|

|

|

I'm in the process of restoring my '79 242GT. I had all the fuel system taken apart for cleaning and repainting, when I saw that a section of the high-pressure steel hose had rusted almost entirely through. It had actually broken open just behind the tranny crossmember just from the weight of the line.

So the question--how sketchy is it to just cut out the rusted section (about an inch), slightly flare the ends, and double clamp in a piece of rubber fuel line hose? Should I just replace the entire thing with rubber hose? I'd rather not deal with even more replacement parts . . . the full restoration job has already cost a significant sum. However, if we're looking at highly dangerous repair, I'll just put in new lines.

Opinions? Thanks!

Nate

|

|

|

|

|

Just thought I'd update everyone.

I did end up ordering and making new fuel lines--both high and low pressure. A 25-foot coil of part number 5176K24 from McMaster Carr was enough to do both, with four or five feet left over. I used a few of their brass fitting as well, part number 50635K563, in place of my rusted old ones.

As I pondered buying a $50+ tool to make four double flares when I already had a cheap-o-matic one, a thought struck me. The biggest problem with mine is that it doesn't hold tight enough to the tubing, so it slips. What to do? I got out two 4" C clamps and clamped that sucker on either side of the flare pushing part. Not one slip!

I did mess up a couple flares when I didn't have things quite straight, but it worked fine, and I just saved myself $50.

Now those rusty lines are in the garbage and the new line sparkes as it waits for me to finish up some engine bay painting prior to install. Yippee!

Thanks again, all who helped and gave thoughts.

Nate

|

|

|

|

|

Why use steel?

The newer 240s use nylon. Couldn't you pull the fuel line from a PnP?

For my carbed 240s, I replaced with 5/16" refrigeration copper line. Fuel pressure is lower for carbs, (it's -ve since it's sucked), but the lines can handle high pressures.

--

1980 245 Canadian B21A with SU carb, M46 trans, 3:31 dif, in Brampton, Ont.

|

|

|

|

|

Can the line be installed in one piece?

Have you actually priced a complete replacement?

If you have bad luck, you could end up with with no car and even some injured friends and relatives to boot. What if someone else is driving your car?

If the line springs a leak, how much fuel might come out before the car gets shut off?

How many GPM does your car pump?

THe fuel system is a REALLY poor place to save money.

--

'96 855R,'64 PV544 driver, '67 P1800 basket case, '72 Yamaha Rd400, '68 Honda 350-4, '12 XC70, the first 5 are mine, heh, heh, 525,000 miles put on 10 bricks James A Sousa

|

|

|

|

Art does it right, no question there. I also do some flared fixes but have probably gone the cheap route more often.

By cheap I mean using 5/16" OD copper tubing sections mated to the still solid steel remains with 5/16" ID Compression Unions. That even goes for 3/16" OD brake lines, using JY remnants of Volvo copper-nickel tubing. Never a problem due to materials or method in all those years

(I'll be 83 in May.)

--

Bruce Young, '93 940-NA (current), 240s (one V8), 140s, 122s, since '63.

|

|

|

|

Hi Nate,

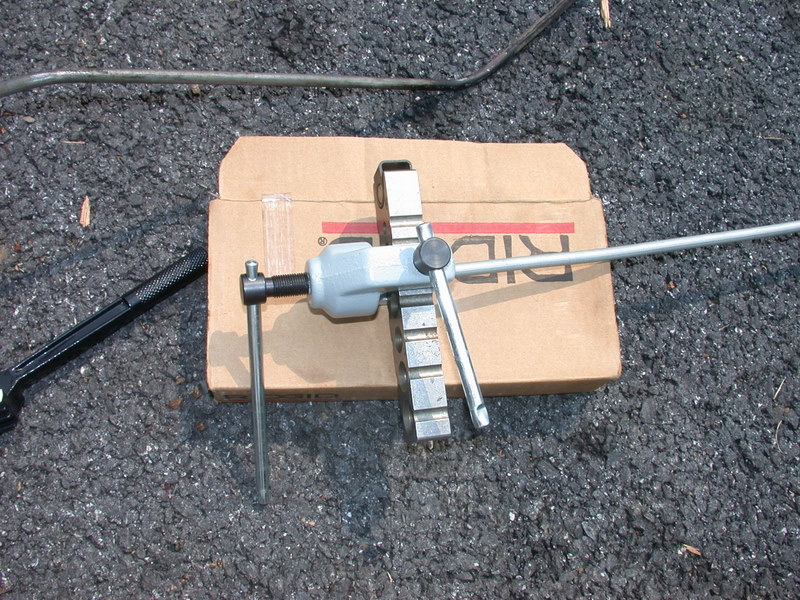

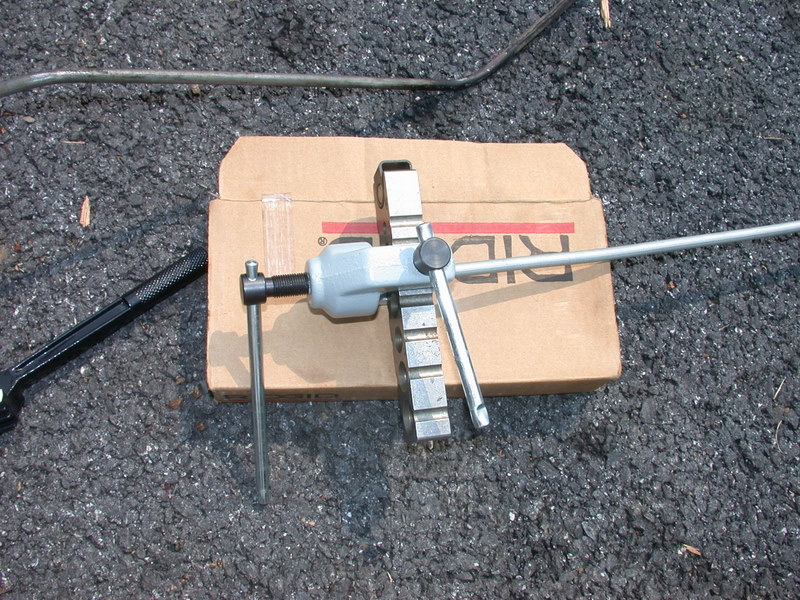

I took that same job (79) as an opportunity to learn how to bend and flare the 5/16 steel line. The skills didn't go to waste, because the auto tranny cooler lines use the same materials and fittings. First investment was in a decent flaring tool -- one that would properly clamp the pipe from being pushed back by the first component of the double flare. The tools at Sears and the auto parts stores would not do, so I waited until a decent Ridgid set appeared on ebay. (those and Imperial were given the most kudos at the time) The pipe, Bundyweld, is available locally, but I purchased from McMaster-Carr in 25' lengths. The bender I used is the most ordinary of multi-diameter benders, worth about $10.

--

Art Benstein near Baltimore

One day, a man came home and was greeted by his wife dressed in a very sexy nightie. 'Tie me up,' she purred, 'and you can do anything you want.' So he tied her up and went golfing.

|

|

|

|

|

Thanks, Art, for the pictures and info! Like most things on this car (grumble, grumble), I fear I am just going to redo the entire thing. The hard lines going to the tank should probably be done, too. It has been a massive snowball effect, but the car is going to be like a four- or five-year-old 242GT by the time it's finished.

A couple questions:

1) I'm McMaster-Carr has the fittings as well? What thread are they? What are they called? I"m striking out looking them up . . .

EDIT: I think I found these on this page:

http://www.mcmaster.com/#brass-flared-tube-fittings/=luyghr

I assume brass fittings are what I want?

2) Do you just double-flare the pipes like a brake line to fit properly? I have a cheapish flaring tool, but I'll probably just have to buy the Rigid tool. Does it do double flares? I guess I have the double flare adapters from my cheap tool that should fit on the Rigid.

3) Would 25 feet do all the lines? Like everything else on this car, if I'm doing it, I might as well do it all. With my luck, I'd probably need 26ft. Hah.

As always, thanks for the suggestions and info. When I get it all done, pictures will definitely be put up.

Nate

|

|

|

|

Hi Nate,

Here are some quick answers. Sorry for the brevity.

A couple questions:

1) I'm McMaster-Carr has the fittings as well? What thread are they? What are they called? I"m striking out looking them up . . .

EDIT: I think I found these on this page:

http://www.mcmaster.com/#brass-flared-tube-fittings/=luyghr

I assume brass fittings are what I want?

The originals were steel. I made the mistake of ordering metric nuts even though it had already sunk into my head the pipe was 5/16" not 8mm: The correct nuts thread easily onto a 1/2-20 thread, like our 240 wheel studs. Anyway, I just re-used the old ones. I'd probably re-order the 50365K553 but I do have a lot of old ones in the junk box.

2) Do you just double-flare the pipes like a brake line to fit properly? I have a cheapish flaring tool, but I'll probably just have to buy the Rigid tool. Does it do double flares? I guess I have the double flare adapters from my cheap tool that should fit on the Rigid.

The Ridgid tool (yeah they spell it with a D for Ridge Engineering) didn't come with the adapters for the double flare. I used the adapters from one of the cheaper sets.

3) Would 25 feet do all the lines? Like everything else on this car, if I'm doing it, I might as well do it all. With my luck, I'd probably need 26ft. Hah.

Have no idea. I just replaced the return line. The rust was aft of the main pump, and the pressure line was still in good shape. I've since purchased more coils because I've made a set of transmission lines too.

For Steve, on the tips, from the stupid mistakes category: Make sure the tubing nut is slid down to the end before putting a ninety bend it can't get around. Mistakes like that can cost you a second roll of tubing, but in trade you get lots more experience. ;)

--

Art Benstein near Baltimore

Annual Performance Review Time...

"Since my last report, this employee has reached rock-bottom and has started to dig."

|

|

|

|

|

Art....Once again you've shown that a picture is worth a thousand words.

steve

|

|

|

|

|

Thanks, Art! I appreciate the brevity. Helpful and succinct.

I ordered bits.

As general info: I took both lines off the GT last night. The high pressure is about 7' long and the return hose is around 10'. Barring horrible errors, 25' should be plenty.

In taking off the low pressure line, I had to twist it a bit to get the nut started in the back, and the rusty part of that one immediately sprung a leak. I guess it is time to just do it all.

I hooked up the rear brakes again last night--new SS lines, and the bracket and proportioning valves have been cleaned and repainted. Looks much better now, and no rust!

Nate

|

|

|

|

|

Art, any more tips on DIY steel line fabrication? Looks like you're an expert.

|

|

|

|

|

See the currently running post regarding the replace/repair of auto tranny hard lines. You can make a fuel hose splice if you use proper fuel injection hose--and the type of clamps that don't have the "threads" digging into the rubber. If you go that way I wouldn't make any flare--double clamp on each side.

Since you've put the work into a restoration a better solution-short of replacing the entire pipe-would be a splice with pipe and compression fittings. -- Dave

|

|

|

|

|