was happy just to obtain the part quickly and get the car back on the road.

|

|

-

|

|

|

Wow -- valuable post!

--

Art Benstein near Baltimore

“The single biggest problem in communication is the illusion that it has taken place.” George Bernard Shaw

|

|

-

|

|

|

based upon reading your request i conclude you have no idea what you are doing.

before you get in a snit this is said as my perception not judgement. fuel lines are dangerous to fix badly.

your line is nylon. it handles pressure really well but can be slit in a heart beat. the fitting coming out of the filter and the fitting into the rail at the block are press in. this is not just squeezing with your hand while holding the line with the other hand. there are tricks to unite these two elements. frankly i think in your case its a bridge to far so i offer a simpler solution which will work as well.

http://www.ebay.com/itm/400657738782

the link above is for fuel rate hose which will slip over the filter fitting once you cut off the nylon and the same at the rail end. two "good" made for fuel line hose clamps will secure the hose to these fitting. snake the line under the car following the original pathway securing the new line to the frame with tiny cable ties where applicable and you ought to be back on the road in no time.

if you insist upon mating the fittings to nylon line reply as such and i will provide a method to do so.

ebay is also a good source for nylon fuel line

|

|

-

|

|

|

I'll try and ignore you're unnecessary condescending comment. I guess my Bachelors degree in Mechanical Engineering isn't enough for you.

In any case you did provide some useful information. Sounds like the assembled part is unavailable (except at a junk yard). The tubing is nylon and the fittings do need to be pressed in.

I haven't taken the bad fuel line off so don't know the required size. I seem mention of 6mm ID, 8mm OD around the internet. That seems about right based on eyeballing it. Art's post seems to indicate 5/16" OD (0.040 wall) will work and indicates that heat helps as I alluded to.

Pointers to press in the fittings would be appreciated. I don't intend buying any fancy tools. I see some talk of creative use of caulk guns and others that have used blocks of wood clamped around the tube. I also see your own recommendation of using metal/plastic tube over the nylon tube. Is this the technique you were alluding to?

|

|

-

|

|

|

I have Bachelors and Masters degrees in Engineering and the hands-on guys on this BB have saved me from making numerous mistakes, and helped me recover from the ones where I forged ahead in confidence my classroom theory should be all I needed. Education is good, experience is usually better, and when the two are combined, you have many of the gurus on this BB. Consider carefully what they say.

--

Bob: Son's XC70, my 83 244DL, 89 745 (Chev LT-1 V8), 98 S90 (recently sold) and 2010 XC60. Also '77 MGB and four old motorcycles

|

|

-

|

|

|

I do carefully consider what the experts say - hence my posting here and asking/getting information. And I agree experience is most important. I just object to unnecessarily condescending comments based on interpretation of my asking a few pertinent questions. I know its the internet so the danger is it gets unpleasant quickly but I thought this board was one of the more civil. In any case, I'm over it.

|

|

-

|

|

|

as you wish

http://www.ebay.com/itm/New-2-Pc-Tubing-Pipe-Flaring-Dies-Tools-Kit-3-16-5-8-Flare-Tubing-Air-Brake-Line-/321347367498

the tubing receiver makes for a snug nylon tube holder while you tap in the two fittings.

do not use heat as it can alter the integrity of the nylon as it clamps to the fitting

a small bit of lubricant on the fitting end will facilitate its installation

|

|

-

|

|

|

I just went through is on my 83 Turbo. Look at Art's post, lots of good info there, especially about not nicking the barbs. I used 8mm OD, bought from McMaster-Carr in the 25' length, and used every bit of it.

The heat method didn't work for me though. After heating it with a heat gun and getting the barb in, looked perfect, reinstalled everything, LEAK! Try doing that several times, talk about being P.O.'d.

With the heat method I could not control how tight the tubing would clinch the barb. I went with the wood block method, made with OAK.

Drill a hole slightly smaller than 8mm, through the block, saw through the block lengthwise bisecting the hole, install wood screws at all four corners, then at one end enlarge the hole so it will except the barb and tubing. It should be a little bit deeper than the barb, so it doesn't get pinched at the end. Put the block in a vice with the tubing flush with the larger opening, Now tap in the fitting. If the tubing wants to slide, put some vinyl tape on it and reclamp it.

The process is called SWAGING, that's what worked for me.

--

Bruce S. near D.C.

|

|

-

|

|

|

I'm surprised you were unsuccessful with heating. Not surprised it didn't work the first time, but after repeated attempts, because this sort of practice is exactly what is needed to help adjust the amount of heat needed.

There's a point, which we cannot describe in words, where the nylon stops being softened and begins actually melting. I think this is close to 200 degrees F, and the reason the book might suggest boiling water as a heat source.

Of course, once the nylon melts, it will not shrink back. My technique was also swaging, but the swaging force needed is tough to deliver to a somewhat flexible tubing; holding it is the problem you solved with the oak equivalent to the tubing clamp used in a flaring tool.

When I heated the tubing with the heat gun, I was applying that swaging force at the same time with the tubing clamped in my left hand, as much as I could, as the heat gun was manipulated in my right hand to GENTLY warm the very end of it. Being careful to confine the heat to the 3/4" at the end, so the swaging force would not distort the pipe further back was the tricky part.

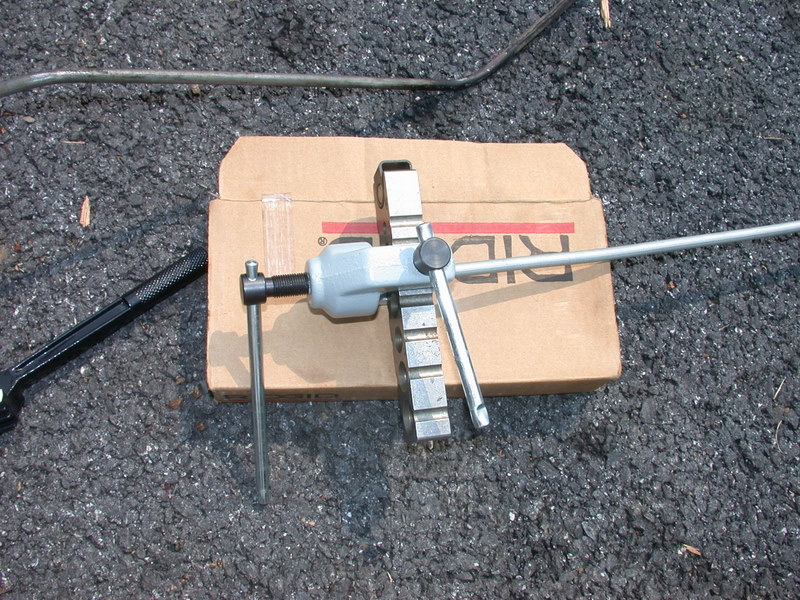

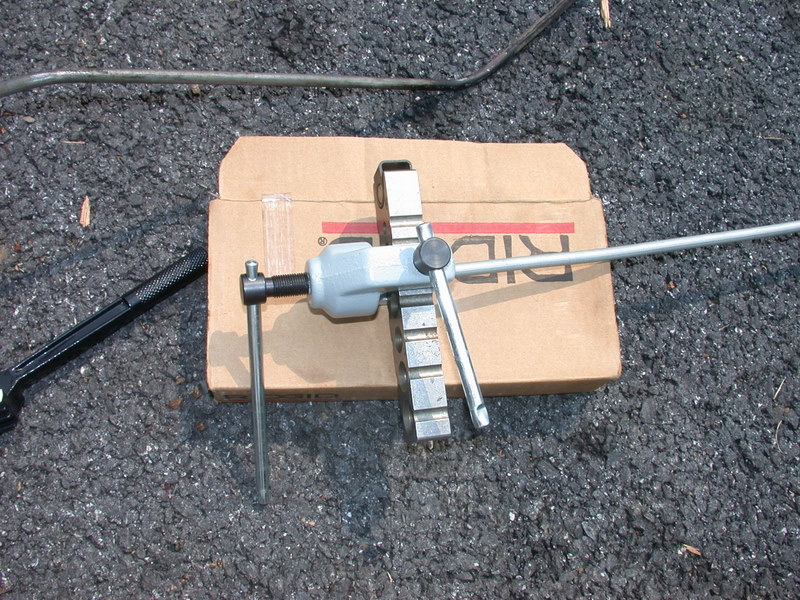

But next time, I'm going to make a clamp like you did. My experience with those for flaring metal tube makes me ask: what length did you make your clamp? In other words, how much of the tube's length was in the clamping portion of the drilled hole? Have a photo? I love the vinyl tape fix, too.

--

Art Benstein near Baltimore

"I don't think you can get cold in Volvo 240 series. The AC can't do it and the heater won't let you." -darkdelta

|

|

-

|

|

|

My block measures 2 5/16 inches tall, and 2 5/8 inches thick.

Here are some pics. I used some very fine sandpaper in mine to combat the slipping problem.

That left some mild abrasion marks on the tubing, hopefully these will not develop into any kind of stress fracture in the future. Hence the reason I recommend vinyl tape if you require a tighter fit.

--

Bruce S. near D.C.

|

|

-

|

|

|

Perfect, Bruce. Thank you!

|

|

-

|

|

|

My block measures 2 5/16 inches tall, and 2 5/8 inches thick.

Here are some pics. I used some very fine sandpaper in mine to combat the slipping problem.

That left some mild abrasion marks on the tubing, hopefully these will not develop into any kind of stress fracture in the future. Hence the reason I recommend vinyl tape if you require a tighter fit.

Sorry this is my first time adding pics, I was trying to add several pics to one post and duplicated the post with one pic each.

--

Bruce S. near D.C.

|

|

-

|

|

|

Or, he could read about how I did this, providing neither he nor anyone else labels this as a "tutorial", or "instructions."

http://cleanflametrap.com/fline.html

--

Art Benstein near Baltimore

All the trouble I've ever been in started out as fun.....

|

|

-

|

|

|

hi art

this fellow is about 15 miles from me.

http://www.ebay.com/itm/130211483659

|

|

-

|

|

|

Amazing to me is "325 sold."

Can there really be that many of us out there??

--

Art Benstein near Baltimore

Why is it that doctors call what they do 'practice'?

|

|

-

|

|

|

i suspect many of his customers are like me and bought a handful. when fixing a car there is nothing quite as satisfying as walking to a shelf and removing just the right item needed 20 feet from the problem.

by the way art i loved those little red door stops you used in your fix a fuel line montage.

|

|

-

|

|

|

Where did you get the second set of ramps, I think I will pass on the red set!

Dan

|

|

-

|

|

|

Those either Rhino Ramps or the knock-offs. I love mine and have had the same set since shortly after they became available.

|

|

-

|

|

|

Yes, Rhino Ramps. The chocks and the ramps both were picked off of the shelf in a Walmart, probably about 10 or 12 years apart. I gave my old steel ramps to the neighbor for his Cavaliers. They would not fit under the Volvos.

I saved the uncrushed chock, and have used it since, but NOT on a gravel-covered hill.

--

Art Benstein near Baltimore

Broken corn chips often resemble Minnesota.

|

|

-

|

|

|

If you have a junk yard near by you may be able to get a complete set.

Dan

|

|

|

|

|