|

|

|

Car still won't start even though I've given up on the electronic ignition and puts my old points distributor in. I'm really getting to the end of my rope here. My only remaining variable is the fuel, but the car began to run badly before I last fueled up and continued running poorly after I put new fuel in from a different station. My fuel filter is clean, but pump is working, there's fuel in the carbs.

The sparks are getting plenty of fuel and I've removed and cleaned the plugs several times in this process.

What I do know is the with the points distributor and with the allison unit, I'm getting spark to all four plugs, but despite setting the static timing a dozen or more times, the car will just crank and crank.

When lucky, it starts a bit, but never fully and dies as soon as I release the ignition. It sneezes a lot when it's not firing. or just does nothing but dry crank.

I've tried three different caps and rotors, two different sets of plug wires and distributors, and cleaned my carbs several times.

I've drained the carbs and refilled them. I've confirmed fuel, fire, and compression, and still this baby won't wake up...

Can bad fuel appear as bad ignition? can it cause the kind of problems I'm seeing? Could something be wrong with the carbs themselves that would look like an ignition problem? Th pistons move smoothly...

This stuff in my tank is NOT e85, we do not have that locally, but I can't say for sure what actually got into the tank. It'd have to be a LOT of water or something else non-combustable. This car also sits under a carport, but was out in the open before the trouble began.

As soon as the freezing fog is over, I'll drain the tank and try again with a couple of gallons of something new. However, spraying carb cleaner into the throat of the carb has done nothing, while in the past, it would cause the car fire up and run for a little bit.

So, while I'm waiting for better weather, does any of this spark any ideas?

Thanks as always.

|

|

|

|

|

I thought those of you who followed this saga might want the final word.

- especially for those of you who have no formal mechanical training (like me) and have a very "un-even" mechanical skill-set (also like me).

Today I switched my distributor gear to the "correct" location, put my allison/crane distributor back on, ordered my wires in a proper fashion, and set my timing with a timing light. The engine now starts and runs like a top.

I've still got no idea what happened back in early December to kill my running condition, but my ignition issue is now COMPLETELY fixed.

It boils down to this - my lack of mechanical knowledge in determining #1 TDC and the lack of clarity in the so-called "bible" tech articles.

#1 will come to TDC with both intake and exhaust valves closed and the timing mark at 16 BTDC more than once. NONE of the articles out there are especially clear on which is the correct TDC. Since the timing marks line up at least **twice** along with the #1 piston being at the top, and if you've removed your distributor gear, you quickly loose an easy reference for what "correct" in.

A conversation with a skilled co-worker *finally* gave me the answer that I was asking for earlier in this thread. I did not have the correct #1 TDC. Yes, it's pretty intuitive when you think about it....

The correct TDC is when the intake has opened and closed (letting air/fuel in), and the piston has cycled down and come back up (thus making the compression needed for ignition) and the exhaust have not yet opened. The timing marks also line up again on this stroke.

That's it. I had my gear 180 degrees out because I did not have my #1 plug spark set for the compression stroke of #1 cylinder.

Aside from the large number of variables in the process, and all the other problems that I introduced and solved along the way, the *biggest* problem was being able to efficiently crank the engine manually in the proper direction.

The dang thing just does not like to crank in the normal running direction (but does fine cranking backwards). The "Mechanics" trick to help here (also a tip from my friend at work) is to loosen (or remove) all your spark plugs. Then there is no compression to fight against your manual cranking and things turn quite easy in the proper direction.

So, finally being set straight, it's unlikely I'll ever need help with this same problem again.

Thanks to all of you who repeatedly offered me suggestions and help.

I'd be taking a cab to work without your help.

|

|

|

|

|

Not fuel. I re-routed the pumped fuel to a gas can, and removed the carb reservoir caps. I flushed the reservoirs and poured some brand new gasoline in.

I then replaced all four sparks and squirted some starting fluid past the carb pistons.

No dice. It just does not start. I checked and re-check the static timing, I've replaced everything but the coil itself, and I know that there's a good solid spark coming from the coil...

I put my crane unit back in, checked my firing order again, and cranked and cranked and cranked.

When it should be firing, instead I get a jet of smoke back out of the carbs.

The twin vents on the carbs now have a wet black mess on them.

I removed the valve cover and checked the rocker assembly and all the pushrods. Everything feels right. no excessive movement, gaps all seem correct. All valves open and close..

This makes no sense.

|

|

|

|

|

Is this the same car that had extra gaskets in place? If so, you may well have false air screwing things up. Make that stuff correct if it isn't already.

Have you cranked the engine over with the valve cover removed to confirm that the valves are actually opening and closing? If not, do. Maybe your engine has one of those crappy soft cams that hit the market several years ago and lost its lobes. Look to see that the rockers are all doing about the same thing. Don't worry about precision - if you've got a flat lobe (or two or more) you'll see it.

Battery's hooked up the right way, right?

Okay:

If it's puffing smoke out through the carbs, then the plugs are firing while the intake valves are still open. Which means the ignition timing is way off. Either the method of static timing you're using isn't working, or something about the execution isn't quite right.

Simpler timing method: have an assistant crank the engine over while you set the timing using a timing light. It probably won't be exactly perfect, but it'll be really really close. Plenty close enough to start the engine. And you can move the distributor while the engine is cranking, which is a lot easier than moving the distributor a little bit, then trying to start the engine, then moving the dizzy a little more, then trying again, etc.

Put the timing light on the coil wire instead of the wire leading to cyl 1. Then you can also check to see if you have a regular - or erratic - misfire.

Given the amount of cranking the engine's had, take the plugs out and squirt some oil into the cylinders. Enough that it'll soak the rings all the way around the pistons. There's a good chance that fuel has rinsed the rings and you're now facing a lack of compression. Yeah, sounds like a long shot. But I've seen it many times before.

If there's any chance at all that the ignition switch (or connections to and from it, or the wires connected to it) is/are at fault, bypass it completely: run a wire from the positive terminal on the battery directly to the coil. At this point, the ignition switch will only be used to engage the starter. Note: if the engine starts, you'll need to pull this "hot" wire to shut it off.

If you have a Smiths tach, remove it from the ignition circuit completely until the engine is running well enough to merit the use of a tach.

So: 1: oil the cylinders.

2: install brand new NGK plugs gapped at .025 - .027". It's true that you can run a bigger gap, especially when using breakerless ignition, but all you're really doing is making it harder for the spark to jump from point A to B. If anyone reads this, they'll likely disagree with me. Trust me. When we dynoed Phil's MPPE, we picked up several RWHP at high rpms by decreasing the plug gap in his engine to .025". Don't use fancy platinum or other whatever BS sales pitch plugs they're trying to sell you: the electrodes are small and prone to fouling. NGK BP6HS.

3: Do what you can to static time the engine.

4: Pour a little gas into the carb throats.

5: Have your assistant crank the engine over while you use the timing light to get the ignition timing close to ideal. Shoot for something around 15 degrees to start with.

If the engine starts, celebrate. If it doesn't, leave the timing at its indicated 15ish degrees and have the assistant crank the engine some more while you spray starting fluid into the carbs.

Now it should start.

[Tangent: Tricky thing about the Crane is getting it "phased." You can get the engine to TDC and have the rotor right exactly where you want it and have zero luck starting the engine if the Crane isn't "phased." Pain in the ass, but necessary.]

Good luck!

Cameron

Rose City

|

|

|

|

|

Cam,

this hot wire sounds a little tricky, but I'll see what I can do.

part of my issue is that I'm running solo and have no help. The spouse keeps the 18 month old out of trouble, so no help there.

If I'm sneezing smoke out the carbs, then the ignition is way off.

OK.

That would explain a lot, but I'm not sure how to solve it, when I crank the thing until rotor is pointing to #1 (about 300 degrees), timing mark is at 0 and #1 is at TDC. Maybe I do have the distributor gear wrong? I've checked it several times. How can I be 100% sure that it is right? it's a multi-stoke engine, so this align more than just once right?

What I've tried is leaving the ignition on, and gently turning the distributor until #1 gives me a flash from the timing light and starting there.

When I try cranking at this first position, it kinda starts... sorta. almost but never fully gets going - or if it does, it's fitfull and dies immediately.

Bill's suggestion is great, except that I already took the whole distributor assembly and ignition module off of the 220 that's in the garage, so it's of no use as a comparison.

The smith's tach is unhooked.

I removed the extra intake gasket a while back when I was hunting fuel economy problems.

I recently checked the timing gear, all lines up on mark. I think I've seen all the valves opening and closing, but I'll double-check that.

I've got new NGK BP7HS sparks in there now.

So far the *only* time I've been able to get the engine going is when the wires have been in the wrong order - usually #2 and #3 reversed, but that has not been consistent enough to help... I think something is very wrong on the timing and this must be the problem. I've eliminated everything else.

I have the greenbook, haynes, clymer, and chiltons manuals, and I have read Ron's article on setting static timing. Is there a better step-by-step trouble-shooting guide for this?

As far as I know, this engine, and it's cam are original volvo, never been serviced or replaced in the last 22 years. The engine is not this car's original, but supposedly came from another 68. It's block numbers check out and compression results are very good.

|

|

|

|

I know you've checked and re-checked it, but when I read this:

So far the *only* time I've been able to get the engine going is when the wires have been in the wrong order - usually #2 and #3 reversed, but that has not been consistent enough to help...

It makes me wonder about this so-called "wrong order." If the engine is having this hard of a time starting in the "right" order, but it managed to start at some point with the wires in the "wrong" order...

It's a simple three steps, and you've probably done it over and over, but...

1) make sure your engine is physically at TDC with cylinder-1 firing (both cyl-1 valves closed), and not TDC with cylinder-4 firing. Now back it up 10 degrees (wrench the engine CCW, standing at the front of the car, to the 10 degree mark).

2) set the static timing @ the dizzy. It doesn't matter if the distributor drive gear was put in 180-degrees off, dead on, or 2-teeth off. I use the continuity tester on my multimeter to find the exact moment the points open up as I twist the distributor CLOCKWISE (to mimic the action of the rotor turning counterclockwise).

3) Wherever the rotor is pointing is where your #1 wire goes. Put the cap on, plug that #1 wire into the right spot, and, working your way around the cap counter-clockwise, plug in the rest of the plug wires: 1-3-4-2.

I'm not trying to sound redundant and re-post what others have said, but when you say you've actually been able to start it (if only once) with what appeared to be the wires in the "wrong order," it makes me wonder...

|

|

|

|

|

I've got to wonder about firing order too. With *most* cars the firing order is clockwise, only engines with cam gears like the B16, B18, and B20 have it counterclockwise. It's a common mistake.

Secondly RJ, the actual angle of the distributor drive gear is not as important as simply having the rotor point at the correct tower of the distributor cap at the correct time. The only problem you might experience if the gear angle is wrong, is interference of the distributor with the block when trying to turn it to set timing. It won't prevent you from starting at all.

One more thing, are you certain the drive gear is seating in the oil pump? If it's not, it will be "high" and the distributor won't seat fully. Then when you rotate the engine, the flat on the gear drops into the slot of the pump, and changes your timing, Tne while cranking it can rise up and down and give variable timing. Just see if the distributor seems to be fully seated. If it is, you are fine there.

|

|

|

|

|

Close, but not exactly.

On B16 engines, the firing order remains 1 3 4 2 but the rotor spins clockwise. Not counterclockwise as with the B18 and B20.

Cameron

Rose City

|

|

|

|

|

does a B16 have a timing chain?

|

|

|

|

|

Nope: it has timing gears, much like the B18/20.

Cameron

122SC, 444

|

|

|

|

|

Well, you guys are very close, and I'm not sure if you're right or wrong... but I checked and re-checked the dizzy gear, and am quite sure that it has seated before I try to crank (I did notice the fit-problem when it has not aligned with the oil pump gear).

Counter-clockwise rotation should have been like so:

___

1 2

3 4

Correct?

Well based on Mr. Happ's note that when it did work, I had the wires "wrong", I reversed wires again to look like this:

___

1 3

2 4

This sorta worked. Badly, but it did catch and fire - but sounded horrible.

I was about to give up again, but I decided to switch the remaining #1 and #4 wires so it now looks like this:

___

4 3

2 1

AND IT WORKED!!!!!

So, unless I've mis-interpreted the results, my dizzy is 180 degree backwards. I suspect that it means the distributor gear is 180 degrees off, which has been suggested and checked *many* times. I've even pulled and reversed the dizzy gear a couple times, but it never worked before.

I've no idea why #1 is TDC, timing mark is 15 BTC, and rotor is pointing to #1 cylinder and the notch on the dizzy is aligned to the rotor - BUT all the wires are 180 degrees off.

I took the car for a whirl and it performed normally. No sign of the problem that killed it several weeks ago. I reinstalled the original plugs so the only thing that has changed is the coil and the addition of magnecore plug wires.

Tomorrow is will be a high of 26 F and I'll see if the car fouls up with a big chunk of ice in the tank...

Sooo....

THANKS to EVERYONE who offered advice, suggestions, and help. I appreciate it, and my wife appreciates it even more (because she can have her 940 back).

|

|

|

|

|

Wow, such wonderful news, it shut the Brickboard down...or did you borrow it's plug wires? ;-)

|

|

|

|

|

I was wondering actually...

I'm glad to have the car back. Gonna try to drive it to work tomorrow...

|

|

|

|

|

RJ;

Are...

1 2

3 4

...and...

4 3

2 1

not the same when going in circles? As a matter of fact, so would...

3 1

4 2

...and...

2 4

1 3

...be. The important point is that the rotational order are absolutely the same...after static timing on #1...AND you connect the wire at the station to which the rotor is pointing, to plug #1 and you're good to go...

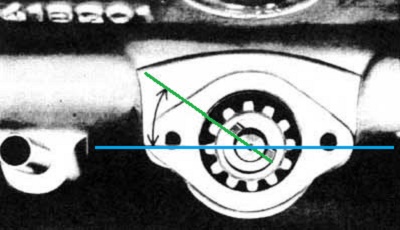

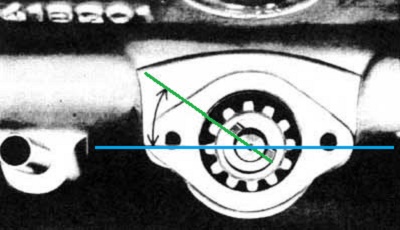

This whole problem happened, because the dist drive gear is not installed per the drawing:

...but this isn't even critical, because the procedure takes it into account...I just double checked my instructions to assure that if you had followed them precisely, you would have had success...I refer you to Item No3. under: Checking Distributor Installation and Setting Motor to Ignition Point, which would accomodate a dist drive gear installed at some other angle than called for...oh well...

In any case, I too am happy for your success...it will allow you to motor happily into and beyond 2008!

Happy New Year Brickboard!

|

|

|

|

|

Thanks Ron,

Yes, I do know that this is the same order, which I why I said it was firing order...sorta. I guess it wanted to fire #4 first...

I'll make this clear again and again. I checked that damn gear a dozen times it looks EXACTLY like your figure, yet it is in backwards. I kept setting #1 TDC, timing at 15-16, dizzy gear as per your diagram. I held a printed copy of your photo up against my engine to compare the angle. I *can* tell that the upper right half of the ring is smaller. I then put on the cap, removed the #1 spark and rotated the dizzy until it sparked (or made that little pop).

This should have worked but the dizzy gear is backwards and that means that the TDC, 16-BTC, and rotor align at TWICE, which is what I could not puzzle out.

The only thing I can think is that the #1 TDC is *not* when #1 intake just closed, #1 exhaust not yet opened, but maybe another cycle around? However, the timing marks line up at precisely this spot and it makes logical sense. None of the articles are especially clear on this point.

Funny, though, I did try inverting the gear 180 and it still would not start, but there must have been too many open variables at that time. I only just today discovered that little notch in the distributor case...

But... a question for you specifically. Since you refer to your article, why do you not discuss the likelihood of inverting that gear, and what kind of problems you see when you do it? Because, it can appear as your diagram shows, but still be wrong.

Knowing how to catch this problem is the lesson I've learned from this whole experience.

|

|

|

|

cheers & happy motoring

v.

|

|

|

|

|

Yes, this is an amazing load off my shoulders. The only thing I still do not know what crippled me several weeks ago on the way to work, and why my firing order is backwards.

|

|

|

|

|

As Ron pointed out, your firing order isn't backwards. It's just that something isn't "properly" indexed. What you have will work just fine - it's just not the 'recognized standard' that was used by the factory. Functionally identical - no worries.

Either the distributor drive gear in installed 180 out, as suggested; or the coupling at the very bottom end of the distributor was installed 180 out. This is the odd piece with two tabs which interface with the distributor drive gear. It's held in place with a pin, and is then wrapped with a wire retainer thingamajig.

Anyway: it's easy and fairly common for someone to put this on wrong way around; if that happens, the result is:

Exactly what you've been facing.

Good news: now that it's working, you don't have to change or fix anything more to drive it happily about. If, at some point, you decide you'd like this corrected, you can get around to it at your convenience.

Best,

Cameron

Rose City

|

|

|

|

|

Thanks Cam.

I'm chalking this up as the one really nightmarish experience that made me understand ignition better.

|

|

|

|

|

Very well explained. Thanks.

Repairman: you'll still have to ensure that the Crane is 'phased' UNLESS you go back to points and condensor.

Best,

Cameron

122SC, 444

Rose City

|

|

|

|

|

Thanks, I did swap the point job back in, when I was having a hard time making the #1 plug spark on manual distributor rotation.

I tried moving the wires around a bit and had no luck. The starting and running I got with the wires in the wrong order has been very intermittent and I've not been able to reproduce it well.

Sadly, this is where the whole enterprise went *way* off track. I got the wires in the wrong order, figured it was the condensor, decided to upgrade to an electronic unit, then nothing would work. messed with the distributor gear, wondered if the fuel was the problem all along, realized that the wires were in the wrong order, but too late to solve the other problems I seem to have introduced.

I am gonna go examine my distributor gearing on the 220, and maybe see if I can get this figured out.

|

|

|

|

|

Following Cam's suggestions sound good to me. I get a little worried reading

"That would explain a lot, but I'm not sure how to solve it, when I crank the thing until rotor is pointing to #1 (about 300 degrees), timing mark is at 0 and #1 is at TDC. Maybe I do have the distributor gear wrong? I've checked it several times. How can I be 100% sure that it is right? it's a multi-stoke engine, so this align more than just once right?"

It looks from that as if you have the basic timing set at 0º and you're trying to start it using that setting. It has to be set to about 12º to 15º BTDC to get it running before fine tuning, if needed. With the front #1 piston at TDC (beware it can be 360º out) the pointer on the timing chest should point to 0º. Turn the engine so it does. Check the rotor position and turn the dizzy so it points to the notch in the rim of the dizzy body. If it points in the opposite direction the engine is 360º and needs another turn. All the timing is now at zero. Carefully turn the engine so the pointer is opposite about 12/15º. Going back to the dizzy you'll see that the rotor has moved round a bit. Twist the dizzy so the rotor points to the notch again. Do up the clamp nut. Spark to #1 plug should now fire at 12/15º BTDC. Check you have the proper cap with the proper notches to match the dizzy body. Cap should locate to put #1 lead at the same position as the notch on the dizzy. Refit the new and dry plugs. Refit plug leads. Dizzy rotates anti clockwise, firing order 1 - 3 - 4 - 2. Check all the other wires are on and secure. Pull out the choke, turn key and them let out a whoop when it fires up.................I hope. Probably lots of smoke from all the gas that's gone into the exhaust system.

Still no luck? Thinking caps on again guys!

|

|

|

|

|

What derek is saying is good, and reminds me of a way to set teh static timing...I think it was Phil who told me this little trick that really works well:

1) With #1 at top dead center, with both valves closed, turn the engine slightly to 10 degrees BEFORE top dead center (after TDC will be too far off to run). The 10 degree before TDC mark will be the driver's side of the "0" mark.

2)Now verify that the rotor is pointing at the #1 tower on the cap. Reinstall the cap and wires.

3) loosen the distributor and turn it all the way clockwise, then turn on the ingition. DO NOT CRANK THE ENGINE.

4) slowly rotate the dizzy counter clockwise until you hear the spark jump the gap in the distributor...yes, you can hear that 'pop'. Lock down the distributor, and you are ready to go.

When I tried that, I found that 10 degrees with the engine off turned into about 12 degrees at idle, which is spec, and so I didn't need to do any more.

|

|

|

|

|

First of, thanks to all of you for the help so far. I'm still trying and it has not yet fired. Here's my procedure

1) hand-crank the motor until #1 comes to TDC.

To confirm #1 TDC, I've remove #1 spark and removed the valve cover.

TDC is when the #1 piston is at the top, the timing marks are aligned to ~10-15 btc (ATC only goes to 10 right?), and the rotor is pointing at the #1 cylinder. Plus, I've just seen the intake valve open and close and the exhaust has yet to open, right?

***I am no longer sure about the distributor gear. It's been removed and reset several times now and there's appears to be TWO times that the marks and #1 TDC match, but the rotor is point 180 away at that point. Which is right?!***

2) turn ignition on, hold #1 spark carefuly and rotate the distributor housing until I see spark (or hear slight pop).

3) Reinstall #1 spark, attempt to start.

4) Still does not start.

I still get a pretty consistent popping and white smoke out of my #1 carb. I'm pretty sure that the timing is still wrong. I've adjust the dizzy slightly forward and backward to see if I can find the right spot. No luck so far.

I'm pretty sure that the distributor gear must be the issue, but checking and re-checking it shows that it is at the right angle.

I get the same behavior with the point dizzy and the crane dizzy.

|

|

|

|

note that it does not matter if the gear was put in a few teeth off. It just means that, all else the same, the timing will be way off. You will take care of this as you set the static timing from scratch. See post above ("firing order").

good luck.

|

|

|

|

|

Hummm.... if that's the case, as long as #1 fires when all else is set (TDC, 15 BTC, etc) if *ought* to fire?

I'm heading back out to check again, but so far, it is just not right.

Exactly what is going wrong when I get little pops and white smoke jets back out of the carbs?

|

|

|

|

Hummm.... if that's the case, as long as #1 fires when all else is set (TDC, 15 BTC, etc) if *ought* to fire?

correct

Exactly what is going wrong when I get little pops and white smoke jets back out of the carbs?

Seems to me like the only way to get smoke and pops coming back out the carbs is for the timing to be way off (i.e. ignition is happening when the intake valve is open, hence allowing a path for pops and smoke to make its way back out through the carb).

when I say "way off," I mean wires-in-the-wrong-order off. If you set the #1 wire up correctly, and then incorrectly plug the rest of the wires into dizzy cap 1-3-4-2 going clockwise, you'll end up with an actual firing order of 1-2-4-3 (3 and 2 reversed). In this case, you'll get cylinders 1 and 4 firing correctly, and cylinders 2 and 3 firing during the valve overlap period, when both the exhaust and intake valves are slightly open (exhaust valve just closing and intake just starting to open).

timing could also be "way off" if it was advanced so far that it fired before the intake was able to fully close. I would guess, from your previous posts, that this is not the case.

alternately, I suppose you'd also get smoke and pops coming out your carb if your intake valves simply weren't sealing. You've already said you checked valve clearances, and the engine recently ran (i.e. the actual sealing surfaces should be OK), so I don't think this is your problem either. A compression check would reveal non-sealing valves.

|

|

|

|

|

well, i do not know how many times I can follow the wires counter-clockwise counting 1-3-4-2 an still be getting it wrong.

If the dizzy gear was in there 180-off then my order would be the same just starting at the opposite side.

I've been out checking and re-checking and I either get a dry crank or after playing with the dizzy, I get pops and smoke.

I'll go check it all again. Knowing that the thing is firing with the intake helps.

|

|

|

|

also probably a dumb point, but...

#1 is at the "front" of the engine, closest to the fan. #4 is closest to the firewall.

that could be another source of mis-wiring.

|

|

|

|

|

maybe not such a dumb point. Weren't some Volvo engines ( maybe the B16) timed with #4 instead of #1?

|

|

|

|

EDIT- my original post here was confusing (and unnecessary). i'm deleting it. sorry for the wasted space.

v.

|

|

|

|

|

Do you have another car with a B18 or B20 that you can use as a frame of reference? If so, I would recommend parking the two cars side by side, and methodically check the placement of every plug wire, rotor position, distributor position, timing mark etc. against the working car, until the non-working car is configured identically right down to the position of the valves and pistons.

Compare the low tension wiring connections against the good car; measure the low tension voltages and compare against the good car. Check the resistance (at a suitable point) between the engine block and the ground terminal of the battery and compare against the good car.

Try starting the car again with fresh gas in the float bowls; if it acts like it's trying to fire start rotating the distributor in whatever way seems to make it fire more often until it starts. Make sure the chokes on the bad car are both fully open; there should be at least a 1/4 inch of jet exposed, if not more.

If you can't get the engine to fire and you can find no discrepancies between the two cars, take a picture of the ignition system of the good car first, and then start swapping assemblies from one car to the other, starting with the entire distributor, including cap and wires. I would start by swapping the suspect distributor onto the good car, and if changing the part doesn't help, return it to it's original location and try another part until you have either found the defective item or not, in which case you can turn your attention to the fuel supply and induction system.

Bill

|

|

|

|

|

Sorry about spawning the new threads for he same problem, but I do not seem to get replies when I resurrect an old one...

Here's the status of things.

-Still won't start - cold out right now, which does not help.

1) Plugs are wired 1-3-4-2 counter clockwise.

2) Plugs are NGK BPHS-6, reasonably new (July 2007)

3) Wires are Magnecor (off my wagon), but same problem with a new set of "stock" wires.

4) Pulled the timing cover and confirmed a perfect gear. Everything synchs up correctly.

6) Set the static timing multiple times and confirmed the dist gear is in the correct spot.

7) flushed the carb chambers.

8) changed the damper oil (MMO for cold weather) in the carbs. Confirmed smooth piston movement.

9) same condenser as when the poor running started. No replacement on hand. points plate is secure.

10) Ignition switch/tumbler was replaced. during this whole fiasco, no change.

11) bypassed the fuel pump and filled carb chamber manually - but used fuel diverted from pump...

12) also changed the coil and battery

13) tried three differnt caps and rotors (one brand new)

14) pulled and cleaned plugs several times, checked gap on plugs

What I have not done:

1) drained the fuel tank and used fresh gas (tank is 10 gal full atm, not simple).

2) tried different carbs.

3) tried a blue bosch coil (I have a spare).

4) witnessed the spark on the plugs themselves (just checked wire currents w/ timing light)

5) entirely new plug set.

6) recheck *all* gaps and clearances.

7) performed a new compression test (all were 175-180 a couple months ago)

8) reinstall "original" coil

A big issues is that there are no condensers at the local auto-parts shops - which was my impetus for installing the crane unit in the first place. I've got a whole bag of used condensers, but I'm not sure if that gets me anywhere. I could find and install the original one. I replaced it to be safe when I tuned up the car in july/august. But still, problem persists even when there's a no-condenser system installed, so I'm thinking this is the wrong tree

Considering I had the same problem with the electronic ignition distributor as well as with the point distributor, I'm thinking I need to be looking away from the distributor/ignition timing. Then again, there are so many variables, it could be a common component that I have not changed.

Tomorrow, I'll check the gas and pick up some starting fluid...

If nobody thinks it's insane, I'm going to try loosening the spark plugs to check the fire. Extinguisher is handy...

Thanks for the suggestions.

|

|

|

|

IMO, a spray can of starting fluid is by far the easiest way to rule out fuel. I don't think you'd have to even bother disconnecting the fuel line; just pop off the air filters, spray some of that magic stuff in there and crank. It's super flammable stuff, so much so that I think it would "overpower" the non-flammability of whatever is coming up your fuel line.

Also- you say you've only tangentially checked spark via the timing light. At some point (now?) you may as well actually check for a physical spark @ the plug, no?

good luck.

v.

|

|

|

|

|

OK, modified response:

1) find a known good condensor

2) Pull those plugs and heat the ends with a propane torch to burn all the gas out of the porcelin.

|

|

|

|

|

If the car has a Crane Electronic Ignition, why are you messing with a condensor? Isn't the whole idea to get rid of the points and condensor with this system?

Will the Crane system even work if you leave the condensor in?

BTW, a condensor is nothing but a capacitor; condensor is an archaic word for a capacitor in the modern (American) electronics field. There's nothing special about the condensor for the Volvo; it's around .2 to .3 microfarads (uF).

Any condensor that matches the electrical characteristics of the Volvo item, and is capable of being mounted to the side of the distributor so that the bare metal outer shell of the part is being grounded through the body of the distributor, should work.

I suspect the condensor (capacitor) may be oil-filled; and I don't know if it's polarized or not (I doubt it) and it's got a high voltage rating, maybe 600 volts or so? Anyone know?

Better quality modern (digital) multimeters often have a capacitance measuring function built right in, if you feel compelled to check the part.

Condensors (capacitors) have two modes of failure; either they become electrically open internally; or they develop a partial (leaky) or complete short circuit internally.

Of course, if you stuck a leaky or shorted condensor on your distributor with the Crane system, and the electrical connection stud was also being used by the Crane system, you would be shorting whatever voltage was being applied to that point to ground.

If the electrical connection stud (condensor) was being partially or completely shorted to ground because of a failure or incorrect assembly of the phenolic insulating shoulder washers on the distributor, same thing.

Bill

|

|

|

|

|

the initial advice regarding my symptoms was that the capacitor was at fault. When I got nothing but funny looks from the carquest guys and a check revealed none at the warehouse, I installed my known-good allison/crane distributor unit.

After that failed to fix the issue, I put the point-distributor back in and tried to no avail. That still leaves the condensor as a potential fault since I never replaced it.

|

|

|

|

|

I had the condesor installed incorrectly so it was grounded,and had no start.

Check installation.

--

71-145-S ; 72-145-E ; 72-1800-ES

|

|

posted by

someone claiming to be shayne

on

Fri Dec 28 12:35 CST 2007 [ RELATED]

|

|

It's water.

Rock the car back and forth to mix up what's in the tank, then crank over and use your fuel pump (carb side hose) to give you a sample in a clear container. Let the container sit for a bit. If you see the fluid in the container seperate, there's your problem.

Undo the hose on the tank side of the fuel pump (to disable it's ability to souce fuel from the tank) and put known-good fuel in the float bowls. Check the plugs are dry. Start the car.

You probably won't have to drain too much from the tank, the water is on the bottom.

I've done this several times since I last checked into the BB (what's it been, eight months?). I give ignition, timing, fouled plugs, etc. about a half-hour of my time before I decide it's a contaminate in the tank. Most recently on a 145E... which is weird...don't know what it was but it wasn't water, and it wouldn't burn.

Best of luck,

Shayne.

|

|

|

|

|

If this is indeed the problem, how can I avoid it happening again? The car spent time in the wet weather before without this problem, but this is the first time it was under 20 degrees out when I tried to take her out. I have a waso cap, not a stock cap, and my fuel tank was recently replaced,

|

|

|

|

|

There is a product called DriGas or some such available at parts houses.

It is an alcohol and will take up small amounts of water into solution in the gas

so as to run it out with the fuel without problems if the amount is small enough.

Might be worth a try in your case.

One of our folks up in Maine had a problem in very cold weather and found

there was about a 5 pound chunk of ice in a 240 gas tank. It rarely got

warm enough to thaw so it was a pretty cryptic problem. She didn't have

any heat in her shop either - it was her son's car.

--

George Downs, Bartlesville, Heart of the USA!

|

|

|

|

Repairman,

You can check the condensor with an Ohmmeter. One lead on the body of the condensor and one lead on the wire. You can hold one lead on the wire or one lead on the body; if you touch both leads, you will be reading your body. Watch the meter. As the condensor charges on the battery in the meter the resistance will increase to megaohms. Reverse the leads. You should have a minus sign in front of the numbers until the reading passes through zero on it's way to megaohms in the other direction.

A bad condensor either will not charge or will charge and discharge without moving the leads.

*LATE EDIT*

Repairman, You suspected a fuel problem early on, why haven't you tried different fuel?

--

Mr. Shannon DeWolfe -- (I've taken to using Mr. because my name tends to mislead folks on the WWW. I am a 51 year old fat man ;-) -- KD5QBL

|

|

|

|

|

poor weather, holidays, and very long hours at work mainly. To many variables and a partial success also. It is also NOT fun to drain 10 gallons of fuel...

I was advised that it was probably water in the carb reservoirs, so I flushed those thoroughly and refilled them with fuel pumped out of the fuel pump.

After that and a lot of other tinkering and cleaning, the car did run a little bit, but only with the firing order reversed - which we know is not counter-clockwise...

I filled my tank with fresh fuel when the trouble started (acting like it was starving for fuel - sort of) so I've got a full tank and know that most of it is good.

My feeling, based on Shayne's comments is that the original advice about water was probably correct, but I did not consider the full scope of how much could be in there and did not go far enough to correct the issue.

My weird engine performance on the morning of the first real freeze may have been a result of ice in my fuel...

Anyway, I'll see to it in the AM Sunshine and report back.

|

|

|

|

|

RJ, my first guess, like others is the firing order, but I beleive somewhere in the past you verified that and even changed the wires around just to be sure. Is that correct?

Next try NEW spark plugs. Certain brands (Champions especially) have somewhat porous porcelin, and even cleaned, will hold enough fuel (or something) in the porcelin to weaken the spark. I really don't know what is happening in or on the plugs, but I've expereinced a bad misfire or no start after flooding a car. Sometimes I've taken a propane torch to the plugs (out of the engine of course) to burn the gas out of the porcelin with good results.

Next in line is one I have said won't happen quickly, but in the past month I've been proven wrong TWICE. That's the cap and rotor. Even ones where there was no visible carbon tracking, or bady erroded contacts, two people who I told that wold not work, replaced them and the cars ran great.

Finally, it still could be bad fuel. Clean or replace the plugs, empty the fuel bowls and pour a bit of fresh gas in them. Disconnect the fuel line between the fuel pump and the fuel tank, so you don't run more bad fuel into the carbs. That'll start it enough to verify if the fuel is good or not.

Good luck!

Ron

|

|

|

|

|

Hi, you said that it may start sometimes but dies as soom as you release the starter. You may have a problem with your ingiton switch. It may not be making contact in the run placement of the key.

Joel the locksmith

|

|

|

|

|

A lot of times when you do ignition work, especially if you pull the distributor

or drive gear, you'll set it up 360 crank degrees off (180° at the distributor).

A quick check for this is to advance all the wires two positions on the cap, or

just switch them directly across on a 4 cylinder engine. If you have made this

VERY common mistake it will make a world of difference!

--

George Downs, Bartlesville, Heart of the USA!

|

|

|

|

Repairman,

Make sure the points are set at 18thou and the plugs at 30thou. Set the carbs at 15 flats out. Squirt some oil in each cylinder. Use a separate battery to power the coil (bypass the key switch entirely). Make sure your plug wires are wired counter-clockwise. Drain the float bowls. Put a gas can on the roof to gravity feed the carbs; you will have to siphon to get the fuel flow started. Remember to plug the hose coming from the pump or disconnect the input to the pump. Choke the carbs. Now crank the car. If it doesn't start, valve and/or spark timing is wrong.

Now reconnect the fuel line from the tank/pump. Start it again. It will probably start and run a few minutes and then die. My guess is the fuel is contaminated. It has been awhile but I seem to recall that the failure occurred after a fill-up.

--

Mr. Shannon DeWolfe -- (I've taken to using Mr. because my name tends to mislead folks on the WWW. I am a 51 year old fat man ;-) -- KD5QBL

|

|

|

|

|

Is the breaker plate secure?

--

71-145-S ; 72-145-E ; 72-1800-ES

|

|

posted by

someone claiming to be lost my password

on

Thu Dec 27 13:39 CST 2007 [ RELATED]

|

|

REALLY stupid question: how about the condenser? Any luck with that? Also if I get really pissed off in that sort of situation I sometimes pull the plugs and ground them close to the plug holes. If you are getting fuel it will blow out on the compression stroke and ignite on the plugs.

Good luck.

Andrew

|

|

|

|

George alluded to it...make sure your wires are correct. I had a local buddy that had the same problem. After changing many things, he hooked the plug wires up wrong...

--

Dale

|

|

|

|

|