posted by

someone claiming to be teal 240

on

Sat May 29 15:30 CST 2010 [ RELATED]

|

|

The old Brick started her oil pressure light flickering after a freeway run last week. I replaced the pressure switch and checked the wire and thought it was going to resolve it. After another high speed run; I still get a flicker at idle. I have noticed a loafing un even idle and if i give it a bit of gas, it stops flickering. I noticed that the idle speed when coming off the gas, dips low and I think that could be what's causing the low pressure. how can I bump up the idle? Anything else I should look at? The engine has 159k well cared for miles, so it shouldn't be the pump, right? Thanks in advance!

|

|

|

|

|

The horror!

It is likely the oil delivery tube seals, one of the most bitchin' 240 repairs known to man. A few years ago I had the pleasure of doing it TWICE in quick succession on the SAME car.

Shortly after I bought a really nice '93 sedan and switched to synthetic, the oil light started to flicker when lumping around a parking lot at low speed. The oil pressure gauge was also reading low after high speed runs. After checking all other possibilities and hooking up a known-good mechanical gauge, I could not avoid the truth of the matter - the oil pressure was low.

Although I thought it was nearly impossible to need an oil pump on a 240, I bought a new one in preparation for the royal pain-in-the-ass of dropping the pan. Once the pan was off, I found the upper seal on the oil delivery tube was partially puked out of its bore. Also, the seal was black which I had never seen before in a 240, so I assumed someone had been in there before and had installed some aftermarket junk seal. BIG MISTAKE.

I installed a couple of OE Volvo seals and, after checking the seating of the seals a half dozen times, figured I had wrestled this pig to the ground. BIG MISTAKE #2.

Before I buttoned up EVERYTHING which had to come off to drop the pan, I ran the engine for an hour or so with a mechanical oil pressure gauge in place just to make sure the pressure was kosher. Once it checked out, I finished the work and lowered the car to terra firma. BIG MISTAKE #3.

As soon as I took the car out for a high speed run, the oil pressure came up lame again! This was getting serious - new oil pump, new seals, same problem. I went through the drill of dropping the pan and I found the upper seal puking out of its socket, again - this time a Genuine Volvo seal.

After MUCH consternation and careful measurements against another block, I concluded that the lead-in (chamfer) of the bore in the block for the upper delivery tube was excessively large. That coupled with the formed shoulder bead on the newer style oil delivery tubes and the ability for synthetic oil to find its way though any gap, caused the seal to slip out of its recess once under high pressure. At least that is my read on what had happened.

In order to keep the seals in place, I machined a couple of short collars (about 2mm in length) which were a sliding fit in the oil delivery tube bores and silver soldered them against the beads on the delivery tube. This provided a good flat for the seals to seat against and held them more deeply in the bores.

Also, I stopped using the synthetic oil. That might be an unnecessary precaution, but I NEVER want to revisit that whore's nightmare again!

Rich

|

|

|

|

|

the more relevant question u need to ask and answer is why is is light flickering. your manual tells you the flicker comes on once oil pressure reaches something like 10psi or even a bit less.

since you have a 93 i will go out on a limb and say .....since you replaced the sender and no change occurs you have that oil pump to block return line o gasket problem. i have repaired 2 of these......240 and 940 and they are not fun to do but must be done or you will loose your engine down the road once the rest of the o gasket lets go.

to confirm remove the oil sender from under the oil filter and thread in temp a manual oil pressure gauge and measure........at cold idle, hot idle and at 2000 rpm hot. if you are not within factory specs suspect the o gasket on the oil pump return line where it joins the block has pulled partially out.

the jobs all labor and a lot of it. part are: o rings.....2 bucks or less and pan gasket 10 bucks.

|

|

posted by

someone claiming to be Teal 240

on

Tue Jun 1 10:25 CST 2010 [ RELATED]

|

|

Thanks for the advice. Harbor Frieght has an oil pressure gauge tool for around $9, I assume that it will fit the threads? anyone have experience using one of these? Thanks in advance, Greg

|

|

|

|

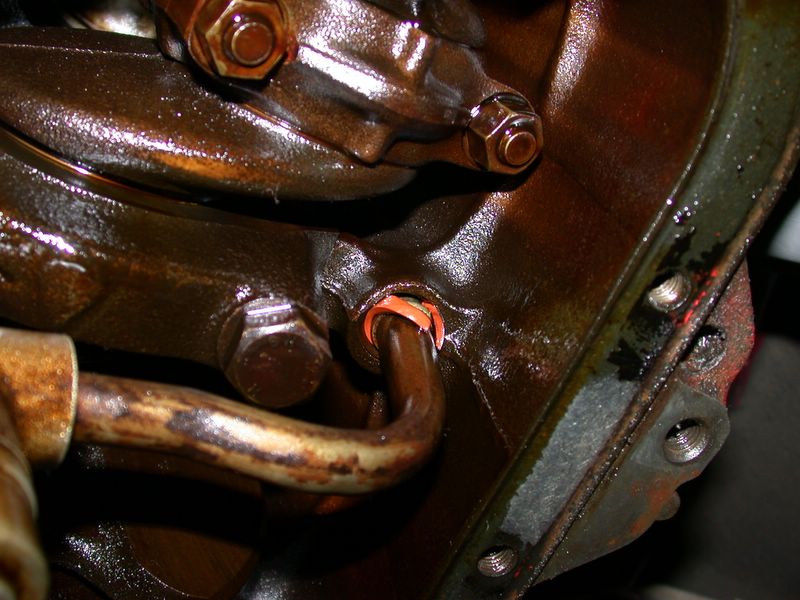

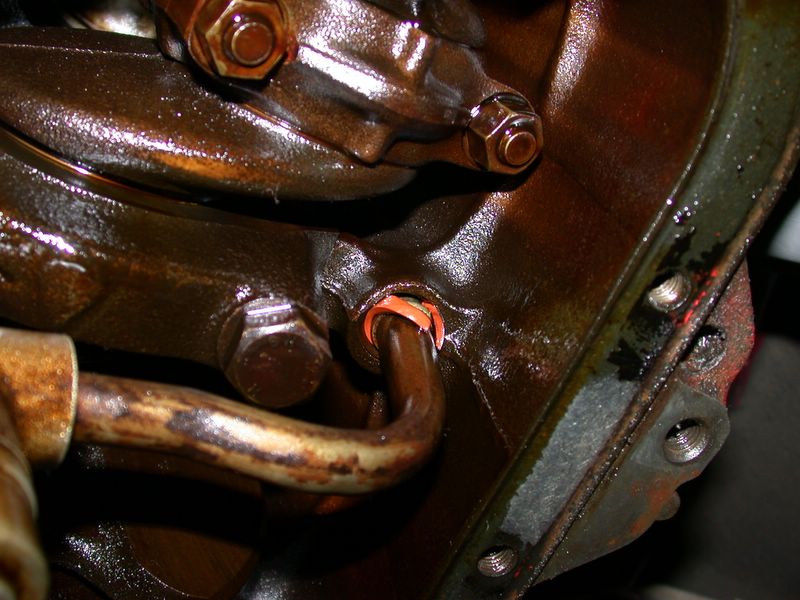

With thanks to Art Benstein's photography:

--

Bruce Young, '93 940-NA (current), 240s (one V8), 140s, 122s, since '63.

|

|

|

|

|

i use that one. it works properly. it has the correct 14mm fitting.

if the o ring is the culprit, let me know. i can give you a literal step by step how to do it with the tools and stuff you'll need to get it accomplished.

no need to re invent the wheel

|

|

posted by

someone claiming to be Teal 240

on

Tue Jun 1 15:47 CST 2010 [ RELATED]

|

|

step by step instructions would be really helpful. Here's the problem- I'm leaving town for a business trip and won't be back until June 13, so I won't have a chance to buy the pressure tester until then. I have a feeling that the o ring will be the culprit, because it came on suddenly. I will contact you when I'm back or if you have time, you could post them before I do the pressure test. I would really appreciate it! Thanks in advance, Greg

|

|

|

|

|

i may have forgotten a thing or two which no doubt i will be reminded of here.

..................

Parts needed: o gaskets, oil pan gasket

Tools needed:

A good set of metric sockets, breaker bar and wrenches covering 10mm-19mm anyway

A few extensions for your sockets….various lengths

Since you are spending nothing for parts I suggest you buy this from harbor freight… you can make your own but for 50 bucks why bother:

1000 Lb. Capacity Engine Support Bar…. Item # 96524…. for 50 dollars

An easy to use jack (preferably compact) or better yet two..one large/one compact, but at least one good one. not a bottle jack

Two GOOD jack stands

The Job:

Description: You are going to be spending several “hours” under your car on your back in the summer. Dress accordingly.

Get the car on a solid level surface.

Disconnect the neg battery.

I prefer to prepare things BEFORE I jack up the car to make room to get underneath. It just makes thing easier if you’re not tall enough to lean over a jacked up car.

Remove the visible belts especially ones to the water pump

Crack the 4 crossmember support bolts. Don’t loosen just make sure they are not reefed.

Setup the engine support bar and place the hooks in the relevant places: thermostat housing, number 3 cylinder, in back of #4 fuel injector…….it is self evident. Tighten but not enough to start lifting.

A combination of jacking while simultaneously tightening of the support bar makes this job easy. Placement of the jack is important.

I prefer after removing the splash pan to cut a beefy piece of wood with one side in a half moon shape rugged enough to sit SAFELY on the jack while the crescent fits under the harmonic balancer.

The engine support bar is going to be doing the holding once the engine is high enough. DO NOT START lifting the engine yet. Just have all the stuff at the ready.

Steps to take:

Jack up the front end high enough to allow you to “comfortably” get under and out and work . give yourself as much room as you can.

Place your GOOD jackstands properly.

This will be all that separates your from death if they fail.

You do not have to but I prefer removing the front two tires. Makes getting under and working easier.

If you have low profile creeper make sure with you on it you have necessary room. I prefer using an old piece of thick carpet. Easier on my back than the asphalt.

Remove both sides nuts holding the motor mounts to the cross member.

Leave in place those securing the right one to the block.

The left mount (drivers side) will be removed to make it easier to get the pan off but NOT UNTIL the engine is safely raised and secured.

You do not really have to do this but I prefer to remove all stress off the exhaust system so unbolt the 3 nuts holding the exhaust manifold to the header pipe. This way lifting the engine does not lift and stress the exhaust system.

Be mindful as you lift the engine the space between the firewall and rear of the valve cover will close. That distance is what you have to work with regarding how high you can lift and tilt backward the engine.

Ultimately what makes this job a bitch to do is the oil pump hangs well down into the pan and fits into the pan centered with baffles welded to the pan around.

Kind of like a two story oil pan. This limitation forces you to have to rotate the pan while lowering it in ridiculous ways to clear the cross member and pump.

Ok, you’re ready to lift the engine. Place the wooden crescent under the harmonic balancer with the jack securely under the wood. As you jack the engine up tighten the support bar. It is easier if you have someone else do the suppoort bar while jacking or vice versa. Get the engine as high as is practical. Secure the support bar holding the engine. Back off on the jack and remove it for now.

You are trying to get enough room between the bottom of the engine block and the top of the crossmember to be able to remove the pan and clear the protruding oil pump.

Once the engine is raised and secured remove the driver side motor mount and then carefully remove the oil pan bolts. It is too easy to shear one off if they have been overtightend or upon re install being to aggressive. You will also need to remove the aluminum guard covering the back of the oil pan.

This is bolted to the bell housing as well. Self evident as you’ll see. Be especially careful removing the front oil pan bolts directly under the crankshaft.

Once done you will soon know if you have enough clearance to drop the pan down and out from under. As you lie on your back your face looking up at the back of the oil pan the offending o gasket is up, forward and to your right while the pump is forward and to your left, surrounded by welded pan baffles.

Lower the pan and begin your contortions to clear the pump and get the pan out. If you find at this point the pan is hung up in the left front area by stuff and or the cross member attempt to raise the engine higher and try again. There is I have found no precise formula.

If this effort still proves unsuccessful, that is, you can not get the engine any higher then plan B comes into play. Since you have to clear the crossmember you will need to loosen the previously cracked two per side 19mm cross member bolts which secure it to the frame. You can if things demand loosen all the way. Between raising the engine and if necessary lowering the crossmember the pan will come out.

Once the pan is out the pump is visible and is likely just fine considering your mileage, although replacing it is your call.

You will know instantly if the o gasket is bad.

It is the one which seals the return pipe into the block. If it is bad you have found your trouble.

The oil pump will unbolt easily.

NOTE the position of the plastic oil separator tube which is located there. Leave it alone but put the pump back exactly the way it came out visa vie this tube.

Please note IMO the reason why these o gaskets fail is a design defect which you need to guard against repeating on the re install.

Once you unbolt the pump the oil return line will pull away along with the pump.

Separate the two and clean them up.

Install new o gaskets on both ends.

Insert the pipe into the pump first, place a new o gasket over the block end snug up against the bulge in the pipe.

Insert the pipe into the cleaned block opening while re bolting the oil pump hand tight.

Here is the important step to be aware. The pipe does not fit truly snug in the block opening. There is a bit of slop as you will see. The oil pump can be re tightened in such a way the oil return line into the block is NOT truly CENTERED.

You must ensure as you tighten the oil pump bolts you also center the pipe into the block so there is EQUAL distance all around.

IMO these gaskets fail because the bulge which secures the gasket to the pipe is NOT wide enough to compensate for the oil pressure IF the pipe is secured off center. IE: too much pressure is applied to the gasket on one side which pushes it out over time.

Replace the oil pan using a new 1 piece or 3 piece gasket.

After securing the oil pan and guard at the back of the pan want NEXT to place the drivers motor mount back.

Jack up the crossmember and tighten the 4 crossmember bolts securely before proceeding to lower the engine, for obvious reasons.

Once secure, lower the engine carefully by first jacking it up slightly to take the stress off the support bar and then loosen as you lower the jack slowly so the motor mounts are secured before you remove all support from the engine.

The rest is self evident

|

|

|

|

Well done Richard,

I might suggest you get a little toque wrench for snugging up the pan bolts. You do not want one a little too loose or over tight, you want them just right.

May I also suggest checking out my personal Hall of Fame Patron website and this link, Art has a write up with pictures on this very problem.

http://cleanflametrap.com/oilpan/

You will never have a better chance to change your motor mounts, and this is also the time to clean your breather box and hoses.

Regards,

Paul

|

|

|

|

|

One of my 93 245 has the same symptom and it is the oil $2 seal. Since I knew that it's going to be a big job, I decided to leave the car on stands for 6 months and replaced everything down there: ball bearings, all suspension and accessory bushings, thoroughly cleaned the cross member and repainted it. I also did did a complete AC flush and changed it to PEG oil and adjustable orffice. It's so much easier to work on those parts when you have everything out of the way. Erwin

|

|

|

|

|