|

|

|

Given the lackluster performance on my part on my timing belt install I wanted to know if driving the car will mess it up. I started it and it seems drivable, but not great. I just drove it off the ramps and parked it better in the driveway. I think in addition to messing up the timing, I didn't get the crankshaft on the thin little nib that sticks out. I don't know how anyone can know whether or not they got it on properly but I will just chalk it up to another mystery of the timing belt install. The crankshaft looks a bit wobbley.

Should I take a chance driving it to the mechanic or should I have it towed?

|

|

|

|

|

DO NOT drive the car if you think the crank pulley is not properly seated.

Worst case scenario will have the pulley loosen, spin & damage the nose of the crank (don't ask me how I know). Good advice has been given by others, having the belt off by one tooth will allow the engine to run with poor performance, 2 teeth = very poor running if at all. The biggest mistake those unfamiliar with the B2xx engines make is that they are a slant 4. As such, the timing marks are also on a slant although they ARE in line with each other and the center-line between the crank and the cam. Be sure the marks are lined up, ignore the painted marks on the belt, I have seen belts with incorrect marks. If your engine has the cam-mounted distributor (back of engine) you can ignore the marks on the lower large timing gear since they are there only for driving the block-mounted distributor (older style).

Bob K

1994 945T - 260K

1988 244 - 310K

1984 242 - 140K

1994 F150 - 306K

1968 GT500KR - under resto

various Benzes as well - all over 120K

|

|

|

|

|

Hi

Can that happen, I mean crank pulley should not sit properly,

You can give it another shot because mechanic is also going to do the same thing and since now you have seen every thing it will be ok. This old post may help a bit.

------------------Old post---------------------

Are you talking about 200. The marks on pulleys need to be referenced against the refrence marks on engine and timing belt cover not ones on the belt.

If you search here you will find the info.

Check out this excellent link

http://www.threefattigers.com/Protocore/Volvo/TimingMarks.htm

Those three are primary reference marks other extra points for cross referencing are

1.

One cross refrence which is not mentioned here is the mark on the distributor .It is below the plastic dust shield on the rim. It is for intermediate shaft. The rotor should point to that mark when you have aligned with the timing belt cover

2.

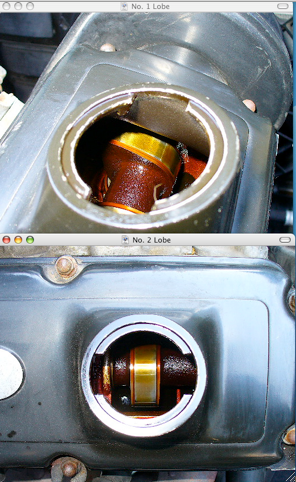

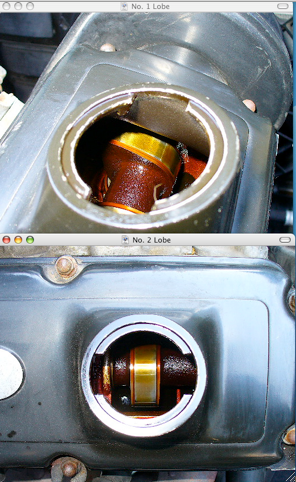

All references are for aligning cylender 1 at TDC between compression and ignition stroke.The no1 cam lobe is horizontal and no2 is pointing slightly inwards . Other are set just by that.

This is basically the summary which I have gathered from here.

Regards

Gopesh

--

DD-1990 240 DL SW M47II FI 3.1 234 K miles

|

|

|

|

Hi Lisa,

I guess it depends on how far to the mechanic to some extent. But I'm more concerned about the crank pulley wobbling in your other post You may be right that the pulley isn't locked to the little nib/nub on the front of the crank sprocket (see pics below).

B230 Crank Sprocket (nib on the front)

and

Crank Pulley B230 (recess on the back)

I'm curious also if you got the pulley bolt tight enough, and suggest you redo it using the rope trick (so you don't have to mess with belt cover and "tool" installation, even though you say, "I read about the rope trick technique, but it gave a warning at the outset to be careful because you can damage the valve."

Don't know where you read that but it's pure BS. Read the procedure in the link below and visualize the piston coming up and compressing soft rope against the fully closed valves — what's to damage?

ROPE TRICK Notice the tightening torque spec. That last 60° is a LOT of torque. I have to use a 2' pipe on my 18" breaker bar to get the last few degrees.

--

Bruce Young, '93 940-NA (current), 240s (one V8), 140s, 122s, since '63.

|

|

|

|

|

Hi Bruce,

I definitely got it tight enough. I used a torque wrench for the 60NM part and then used a very long pipe over my breaker bar to go the extra 60 degrees without much effort. The pipe was critical to the last 60 degrees otherwise I would have not been able to do it.

I'm really afraid to do this again, since the alignment has been lost at this point. I can't trust what is TDC anymore. There is really no way for me to know. As far as "#1 cam pointed slightly up and inboard, #2 pointed horizontally outboard", I would need to see a picture of what this looks like in order for me to feel confident. "Slightly up and inboard" to me might look different than it does to the author of this writeup. And what does "inboard" mean? Does that mean tilted towards the back of the car?

Thank you for encouraging me to try this, but I think my best choice right now is to take it to the mechanic. I guess my question is really, "Will I damage the engine driving it with a timing belt that is not aligned properly".

Thanks!

|

|

|

|

|

Lucid posted a method of removing drive belts easily some time ago. I have used a number of times since. If the belts are not extremely tight you can many times just slip a screw driver under the belt and rotate the balancer with the correct size socket/rachet on the crankbolt.

These images may help in understanding how to just roll them off. Once the belt is on the shaft of the screwdriver pry down to guide the belt off. Rolling them back on is even easier- simply get it started and turn the dampner in the other direction, the edge of the pulley grasps the belt and acts as a guide (no screwdriver needed).

Randy

|

|

|

|

|

Thank you!! This is awesome! I wish I had known about this before, it would have saved me a few hours off of my timing belt install. But, at least I will know it for next time. And thanks for the pictures. It is much appreciated!!

|

|

|

|

Lisa,

I understand your reluctance to dig back in at this point. I'd feel the same way. But I'd suggest maybe loosening the pulley bolt enough to try manually rotating the pulley to feel for the pulley recess to engage the sprocket "nub".

[See sprocket and pulley hub pics in THIS POST]

You might have to relax the belt tension in order to slip the pulley by hand, but I think it would be possible. Especially on a 900 (compared to 200 with belt driven fan and shroud in the way). If so, IMO it would make for a safer drive to the mechanic, with a minimum of effort (more on rope trick below).

"I'm really afraid to do this again, since the alignment has been lost at this point. I can't trust what is TDC anymore. There is really no way for me to know."

• Maybe Art's pictures below will help

"As far as "#1 cam pointed slightly up and inboard, #2 pointed horizontally outboard", I would need to see a picture of what this looks like in order for me to feel confident. "Slightly up and inboard" to me might look different than it does to the author of this writeup. And what does "inboard" mean? Does that mean tilted towards the back of the car?"

• The picture below may be worth adding to my blurb. I was trying to keep it brief, and thought those words would do the job — which was to ensure the pulley was really at TDC for the #1 cylinder and NOT #4 (in which case the cams would not even be close to my attempted description).

By "inboard" I assumed too much but meant with the cam "lobe" (high point) pointing toward the car's centerline, as opposed to straight up/down, or "outboard" (away from the centerline). I guess those nautical terms aren't as universal as I'd assumed. Let me know if the picture adds anything...

--

Bruce Young, '93 940-NA (current), 240s (one V8), 140s, 122s, since '63.

|

|

|

|

|

Hi Bruce,

Thank you so much for including the pictures. They do help a lot. If I ever attempt this again (which I probably will) I will refer to them. I am still leaning towards a full surrender and driving the car straight to the mechanic tomorrow. I'm sure I will get an earful for trying to do this on my own.

|

|

|

|

Hi again,

I too am worried more about your suspicion the key in the crank pulley is not locked into the crank sprocket. If the motor runs at all, you have to be close, and there's no reason not to go ahead and check your work to be sure it is exact.

Here's how to do that:

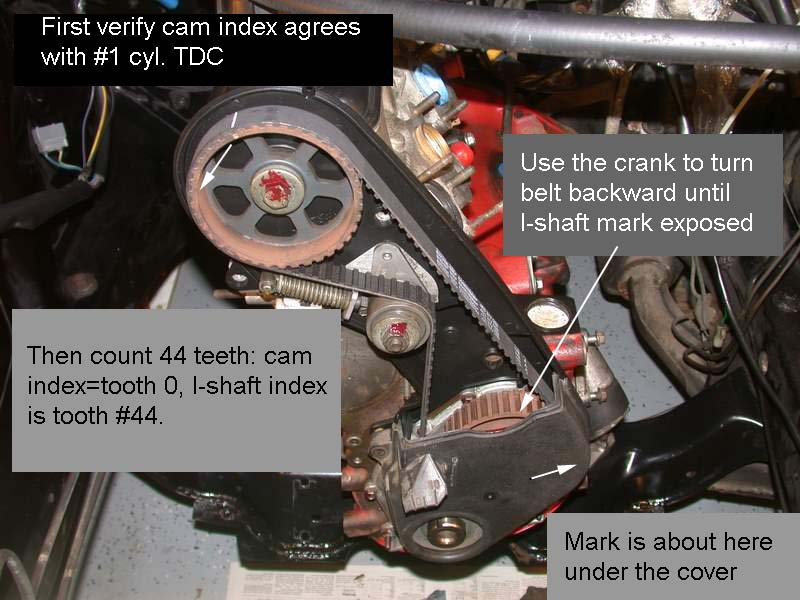

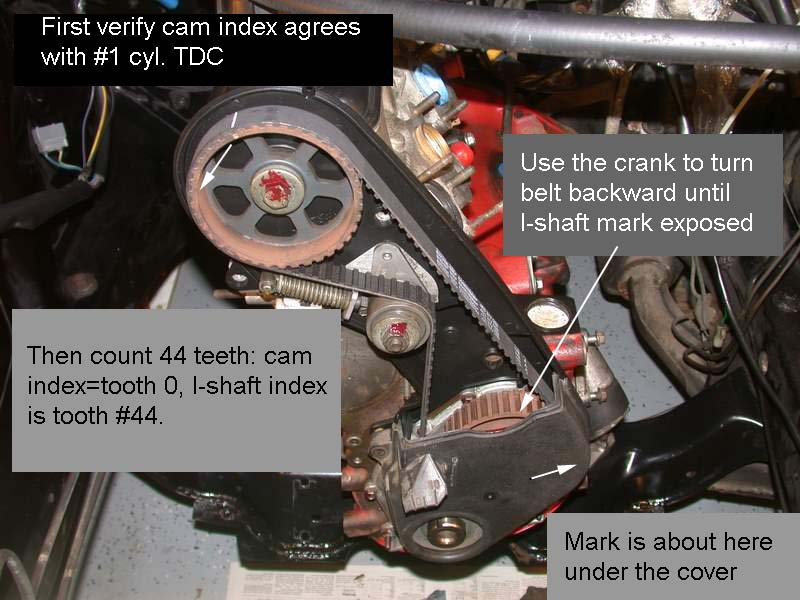

1) Check the crank pulley. In this step you want to verify you torqued the crank bolt with the key properly seated. Put your 15/16 or 24mm socket on a ratchet and turn the crank bolt clockwise until the index mark lines up with 0 top dead center (TDC) on the timing cover. Note, the 0 is not on the little tab adjacent to the pulley, like the other marks indicating 10 and 20 degrees before TDC. Photo below is just to remind you of what the cover looks like. TDC refers only to the piston - not the cam lobes or anything else in the engine.

Now, remove the #1 spark plug. Get a popsicle stick or chopstick and feel the top of the cylinder through the spark plug hole. Rock the crank back and forth with the ratchet, around that zero mark, while feeling the piston, and assure yourself the mark lines up exactly at 0 when the piston is highest. If so, it is a good bet you did lock in the little nib. But if the pulley seems to wobble, then it might be very close but not in. Fix that first.

2) Now that you've determined TDC, put the plug back in. The next verification is cam timing, which is easier and more clearcut. Open the top timing belt cover and look at the dot on the cog (sprocket) in relation to the dot on the plastic back behind it. It must match. It must match when the crank pulley is at zero. In fact you'll not have to worry about observing the cam lobes inside the cam cover, because that dot on the cog assures you the valves on #1 are closed when it is lined up with the mark on the back cover. Works the same for the rope trick -- if the dot on the top sprocket is lined up, the valves are shut.

3) Next is the intermediate shaft (I-shaft), the large cog down low on the right. That dot must match its corresponding mark on the timing cover. That one can be hard to see, so the photo above provides a way to count the teeth between the top sprocket and it without removing any more parts like the bottom cover. Of course, if it does not line up, and you need to adjust it, you'll have to compress the tensioner spring, and then slip the belt to the correct teeth on the cogs.

On the other hand, if the motor runs well enough to drive safely, it won't be harmed by being out of time a small amount for a trip to town. This motor is non-interference, meaning the valves will never collide with the pistons as would happen in most of today's engines.

--

Art Benstein near Baltimore

Remember what Cardinal Cooke once said:

"A man would do nothing if he waited until such time as no one would find fault with what he has done". - originally John Henry Cardinal Newman

|

|

|

|

|

Art,

The car is a 900, I do not recall what year, but I am guessing it has the distributor on the back of the head. Won't the verification of component timing only involve checking the cam position when the crank is at TDC?

Randy

|

|

|

|

|

Hello

unless its a rex/regina with front mount dist.

nice writeup guys.

|

|

posted by

someone claiming to be MOTOHED

on

Sat Jan 30 18:50 CST 2010 [ RELATED]

|

|

I have used a impact driver to both loosen and tighten the crank bolt.I must have done it 10 times without a problem.I also put a little thin oil on the harmonic balancer where its seats to the crankshaft.Just spin in back and forth and you will know when its seats into the nub...there will be no doubt when it locks in place.

|

|

|

|

|