|

|

|

Hi all,

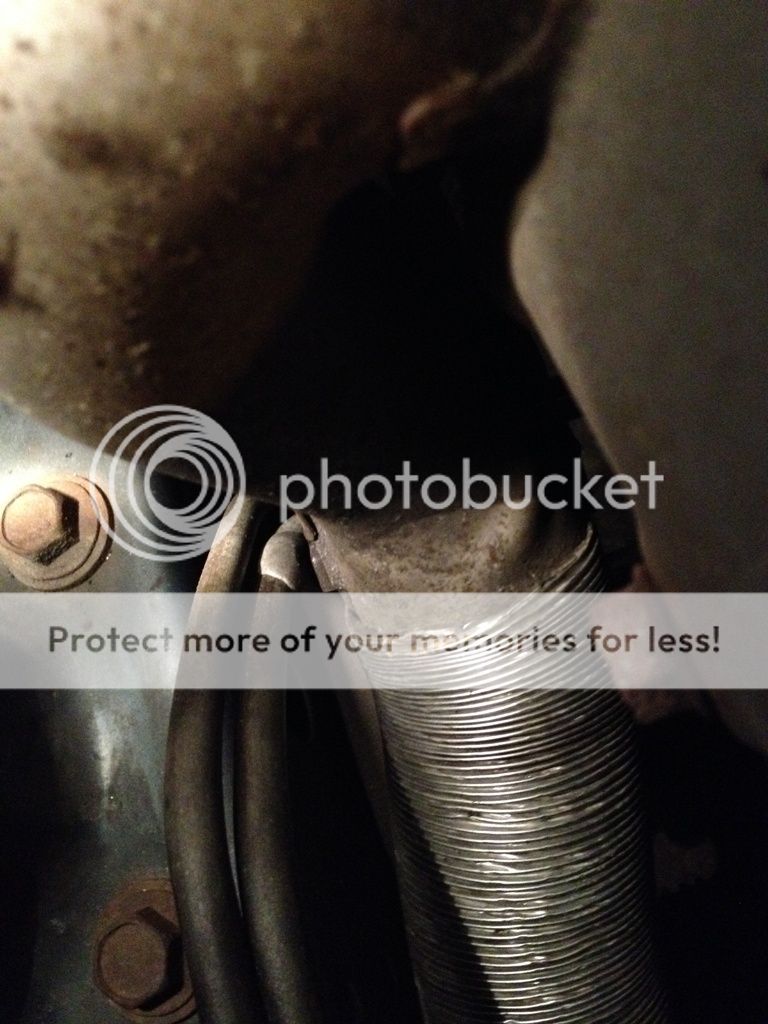

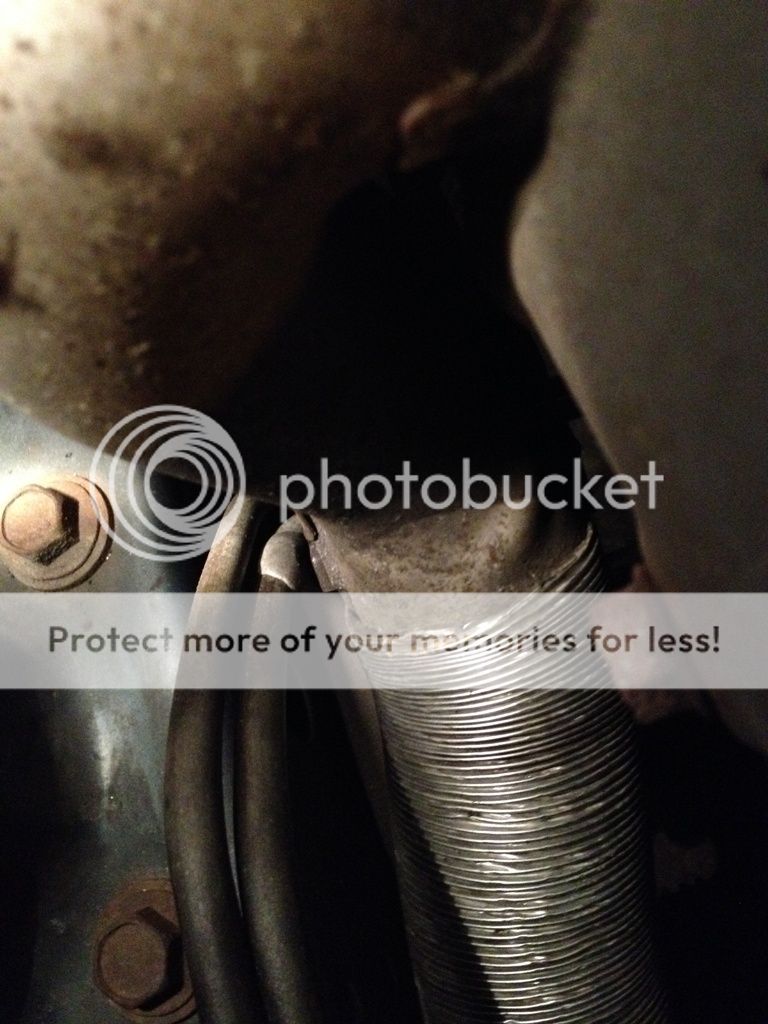

I can't tell which line is leaking but it looks like there is more than one leaking source. I was hoping to cut a section of tube and slide over 5/16" fuel line/clamp it. I may have to replace the both lines.

How hard is it to disconnect lines at transmission? It looks very tight in there, do I need special tool to reach in there? I just have a set of combo wrench.

The BQE is just killing my Volvo faster than I expected. I am pretty sure that the most of roads are just as bad. BTW, I did put rubber spacer by the clamping area like you guys recommended but it didn't help.

Thank you as always.

|

|

-

|

|

|

For such an old fitting at your radiator, use only a flare-nut wrench to avoid risking the nut. And use a good amount of PB-Blaster (a rust release spray) over a few hours ahead of time.

If you're not familiar with what a flare-nut wrench is, imagine a 6-point box wrench (don't ever even think of 12-point wrenches for any work) that goes all the way around a nut, but with a small section cut way (to pass a line through it) so that there is still just a little portion of wrench that grasps the fourth and fifth lands of the nut on both sides. The advantage is that the wrench is grasping (let's say) 4-1/2 of the six lands, instead of maybe two of them with a traditional crescent wrench. A flare-nut is far less likely to slip and round the nut's high points.

You can get a flare-nut wrench of the right size at most automotive parts stores, and some big-box stores in the tools department.

And if you think you need more room to rotate the wrench, you can even buy a "crow foot" socket in a flare-nut style -- this allows you to put a socket extension on an offset flare nut end of a wrench, so you can still grasp the nut securely, but you turn it with a socket handle some distance away. This makes working in tight corners easier.

Below is a photo of two of my crowfoot sockets in flare-nut style:

|

This post has been marked as an answer to the original question.

|

-

-

|

|

|

I feel your pain, I just took a set off a car it wasn't fun!

Dan

|

|

-

|

|

|

Hi jwalker, Dan, Ken and Dave,

I used a small patch of JB SteelStick. I just put over 50 miles and it's holding up very well. There is no more leak. Again and again, I just want to thank you for everyone.

BTW, what's an average product span for unused JB SteelStick?

|

|

-

|

|

|

"what's an average product span for unused JB SteelStick?"

Useful stuff. I keep one in my car. Dries out over time but can be revived a bit by dipping it in water while squeezing it.

--

1980 245 Canadian B21A with SU carb, M46 trans, 3:31 dif, in Brampton, Ont.

|

|

-

|

|

|

Hi Trev29,

Thank you for the tip. I will cut in three pcs; one chunk for MD, second one for NY and one in my car.

Happy Friday.

|

|

-

|

|

|

Hi all,

Even after 5000 miles, a piece of metal putty is holding up pretty good. As Lucid/Bruce mentioned on his past threads, it's low pressure so I figured it's going to be ok. As a late preventive measure, I placed a bigger rubber piece by the line holding bracket area and wrap the cooling lines with heavy gauge vinyl sheet before I clamped them together.

I bought a set of used cooling lines, it's very "burnt" dirty inside. I would like to clean it and set them aside for back up. Should I use brake cleaner to clean them? What's the best method for cleaning?

Thank you as always.

|

|

-

|

|

|

Yes, brake or carb cleaner would probably work just fine. Be sure to get it all out before installation.

|

|

-

|

|

|

Hi Ken,

Thank you for educating me. I have seen them but I hadn't a clue when to use them. Now, I know. Thank you for your very detailed description and beautiful picture!

I got it! :D

|

|

-

|

|

|

I have a good set of lines already off a car - and line wrenches if you want to use them. Let me know---Dave

|

|

-

|

|

|

Hi Dave,

I was able to return those lines and we had a good laugh. I will buy/pick up your set when you have time. Thank you.

|

|

-

|

|

|

Hi Dave,

A little late... but I thank you so much! I did placed an order from the Volvoville guys. I don't think I can return special order items. I will bring it up see what they say. I do make very aggressive decision when it comes to fixing my car.

I just sent you a private email. :D Thank you once again.

|

|

-

|

|

|

The BQE is like driving through a war zone. I drive in Boston regularly and NYC occasionally and it is one of the worst roads I've ever driven on. Good luck....:)

Sorry can't help you with the lines. Didn't replace mine. Cut them and patched them back together with fuel hose. Worked, but not the best method as still leaked a little.

|

|

-

|

|

|

Hi jwalker,

I needed that pep talk. It's not my Volvo, it's the road. ;-) LOL

I am hesitant to use a fuel line since it's right next to the exhaust manifold cover, it gets so hot...

I got a bottle of JB weld for quick fix while I am waiting for the parts.

Thank you as always.

|

|

-

|

|

|

My pleasure, SB!

My lines were cracked at the small frame clamp further back so heat wasn't such an issue for me.

Other BBers have cut them and used some sort of compression(?) clamp to pull the line back together. If interested, try a search for more info...

|

|

-

|

|

|

Hi jwalker,

I did look into that compression sleeve/fitting... but the leak is right at the bend. Also, it scrapped off a junk of metal.

I only put rubber pads at the bottom mounting bracket area. A big no no.

BTW, where is Klaus?

|

|

-

|

|

|

You're right. Klaus hasn't been on the BB much lately but he is still around. Probably enjoying his retirement and staying away from his computer as much as possible...:)

|

|

-

|

|

|

I hope he comes back. :-)

|

|

-

|

|

|

Check out this thread....

http://www.brickboard.com/AWD/volvo/1589600/V70-XC70/oil_tb_timing_gear.html

|

|

-

|

|

|

He's just amazing. One of many great Brickboard member like yourself! Happy Friday.

|

|

-

|

|

|

Looks like it is time to replace them.

Dan

|

|

-

|

|

|

Hi Dan,

Yes, it was pretty much beat up when I got it. The new line is $71.50 each at a dealer. I decided not to pull ones from my 93 Swedish Toast. You just motivated me to try again! I know it's a long way to go but I want to try one more time.

Thank you as always.

PS

Just put a patch of JB epoxy putty and based on the impression, it looks like the leaky hole is about 1/32" diameter.

|

|

-

|

|

|

I would suggest junk yard replacements but they are just as old as what you have. You might find one with the elbow you need and splice it in with compression fittings.

Dan

|

|

-

|

|

|

"You might find one with the elbow you need and splice it in with compression fittings."

Hi Dan,

Very clever and fluent in thinking. Thank you. Happy Friday, almost... :-)

|

|

-

|

|

|

Hi all,

The lower cooling line is leaking. It's by the heat shield cover, I am guessing that it scraped on the sharp metal flange. I have found only one leaking source for now. Can I use a metal epoxy to patch it up?

The cooling line connection at the trans looks doable but I would appreciate if you can share your advice or tip.

Thank you as always.

|

|

|

|

|