|

|

|

It looks like the 245SE will need a new rear brake caliper. The outer piston is stuck. I could try to break it loose but replacing the caliper is faster, if I can remove the brake line nut. Research on the BB seems to center on using a Snap-ON flare wrench, It's 11mm right?

Someone mentioned a torch on the not, but I must remember to empty the fluid out first. Last time I did that the line exploded,,,DUH, I boiled the fluid!

Looking for confirmation before I order from Snap On, $34 ! for the wrench !!

--

84 242Ti IPD bars&springs, 89 745 16v M46 IPD bars, 89 744 16v M46 IPD bars, 93 945 Turbo AW71, 91 245SE AW70 IPD bars, 93 245 CLassic M47

|

|

-

|

|

|

I buy tools when I can afford them but that is unfortunately not too often. So, I'd sacrifice a 6 point box wrench by using a small grinder and cutoff wheel to cut thru one of the flats at 7 o'clock or 4 o'clock position wide enough to just slip over the brakeline. It might do the trick at zero initial cost. Put the thing over the nut oriented so your torque is going from the handle toward the cut. Keep the longer wrap of the box head dragging behind your pull direction. You could finegle vise grips over it to keep it from springing loose, etc.. just a "get 'er done" suggestion that everybody else has probably tried once.

--

Genesis 7:11

|

|

-

|

|

|

Soak it in PB Blaster overnight. I've found that stuff works miracles. I use regular Craftsman flare nut wrenches and they have always done the job for me. I'm sure the Snap-On version is better, but personally I have not had to go there.

|

|

-

|

|

|

Second the craftsman wrenches and PB blaster. I have the craftsman professional line wrenches (made by SK, I think?), and they seem to work ok.

--

'92 240 wagon, 306k, '90 240 sedan 243k

|

|

-

|

|

|

I disassembled and reassembled the entire braking system on a 92 245 using a Craftsman double ended line wrench, no problems at all, didn't even have to use penetrating oil. That being said, it is a North Carolina car and had 236K miles on it at the time.

As someone else mentioned, it is a "polished" Craftsman wrench.

jorrell

--

92 245 284K miles, IPD'd to the hilt, 06 XC70, 00 Eclipse custom Turbo setup...currently taking names and kicking reputations!

|

|

-

|

|

|

I would buy a craftsman 7/16 its somewhat tighter than the 11mm(which i also have but never use)I live in serious rust belt but have never had problems

removing brake line nuts.I do always presoak with PB blaster or other rust

penetrant. Good luck!

--

Rene

|

|

-

|

|

...a thick 70+ year old Proto brand line wrench that was my Dad's. Art's tip to tap the wrench with a hammer (while applying moderate torque) is a good idea too.

I think the7/16" is actually a bit looser, not tighter, than the 11mm wrench...

(7/16) 7 x .0625" = .4375"

(11mm) 11 x .0394" = .4334 [.041" less]

--

Bruce Young, '93 940-NA (current), 240s (one V8), 140s, 122s, since '63.

|

|

-

|

|

|

7/16" is 0.4375 as you said

My calculator converts 11mm to 0.43307in, 0.00443 less. But that's not what matters.

ASME B107.17M, "Gages, Wrench Openings, Reference", the spec that governs the standard size limits for wrench openings, states the following:

The maximum opening for a 7/16" wrench is 0.4463 (No-Go gage maximum size)

The maximum for an 11mm wrench is 0.4427 (a difference of 3.6 thousandths of an inch).

Per ASME B107.100 the "correct" term is "Flare-Nut" wrench. They also use the term "Diagonal Cutting Pliers", but I still call them Dykes.

Regards,

Will

--

854 - 244 - Mini

|

|

-

|

|

Hi Will,

Having done many (ebay) searches for a bargain on a 15/16 or 24mm line wrench I concluded the best results were obtained calling it a "flare-nut" wrench. So popularity (with a pecuniary motive) supports ASME's decree. And though I surely know what you mean, being firmly entrenched in the electrical industry, I would think asking for "a pair of dikes" may on the wane.

--

Art Benstein near Baltimore

One day, a man came home and was greeted by his wife dressed in a very sexy nightie. 'Tie me up,' she purred, 'and you can do anything you want.' So he tied her up and went golfing.

|

|

-

|

|

Once I break the nut loose with the 11 mm line wrench, I have a 7/16" open-end handy to back it out of the caliper. The 7/16, being looser, lends speed to the operation once torque is no longer the primary objective.

--

Art Benstein near Baltimore

"I've got a snapper. You won't see a snapper too often."

|

|

-

|

|

|

I just went through this with both rear calipers, and after a week of PBlaster all fittings came off easy. I have a snapon set but they would have come off with an open ended wrench. Car is a 95 940 230,000 miles raised exclusively in St. Paul, MN. Good luck.

Bill

|

|

-

|

|

|

The polished Craftsman are rumored to be built by the same folks who build snap on. I have both and they look alike, thick and beefy at the head.

Dan

|

|

-

|

|

|

Just as an aside, I think you'll find that the Danaher Corporation makes most of the hand tools for Sears marketed as Craftsman. Danaher owns the NAPA car parts chain, MATCO tools, Allen, and a host of other companies.

|

|

-

|

|

Since hopefully you'll be opening the line at the caliper, here's a Brake Tip I toss in at every opportunity:

You can prevent Master Cylinder Brake Fluid Loss from any/all open brake line(s) by blocking the brake pedal depressed before you start. It only takes an inch or two on the pre-ABS 240s. NOTE: The ABS 240s need more pedal travel, like the 700/900 cars (in which case the bleeder needs to be open while pedal is being depressed).

The 700/900 Green Book shows the pedal fully depressed by a special tool (easy to replicate with a 2x4, etc.). The book also says to open a bleeder first, using a tube and container to catch the fluid expelled when the pedal is depressed.

I've been using this on '80s 240s for years now—since I learned it from an independent Volvo specialist. I made a wooden prop that hooks to the bottom edge of the pedal and bears against the 240 seat adjuster bar. It's handy for checking brake lights too.

>>Disconnect the battery (or pull fuse) to keep brake lights off while the pedal prop is in place.<<

--

Bruce Young, '93 940-NA (current), 240s (one V8), 140s, 122s, since '63.

|

|

-

|

|

Set me back $43 CAD. I tried my cheapo mastercraft and my craftsman but they wouldn't do it. I am in the rust belt. The snap-on was the only tool that would do it

--

73 ES, 91 240, 98 S90

|

|

-

|

|

I have a set of S-K's. Three double ended wrenches for 6 metric flavors. They have served me well.... and having a 14mm around is nice for hoses.

Of course, Snap-On is nothing to sneeze at. :-)

A torch won't help too much at the caliper itself... heat will just expand the nut even more.... though maybe getting the area good and toasty and then zapping the nut with a wet paper towel will help? Hmmmm.

-Ryan

--

Athens, Ohio

1987 245 DL 314k, Dog-mobile

1990 245 DL 134k M47, E-codes, GT Sway Bars, GT Braces, Draco Wheels

1991 745 GL 300k, Regina, 23/21mm Turbo Sway Bars

|

|

-

|

|

Hi there,

Yes, the nut (wrench) is 11mm. And if you order the Snap-On, I believe you will own a fine wrench indeed. Personally, I haven't made that leap. Been getting along on my cheap Craftsman 11 mm line wrench and a sharp whack with a small ball-pein hammer. Haven't put the torch to one as yet, either. But conditions vary, especially as your community spreads salt.

--

Art Benstein near Baltimore

Don't be irreplaceable. If you can't be replaced, you can't be promoted.

|

|

-

|

|

|

Is a "line" wrench different in some way, or just another flare end wrench?

Exactly where do you whack the wrench, at the nut, on the end, or along the body in the direction of the torque application?

--

84 242Ti IPD bars&springs, 89 745 16v M46 IPD bars, 89 744 16v M46 IPD bars, 93 945 Turbo AW71, 91 245SE AW70 IPD bars, 93 245 CLassic M47

|

|

-

|

|

|

Oh! Man your so funny!

Of course you start with the nut on the end of the wrench! You just lift up the hair and give it a good whack where it was!

Just having a cheap shot, sorry!

A brake line has a flare on its end. Several designs are used.

That is where they get the name flare nut wrench.

A tubing line wrench is the "flared line" & its "nut" with the applied "wrench".

Now to get to the place to hit it. Well that's called the "sweet spot"!

That term I should leave up to your imagination. Or if you play baseball? It's the place on the bat that is "trademarked" in relation with the grain of the wood. I think I was told that the mark faces you when in the upright positon.

In the case of the wrench. It has a forged grain in the metal to make it stronger in the direction around the direction to be used.

You take out any play of the fit. Then preload with "some" pressure. Then its the bump you give it.

The trick is obtaining enough force to quickly to jump the torque up before any flexing of the wrench and compression of the hex flats can happen.

A "nack of the wack" is a mechanic's skill learned from experience or luck. Take your pick!

If it works you found the "sweet spot". It's as good as a home run feels for us that getting paid or not to be "grease monkeys"!

At my age, if you don't have the hair you fake it with the grease. I try to walk around and under more than hang over low fenders anymore? Lifts are made for us old guys.

When I see a man over his engine and the hoods up. It looks like a car eats man situation!

Phil

|

|

-

|

|

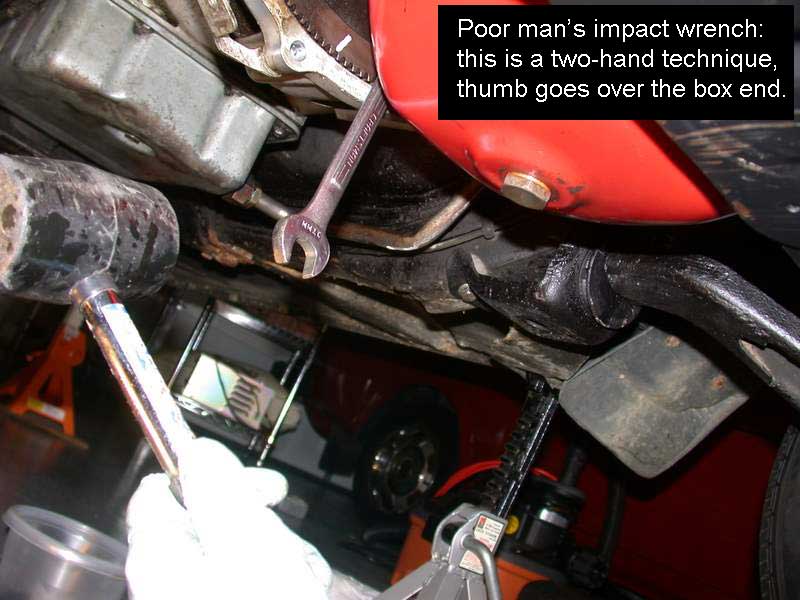

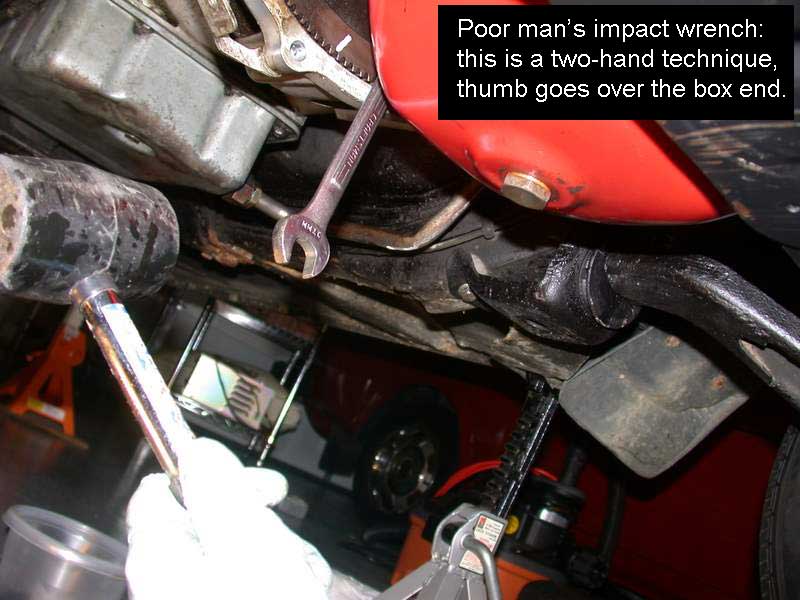

Phil, you are the funny one. Truth rolled up in humor!

Here's a depiction of the principle, though on a much larger "nut".

--

Art Benstein near Baltimore

"One sharp whack deserves another."

|

|

-

|

|

|

We could easily lead ourselves astray here, but I just had to include I really enjoy reading most of these little asides on BB. There is SO much that goes into mechanicing that you can't really relay to a beginner without taking up the whole day on little pointers. How much? How little? Is this too tight? It is part of why I enjoy wrenching, and I'm always on the lookout for more good tips.

|

|

|

|

|