|

Oh, a 940. Well, that prolly doesn't make any difference -- My beliefs about the composition of the pipe are based on just what you said -- it has the original through 300K of salty exposure, while the rest of the exhaust system may have been changed several times.

Dunno if the nickel added is enough to keep keep it shiny, but I checked my stash of old cats (slated for reclamation) and they have a patina of rust, but remain quite solid. I think it was a requirement, even then, that the catalyst be warranted for 10 years.

A magnet is attracted less to them than to one of the head pipes they're stored with, so I figured it cracked due to being more brittle than mild steel and under some stress. Could it be some of that life in Wisconsin was under the care of someone else?

Maybe the stress is long gone, fixed in a previous repair, but the crack originated then?

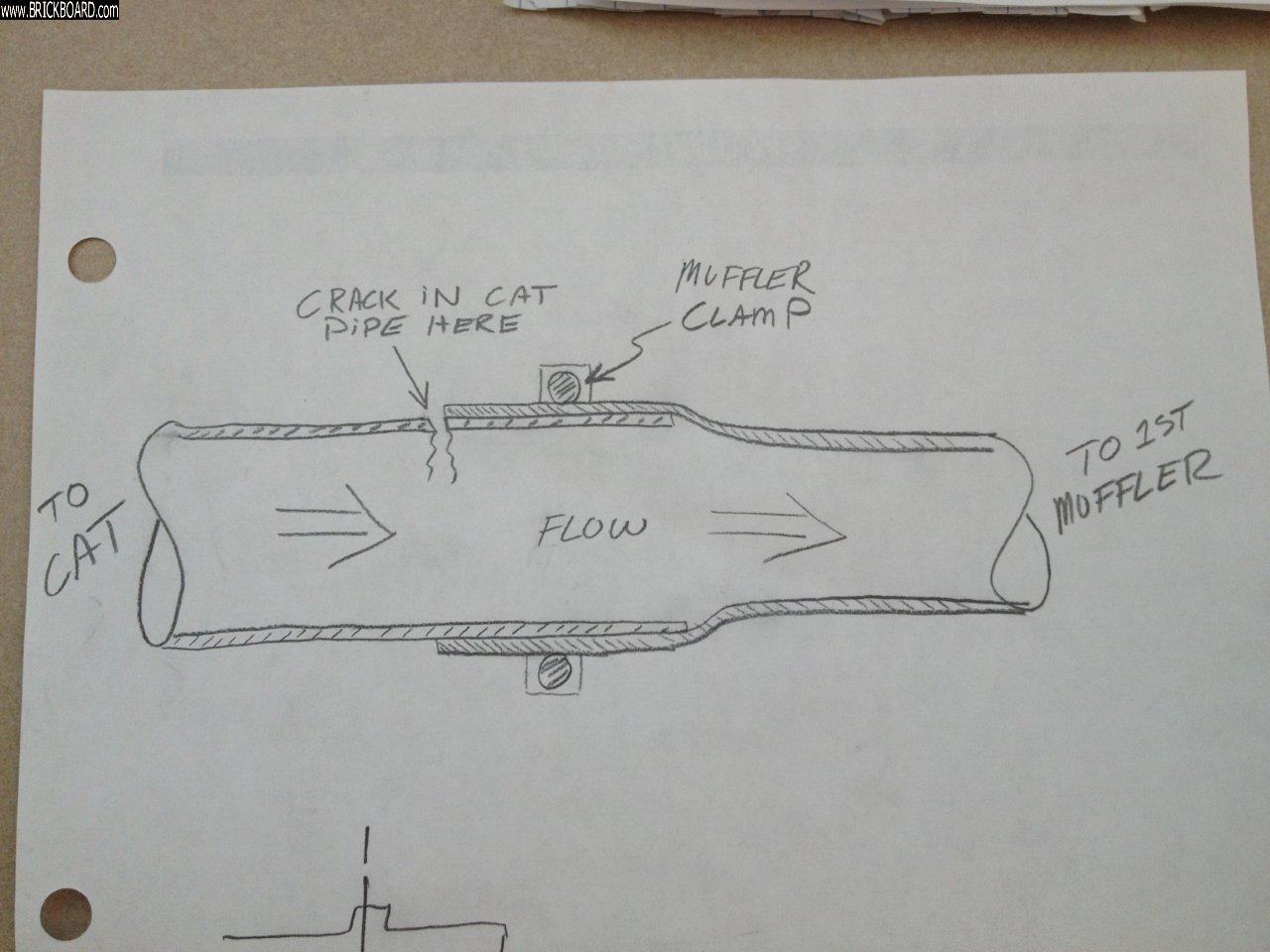

Either way, unless you have a warm shop or a good rapport with a muffler shop, you might want to go with the band-aid. This bandage they sell at Walmart. That was a Walmart parking lot where I took the photo, in Michigan. After getting home that fiberglass-based material was like heat-shrunk cement. I know it would have lasted months.

--

Art Benstein near Baltimore

Two peanuts walk into a bar, and one was a salted.

|